Dry limestone powder making Air screening

.jpg)

Evaluation of the Efficiency of Limestone Powder in Concrete and

2018年2月21日 The main goal of this research project is to evaluate the efficiency of limestone powder as a partial cement replacement, in order to reduce energy consumption and CO2 emissions This study2024年1月12日 The compound admixtures of fly ash, metakaolin and expansion agent is more effective in mitigating drying shrinkage in limestone powdercement paste, and its impact on Study on the mitigation of drying shrinkage and crack of limestone 2024年3月5日 To investigate the potential impacts of varying limestone powder replacement ratios and fineness on the properties of limestone powder cement concrete, researchers undertook a comprehensive examination Effectiveness of Limestone Powder as a Partial 2020年5月1日 This paper aims to optimize highvolume limestone powder in sustainable ultrahigh performance concrete (UHPC), and characterize its roles on plasticization effect, hydration kinetics,Optimization and characterization of highvolume

Optimization and characterization of highvolume limestone

2020年5月10日 50 vol% limestone powder with comparable size and morphology to cement is suggested as optimal in UHPC This paper aims to optimize highvolume limestone powder in Potential air pollutant emission points in lime manufacturing plants are indicated by SCC in Figure 11171 Except for gaseous pollutants emitted from kilns, particulate matter (PM) is the only1117 Lime Manufacturing US EPA2021年3月28日 The drying shrinkage was mitigated with the inclusion of LSP The inclusion of 15% LSP enhanced the 28day compressive strength and flexural strength by 1141% and Effect of limestone powder on mechanical strength, durability and 2018年8月30日 Incorporating superfluous fine limestone powder or coarse limestone powder increases the porosity of cementbased materials due to dilution effect The chemical effect of A review on use of limestone powder in cementbased materials

Harnessing Limestone powder to enhance the thermal crack

2024年10月31日 We have adopted the method of mixing limestone powder (LP) to make MSC with four mass fractions (wt%) of 5%, 10%, 15%, and 20% of LP content, designed the mix 2023年12月7日 This study investigates the alterations in the ratios of components such as class C fly ash (FA), blast furnace slag (BFS), and waste stone powder (WSP) types of limestone powder (LP) used in the production of The Effects of Fly Ash, Blast Furnace Slag, and the amount of material a screening machine can carry over the decks before the momentum of the screen body is overcome by the weight of the material (Wet, dry, slivers, openings) • Screen setup • Speed, stroke, slope, direction of rotation, Principles of Screening and Sizing 911 Metallurgist2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder Limestone Grinding Mill That You Need To Know

Powder screening machine HiSifter Elcan

The HiSifter (powder sifting machines) are the latest breakthrough in advanced powder screening technology and is offered in North America exclusively by Elcan Industries This industrial sifter excels in the pharmaceutical, batteries, 2024年5月20日 Contamination can lead to impurities that compromise the quality of the Limestone Powder and impact its performance Here are some key strategies to prevent contamination: Sealed Packaging: Keeping Limestone Powder in sealed packaging helps prevent dust and foreign particles from contaminating the product, ensuring its purity7 Surprising Uses for Limestone Powder You Need to Know Zme2023年9月18日 Results showed that dolomitic limestone powder can substitute cement by 16% by weight, using a concrete mix of 523g cement, 936g sand, 1,868g gravel, 100g dolomitic limestone powder, and 166g Dolomitic Limestone Powder: Cement Substitute in the 2024年10月10日 Limestone powder 250 mesh is a finely ground form of limestone that has a variety of particularly in water treatment and air pollution control It can be used in flue If regular cleaning doesn't work, you must use a poultice This method involves applying a mixture of dry powder and a liquid that can dissolve the stain Uses of Limestone Powder 250 Mesh

.jpg)

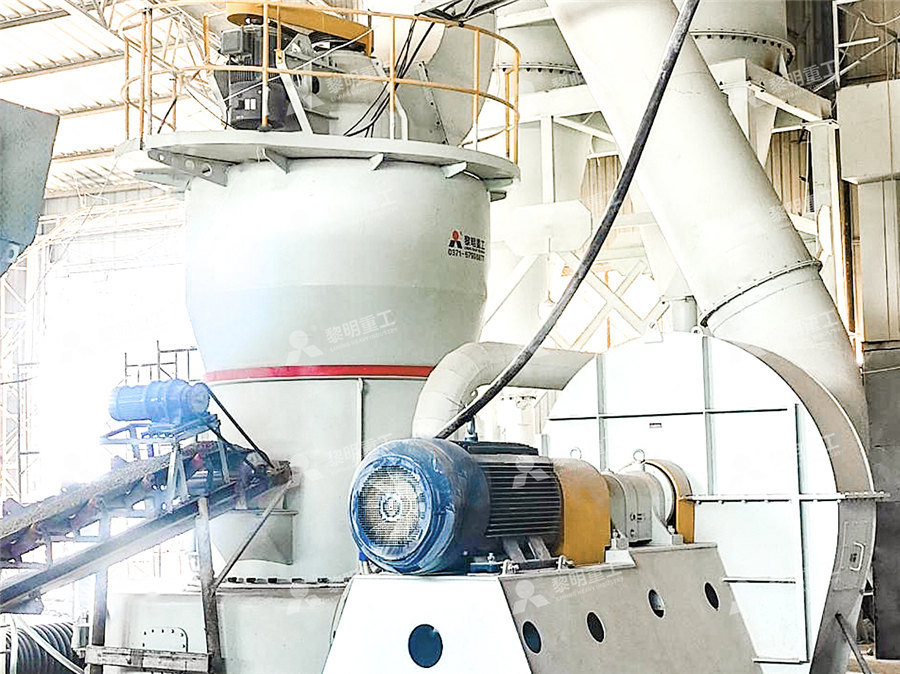

6 Types Of Limestone Dry Powder Grinder Machines

2024年8月9日 Working Principles Feeding: Limestone is fed into the machine through a feeder, which controls the amount of material entering the grinding chamber Grinding: The material is crushed between grinding rollers and rings (in Raymond and Vertical mills) or by grinding media (in Ball mills)The material is continuously ground until it reaches the desired fineness2022年9月11日 Limestone Mill : Limestone Mill is widely used for the grinding field of limestone After being grinded by the limestone grinding mill (Raymond Mill), the limestone powder can be from 40 mesh to 325 mesh The final powder size can be adjusted by the analyzer machine continuously Limestone Grinding Mill Advantages : 1Limestone Mill Powder Making Machine Rotary Dryer, Drying UTILIZATION OF LIMESTONE DUST IN BRICK MAKING 915 Fig1: The sieve analysis of limestone dust head sample PROCEDURES Limestone dust and cement were mixed and homogenized together in a laboratory Jar mill for 5 min The mixture was humidified by spraying an adequate amount of water to produce an workable mix Details of mixes are given in Table 2 UTILIZATION OF LIMESTONE DUST IN BRICK MAKING2023年11月6日 In this investigation, a comprehensive assessment was conducted on the cooperative effects of Super Absorbent Polymers (SAP), limestone powder, and white cement within the realm of fairfaced concrete We discerned that while white cement augments the color vibrancy of the concrete, its accelerated hydration rate potentially induced earlystage cracks Synergistic Effects of SAP, Limestone Powder and White Cement

Limestone Crusher Manufacturer, Ore vibration screening

Limestone Crusher Supplier, Ore vibration screening equipment, Limestone Crusher Manufacturers/ Suppliers HEBEI HONGWAN MACHINERY MANUFACTURING CO, LTD Menu Sign In Join Free For Buyer VSI Sand Making Machine Vertical Shaft Impact Crusher Mine Machine for Construction FOB Price: US $3,00020,000 / PieceNFLG V7 dry sand making plant can effectively utilize key technologies such as vertical shaft impact crushing and air screening It adopts a fivehole rotor structure and cooperates with the gap adjustment between the rotor blow bar and the annular liner Based onV7 dry sand making plantHowever, there is one material that should NEVER be used with hardscapes yet we still see it being stocked by suppliers and used by some contractors Even when we search online, we see some information recommending this material Stop Using Limestone Screenings / Crusher Dust / 2021年7月14日 After centrifugation, the water content is only about 50%, put the powder on the drying rack directly or dry it with hot air in a rotary kiln The drying temperature is 110 Censius degree, the obtained product has a moisture content of ≤ 050% The dry powder is ground through a hammer millPrecipitated Calcium Carbonate Making (light powder CaCO3)

Ultrafine Screening Of Dry Mineral Powders AggNet

2008年8月27日 The air flows, which, because of the positioning of the airextraction outlet, pass both up through the mesh and then back down, work to keep the mesh apertures clear, while the ultrasound, which can apply particle accelerations of up to 15,000g, breaks up agglomerates and also helps to keep the meshes free of powder buildup Recent screening This double deck screening machine processed the 6″ crushed limestone with an upper grizzly deck making a 25″ separation and the lower screen deck making a secondary separation at 1/2″ – 3/4″ Shortly after installation of the new screening machine, the second old screen was deemed redundant and has been eliminated from operationLimestone Screening Machine Tinsley Equipment CompanySieve Analysis of Dry Limestone, Quicklime, and Hydrated Lime 16 Fineness of Pulverized Quicklime and Hydrated Lime by Air Permeabiity 17 Particle Size of Pulverized Limestone 18 Dry Screening of Hydrated Lime, Pulverized Quicklime, and Limestone by Air Jet Sieving 19 Wet Sieve Analysis of Agricultural Liming Materials 20 Density MeasurementPhysical Testing of Quicklime, Hydrated Lime, and Limestone12021年4月1日 Characterization and assessment of crushed limestone powder and its environmental applications April 2021 IOP Conference Series Earth and Environmental Science 727(1):Characterization and assessment of crushed limestone powder

.jpg)

Limestone Pulverizing and Drying System and Machinery

2024年3月8日 Flash dryers: Flash dryers use hot air to quickly dry limestone particles Fluidized bed dryers: Fluidized bed dryers use a stream of hot air to suspend limestone particles and dry them System and Machinery The pulverizing and drying of limestone can be done using a variety of systems and machinery A typical system might include the following:2023年2月15日 Comparison Table of Investment Estimates for the 3 Methods Presume that the life of WFGD is 30 years, regarding the powder purchase method as a benchmark, the price difference between the dry limestone mill and it is 129 million yuan, and the annual fixed investment after equalization is 430,000 yuanSuitable FGD limestone mill, low investment in power plantsPure limestone screenings passing a 5 mm (3/16rdquo;) screen USES Provides an excellent base for leveling interlocking pavers and patio slabs Prevents growth of weeds and establishment of ant colonies between bricks SAKRETE Limestone Screenings, 30 Kg, Excellent Base Garden Club Limestone Screenings offer a fine, crushed limestone material for creating a solid underlay when working with patios or driveways These limestone screenings can be molded together to create a hard and reliabGarden Club Limestone Screening Landscaping Base,

.jpg)

Centrifugal air classifiers offer effective fines

2020年3月19日 C entrifugal air classifiers are used extensively to process aggregates, foods, metals, chemicals, minerals, fly ash, ceramics and other materials Air classifiers are used for dry processing; to effectively remove fine 2022年5月1日 Request PDF Intelligent dry fog dust suppression system: An Efficient technique for controlling air pollution in mineral processing plant Dust suppression system plays a significant role in Intelligent dry fog dust suppression system: An ResearchGate2022年5月22日 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research investigations have not yet been published on the combination of energy and life cycle modeling Therefore, the first aim of this research work was the examination of main grinding parameters EnergyModel and Life CycleModel for Grinding Processes of Limestone 2023年2月15日 Advantages of dry wet production line 1 The finished sand and gravel aggregate has good appearance and beautiful particle shapes; 2 During the production process, the soil and stone powder are taken away by the water flow, generating no dust and air pollution; Dry sand and wet sand production lines face their own limitations Limitations of dry sand production lineThe Differences between Dry Sand Production Line and Wet

.jpg)

Air Breather Air compressor For Sale In India Limestone Powder

Air Breather manufacturer supplier of Air compressor, Portable Abrasive Blaster; Dust Collector (Cyclone / Fabric / Pleated) for sale at low price in India Enqiury Now 72021年3月28日 The use of limestone powder (LSP) as a cement replacement is used in abundant applications due to its low cost and wide availability Adversely, the use of LSP as a part of the precursors of alkaliactivated materials (AAMs) is still in the developing stage This scarcity of studies opened the door and encouraged the researchers for more investigations Thus, this Effect of limestone powder on mechanical strength, durability Limestone before and after pelletizing and drying in the FEECO Innovation Center Limestone Dryers Limestone drying may be carried out in different types of industrial drying equipment, with the most common being rotary dryers, followed by fluid bed dryers Rotary Dryers 3D Rendering of A FEECO Rotary Dryer with flights visibleA Detailed Look at Limestone Drying FEECO International IncRaymond mill has very long history and is widely used in powder making industry, first appeared in 1906 in Berlin Curt Von Grueber machinery manufacturing factory, development so far and has a history of more than one hundred Raymond Mill Raymond Mill Working Principle

What Is The Difference Between Dry And Wet

Dry screening and wet screening are two commonly used screening processes in mechanism sand production lines, the problems of the high content of soil and stone powder and dust pollution of dry screening have been initially solved 2023年5月17日 Sieve Analysis of Dry Limestone, Quicklime, and Hydrated Lime 16 Fineness of Pulverized Quicklime and Hydrated Lime by Air Permeabiity 17 Particle Size of Pulverized Limestone 18 Dry Screening of Hydrated Lime, Pulverized Quicklime, and Limestone by Air Jet Sieving 19 Wet Sieve Analysis of Agricultural Liming Materials 20 Density MeasurementPhysical Testing of Quicklime, Hydrated Lime, and Limestone148 EFFECT OF LIMESTONE POWDER ON MECHANICAL PROPERTIES OF CEMENT COMPOSITE BOARD ESHMAIEL GANJIAN1 and MORTEZA KHORAMI2 1Coventry University, Department of the Built Environment, Faculty of Engineering Computing, Sir John Laing Building, Coventry, CV1 5FB 2 Eslamshahr Azad University, Building Housing Research EFFECT OF LIMESTONE POWDER ON MECHANICAL PROPERTIES the recent evolution of dry screening technology New Dry Sizing machines utilize true linear motion to achieve higher capacity with small floor footprints Alternate Dry Sizing machine designs utilize paralleltoflow screen panel tensioning system (“FrontTo DRY SCREENING OMIM

.jpg)

Screening Machines Screeners

Dry Mortar ReadyMix Plaster Screening mortar precisely into several fractions When processing dry mortar into different fractions, the fluctuating grain size distribution of the crushed limestone, as well as its tendency to clog up the screen Food industry: Limestone is used to adjust the acidity of food, clarify juices and wines, etc Environmental protection industry: Limestone can be used to control acidic substances in polluted water bodies and waste gases For example, calcium oxide in limestone can be used to neutralize acidic substances in wastewater and purify water qualityLimestone powder making plant Raymond MillVertical Roller 2016年6月10日 Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of sizeScreening 101 911Metallurgist2023年3月3日 This study investigated the effect of ultrafine limestone powder on the calcium leaching performance of cement mortar Ammonium chloride solution (3 mol/L) was used as the accelerated medium with a controlled pH disposal, and leaching tests of cement mortar were conducted using continuous immersion and wet/dry cyclesEffect of ultrafine limestone powder on leaching resistance of

Drying Soils Mud Chemically Using Lime ECSLimited

Quicklime is manufactured by heating limestone (calcium carbonate) to approximately 900°C and grinding it into gravel, sandsized particles, or a powder Hydrated lime (calcium hydroxide) is produced by adding a controlled amount of water to quicklime, a process commonly referred to