How many meters should the lithium ore grinding machine be away from the residential area

ReviewProcessing of lithium ores: Industrial technologies and case

2021年5月1日 Since petalite contains 37–39% of Li 2 O, fine grinding of ore up to 025 mm was required for full opening Leaching was carried out in 100 mL steel autoclaves with a stirring speed of 32 rpm at a temperature of 280 °C2023年1月1日 The global lithium resource reserves are 22 Mt (metal) (USGS, 2022), of which 34% are from hard rock lithium mines (Li LJ et al, 2018), mainly including Australia Lithium extraction from hard rock lithium ores (spodumene, Spodumene ores are typically consolidated from ore comprising 1–15% Li20 to a concentrate of about 6–65% Li20 To achieve this, the ore passes through a typical concentratortype plant, Lithium processing technology Complete solutions that FLSmidth2024年9月30日 Under optimal conditions, the total Li extraction efficiency could reach 899%, with 841% converted into Li 2 SiO 3 and 58% converted into the liquid phase: an initial KOH concentration of 50 wt%, a stirring speed of 500 Aspects of Spodumene Lithium Extraction Techniques

Hard Rock Lithium Processing SGS

SGS provides the comprehensive range of testwork capabilities required to extract lithium These capabilities include: Environmental testing Lithium is found in very low concentration in 2021年2月1日 The global lithium resource reserves are 22 Mt (metal) (USGS, 2022), of which 34% are from hard rock lithium mines (Li LJ et al, 2018), mainly including Australia Processing of lithium ores: Industrial technologies and case studies 2022年12月21日 This paper reviews the recent technological developments in the extraction of lithium from natural resources Existing methods are summarized by the main resources, such A review of lithium extraction from natural resources2021年12月1日 The production of extracting lithium from ores uses coal as fuel, and this coal must first be ground into pulverized coal or converted into coal gas to heat the calcining kiln, Sustainable production of lithium salts extraction from ores in

.jpg)

Guidance on Lithium Mining and Extraction Sierra Club

In general, largescale mining is environmentally destructive and often disruptive to nearby communities As such, the process of developing mining operations, including lithium, needs 2024年1月23日 For example, with hard rock mining, spodumene ore is mined and then processed to extract lithium The ore undergoes crushing, grinding, and a series of flotation processes to recover lithium concentrates This method, Beginners Guide to the Lithium Mining Process: What 2022年9月28日 Lithium ore flotation process generally includes the following operations (1) Lithium ore fine grinding, so that the useful minerals to achieve dissociation This operation is usually done by a mill with a classifier (2) Adjustment of the lithium ore slurry concentration to suit the flotation requirementsLithium Ore Process Flow How is Lithium Ore Processed?2023年7月31日 Ball mills are commonly used for grinding lithium ore due to their effectiveness However, it is important to choose the :; PhoneNo/WhatsApp:+06; Address:36# Xueyuan Road, Mazhai Industrial Zone, Erqi District, Zhengzhou, China WhatsAppWhat ball mill for grinding lithium ore? What is the Zoneding Machine

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日 There are two economic sources of lithium; brines and hard rock ores The majority of the global lithium production, greater than 60%, is produced from brines while lithium ores accounted for the remaining production (Ebensperger et al, 2005)Table 1 summarises the world’s major lithium producers from ores and brines, and the total reserves2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?2024年7月9日 SBM's lithium ore grinding machines are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill +17 [ protected] The contact area between the grinding roller and the grinding disc is large, the grinding efficiency is high, and the energy consumption is lowLithium Ore Grinding Mills SBM Ultrafine Powder Technology2023年10月6日 The conventional methods of lithium extraction include mining lithium from ore deposits and extracting lithium from brine sources These methods have been used for decades and have undergone continuous improvements to increase efficiency, reduce environmental impacts , and enhance the quality of the extracted lithiumSustainable Lithium Extraction: How is Lithium Mined and

.jpg)

How to Choose the Correct GRINDING MEDIA PCI Mag

GRINDING MEDIA The Grinding Media Depot Division of Norstone, Inc Daniyel Firestone, President 4846846986 norstoneinc January 2021 MEDIA SHOULD WEAR, NOT THE MACHINE Media should be chosen to be the major wearing part of the mill OR the least destructive to the mill because it’s cheaper to replace media than mill parts2024年4月8日 The lithium processing plant equipment includes a jaw crusher, a fine jaw crusher, a storage bin, a ball mill, a hydraulic cyclone, a mixing tank, and a flotation machine The hydraulic cyclone and ball mill constitute a closed circuit grinding and classification cycle, which improves the efficiency and fineness of classification grindingSelection Of Lithium Ore Processing Plant Equipment2022年1月1日 All content in this area was uploaded by Tianming Gao on Dec 15, 2023 Geochemical characteristics and genetic type of a lithium ore (mineralized) body in the central Yunnan Province, China(PDF) Lithium extraction from hard rock lithium ores: technology 2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage Ball Mill Is Indispensable For Lithium Ore Processing

.jpg)

Lithium extraction from hard rock lithium ores (spodumene,

2023年1月1日 The global lithium resource reserves are 22 Mt (metal) (USGS, 2022), of which 34% are from hard rock lithium mines (Li LJ et al, 2018), mainly including Australia Greenbushes, Canada Quebec, China Jiajika, Zimbabwe Bikita and other pegmatite lithium deposits (Zhang SJ et al, 2020; Yang HP, et al 2019)There are more than 150 kinds of lithium minerals (Pan T et Lithium Harvest's proprietary Direct Lithium Extraction (DLE) utilizes stateoftheart adsorption technology combined with advanced water treatment, revolutionizing lithium production by leveraging oil gas wastewater as Lithium Extraction Methods2023年5月14日 In conclusion, the lithium ore flotation machine offers many advantages over other methods of lithium extraction Its high efficiency, low energy consumption, ease of operation, high selectivity, and scalability make it a reliable and costeffective option for lithium producersFlotation Machine for Lithium Ore: Efficient Separation and 2023年5月27日 By optimizing these parameters, lithium ore can be efficiently processed to produce highquality lithiumion batteries 3 Milling Media Milling media refers to the materials that are used to grind and crush the lithium ore into smaller particlesBall Milling in Lithium Ore Processing: A Comprehensive Guide

How Australia became the world's greatest lithium supplier BBC

This material, which contains about 6% lithium, is then shipped from Australia to China, which refines 60% of the world's lithium and 80% of the world's lithium hydroxide – though this may be 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLink2024年7月21日 The normal working room temperature of the machine should be controlled between 10 and 30°C (3) Ambient humidity The normal working relative humidity of the machine should be controlled between 30% and 90% (4) Pollution The machine should not be used in severely polluted environments (5) PersonnelGrinding Machine Safety: Essential Tips for Operators2024年11月21日 In the mining and mineral processing industry, ore handling or ore preprocessing, which may account for 3060% of the total delivered price of raw materials, usually covers the processes of transportation, storage, feeding, and washing of the ore en route to, or during, its various stages of treatment in the millHow to Remove Harmful Materials on Ore Handling Stage

.jpg)

Review of analytical techniques for the determination of lithium:

2023年8月1日 PDF Citation: Rohiman A, Setiyanto H, Saraswaty V, Amran M B (2023) Review of analytical techniques for the determination of lithium: From Find, read and cite all the research you need 2016年5月9日 They forecast the lithium demand to grow by 81% from the current 192kt lithium carbonate equivalent (LCE) to 347kt LCE by 2020, and by 259% to 687kt LCE by 2025 (Figure 88), representing a CAGR of 14% across all demand sectors, driven by demand for Liion batterybased electric vehicles accounting for 38% of all lithium demand by 2025 (from ~6% in 2015), Processing Spodumene by Froth Flotation for Lithium Extraction2022年12月15日 After the mining of lithium ore, the bulk material is first crushed by electromagnetic dressing equipment; Then under the action of belt conveyor, it is evenly sent to the grinding machine for deep grinding treatment; After grinding, lithium ore powder should be reasonably screened by spiral classifierlithium ore beneficiation and crushing and milling process2021年5月1日 The role of lithium in chemical and nuclear industries could hardly be overestimated (Babenko et al, 2007)World lithium consumption in 2019 was estimated as ~58∙10 3 tons, with an increase of 18% compared with the previous year (National Minerals Information Center, 2020)Nevertheless, excluding the USA, worldwide lithium production in 2019 Processing of lithium ores: Industrial technologies and case

Gold Extraction Recovery Processes 911Metallurgist

2016年2月29日 Some of the metallurgical relationships that must be considered from the testwork program as follows: ore grade relationship to gold recovery, crushing and grinding parameters and their relationship to the ore variability in the ore body, effect of other minerals on the process, minerals and/compounds that negatively impact processing cost such as oxidized June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2020年6月14日 In throughfeed precision centerless grinding, the regulating wheel is canted away from the plane of the grinding wheel to control the liner travel of parts through the grinding machine The angle of the wheels relative to each other exerts a lateral force that feeds a workpiece straight through the grinding wheelsPrecision Metal Grinding Metal Cutting Corporation2023年9月11日 1 Lithium ore grate ball mill In lithium ore dressing plants, grate ball mills are mainly responsible for grinding coarser minerals and are mostly used in onestage grinding operations Due to its unique ore discharge plate design, the ball mill has a large ore discharge particle size and less grinding blockageBall Mills for Lithium Ore JXSC Machine

Transformations of Critical Lithium Ores to BatteryGrade MDPI

2024年10月28日 The escalating demand for lithium has intensified the need to process critical lithium ores into batterygrade materials efficiently This review paper overviews the transformation processes and cost of converting critical lithium ores, primarily spodumene and brine, into highpurity batterygrade precursors We systematically examine the study findings Selecting the right size of the grinding machine is vital for peak performance in industrial and manufacturing processes Few millimeters to Several meters: Centerless Grinder: Medium: N/A: 1224 inches: Long, thin workpieces: Tool and Cutter Grinder: Small to Medium: Varies: 610 inches: N/A: Internal Grinder: Medium:Grinding Machine Size Chart – SizeChartly2024年10月23日 There’s a common misconception about the environmental impact of lithiumion batteries While some studies claim lithium is one of the least toxic metals used in battery production, this doesn’t tell the full story Many other materials in these batteries can cause significant harm to the environment What’s Inside a LithiumIon Battery?LithiumIon Battery Recycling: The Complete GuideWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS The six main steps of iron ore processing Multotec

.jpg)

Grinding Mills and Their Types – IspatGuru

2015年4月9日 Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grinding Milling, sometimes also known 2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car Aspects of Spodumene Lithium Extraction Techniques2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation Ore Grinding SpringerLinkflotation of other lithium minerals, although lepidolite has received increasing attention recently (eg, Choi, 2015) For standard chemical grade spodumene, ie 60% Li2O, the flotation concentrate should require no further treatment The newer entrants into the lithium market are unlikely to have the capability, orLithium Ore Processing – an Overview of the Current and New

.jpg)

Sustainable production of lithium salts extraction from ores in

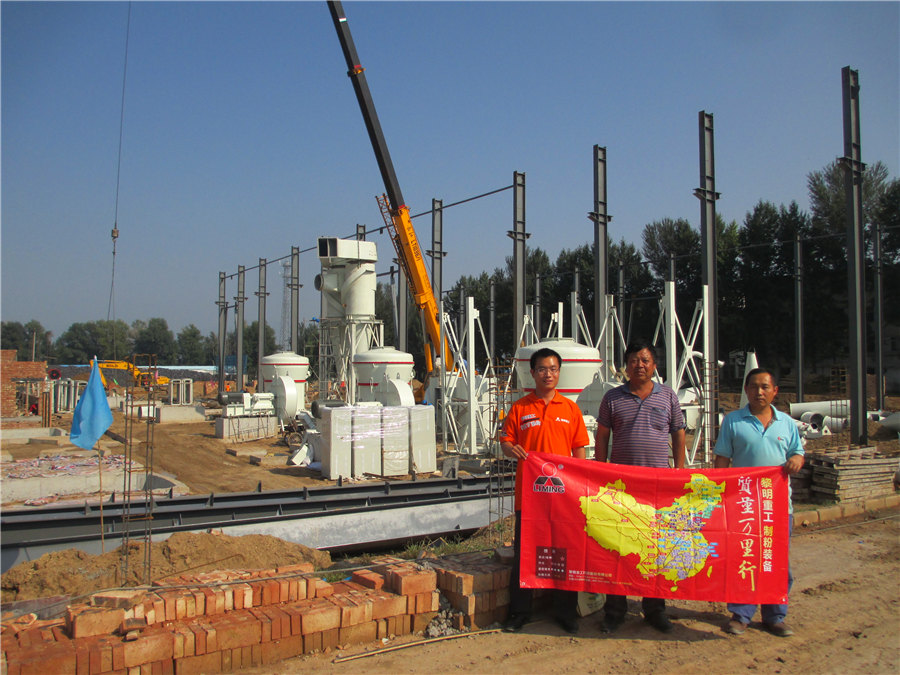

2021年12月1日 In the third stage (July–November 2019), We first constructed a questionnaire (supplementary information) based on these indicators; then, we investigated the data from the 36 indicators from the following 16 orebased lithium extraction plants in China (Fig 2): Shehong Tianqi Lithium (ST), Huludao Hongjing Lithium (HH), Wudi Jinhaiwang Lithium (WJ), Pingxiang 2023年6月21日 As a priority, machine location must be configured to minimize worker risks Machinery, particularly in manufacturing and construction environments, can be hazardous Placing machinery strategically can prevent accidents like entanglement, cuts, or crushing injuries by keeping dangerous moving parts away from areas where workers are presentMachine Location And Safe Working Distances Around Machinery2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration 67% and filling ratio 35% For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding Grinding Modeling and Energy Efficiency in Ore/Raw Material 2023年10月9日 The processing of lithium ore involves several steps, from mining and extraction to refining and purification limestone grinding machine price 55 feet short head tertiary crusherLithium ore processing plant machinery and equipment LinkedIn

Spodumene: The Lithium Market, Resources and Processes

2019年5月29日 Lithium is the third element of the periodic table It is the lightest of all solid elements (d = 053 g∙cm −3 at 20 °C), has the highest specific heat capacity, the smallest ionic radius of all the alkali metals, and a high electrochemical potential []Its two stable isotopes are 6 Li and 7 Li, with 7 Li being the most abundant (925%) [2,3]