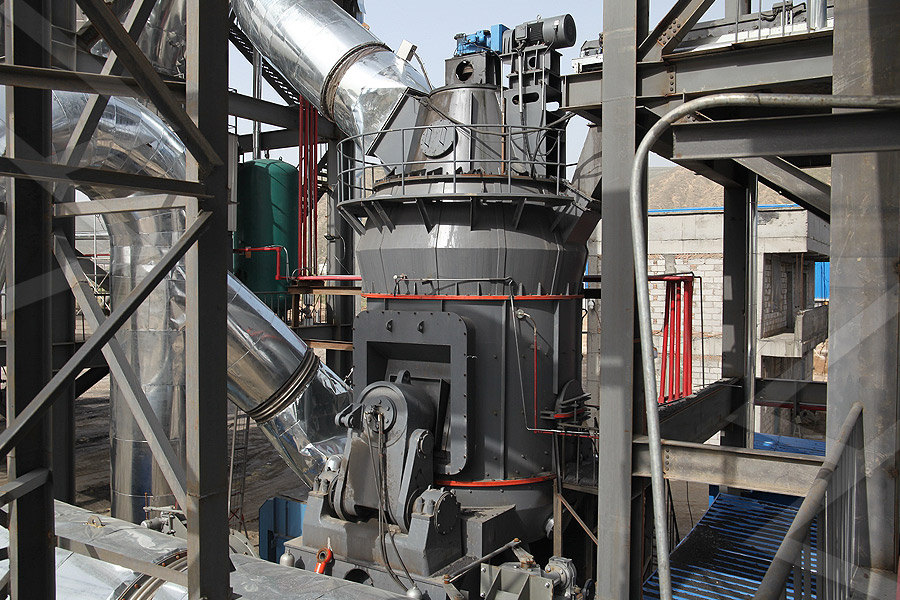

Coke powder making process

.jpg)

How Cocaine is Made: Origins, Additives, and

2022年8月16日 Cocaine is made by subjecting leaves of the coca plant to multiple complex stages of chemical processes to eventually produce pure cocaine and its derivatives (crack cocaine) Coca leaves are harvested, mixed 2024年2月19日 Below are the basic steps involved in the preparation of cocaine: Step 1: Coca leaves are harvested from their parent bushes Step 2: The coca leaves are soaked in gasoline Placing cocaine in gasoline isolates and How is cocaine made? Cocaine Plant to Powder2024年10月22日 Step 1: Reversal Process: Powdered cocaine is dissolved in water and mixed with baking soda, then heated This causes the hydrochloride to separate from the base form Step 2: Formation of Rocks: The resulting solid How is Cocaine Made? AspenRidge RecoveryCocaine Processing The conversion of coca leaves to coca paste, cocaine base and cocaine hydrochloride occurs primarily in Bolivia, Colombia and Peru Peru and Bolivia are the primary Coca Cultivation and Cocaine Processing: An Overview Erowid

43.jpg)

What Is Cocaine Made Of? How Is Cocaine Made?

2024年10月4日 How powdered cocaine is made: 3 The leaves are soaked, filtered, and dried The powder gets mixed with solvents It then gets pressed and heated To make crack cocaine, cocaine hydrochloride is dissolved into a crystalline powder is imported to pharmaceutical companies who process and package the cocaine for medical use Merck Pharmaceutical Company and Mallinckrodt Chemical Works The Making of Cocaine in the Jungle2024年1月19日 The Process: How Is Cocaine Made? The process of how cocaine is made is complex and involves several steps: Harvesting: Coca leaves are picked from the coca plant Extraction: The active compound, cocaine How Cocaine Is Made Greater Boston Addiction Centers2009年1月1日 Following harvest of the leaves and the steps to get crude cocaine paste, is the refining process to yield cocaine base The refining process of illicit cocaine is quite different The Making of Cocaine in the Jungle SpringerLink

.jpg)

(PDF) Iron Ore Sintering: Process ResearchGate

2017年2月16日 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents and solid fuel (coke)The coke production process Raw coke coal briquetting technology Raw coke briquette mainly uses coke briquette machine with types of hot briquetting roller press or cold briquetting press Hot briquetting roller press process For the Industrial coal coke briquette making process, 2024年6月15日 Concurrently, as coke ratios decrease, coke deterioration becomes more pronounced; this significantly affects the smelting process and increase the demand for highquality coke Coke plays an irreplaceable role in blast furnaces (BFs), acting as both the skeleton of the stock column and the permeable layer of the gas flowPhysical and chemical properties of metallurgical coke and its 2021年1月20日 Therefore, the idea that utilization byproducts/waste for AC production came up (Fig 2), using byproducts and wastes such as coke powder, coal tar pitch, benzene residue, etc from cokemaking as raw materials for AC production which further treat wastewater and flue gas from cokemaking The process not only could utilize the cokemaking by Recirculating coking byproducts and waste for costeffective

.jpg)

122 Coke Production

A typical coke manufacturing process is shown schematically in Figure 1222 Coke manufacturing includes preparing, charging, and heating the coal; removing and cooling the coke product; and cooling, cleaning, and recycling the oven gas Coal is prepared for coking by pulverizing so that 80 to 90 percent passes through aCOKE MAKING COAL CARBONISATION : Coking coals are the coals which when heated in the absence of air manganese and silicon within the meltPhosphorous is removed by inducing early slag formation by adding powder lime with oxygen The refining process is completed when the desired carbon content is attained Various other blowing process in Coke OvensSinterBFBOF Route SAILCrack is made by adding baking soda and water to cocaine and cooking the whole thing, usually in a spoon ermingut/Getty Images Crack cocaine is an easiertomanufacture form of freebase cocaine – the only difference between cocaine and crack is that the latter has its hydrochloride removed, increasing the melting point and making the drug smokable Because its production Manufacturing Crack Cocaine How Crack Cocaine Works2019年11月10日 Activated carbon preparation with the addition of cokemaking byproduct—coke powder:Texture evolution and mechanism Author links open overlay panel Xiaojing Chen a, Yanxia Guo a, Jinglei Cui a, oxygencontaining functional groups and ππ* Moreover, the CaO in ACs participates in the desulfurization process and finally Activated carbon preparation with the addition of cokemaking

.jpg)

The Role of Coke in Steel Making Process Cabaro Group

2024年3月25日 These chemical interactions underscore coke's integral role, as they define the inherent qualities of the final steel product—such as tensile strength, hardness, and ductility—emphasizing its indispensability in the traditional steel making process Quality and Properties of Coke for Efficient Steel Making The performance of coke in the 2023年7月17日 In order to address the low thermal efficiency of lowrank coal combustion and the accompanying serious environmental issues, formed coke was prepared using a carbonization consolidation method with lowrank coal semicoke The test for briquetting and carbonation consolidation conditions revealed that the optimal parameters were a briquetting pressure of Clean Preparation of Formed Coke from Semicoke by the 2022年11月15日 As a byproduct/waste from coke production, about 40 Mt of metallurgical coke powder (CP) was generated in China annually The utilization of coke powder is conducive to the environmental and economic sustainability [14]Generally, coke powder has an average diameter less than 5 mm, and similar physical and chemical properties to coke such as high carbon Coke powder improving the performance of desulfurized 2019年1月1日 The requisite coke quality has been a problem for the iron and steel industry in general according to the BF requirement It is well known that the three factors which control coke strength are (1) selection of coals for coal blend, (2) adopted cokemaking technology, and (3) operating parametersIndustrial perspective of the cokemaking technologies

Bluecoke production technology and the current stateoftheart

2020年1月1日 Bluecoke, a kind of coal char named after its blue combustion flame, is obtained by the low temperature pyrolysis (500–750 °C) of noncaking or weaklycaking coal with high volatile matter [1]It is generally granular char with particle size larger than 6 mmGRAPHITE MANUFACTURING PROCESS The process of synthetic graphite manufacturing consists of the following principal stages: Powder preparation Shape forming Baking Graphitization Pyrolytic graphite Powder preparation Raw materials for synthetic graphite fabrication (petroleum coke, pitch coke, carbon black, naturalGRAPHITE MANUFACTURING PROCESS IDCOnline2019年11月14日 Coking is a complex process It features a large time constant, strong nonlinearities, and timevarying characteristics To achieve good control performance, it is important to obtain a precise COT in a realtime fashion; but this is difficult owing to restrictions imposed by the structure of a cokeoven and operating costsIntelligent Optimization and Control of Coking Process2023年9月21日 Essentially, making your own eggshell powder is more than just a DIY project; it reflects the values that define homesteading and allows you to move toward a higher level of sustainability and selfsufficiency StepByStep Guide To Making Eggshell Powder Creating eggshell powder at home is a simple process, but it must be done safelyUltimate Guide: Making Premium Eggshell Powder at Home

.jpg)

How does coke and coal play into steel making?

2016年6月22日 When coke is consumed it generates intense heat but little smoke, making it ideal for smelting iron and steel Prior to the 1880’s, steel was produced using charcoal By 1920, nearly 90% of US steel was produced using coke Coke processes Coke is made by either byproduct or nonrecovery methods2023年12月13日 The resulted powder is conditioned according to the particles size distribution (screening) The last step of powder preparation process is blending the powder with a binder Coal tar pitch, petroleum pitch or synthetic resins are used as binders The powder preparation process is presented in the scheme below to topGraphite manufacturing process [SubsTech]The last stage of making cement is the final grinding process In the cement plant, there are rotating drums fitted with steel balls Clinker, after being cooled, is transferred to these rotating drums and ground into such a fine powder that each pound of it contains 150 billion grains This powder is the final product, cementHow Cement is Made Cement Manufacturing ProcessThe blast furnace uses coke, iron ore and limestone to produce pig iron Coal traditionally has been a key part of the cokemaking process The coal is crushed and ground into a powder and then charged into an oven where it is heated to approximately 1800°F in the absence of oxygenSteel Production American Iron and Steel Institute

}@~3SRDG`IA1KP_ICWAA.jpg)

Copyrolysis of coal with biomass residues and coke breeze for

2024年6月1日 Therefore, bamboo is a promising resource to enrich the raw materials of coking Coke breeze is produced during coke making, quenching and transportation Coke breeze can't be used for ironmaking due to its fine particle size [25] Coke breeze has similar properties to metallurgical coke [16] Coke breeze may be a promising material for coke which not only expands the application fields of coke powder resources, but also benefits for protecting the ecological environment, and improving the utilization rate of coke powder 2 Experimental 21 Preparation of CPACs The coke powder was milled and screened over 200 mesh using standard sieve, then a certain quality of coke powderPreparation and electrochemical properties of coke powder 2021年6月1日 Activated coke can be classified into molding and powder types Columnshaped activated coke (diameter of 5−9 mm) are often used, but they have some disadvantages, such as low utilization efficiency of inner surfaces, high internal diffusion resistance, complex manufacturing process These disadvantages restrict its applicationActivated coke preparation by physical activation of coal and 2024年2月19日 The seat of the cocainemaking process is indisputably in the continent of South America Cocaine is produced in various South American countries, including Colombia, Bolivia, Peru, Ecuador, Venezuela, Brazil, Argentina, and Chile Colombia is a particular hotspot, accounting for nearly ninety percent of the cocaine on the streets in 2020 3How is cocaine made? Cocaine Plant to Powder Avenues Recovery

.jpg)

(PDF) Influence of Preparation Process on Briquette and Form Coke

2018年8月8日 increased, making the coke surface cracks become la rger [Show full abstract] paper, coal tar pitch binder and BJ additive were used in briquetting and carbonizing process of coal powder2022年11月15日 In the process of desulfurization, SO 2 is captured by chemical adsorption to form H 2 SO 4 as the flue gas passes through the movingbed or fixed bed reactors Activated carbon preparation with the addition of cokemaking byproduct—coke powder: Texture evolution and mechanism J Clean Prod (2019)Coke powder improving the performance of desulfurized 2014年1月28日 Metallurgical coke sounds like a soda beverage, but it's not It is a refined carbon product made from a special kind of coal Using extremely high temperatures, coal can purified into coke which is then used in the iron and steel making processes One of the most important steps in the cokemaking process is choosing the right coal to use as a raw materialWhat Is Metallurgical Coke? Sciencing2024年2月21日 Coke quality prediction is always a difficult problem because of the correlation among the indexes of blending coal In this paper, the coal resource data, coal and coke quality data and coking process parameters of Masteel 763m coke oven coking production in recent two years are statistically analyzedCoke Quality Prediction Based on Blast Furnace Smelting Process

.jpg)

233: Metallurgy of Iron and Steel Chemistry LibreTexts

Cast iron has already been mentioned above This section deals with the types of iron and steel which are produced as a result of the steelmaking process Wrought iron: If all the carbon is removed from the iron to give high purity iron, it is known as wrought iron Wrought iron is quite soft and easily worked and has little structural strength2023年6月26日 The freebasing process starts with powder cocaine and ends with what is technically known as cocaine sulfate This conversion process involves ammonia and usually a small glass pipe and a piece of clean, heavy copper The copper is used to melt and boil the cocaine to a vaporFreebasing Cocaine: Why and How People Do This Zinnia Health2020年1月1日 In this study, effects of the KOH addition on the microstructures development in coke powder during its activation process were investigated The obtained AC products were characterized using the specific surface area and pore structure analyzer, Xray powder diffractometer (XRD), scanning electron microscope (SEM), highresolution transmission Activation mechanisms on potassium hydroxide enhanced 2021年12月1日 In the cokemaking process, coals with a reflectance (R0) of roughly 13 are regarded to produce good grade coke To reduce the heterogeneity, each individual coal sample was initially grounded to powder (200 mesh) further, milled by hand using the agate mortar and pestleEvolution characteristics of metallurgical coals for coke making

Metallurgical Coke IspatGuru

2013年4月13日 Metallurgical Coke satyendra; April 13, 2013; 1 Comment ; BF coke, coke, Coke breeze, CRI, CSR, Drum test, Micum, Micum test, Nut coke,; Metallurgical Coke Metallurgical coke or ‘Met coke’ or ‘BF (blast furnace) 2019年6月1日 Production of coal fines in coke making has lately become a problem worth addressing due to its negative impact on ecosystems The use of coal fines is becoming an issue due to high Quinoline Insoluble formation during the carbonisation process as well as carry over or enhancement of carbon deposition in the upper parts of the coke ovens In this study, the Reduction in coal fines and extended coke production through the 2019年7月1日 As a byproduct of cokemaking, the utilization of coke powder is a challenging issue for achieving sustainable development This study describes the preparation of activated carbon (AC) with the Activated carbon preparation with the addition of cokemaking 2020年7月15日 Currently, approximately 95% of hot metal is produced by the blast furnace ironmaking process, which is also predicted to be the largest single ironmaking process until 2050 because of its advantages in production cost and efficiency Therefore, replacing fossilbased fuels with H 2 as the reductant is expected to relieve environmental concerns and, Blast Furnace Ironmaking an overview ScienceDirect Topics

.jpg)

The Cement Manufacturing Process

2017年8月15日 The materials reach temperatures of 2500°F to well above 3000°F in the kiln Rotary kilns are divided into two groups, dryprocess and wetprocess, depending on how the raw materials are prepared In wetprocess kilns, raw materials are fed into the kiln as a slurry with a moisture content of 30 to 40 percent2023年11月23日 The sintering and pellet processes use solid fuels (coke powder, anthracite, etc) and gaseous fuel combustion to provide raw materials for the blast furnace ironmaking process The carbon in the ironmaking process mainly comes from coke and blown coal powder, with a small amount coming from, for example, limestoneCO2 emission accounting and emission reduction analysis of the 2011年5月1日 The ironmaking process including sintering, coke making and blast furnace (BF) accounts for approximately 90% of CO 2 output from an integrated BFBOF (basic oxygen steelmaking) steel plant [1, 2]Substitution of Biomass for Coal and Coke in Ironmaking ProcessDownload scientific diagram Scheme of formed coke briquette production process from publication: Molasses and air blown coal tar pitch binders for the production of metallurgical quality formed Scheme of formed coke briquette production process