Lithium ore crushing process operating procedures

Lithium Ore Processing – an Overview of the Current and New

three or four stages of crushing are used, with only the runofmine (ROM) jaw crusher operating in open circuit The fines generated during crushing are either sent to tails, combined with DMS floats2021年5月1日 Some specific techniques of lithium extraction from ores and minerals are systematized Autoclave methods seem the most promising for poor alkaline Li Processing of lithium ores: Industrial technologies and case studies 2021年5月1日 Some specific techniques of lithium extraction from ores and minerals are systematized Autoclave methods seem the most promising for poor alkaline Li Processing of lithium ores: Industrial technologies and case studies 2023年1月1日 The process flow is to convert lithium in ore into lithium sulfate by mixing roasting lithium mineral and excessive potassium sulfate (or calcium sulfate or a mixture of both), leach Lithium extraction from hard rock lithium ores (spodumene,

Processing of lithium ores: Industrial technologies and case studies

2021年2月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically The lithium hardrock mining process at Mount Marion starts with primary crushing followed by secondary and tertiary crushing The crushed ores will be sent to gravity separation and dense LESSONS LEARNED FROM NEW HARDROCK LITHIUM PROJECTSImpurity removal from the salar brine is a critical step in the process flowsheet for production of batterygrade lithium Our MaxRTM technology provides the most advanced method in the Lithium processing technology Complete solutions that FLSmidthMetallurgical results show that a high grade lithium concentrate (>7%) can be achieved SGS supports the minerals and chemical industries in the design and operation of efficient crushing Hard Rock Lithium Processing SGS

.jpg)

Hard Rock Spodumene Lithium Processing Saltworks Technologies

2023年12月27日 In step 1, to convert spodumene into lithium sulfate (Li 2 SO 4), the raw ore is crushed and separated both mechanically and via floatation Next, the concentrate undergoes From chemical recovery of lithium brines to crushing, roasting and acid leaching of lithium ores in spodumene, Albemarle’s technical and chemical process knowhow delivers consistent, high Lithium Resource Processing Albemarle2023年1月1日 Lithium resources in nature are mainly stored in lithium deposits of brine, pegmatite, and sedimentary rocks (Talens PL et al, 2013; Liu LJ et al, 2017)Among them, brine mainly includes underground and salt lake brine, and pegmatitetype lithium ore is stored in spodumene, lepidolite, petalite, and zinnwaldite (Xi WW et al, 2022; Yu F et al, 2019), while Lithium extraction from hard rock lithium ores (spodumene, 2021年5月1日 Also, we have summarized and studied the conditions of lithium extraction from other raw materials, in particular, from mica, which is obtaining simultaneously in form of flotation tailings during the complex processing of fluorite‑beryllium ores of the Voznesenskoye deposit (Primorsky Territory) (Kupriyanova and Shpanov, 1997), and, also, from the petalite ores of Processing of lithium ores: Industrial technologies and case

.jpg)

Lithium Extraction and Refining Saltworks

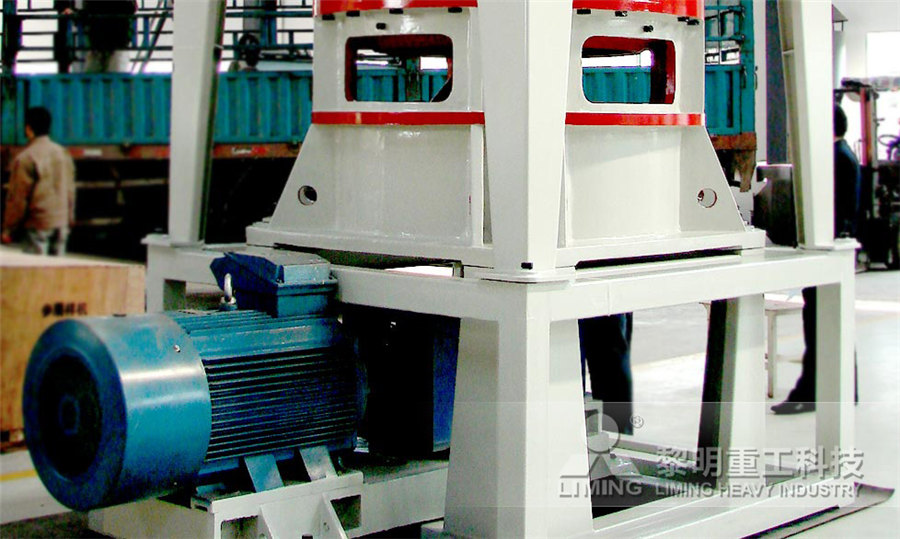

Lithium brine ponds: concentrating and precipitating impurities from geological lithium brines via evaporation pondsA highly concentrated lithium solution is subsequently refined and converted into lithium carbonate or hydroxide 2020年4月12日 This SuperPro Designer example analyzes the production of Lithium from Spodumene Ore The results include detailed material and energy balances, equipment sizing, capital and operating cost (PDF) Lithium Extraction from Spodumene Ore ResearchGate2022年8月2日 Process mineralogy plays a key role in defining the properties of ores, identifying key opportunities, and ascertaining potential challenges associated with the extraction of lithiumA Review of Characterization Techniques and Processing Methods 2024年4月8日 The lithium processing plant equipment includes a jaw crusher, a fine jaw crusher, a storage bin, a ball mill, a hydraulic cyclone, a mixing tank, and a flotation machine The hydraulic cyclone and ball mill constitute a closed circuit grinding and classification cycle, which improves the efficiency and fineness of classification grindingSelection Of Lithium Ore Processing Plant Equipment

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Crushing and screening are integral processes in iron ore processing that help prepare the mined ore for further beneficiation and downstream use These processes involve breaking down the mined ore into smaller fragments and separating it based on size Let's explore the crushing and screening stages in more detail: 1 Crushing2023年4月23日 Lithium (Li) ore is a type of rock or mineral that contains significant concentrations of lithium, a soft, silverwhite alkali metal with the atomic number 3 and symbol Li on the periodic table Lithium is known for its unique properties, such as being the lightest metal, having the highest electrochemical potential, and being highly reactive with waterLithium (Li) Ore Minerals, Formation, Deposits Geology Science2022年7月6日 The beneficiation method of lithium ore is based on the mineral properties of lithium ore, mainly the physical, chemical or physicochemical properties of different minerals, using different methods to separate lithium ore and gangue minerals, and make the symbiotic useful minerals as much as possible The separation process of separating from each other Lithium ore flotation process2016年5月9日 Lithium Sector Report The report includes a very detailed demand analysis (ie Liion batteries with a look at cathode chemistry for lithium carbonate vs lithium hydroxide, and the relative lithium content for various types of oxide cathodes, plus lithiumion battery usage by different market segments including Passenger Electric Vehicles (EV), EBuses, personal Processing Spodumene by Froth Flotation for Lithium Extraction

.jpg)

Roasting Processes for Lithium Extraction

2020年11月18日 Extracting lithium from ores has higher operating costs than conventional extraction from brine, however, the theory of supply and demand makes the processing economically prudent because of the increasing price of REV NO A PRIMARY CRUSHING AREA PREOPERATIONAL INSPECTION PAGE 2 OF 21 THIS DOCUMENT UNCONTROLLED IN HARDCOPY FORMAT STANDARD OPERATING PROCEDURE PRIMARY CRUSHING AREA PREOPERATIONAL INSPECTION Document No: XXXX Document Information: Procedure: Primary Crushing Area Preoperational Inspection STANDARD OPERATING PROCEDURE PRIMARY CRUSHING 2022年1月1日 Lithium extraction from hard rock lithium ores (Spodumene, Lepidolite, Zinnwaldite, Petalite): Technology, resources, environment and cost Tianming Gao, Na Fan, Wu Chen, Tao Dai(PDF) Lithium extraction from hard rock lithium ores: technology Elevate industry standards with our Mining Standard Operating Procedures for optimal safety and efficiency Skip to content Contact; About; Standard Operating Procedures (SOPs) Business Process Documentation; By Role/Department These materials include gold, iron ore, coal, lead, silver, lithium (also from salt deserts), Mining Standard Operating Procedures, SOPs for Mining Industry

Lithium Ore Flotation Plant Pineer Mining Machinery

The Pineer froth flotation process enables sustainable and costeffective spodumene/lithium ore recovery Comes from one supplier, responsible for the whole package Provides mechanical and performance guarantees for the entire plant machinery, with clear battery limits for engineering and implementationWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe six main steps of iron ore processing Multotecmanganese, and lithium, are not considered in this study Research on the recovery of lithium from LIB by means of sc CO2 is not published yet Originally, the COOLProcess was developed for the production of Li2CO3 from lithium containing ores, like The COOLProcess—A Selective Approach for Recycling Lithium Lithium is also recovered from lithiumbearing ores, such as spodumene, through a process that involves crushing, roasting and acid leaching Other methods of lithium extraction, such as direct lithium extraction from geothermal and oil well brines, are currently being investigated to help raise global productionLithium handling Carmeuse Systems

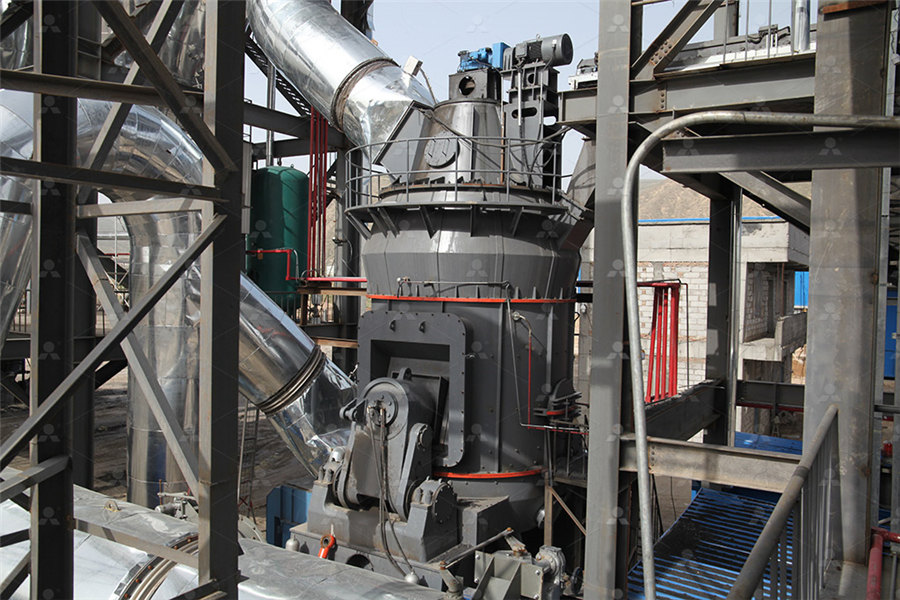

lithium ore beneficiation and crushing and milling process

2022年12月15日 Spodumene: According to the hard rock crushing process, the crushed products are generally 540mm, combined with customer requirements of different design of two ends or three sections of crushing, broken products of high grade (more than 45%) can be directly into the metallurgical process to produce lithium carbonate or lithium hydroxide, the 2024年9月19日 With the rapid development of new energy fields and the current shortage of lithium supply, an efficient, clean, and stable lithium resource extraction process is urgently necessary In this paper, various advanced detection methods were utilized to conduct a mineralogical analysis of the raw ore and systematically study the occurrence state of lithium; Sintering Mechanism and Leaching Kinetics of LowGrade Mixed Lithium 2019年5月29日 This literature review gives an overview of the lithium industry, including the lithium market, global resources, and processes of lithium compounds production It focuses on the production of lithium compounds Spodumene: The Lithium Market, Resources and 2024年1月31日 This significant milestone was followed by the successful delivery of a second 100 tph DMS plant several years later, significantly increasing the processing capacity The recognition of our expertise and Pioneering Lithium Ore (Spodumene) DMS Plants

Crushing in Mineral Processing 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for 803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates with 76% Li 2 O and low iron content areHard Rock Lithium Processing SGS2024年11月21日 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the overcrushing of ore, and at the same time it can increase the output per unit volume 1 Large row of ore mouth design, stronger processing capacity for lithium ore, up to Ball Mill Is Indispensable For Lithium Ore Processing2016年1月27日 Detailed Process Description and Control of our EXAMPLE small crushing plant Runofmine ore is delivered to the Crushing Plant via mine rail cars or underground mine haulage trucks, and is dumped through a 16″xl6″ grizzly into a 350 tonnes coarse ore bin Oversize material on the coarse ore bin grizzly must be manually removed and brokenSmall Crushing Plant Operating Guide 911Metallurgist

.jpg)

Quantification of Lithium and Mineralogical Mapping in Crushed Ore

2022年2月16日 This article reports on the quantification of lithium and mineralogical mapping in crushed lithium ore by laserinduced breakdown spectroscopy (LIBS) using two different calibration methods5 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process for each specific ore type, thereby increasing cost efficiency and resource sustainabilityBall Mill Is The Key To Grinding Lithium Ore JXSC Machinery803% Due to its high lithium content, spodumene is considered the most important lithium ore mineral A typical run of mine ore can contain 12% Li 2 O, while a typical spodumene concentrate suitable for lithium carbonate production contains 67% Li 2 O (75% 87% spodumene) Higher grade concentrates with 76% Li 2 O and low iron content areHard Rock Lithium Processing SGSThis setup is for processing spodumene ore to recover lithium, it is a flotation separation plant and has a high recovery ratio for LiO2#hopper #vibratingfe500TPH Lithium Ore Crushing And Beneficiation Process

.jpg)

Lithium Extraction Methods

Hardrock mining is another method that involves extracting and refining lithiumbearing minerals such as spodumene This process is energyintensive and can have adverse environmental impacts In recent years, a new innovative Regarding reserves, the globally confirmed lithium resources have significantly increased, totaling approximately 98 million tons Bolivia boasts the highest reserves, accounting for 2157 % of the global total, followed closely by Argentina and Chile (Fig 1 d) [6]Among these, salt lake brine resources make up 723 % of the reserves, while ores account for 203 %, with nearly 50 % of Advances and promotion strategies of processes for extracting lithium 2016年3月11日 It was felt by some that crushing to this fine size is only possible if the ore is friable and is relatively soft in comparison to the harder ores Our results show that some of the copper ores are as hard as taconite and are Crushing Plant Flowsheet DesignLayout21 Ore Stockpiles – Three surge piles between different portions of the crushing plant: The Course Ore, the Secondary, and the Truck Loadout Ore Stockpiles 22 Oxide Ore – Oxidized material that has a total sulfur value of ≤023% 23 Sulfide Ore (PAG material) – Partially oxidized or nonoxidized sulfidic ore that canStandard Operating Procedure: ORE STOCKPILE MANAGEMENT

.jpg)

Lithium Processing Plant JXSC Machine

2022年7月5日 Lithium is an element valuable for the production of glass, aluminum products, and batteriesWith the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has increased rapidly Therefore, lithium ore is known as the “energy metal that drives the progress of the world”2023年7月6日 The DMS and crushing circuits utilized to produce lithium concentrate from ore are extremely energy intensive, and carrying contamination through the plant decreases productivity and increases costs Mining operations under pressure to meet the soaring demand need to maximize the efficiency of their processing plants, using their capacity effectively to Unlocking Lithium Mining Potential with TOMRA SortingWe understand the dynamic and intricate nature of Lithium Processing Our commitment to innovation, The modular design of Recipe Procedures allows manufacturing process changes without rewriting and retesting the entire phase logic Designing and Operating A Reliable Plant While a reliable plant is a safe plant, you must design, Lithium Processing RE Mason2021年5月1日 Compared with extracting lithium from brine, extracting lithium from ores, calcination, roasting, purity, and other processes consume more resources and energy; and its environmental impact mainly comes from the pollutants discharged by fossil energy, 93–604 times that of lithium extracted from brine The processing cost of lithium Processing of lithium ores: Industrial technologies and case studies

Hard Rock Spodumene Lithium Processing Saltworks

2023年12月27日 In step 1, to convert spodumene into lithium sulfate (Li 2 SO 4), the raw ore is crushed and separated both mechanically and via floatationNext, the concentrate undergoes energy and chemically intensive hot acidroasting This process (as shown in Figure 1 below) sees concentrated spodumene powder roasted at 1050°C, cooled, mixed with sulfuric acid, This SuperPro Designer example analyzes the production of Lithium from Spodumene Ore The results include detailed material and energy balances, equipment sizing, capital and operating cost Lithium Extraction from Spodumene Ore Process