Slag micro powder grinding project construction design

Analysis and multiobjective optimization of slag

2020年7月1日 Slag powder is a process with characters of multivariables, strongly coupling and nonlinearity The material layer thickness plays an Grinding options for slag and pozzolan While the use of supplementary cementitious materials is increasingly popular, the use of granulated blastfurnace slag and pozzolans presents extra GRINDING Grinding options for slag and pozzolan PEC 2022年3月7日 To improve the application performance and utilization of tailings slag in building materials, a composite microslag composed of ultrafine tailings particles was prepared based Preparation of composite microslag based on the application of 2021年7月11日 Six different recycled micro powders were prepared by grinding the construction wastes that composed of concrete, tile, brick, and concrete Experimental researches on their Characteristics of Recycled Micro Powder Produced Using

.jpg)

Preparation and Performance of UltraFine High

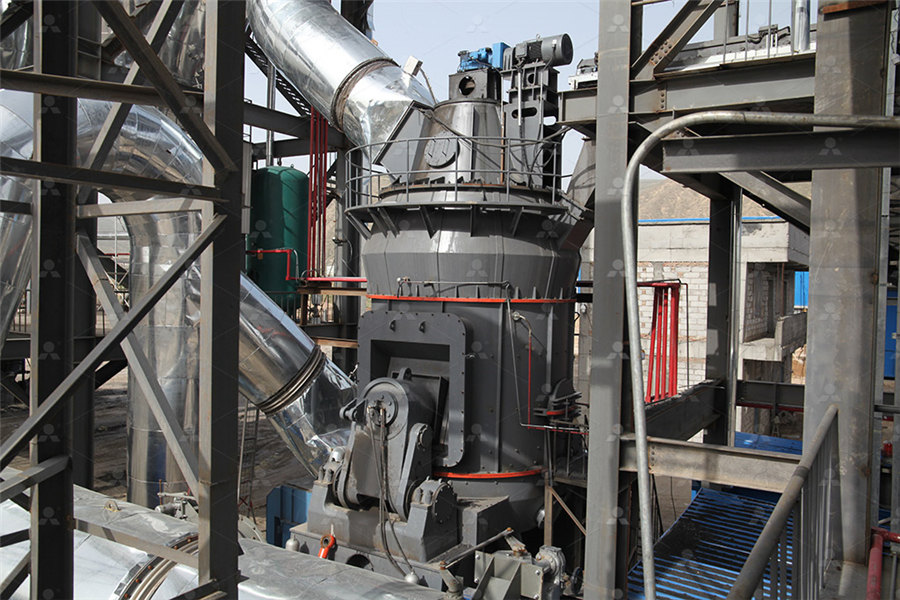

2023年12月11日 The composite micronized powder is prepared by using blast furnace slag (BFS), waterquenched manganese slag (WQMS), manganese tailing slag (MTS) and desulfurization gypsum (DG) and grinding aid (GA) 2024年3月28日 Steel slag micronized powder, granulated blast furnace slag, and cement were used as cementitious materials to prepare a foamed lightweight soil for roadbed filling to reduce the settlement and additional stress of the Features of Processes for Preparation and Performance 2024年11月2日 This study addresses the issues of low strength and high cost associated with the backfill of ultrafine tailings in metal mines by developing a novel slagbased backfill Development of slagbased filling cementitious materials and their Project Introduction Customisable The production line adopts the highpressure mill and environmental protection equipment produced by Jianye Heavy Industry, using advanced Slag micro powder production line project建冶重工机械官网

.jpg)

The Vertical Mill Slag MicroPowders' Particle Size ResearchGate

In this paper, through the industry vertical mill grinding GGBS carried out a detailed analysis of particle size, on this basis, using the attached to the sample preparation method, obtained the2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirectThe construction contents of the slag powder project include slag conveying to slag grinding, powder storage, automobile bulk, packing and leaving factory, main production process of train bulk, general plane engineering, electrical, automatic control, power supply and drainage engineering, etc Slag grinding mainly adopts the international advanced and mature Slag mill, slag powder mill, slag uZhengzhou Vanguard Effect of grinding method on properties of steel slag powder: DUAN Siyu 1, LI Xi 2, MA Zhuohui 1, LIAO Hongqiang 1, CHENG Fangqin 1: 1 State Environment Protection Key Laboratory of Efficient Utilization Technology of Coal Waste Resources, Institute of Resources and Environmental Engineering, Shanxi University, Taiyuan , China; 2 Shanxi Architectural Effect of grinding method on properties of steel slag powder

.jpg)

News Application prospect of ultrafine steel slag grinding

To sum up, the construction of steel slag micropowder projects in iron and steel enterprises can not only turn waste into treasure, improve the added value of steel making, create considerable economic benefits for iron and steel enterprises, but also protect the environment, in line with the policy direction of steel and cement industry VRMs have been gaining popularity in new projects as energy consumption can be up to 40 per cent less than that of ball mills, 6 in addition to allowing materials with a higher moisture content than competing grinding systems Many advances in VRM technology have been made for clinker and slag grinding as well as for the production of pozzolanic blended cements 7Options for Grinding Slag and Pozzolan for Use as Construction 2021年8月1日 Steel slag micro powder is steel slag after special process grinding, is a byproduct in the process of steel production This paper studied the basic mechanical properties and crack control (PDF) Effect of Polyvinyl FiberSteel Slag Powder on Mechanical 2023年7月1日 One of the most important ways of utilizing steel slag is as the aggregate in road construction It has been stated that steel slag can replace coarse aggregate (whose particle size is larger than 236 mm) when using steel slag in asphalt mixture [4]However, the coarse aggregate is porous, containing a lot of free calcium and magnesium oxides, which would Creep and fatigue properties of asphalt mastic with steel slag powder

.jpg)

Slag Ultrafine Powder Processing Technology

2024年10月25日 Using the HGM series Micro Powder Grinding Mill to grind slag into ultrafine powder and mix it with silicate cement, a new type of slag silicate cement can be prepared This new type of cement can not only reasonably control the fineness of cement, but also achieve the optimal ratio of silicate cement and slag powder, thereby improving the performance of cement2019年5月23日 Steel slag is the waste generated in the steelmaking process and includes ferric oxide and the impurities of some infusible matters It is the byproduct when slagforming constituents (such as fluorite, lime, and deoxidant) are added for deoxidization, desulfurization, and dephosphorization in prehensive Utilization Technology of Steel SlagThe ground granulated slag powder is drying by the hot air supplied by the project design, civil construction and equipment manufacturing of 300,000 t/y nickel slag grinding plant for Indonesian 2016, 300,000 t/y nickel slag grinding plant EPC project of Indonesia was completed and put into production! Auxiliary Equipment Ball millslag grinding plant CHAENG2023年7月19日 Homogenized microcrack crushing can fully retain the bearing capacity of concrete pavement, but local weak road base needs to be reinforced before being directly overlaid with hotmixed asphalt Therefore, indoor tests Mechanical Properties of SlagBased Geopolymer

.jpg)

Slag Grinding Plant Manufacturers NT Engitech

Slag Grinding Plant Manufacturers Nand T Engitech specializes in the design, raw meal, slag, nickel slag, manganese slag, cement, ground granulated blastfurnace slag (GGBS) powder, fly ash, coal, clinker, and more Planning 2024年2月14日 With the rising costs of highactivity materials like slag (Han et al 2017), the focus has shifted to economically viable alternatives such as steel slag (SS) and ceramic powder (CP) SS, a byproduct of the iron and steel industry, contributes significantly to China's annual production (Francisca and Glatstein 2020 ; Cui et al 2021 ), offering a sustainable resourceSustainable assessment and synergism of ceramic powder and steel slag 2024年7月30日 Steel manufacturers around the world are looking for ways to produce higher quality, lowersulfur steel This requires an additional desulfurization step using the Kambara reactor (KR) during steel production As a side effect, the Kambara reactor’s slag processing generates emissions that are captured and concentrated in dust collectors such as bag filters, Recycled Kambara reactor slag powder as a sustainable stabilizer Brief Introduction of superfine powder grinding mill (for slag) : Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is Superfine Slag Powder Production Line FTM Machinery

.jpg)

What is a ultrafine slag grinding plant? ultrafine slag grinding

2023年10月19日 The project involves mixing steel slag powder, mineral powder, and coal ash in certain proportions, grinding them into ultrafine powder, and using the resulting product as a substitute for 2023年1月10日 Its grinding efficiency and grinding quality directly affect the cost and quality of slag grinding production As the core equipment in the production process of slag grinding, the LM slag vertical roller mill of SBM integrates fine crushing, grinding, drying, powder selection and transportation, ensuring the continuity and stability of slag Slag Vertical Roller MillThere are so many types of cement mills that can be selected for slag grinding plants Vertical mills are generally used for grinding slag powder A vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grindingSlag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill2022年3月7日 The main components of the three tailings slag are CaO, SiO 2, and Al 2 O 3 (Table 2), which are consistent with the main chemical components of limestone powder and red clay, it can be used as a mineralizer, especially the content of Fe 2 O 3And Fe 2 O 3 in lead–zinc tailings accounts for 1392% Nickel tailings contain relatively high MgO When they are Preparation of composite microslag based on the application of

.jpg)

Review Use of steel slag as sustainable construction materials: A

2021年10月1日 Three methods have been widely employed to improve the reactivity of steel slag and concurrently reduce its potential harm on cementbased host materials: (i) physical excitation, which stimulates the hydration activity by physically grinding steel slag into finer powder (Liu et al, 2016), (ii) chemical excitation, which adds chemical admixtures, such as In 2012, 1000,000t/y slag powder production line for Meng Electricity Cement has been put into production, several industrial waste slag powder grinding turnkey projects for Huangye have been put into production successively, which marked the company has achieved gorgeous turn from a single equipment supplier to grinding system integrated service providerAbout CHAENG2024年10月24日 The objectives of this research are: (1) to examine the influence of using steel slag micropowder UHPC on the performance of steel tube UHPC composite members; (2) to analyze the failure mechanisms and Experimental Performance Study on Axial Compressive HGM Micro Powder Mill is the new type mining equipment for making micro powders, fine powders,which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, and so onThe purpose of the micro powder grinding millis for superfine grinding materials with hardness less than 9 in Moh's scale and humidity micro mills for powder grinding Sebocom Construction

Effectiveness of waste steel slag powder on the strength

2020年4月20日 Dredged sludge (DS) is regarded as the sediments dredged from rivers, waterways and harbor basins based on the demand for better water quality and adequate navigation channel [1], [2]The DS has the natural properties of high compressibility, highwater content, low bearing capacity and rich organic matter [3], [4], [5]Unsolidified DS is difficult to HVM type slag vertical mill is a common equipment for processing slag micro powder It integrates fine Mining slag bond index≤25kWh/t,Steel slag bond index≤30kWh/t,The output will decrease by 30%40% when grinding steel slag micro lime kiln industry quicklime Engineering design projects such as pulverizing and pneumatic Slag Grinding Mill, High Efficiency Vertical Roller Slag Grinding 2023年12月8日 Orthogonal experimental design for compressive strength of recycled coarse aggregate concrete with silica fumeslagfly ash hybrid micropowders Author links open overlay panel Chengyuan Wang a b , Juan Wang b , Xu Liu b , YunFang Cai c , YuCheng Zhang bOrthogonal experimental design for compressive strength of Slag ball mill is a kind of equipment used to grind the slag into powder particles The technical that uses the tube mill on the production of slag has been very mature The slag produced can be used as concrete admixture, reducing the project costs significantly and enhanced the compressive strength, tensile strength, shear strength and bending strength of the concrete Per machine slag production ball mill

.jpg)

Research on the Flexural Performance of Steel Pipe Steel Slag Powder

2023年8月30日 The analysis of Table 9 shows that when the strength of the UHPC filled with steelslag micro powder increased from 120 MPa to 130 MPa, 140 MPa, 150 MPa, and 160 MPa, respectively, the ultimate flexural bearing capacity of the member increased by 16%, 32%, 49%, and 66%, respectively, and the rate of the increase in the flexural bearing capacity was less Project management The Schenck Process Group delivers » Truck or railcar loading, unloading and bulk storage systems » Inplant transfer for major, minor and micro ingredients » Minor and micro ingredient scaling systems » Low pressure continuous dense and dilute phase handling systems » Plant controls systems » Dust collectionPowder Processing Equipment Systems Qlar2014年9月30日 To improve the properties of grinding and cutting wheels, copper slag granite saw dust, steel slag, crushed clay brick powder, are simply leftover tiles from construction projectsCONCRETE MIX DESIGN USING COPPER SLAG AS FINE 2022年5月25日 In order to study the law of evolution of erosion time on the impermeability of soilcement in the marine environment, permeability tests, Xray diffraction (XRD) tests, and scanning electron Impermeability Characteristics of Treated Marine Soft

Preparation for microlithium slag via wet grinding and its

2020年3月20日 Industrial wastes consumed by the preparation of building materials is a potential method to ensure the sustainable development In this study, lithium slag (LS), as the byproduct of lithium salts production, was treated by wet grinding process to prepare micro particles and used to expedite the early hydration of Portland cement (PC) The physicalchemical 2021年6月8日 Steel slag is a byproduct discharged from the steelmaking process, which is characterized by abundant free calcium/magnesium oxide, low cementitious properties, and high contents of heavy metalsUse of steel slag as sustainable construction materials: A review 2024年8月30日 Circulating fluidized bed combustion slags (CFBCSs) are solid wastes produced after limestone and other desulfurizers are added to a circulating fluidized bed (CFB) boiler for achieving desulfurization by reducing the concentration of SO 2 in the flue ash produced by combustion [1]The mineral compositions of CFBCSs from different power plants are similar, Modification of cementbased circulating fluidized bed combustion slag Characteristics of Recycled Micro Powder Produced Using Construction Waste Jinjin Shi1,2,3(B),MiaoXu1,3, Yingbiao Wu1,2,3, and Jinyan Liu1,2 1 Cangzhou Municipal Engineering Company Limited, Cangzhou , China 2 Hebei Province Road Materials and Technology Engineering Technology Research Center, Cangzhou , China 3 Hebei Industrial Characteristics of Recycled Micro Powder Produced Using Construction

.jpg)

About CHAENG

In 2012, 1000,000t/y slag powder production line for Meng Electricity Cement has been put into production, several industrial waste slag powder grinding turnkey projects for Huangye have been put into production successively, which marked the company has achieved gorgeous turn from a single equipment supplier to grinding system integrated service providerThe micropowder processing scheme of steel slag grinding mill is customized by HCMilling(Guilin Hongcheng), providing a complete solution for your steel slag project The experiment shows that steel slag powder can be mixed with water slag powder as composite mineral powder, which can be used in cement concrete to replace part of cement and water slag powder, saving Introduction To The Way Of Steel Slag Recycling The Micropowder Project Case In addition to 600,000 tons of steel slag production line, we can also provide the full set of equipment and its technical parameters of annual output of 300,000 tons of steel slag powder production line, annual output of 450,000 tons of steel slag powder production line and annual output of 1 million tons of steel slag powder production lineSteel Slag Grinding Plant2021年9月30日 It is a highly efficient industrial micro powder grinding mill +17 SBM also provides complete analysis reports and project descriptions to ensure that the solution design The vermiculite industrial milling equipment can process vermiculite into vermiculite powder, which can be used in construction, agriculture Chalk Micro Powder Mill SBM Ultrafine Powder Technology

.jpg)

Global Slag Knowledge Base

Paper 12 15 years of slag grinding with Loesche 2+2/3+3technology: Daniel Strohmeyer: Loesche Paper 13 Operation data of MPS vertical roller mills producing slag powder and slag cement: York Reichardt: Gebr Pfeiffer Paper 14 State of the art handling for slag: Davide Gambarotta: GambarottaGschwendt srl