Crushing and powder making process equipment factory

.jpg)

Industrial Powder Processing Production Machine Factory

Jiangyin Wanling Factory is manufacturer of Powder Processing Production Equipment We manily manufacture powder grinding, dryer, mixer, granulator, sifer, machine, etc HomeAs a professional powder handling systems manufacturer and factory in China, yinda has been in the powder handling industry for over 20 years We manufacture and supply all types of powder handling systems, including China Powder Handling Systems Baichy company is factory supplier on mining machinery , mainly focus on stone crushers, powder grinding mill and mineral beneficiation plant We can offer you free design and completed solution according to your projectBaichy Heavy Industrial Machinery Co, LtdChina Crushing Equipment wholesale Select 2024 high quality Crushing Equipment products in best price from certified Chinese Crusher manufacturers, Exhibition Equipment suppliers, wholesalers and factory on MadeinChinaCrushing Equipment MadeinChina

.jpg)

ALPA Powder Technology

Based on the ultrafine powder field, we provide you with mature processes and solutions for Jet Mill, Impact Mill, Classifier, Laboratory grinding and classifying equipment, steam kinetic energy Jet Mill, nonmetallic mineral powder China Powder Crushing Machine wholesale Select 2024 high quality Powder Crushing Machine products in best price from certified Chinese Machine Machinery manufacturers, Machine Powder Crushing Machine MadeinChinaHenan Jiaozuo Heavy Mining Machinery Co,ltd (JHM) has more than 30 years experience in stone crushing, industrial powder making, mineral calcination drying and ore beneficiation fieldJHM provides onestop mining equipment JHMBaichy Heavy Industrial Machinery Co, Ltd is a famous Mining Machinery Manufacturer and Exporter, integrating RD, design, sales, and aftersale services, focusing on stone crushers, powder grinding mills, mobile crushing Jaw Crusher Manufacturer, Stone Crusher, Cone

.jpg)

Fine Powder Crushing Machine MadeinChina

These essential parts work together to crush, process, and heat gypsum into the desired powder form, facilitating efficient production processes China manufacturing industries are full of In the cow dung powder fertilizer production process, composting is the most important step So, you need choose the compost making machine carefully Now, the bestselling manure composting equipment on the market is trench Cow Dung Powder Making Machine Making 2024年1月11日 The equipment for the coarse crushing is the jaw crusher, the medium crushing system uses the impact crusher, and the fine crushing system uses the sandmaking machine 1 Jaw crusher When processing limestone, Limestone Crushing And SandMaking PlantCement manufacturing equipment needs to withstand the heat and the abrasive material from which cement is made Making cement involves combining raw materials including limestone, clay, and shale, which are milled into a very fine Cement Making Process: Equipment Manufacturing

Pearlite Sand Production Line Equipment And Process Flow

2024年2月26日 Process flow Large pieces of perlite enter the vibrating feeder and uniformly go to the jaw crusher for coarse crushing; The material from the jaw crusher enters an impact crusher for fine crushing; The perlite from the impact crusher enters a circular vibrating screen for screening and grading; The perlite particles that meet the feeding particle size requirements The first step in the overall powder metallurgy process is making metal powders There are four main processes used in Power Metallurgy Equipment Association Metal Injection Molding drying, reducing, annealing, and crushing—is often required, ultimately yielding highpurity and highdensity powders Copper is the primary metal Making Metal Powder MPIF2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding process2021年12月20日 The equipment used during the processing of calcium carbonate powder affects grain types and particle size distribution Prater Equipment for Calcium Carbonate Manufacturing Processes Prater Industries makes a number of machines wellsuited for breaking apart aggregates like limestone, chalk, or marble to make calcium carbonateCalcium Carbonate Manufacturing Process and Equipment

.jpg)

Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Process variables, factors and Process interaction Air flow rates; Kiln hot gases pass upward in countercurrent to fed meal flow The hot gases have vital role in controlling thermo chemical process These gases can be divided into two categories: primary air, and tertiary airThe waste glass is recycled and reused after crushing, grinding, modification, and other technological processes, which can realize resource recycling The glass powder making machine developed and produced by SBM is an industrial ultrafine grinding mill, which is mainly used for the crushing and grinding of nonmetallic oresUltrafine Glass Powder Making MachineFind production technology for making , Spice Processing Equipment turmeric, cumin, or pepper, as well as premixed blends such as Masala, FiveSpice Powder, or Old Bay Which spices technology do you need? Select your production process All Select your operation type All Select your product format AllSpice Processing Equipment and Machinery Making2023年12月27日 The steel slag waste after various mechanical equipment processes will be reused in multiple industries, directly turning it into treasure For example, the steel industry produces a large amount of steel slag during the Steel Slag Processing Plant Equipment Selection

.jpg)

The selection and design of Crushing equipment Performance

2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact 2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments The primary objective of crushing is to reduce the ore size for subsequent processing and Iron Ore Processing: From Extraction to ManufacturingHere we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Fine Powder Making Machine We will do everything we can just to keep every buyer updated with this highly competitive industry factory and its latest trendsFine Powder Making Machine MadeinChinaHenan Jingying Machinery Co, Ltd is a leading manufacturer of crushing and screening equipments in China Manufacturing and 100% OEM full range of crushing and screening machines Including mobile crushing and screening plants,jaw crusher,cone crusher,impact stone crusher,VSI sand making machine,vibrating screens, fine sand recovery,as well as providing Gongyi Jingying Machinery Manufacturing Factory

Powder Making Machine Yinda

Powdermaking machines are size reduction equipment used to convert materials into powder form through milling or grinding On the contrary, powder filling machines fill the powder product into pouches, bottles, or containers It is true to say that a powder filling machine is ancillary equipment for a Powder Making Machine, and not vice versaDescription The chilli powder grinding machine can grind dry chili into 20120 mesh chili powderThrough the relative movement between the movable toothed disc and the fixed toothed disc, the pepper grinder makes the dried hot peppers pulverized by tooth impact, friction and impact between the peppers The pepper grinder has the characteristics of good crushing Commercial Red Chilli Powder Grinding Making Machine Chili 2024年9月6日 Yes, it is effective The final sand has uniform particle size, low overcrushing rate, low needlelike content, and no internal cracks In addition, the particle size distribution, mud block content, stone powder content, crushing index, apparent density, bulk density, and other technical indicators meet the requirements of construction sand, and the overall effect is still Double Roller Crusher Machine For Sand MakingWe warmly welcome you to buy powder making machine for sale here from our factory chemical, food, magnetic material, powder and other industries It is a new generation of crushing equipment The machine is made entirely of stainless steel, and there is no dust flying in the production process Usage This powder making machine China Powder Making Machine Manufacturers, Suppliers, Factory

Copper ore crushing equipment and beneficiation process

In the crushing process, the threestage closedcircuit crushing is more modern and suitable for highhardness copper ore crushing, and can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency; The efficient grinding process can make the copper ore grind more fully; in the beneficiation process, the more successful Manufacturing of Jaggery is from sugar cane followed by clarification and concentration process It is Uncentrifuged sugar (ie Without separation of molasses) with minimum sucrose 70 to 80% by mass It is also called as Gur Jaggery Making Process from Sugar Cane Gur The talc milling process is generally divided into two stages: crushing and grinding The equipment used includes a jaw crusher, talcum powder making machine, bucket elevator, electromagnetic vibrating feeder, fan, analyzer, Talcum Powder Making MachineGypsum powdermaking process According to the process requirements, the construction gypsum production line is usually divided into five parts, including crushing system, storage conveying system, grinding system, calcining Gypsum Powder Manufacturing Gypsum Powder

.jpg)

Bentonite Processing Methods And Required Equipment

The product fineness of bentonite powder processing equipment Raymond mill is generally around 325400 mesh With the development of technological progress, the demand for finer powder products is increasing Improve the ability to capture fine powder and reduce pollution to the surrounding environment2020年8月25日 Before you send inquiry Please provide us with project information as much as possible: For a complete project: the material availability, the required output capacity, the process technology, your budgetary and financing status, the estimated starting time, etc For singular machinery: the model, the capacity, your budgetary information, other requirements, etcCement Production Process Cement Manufacturing ProcessThe block diagram of the production process of cement is given below : Figure 1 : Cement production process block diagram 2 Cement production step by step 21 Limestone rock crushing Limestone rock crushing typically involves the use of a crusher machineCement Production Demystified: StepbyStep Process and Organic jaggery powder manufacturing process; 2530 tcd sugarcane crusher with planetary gear box motor Commercial sugarcane juice extractor om kailash no4; 200 tcd sugarcane crushing machine; 500 tcd sugarcane crushing machine; Semiautomatic jaggery making plant, capacity: 15 to 500tcd; Industrial jaggery plant; 100 tcd sugarcane Jaggery Plant Jaggery Making Machine Latest Price,

Stainless Steel Moringa Leaf Powder Making Machine Spice Pulverizer Machine

Moringa leaf powder making machineis to grind Moringa leaf We must first dry the moringa leaves It can be dried naturally or machinedried For moringa processing, it is recommended to use Moringa leaf drying equipment This can increase the output of Moringa leaf powder Moringa leaf powder grinding machine has simple structure, stable operation, low noise and good 2024年4月22日 The equipment is developed for the properties of bentonite, with strong processing capacity and high powder production efficiency The vulnerable parts are cast with strong wearresistant materials, resulting in low wear during powdermaking operations, long service life of the entire machine, and low costBentonite Processing Plant And Grinding Machine2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine Powder Manufacturer, Exporter suppliers of Grains, pulse processing machine, industrial crushing, grinding and pulverizing equipment vibrating and rotating screens mixing and blending machinery chapati making machines papad making Grains, pulse processing machine, industrial crushing,

.jpg)

How Does The Graphite Grinding Plant Process?

2024年9月20日 2 Impact crusher The impact crusher can process materials with a side length of 100500 millimeters or less, with a maximum pressure resistance of 350 MPA It has the advantages of a large crushing ratio and with cubic material particles This machine is widely used in building materials, ore crushing, railways, highways, energy, transportation, cement, mining, The equipment operates with low noise There is a dustproof movable trolley at the bottom, which is convenient for material transfer 6 Cocoa Powder Making Machine The coarsely crushed cocoa cake has a large particle size and requires further grinding We use fine crushing equipment, and the design speed of the pendulum can reach 3800r/minSmall Scale Cocoa Processing Equipment 100 KG/HDetergent Powder Making Machine The speed of the shaft driven by the reducer and the blade structure will weaken the gravity of the material Since there is no gravity, the difference in particle size and specific gravity of each material during the mixing process is negligibleChina Customized Detergent Powder Making Machine Suppliers Tomato processing in a factory is a complex and highly regulated process that varies depending on the intended end product Whether it's canned tomatoes, tomato sauce, ketchup, or other derivatives, each step plays a crucial role in delivering a highquality product to consumersTomato Processing Steps in Factory

Graphite Ore Processing: Optimal Processes and Equipment

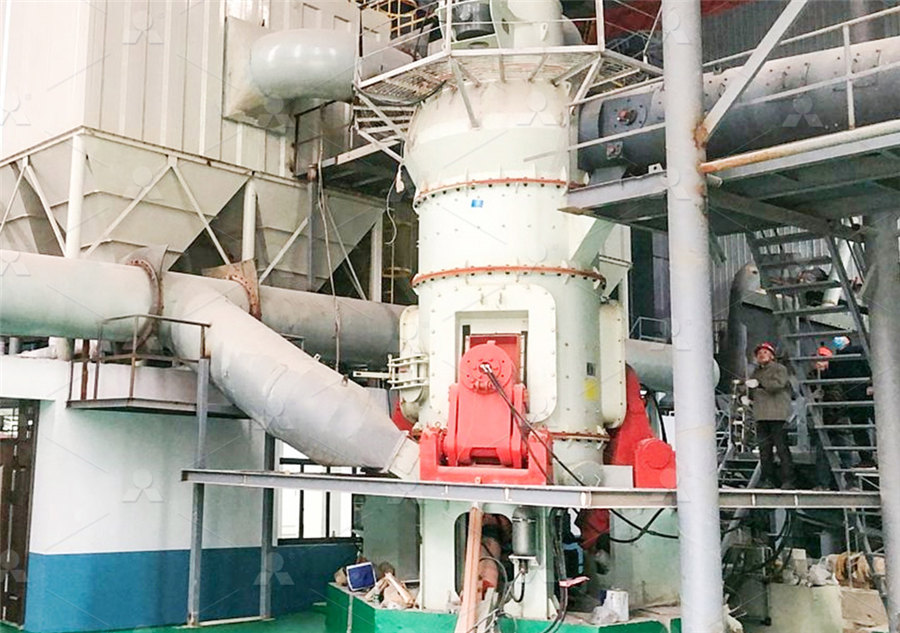

2023年5月12日 Graphite ore crushing (1) Raw ore feeding particle size: 300~500mm; (2) Final product particle size: 10~20mm; (3) The commonly used crushing process is a twostage open circuit or a threestage open circuit; (4) The equipment is a jaw crusher for primary crushing, a cone crusher, or a hammer crusher for final crushing① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill system, and it can be arranged in the open air, greatly reducing investment costsStone Powder Making Machine2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball Quartz Processing Mastering the Art of Stone to PowderLarge stone → Jaw Crusher (I period crushing)→ medium stone → cone crusher/ impact crusher (II period crushing) small stone → sand making machine (III period crushing)→ fine sand (aggregate finished product)→ mill → fine powder → powder separator equipment(dry sand dry powder) AIMIX crushing and screening equipment are mainly Crushing And Screening Plant Process Flow Video! Aimix