Handheld cement ore grinding mill

Handheld Concrete Grinders CS Unitec

A Handheld Concrete Grinder is one of the best tools to efficiently grind and smooth surfaces such as concrete, stone, and more CS Unitec’s professional grade handheld surface preparation equipment include features like Our OK Mill grinding solution skilfully comminutes raw material, cement and slag You can easily adjust it to grind any feed material and produce multiple cement types in the same mill Due to its highly effective drying performance, the OK OK™ Raw and Cement MillOur wall chasers can be used to cut slots and channels in concrete, limestone or masonry with continuously variable cutting depths of up to 45 mm An included 3blade spacer disc set Wall Chasers and Handheld Concrete Grinders TyrolitPlugGrind® world patented modular and portable grinding station PlugGrind® is the only portable grinding station with ball mill or vrm solution from 12 tph to 75 tphMODULAR AND PORTABLE GRINDING STATION PLUG

.jpg)

Roller Press KHD Humboldt Wedag

Our roller presses are able to grind various feed materials, giving you the option of producing a range of cements at one site For example, with the appropriate grinding circuit and drive train arrangements, you can switch quickly and Handheld concrete and masonry grinders rotate a cutting disc or grinding wheel to remove material from concrete, masonry, brick, and stone They provide a twohanded grip for stability Handheld Concrete Masonry Grinders Grainger Industrial SupplyCompact and easy to install, the FCB Horomill® offers process specificities that are ideal for modern cement plants Thanks to its advanced technology and its use in combination with the FCB TSV™ high efficiency classifier, the mill Fives Sustainable grinding with FCB Horomill®2016年10月5日 Energyefficient equipments such as highpressure grinding rolls, vertical roller mills, CKP pregrinders, Cemex ® mills and Horomills ® are used at both finish grinding of cement and raw materialgrinding stages due to EnergyEfficient Technologies in Cement Grinding

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

CEMENT GRINDING COURSE The Cement Institute

The training aims to identify and understand necessary known and unknown information towards the grinding system’s completed cycle, whether it is a ball or vertical millElectric handheld concrete grinders are available up to 7" grinding width and can mill very close to the edge Walkbehind concrete floor grinders are available in electric and gas models with WalkBehind, Floor HandHeld Concrete Grinders CS Unitec2023年4月23日 grinding media in a grinding mill with about 2630 wt% chrome by Chen et al [37] using a phosphate ore in a modified ball laboratory ball mill whose electrochemical potential could be controlled(PDF) Grinding Media in Ball MillsA Review2014年10月1日 VRM has been widely researched in processing of cement (Ito et al 1997;Jorgensen 2005;Wang et al 2009, Ghalandari et al 2021), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in The OK™ Mill was originally designed for cement grinding In 2017 we released the OK™ vertical roller mill for raw materials grinding The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and applicationOK™ Raw and Cement MillRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermillThe final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 45% gypsum and possible additives, into the final product, cement In a modern cement plant the total consumption of electrical energy is about 100 kWh/t The cement grinding process accounts for approx 40% if this energy consumptionCEMENT GRINDING SYSTEMS INFINITY FOR CEMENT EQUIPMENT

.jpg)

Predictive Controller Design for a Cement Ball Mill Grinding

Chemical process industries are running under severe constraints, and it is essential to maintain the endproduct quality under disturbances Maintaining the product quality in the cement grinding process in the presence of clinker heterogeneity is a challenging task The model predictive controller (MPC) poses a viable solution to handle the variability This paper addresses the Coal mill is the main equipment in the pulverized coal preparation processBecause calcining topgrade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal preparation system is one Cement Mill Cement Grinding Machine AGICO Cement Grinding MillAs a leading cement plant builder, AGICO offers an expert cement grinding plant EPC service Cement Grinding Unit EPC Solution With a strong RD team, experienced engineers, and firstclass technical services, we aim to provide users with the most advanced and optimized cement production solutionsCement Grinding Plant Expert Cement Grinding Solutions from Explore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines The ability to finely grind materials and control the grinding process makes ball mills crucial equipment in cement manufacturing Mining and Ore Processing: Ball mills are used for grinding ores and minerals, Ball Mill Grinding Machines: Working Principle, Types, Parts

Cement Grinding Cement Plant Optimization

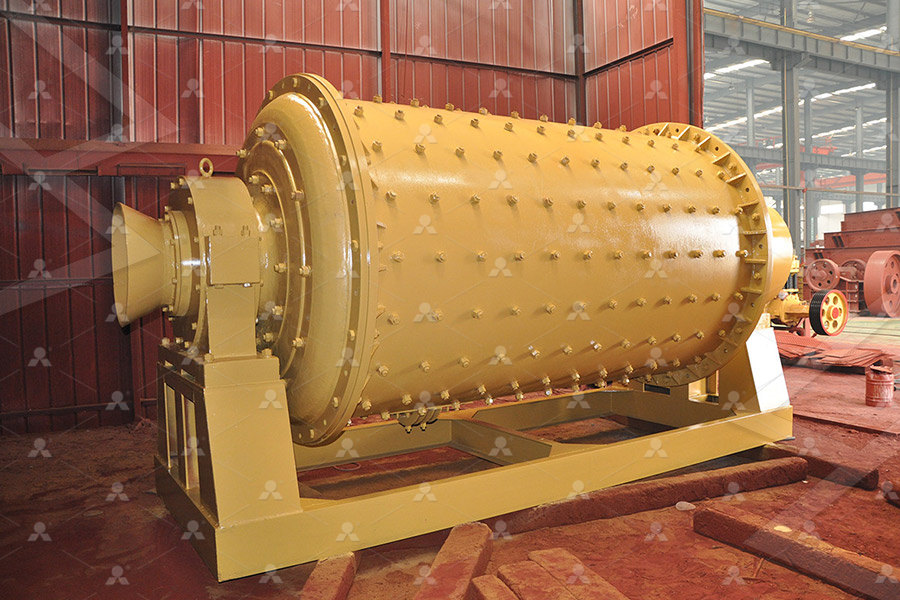

Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills2019年2月9日 Introduction Vertical roller mills (VRM) have become the standard for grinding raw materials in the cement manufacturing process However, despite the fact that more than 10 years has passed since Cement grinding: VRM or ball mill?2014年1月1日 This article analyzes the problems of perfecting grinding equipment for largescale production – cement, ore, coal An improved design of a ball mill, equipped with internal energy Exchange (PDF) MPS mills for coal grinding ResearchGateSpeed also plays a role in ore grinding; too high of a speed can cause damage to the mill gears and other components, while too low of a speed can cause excessive wear on these same components It is important to find a balance between these two variables in order to achieve optimal grinding performanceFactors affecting ores grinding performance in ball mills

Ball Mill For Cement Grinding – Cement Ball Mill Ball Mill

Ball mill for cement grinding is a kind of important cement equipment in cement plants IRON ORE PELLETIZING Pelletizing Disc Annular Cooler Grate Kiln Damp Mill Rotary Drum Mixer Iron Ore Dryer Traveling Grate CONTACT US : info@cementplantequipment PHONE: +86 Ball Mill for Gold Ore, Rock, Copper, Cement Grinding, Find Details and Price about Ball Mill Grinding Machine from Ball Mill for Gold Ore, Rock, Copper, Cement Grinding Changsha Mining Equipment Co, LtdBall Mill for Gold Ore, Rock, Copper, Cement Grindingpower consumption [1, 34, 36] Optimization of cement grinding using standard bond grinding calculations based on population balance models is successfully applied [4, 38] Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37] Figure1 Vertical roller mill for cement PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), Mill (grinding) Wikipedia

.jpg)

A comparison of wear rates of ball mill grinding media

2016年1月1日 In wet grinding practice, highstress abrasion occurs over a small region when ore particles are trapped between the grinding balls and the mill liner, and the load is sufficient to fracture 2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRMThe opencircuit grinding system of the ball mill is shown as follows: materials (including clinker, gypsum, mixed materials, etc) mixed according to a certain proportion will be directly stored in the steel silo as finished cement products Ball Mill In Cement Plant Cement Ball Mill AGICO Typical advantages of grinding cement raw materials using a roller mill are as follows: • Reduced energy consumption; • Simplified processing system, with drying, grinding and classification processes combined in one machine; • Simplified and rapid control of product parameters such as fineness and chemical composition; and •Grinding Mill an overview ScienceDirect Topics

1 Cement Mill PDF Mill (Grinding) Scribd

1 cement mill ppt Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses cement grinding systems It describes open circuit mills which have A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 micronsGrinding Mill an overview ScienceDirect Topics2016年10月12日 Stockpiling of ore ahead of the mill can aid in smoothing out some of the fluctuations although it must be stored in such a manner that no segregation occurs In operating a grinding circuit, like any other unit process, variables key to the performance must be dealt with Below are some of the principal variables affecting control of grinding Closed Circuit Grinding VS Open Circuit GrindingThe polysius® booster mill should be the next level in cement grinding You developed this new technology together with Netzsch Feinmahltechnik? Wilczek: Yes, indeed After the horizontal agitated bead mill for a wet process (in ore benefication) was established decades ago by Netzsch Feinmahltechnik, the polysius® booster mill as an application for a dry process has Let’s talk: polysius® booster mill – the next level in cement

Cement Grinding Plant Overview Cement Grinding Unit AGICO Cement

AGICO Cement is a cement grinding plant manufacturer, we'd like to helps you learn more about cement grinding plant and cement grinding machines Skip to content +86 Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals Award for Innovation 2015Mills for minerals and ores LoeschePerformance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement Plant D Altun, NA Aydogan, and then Axb was determined that is used as ore hardness indexPerformance Evaluation of Vertical Roller Mill in Cement GrindingVertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or equal to 30mm) Cement vertical mill occupies less space and saves 30% of construction costVertical Cement Mill Cement Clinker Grinding Equipment in Cement

Cement clinker grinding: Evaluation of mill spin speed,

2009年6月1日 In this study, the milling of clinker was evaluated by varying the mill speed (24 and 72 RPM), residence time (3 and 5 hours) and grinding media load (30 and 40 %) in a ball mill2016年11月7日 Why is Ore Grinding Necessary whilst in Fig 12 is shown a tube mill used in the cement industry the tube having a diameter of about 8 ft and length of about 45 ft In Fig 13 is shown a large ball mill, designed for the dry Grinding Mills Common Types 911MetallurgistBall mill is the key equipment for grinding after the crushing process in the beneficiation plant, it is used to grind kinds of materials such as copper ore, gold ore, magnetite ore, quartz, lead zinc ore and other materials into fine powder 2075micrometerMining and Grinding Ball Mill for Gold/Copper/Ore/Cement2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant

(PDF) Effect of Grinding Conditions on Clinker Grinding Efficiency

2024年7月31日 PDF The production of cement, and mill speed, on grinding efficiency Nine spherical balls, ranging from 15–65 mm, In a silica ore grindingThe Autogenous Mill, also known as AG Mill, is a type of grinding mill used in the mining industry This machine uses ore and rock itself as grinding media to perform its job Unlike other types of mills that use steel balls or rods for grinding materials, the Autogenous Mill relies on the material being ground to break itself into smaller piecesUnderstanding the SAG Mill in Copper Ore Mining ProcessUnit82 Cement Mill Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This document provides information on industrial drives used in cement manufacturing plants It discusses the different types of drives used including raw mill and cement mill drives, kiln drives, crusher drives, and waste gas fan drivesUnit82 Cement Mill PDF Mill (Grinding) ScribdApplication: Cement Plant, Clinker Grinding Unit: Capacity: 21155 t/h: Motor Power: 8003550 kw: Fineness: 3300~3800 cm²/gCement Ball Mill

Best Concrete Planers Concrete Giners and Scarifiers Reviews

Not to ignore the obvious, the handheld unit requires the user to get on his hands and knees That’s a bummer and there’s no way of getting around it However, you can mitigate the discomfort with knee pads or a kneeling cushion How to You can apply our ball mill in ore beneficiation plant to grind iron ore, copper ore, gold ore, lead ore, zinc ore, kaolin, bentonite, feldspar, silica, etc The wet ball mill is the key equipment for grinding mineral after the crush process It is mainly used in ore beneficiation plant Output Size: 0074089mm; Milling Capacity: 1600t/h;Ball Mill Ball Grinding Mill SKE