Zinc oxide ore

氧化锌矿处理方法现状

2020年4月1日 阐述了酸法、碱法两大类处理氧化锌矿的方法,酸法如溶剂萃取法、氧压酸浸法、堆浸法及浓硫酸焙烧法等,碱法如机械活法碱法浸出、氨电积法、硫酸铵焙烧法及碱焙烧法等, Zinc is used for the galvanising process, to protect steel in construction, transportation and products It is also used as an alloying element with copper Zinc is produced from ore mining, Zinc Ore an overview ScienceDirect TopicsAbstract: With the increasing demand for zinc and the gradual scarcity of the zinc sulfide ore resources, the development and utilization of the zinc oxide ore has become a research 氧化锌矿选冶技术研究进展2021年2月3日 In this paper, the existing technology principle, process flow and effect of the comprehensive utilization of low grade zinc oxide ore resources are summarized and analyzed from two aspects of roasting method and leaching 综合利用低品位氧化锌矿的技术现状及研究进展

氧化锌矿石选矿研究现状及发展趋势

2018年12月1日 主要介绍了氧化锌的硫化胺法浮选、硫化黄药浮选及其他选矿方法的工艺现状,并从硫化方式和强化硫化过程等角度阐述了氧化锌选矿研究的发展同时,提出了氧化锌矿泥砂 2021年1月15日 The Skorpion zinc processing method demonstrated the viability of the production of zinc from zinc oxide ores, using hydrometallurgical route including the leaching, Leaching and solvent extraction purification of zinc from 2014年4月1日 There are three basic ore varieties of zinc oxide which are of economic value: (a) hemimorphite (gangue minerals: dolomite, goethite, quartz and kaolinite); (b) smithsonite A review of zinc oxide mineral beneficiation using flotation method2019年6月24日 In this article, surface modification of zinc oxide ore in the presence of sulfur and carbon was carried out, resulting in a hydrophobicity improvement of zinc and lead oxide Flotation of a LowGrade Zinc Oxide Ore After Surface Springer

.jpg)

A review of zinc oxide mineral beneficiation using flotation method

2014年4月1日 Usually, the zinc oxide ores have a complex gangue composition and, therefore, selection of depressants is dictated by the gangue composition present in the ore Carboxylic acid is applicable to smithsonite separation from silica or clay minerals [23] , but calcareous material such as calcite or dolomite will float during smithsonite flotation [59] 2023年9月29日 Zinc oxide minerals (primarily smithsonite and hemimorphite) are important sources of Zn Flotation is the most widely used method of enriching zinc oxide minerals for mineral processing Chelating reagents have Recent Progress on Chelating Reagents in Flotation of 2021年11月1日 The feed ore of zinc oxide ore flotation process was the underflow of the hydrocyclones, and the flowsheet of industrial tests of zinc oxide ore flotation is shown in Fig 8 The industrial tests were carried out for 17 days (from June 7, 2017 to June 23, 2017) for a total of 38 work shifts, and the cumulative results of industrial tests are presented in Table 7 Efficient flotation recovery of lead and zinc from refractory leadzinc Zinc ores were used to make the zinc–copper alloy brass thousands of years prior to the discovery of zinc as a separate element Zinc oxide is generally recognized by the FDA as safe and effective [186] and is considered a very photostable [187]Zinc Wikipedia

Zinc processing Extraction, Refining Uses Britannica

zinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds for use in various products Zinc (Zn) is a metallic element of hexagonal closepacked (hcp) crystal structure and a density of 713 grams per cubic centimetre It has only moderate hardness and can be made ductile and easily worked at temperatures slightly above NH4HCO3 conversion followed by HCl leaching was performed and proven to be effective in extracting Pb and Sr from zinc extracted residual The mechanism and operating conditions of NH4HCO3 conversion, including molar ratio of NH4HCO3 to zinc extracted residual, NH4HCO3 concentration, conversion temperature, conversion time, and stirring velocity, were discussed, Extraction and kinetic analysis of Pb and Sr from the SpringerZinkgruvan, a zinc mine in Askersund Municipality, Sweden Zinc mining is the process by which mineral forms of the metal zinc are extracted from the earth through miningA zinc mine is a mine that produces zinc minerals in ore as its primary product Common coproducts in zinc ores include minerals of lead and silverOther mines may produce zinc minerals as a byproduct of Zinc mining Wikipedia2014年4月1日 In recent years, extraction of zinc from lowgrade mining tailings of oxidized zinc has been a matter of discussion This is a material which can be processed by flotation and acidleaching methods Owing to the similarities in the physicochemical and surface chemistry of the constituent minerals, separation of zinc oxide minerals from their gangues by flotation is an A review of zinc oxide mineral beneficiation using flotation method

(PDF) Leaching and solvent extraction purification of zinc from

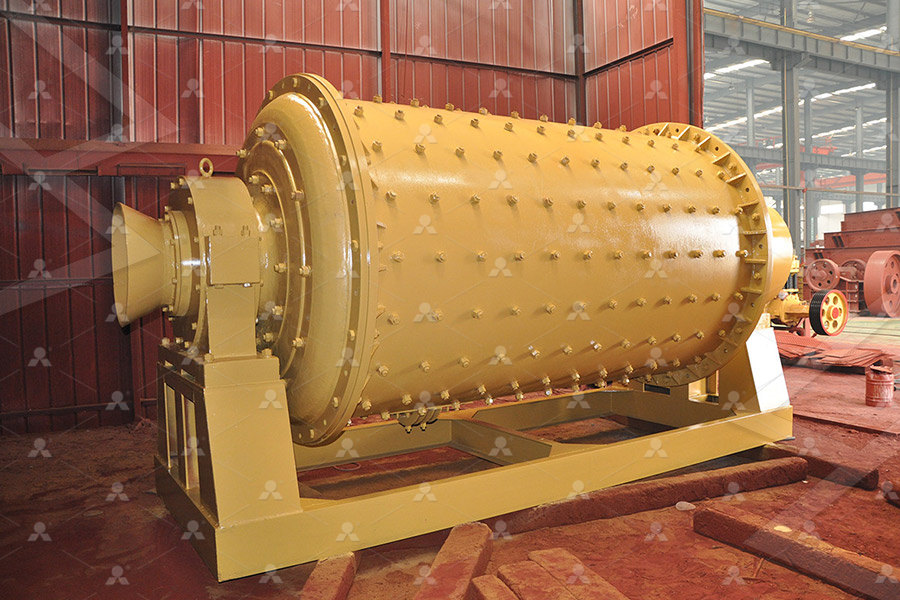

2021年1月15日 low grade zinc oxide ore con taining 52% zinc using ammonium sulpha te was carried out and 922% of zinc was dissolved 6 Chen et al 8 discovered that when the zinc oxide ores of 65–76 µm 2024年6月1日 Although China has abundant zinc oxide ore resources, especially Lanping Lead−Zinc Mine in Yunnan Province, the distribution characteristics of zinc oxide ore resources and their own characteristics (such as difficult to concentrate, high silicon, and high iron) lead to difficulty in relevant processing and smelting technologies [2,5]Efficient mechanochemical leaching of zinc from zinc oxide ores2016年8月24日 With the gradual depletion of zinc sulfide ores, exploration of zinc oxide ores is becoming more and more important Hemimorphite is a major zinc oxide ore, attracting much attention in the field of zinc metallurgy although it is not the major zinc mineral This paper presents a critical review of the treatment for extraction of zinc with emphasis on flotation, Hemimorphite Ores: A Review of Processing Technologies for Zinc 2016年12月1日 The lowgrade zinc oxide ore in the present study was from Lanping County in Yunnan Province of China After crushed and ground in a ball grinder, it was screened to a particle size of less than − 200 mesh with Tyler SievesThe materials ground were characterized by chemical method and examined by XRDRecovery of zinc from a lowgrade zinc oxide ore with high

.jpg)

Extraction of Zinc: Process, Ores, Diagram EMBIBE

2023年1月25日 2 Conversion of zinc blende to zinc oxide through the roasting process 3 Conversion of zinc oxide to crude zinc by reduction through coke 4 Electro refining of crude zinc to pure zinc metal through electrolysis Q3 What is the main ore of zinc? Ans: The main ore of zinc is zinc blende \({\rm{ (ZnS) }}\) Q4 What is the first process of 2018年5月17日 Zinc ore is produced also at Rosebery in Tasmania; Elura in New South Wales; and Scuddles and Gossan Hill in Western Australia Zinc oxide and zinc dust is produced from primary and scrap zinc at West Footscray in Melbourne, Victoria and in minor amounts in Brisbane, QueenslandZinc Geoscience AustraliaThe sphalerite ore found here was presumably converted to zinc oxide via roasting, although no archaeological evidence of this has been found Smelting is thought to have been done in sealed cylindrical clay retorts which were packed with a mixture of roasted ore, dolomite , and an organic material, perhaps cow dung , and then placed vertically in a furnace and heated to around Zinc smelting Wikipedia2024年2月3日 The production of zinc oxide incorporates a series of metallurgical and chemical processes, the two main metallurgical processes are; (I) Direct process; this involves the reduction of zinc ore in the presence of coal and, followed by vaporization and oxidation [1, 2], (II) Indirect process; involving the melting and vaporizing of zinc metal at 910 °C followed by the Production of Zinc Oxide from Willemite Containing Ore from

.jpg)

Zinc Ore HorizonXI Wiki

Chunk of zinc ore This ore contains the metal zinc Stackable: 12 Other Uses Used in Quests: Beauty and the Galka; Shady Resale Price: 24~25 gil Synthesis Recipes None Used in Synthesis Recipes 01 Zinc Oxide; 9, 10 Brass Ingot; 20 Paktong Ingot; Desynthesis Recipe None Obtained From Desynthesis None; How to Obtain Auction House 2024年6月1日 Lead–zinc oxide ores are commonly found in the oxidation zone of sulfide deposits, which are secondary oxidized minerals formed by the longterm weathering of sulfide ores, and are mainly located near the surface and are easy to mine [14], [15]There are various types of natural lead–zinc oxide minerals, and the main minerals are shown in Table 1Efficient flotation separation of lead–zinc oxide ores using mineral The processing mineralogy characteristics of an oxidized leadzinc ore from Sichuan were studied systematically using numerous modern instruments Results showed that lead and zinc oxide content in the ore exceeded the minimum industrial grade, and also included a relatively high concentration of silver and iron This ore is composed of many different minerals Major zinc Processing Mineralogy Study on Lead and Zinc Oxide Ore in Zinc oxide crystalizes in the wurtzite structure and has a band gap of 33 electronvolts at room temperature, Direct/American Process: Here, zinc ores or concentrates are mixed with coal and heated in a furnace, generating zinc vapors which react with oxygen to form zinc oxideZinc Oxide (Zincite) Formula, Properties Application

.jpg)

Preparation of high purity zinc from zinc oxide ore by vacuum

2017年12月1日 Zinc oxide ore from Lanping County of Yunnan province was used in the experiments Table 1 and Table 2 illustrate the chemical content and phase compositions of the original mineral Table 1, Table 2 show that the content of zinc is 3346% and the major mineral is smithsonite (ZnO) in the original mineral Coking coal from Douli Mountain Town of Lianyuan The recovery of zinc from lowgrade zinc oxide ores with solvent extractionelectrowinning technique was investigated by using D2EHPA as extractant and 260# kerosene as diluent The results show that it is possible to selectively leach zinc from the ores by heap leaching The zinc concentration of leach solution in the first leaching cycle is 3257 g/L, and in the sixteenth Recovery of zinc from lowgrade zinc oxide ores by solvent2015年5月13日 Thermodynamic analyses and kinetic studies were performed on zinc oxide ore treatment by (NH4)2SO4 roasting technology The results show that it is theoretically feasible to realize a roasting reaction between the zinc oxide ore and (NH4)2SO4 in a temperature range of 573–723 K The effects of reaction temperature and particle size on the extraction rate of zinc Thermodynamics and kinetics of extracting zinc from zinc oxide ore 2010年11月1日 Alkaline leaching is an important way for treating low grade metal oxide ore, which has some advantages such as low corrosion and low pollution compared to acidic leaching In order to recover the zinc from a low grade complex zinc oxide ore in which the grade of Zn and Fe are 13 wt% and 402 wt%, respectively, and 528% of Zn is contained in siderite, 3463% Alkaline Leaching of Low Grade Complex Zinc Oxide Ore

Experimental and theoretical evaluation of zinc recovery from zinc

In the present study, the production process of zinc sulfate from the zinc oxide ore was experimentally investigated The effect of main operating condition such as weight ratio of sulfuric acid to zinc content of ore (H 2 SO 4 /zinc), leaching temperature (°C), stirring speed (rpm), leaching time (min), particle size (mm), solid to liquid ratio (pulp density, wt %), additives 2018年6月22日 Zinc is an important base metal required for various applications and is mainly recovered from primary sulfide ores via flotation and metallurgical processes 1With the rapid development of Sulfidation mechanism of ZnO roasted with pyrite2022年10月7日 Firstly, zinc oxide ores are concentrated by conventional physical separation methods such as flotation, gravity separation, or magnetic separation, with low metal recovery and high operating costs [13–16] Secondly, zinc oxide ores can be treated via pyrometallurgical or hydrometallurgical methodsStudy on Hydrometallurgical Treatment of Oxide Ores Bearing ZincZinc oxide ores are subjected mainly to two treatments, namely, pyrometallurgy and wet metallurgy [7,8] The former brings about serious environmental pollution, whereas the latter, with favourably high metal leaching rate and low cost, could better satisfy environmental requirements Two principal Dissolution Kinetics of Zinc Oxide Ore with an Organic Acid

.jpg)

Leaching kinetics of low grade zinc oxide ore in NH

2008年10月1日 The leaching kinetics of low grade zinc oxide ore in NH3NH4ClH2O system was studied The effects of ore particle size, reaction temperature and the sum concentration of ammonium ion and ammonia on the leaching efficiency of zinc were examined The leaching kinetics of lowgrade zinc oxide ore in NH3NY4ClH2O system follows the kinetic law of iron, lead, silver, calcium, and silicon from zinc oxide ores However, due to a large number of stages, long duration and lack of information about transition of the metals in products, this method cannot be classified as a promising one The Waelz process is the main pyrometallurgical method for processing oxide ores (Romanteyev et al, 2006)Complex processing of oxidized copper and zinc oxide ores with 2024年3月12日 Zinc extraction from oxide ore has been paid more and more attention to due to the exhaustion of zinc sulfide ore resources In this work, the volatilization kinetics of Zn from the flotation products of lowgrade lead–zinc Volatilization Kinetics of Zinc from the Flotation 2013年1月1日 And the kinetic study indicates that the calculated activation energy is 457 kJ/mol, which illuminates that alkaline leaching the refractory hemimorphite [Zn4(Si2O7)(OH)⁎H2O] zinc oxide ores is Leaching of zinc from low grade oxide ore using

Smithsonite Flotation from Zinc Oxide Ore using Alkyl Amine

2014年1月17日 zinc oxide ore; ACKNOWLEDGEMENTS The authors would like to thank the Calcimin Company and Amirkabir University of Technology for the financial support of this research Log in via your institution Access through your institution Log in to Taylor Francis Online Log in 2017年11月11日 The orthogonal test was used to optimize the reaction conditions of roasting zinc oxide ore with NaOH aiming to comprehensively utilize zinc oxide ore The optimized reaction conditions were molar ratio of NaOH to zinc oxide ore 6:1, roasting temperature 450 °C, holding time 150 min The molar ratio of NaOH to zinc oxide ore was the most predominant factor Extracting reaction mechanism analysis of Zn and Si from zinc oxide ore 2016年11月4日 The leaching kinetics of a lowgrade zinc oxide ore in different acid media was investigated with respect to the experimental variables including acid concentration, temperature, liquid to solid (L/S) ratio, and stirring speed The results obtained showed that the leaching reagent concentration and the reaction temperature exerted significant effects on the Investigation of leaching kinetics of zinc from a lowgrade ore in 2022年4月20日 Furthermore, hydrometallurgical processes have evolved in recent years to meet the challenge of mining low metal concentrations in ores Historically, the majority of zinc metal was extracted from zinc sulfide ores However, due to the current depletion of zinc sulfide ores, the exploitation of zinc oxide ores has increased [85,87]Accessing Metals from LowGrade Ores and the Environmental

.jpg)

[PDF] Leaching and solvent extraction purification of zinc from

2021年1月15日 An integrated hydrometallurgical process was used for the zinc leaching and purification from a zinc ore containing 975 wt% zinc, which showed that after precipitation of iron, Zn extraction of 885% was obtained with the 2 stages extraction system composed of 30 vol% D2EHPA as extractant An integrated hydrometallurgical process was used for the zinc 2008年10月10日 The leaching kinetics of low grade zinc oxide ore in NH3NH4ClH2O system was studied The effects of ore particle size, reaction temperature and the sum concentration of ammonium ion and ammonia on the leaching efficiency of zinc were examined The leaching kinetics of lowgrade zinc oxide ore in NH3NY4ClH2O system follows the kinetic law of Leaching kinetics of low grade zinc oxide ore in NH3NH4ClH2O 2009年7月1日 Affecting factors, such as ore size, leaching temperature, holding time, alkaline concentration and liquid: solid ratio (volume/weight) (L/S), were studied to leach refractory hemimorphite [Zn 4 (Si 2 O 7)(OH)H 2 O] zinc oxide ores with NaOH solution in this paper The impact of leaching recovery of Zn and its concomitant metals was checked through experimentsAlkaline leaching Zn and its concomitant metals from refractory A process for recovering zinc oxide from a zinc ore, the process including the steps of: leaching the zinc ore with an alkaline lixiviant comprising an aqueous mixture of NH 3 and NH 4 Cl, or ionic equivalent, having a NH 4 Cl concentration of between about 10 g/L and about 150 g/L H 2 O and a NH 3 concentration of between 20 g/L H 2 O and 250 g/L H 2 O, to produce a zinc Process for zinc oxide production from ore Google Patents