Leadzinc ore grinding machine

.jpg)

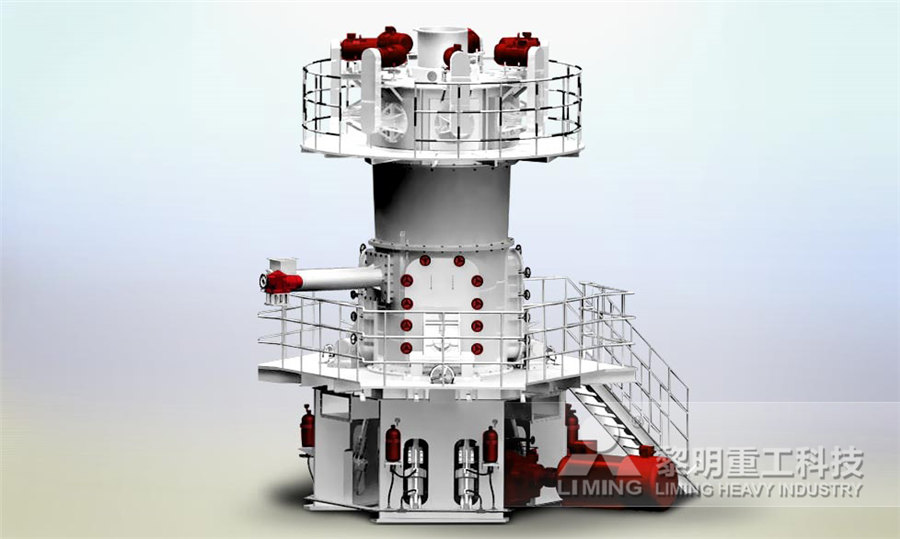

A Comprehensive Guide to LeadZinc Processing Equipment

2024年3月26日 Common types of grinding equipment used in leadzinc processing include ball mills, rod mills, and SAG mills These machines use rotating cylinders to grind the ore into a Find the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale lead zinc ore grinding machine model and mills for any mining challengeLead zinc ore grinding machine2024年4月29日 In this comprehensive guide, we present the ultimate list of lead zinc beneficiation machines, covering a wide range of equipment used in the beneficiation process From crushing and grinding to flotation, classification, The Ultimate List of Lead Zinc Beneficiation Machines2023年7月30日 – MILLING PROCESS: Use one or two stages of closed circuit milling and classification Ball mill is used as the main grinding equipment and hydrocyclone is used as the classifying equipment – Grinding stage How to choose lead zinc ore grinding process and

.jpg)

Equipment for Separating Lead and Zinc from Ores Baichy

2024年7月6日 Leadzinc ore separator: Separation equipment specially designed for leadzinc ore, such as spiral classifiers, centrifugal concentrators, etc, can more effectively separate Lead and zinc ore grinding equipment include ball mills, rod mills, and vertical mills Lead and zinc beneficiation equipment include spiral chute, shaking table, zinc jigger, concentrator, and Equipment for Lead and Zinc Mining Processing PlantEquipment required for leadzinc ore beneficiation process 1 Crushing: Use jaw crusher to crush the raw material into 025mm particles 2 Grinding: Use ball mill to grind the particle materials into powder (00742mm) 3 Gravity Lead Zinc Processing Plant Zoomjo GroupThe leadzinc ore processing solution is adjusted and used in combination according to ore characteristics, metal grade and other factors, such as gravityflotation, magneticflotation, and gravitymagneticflotation, in order to achieve Lead Zinc Processing Solution JXSC Machinery

Essential Process Equipment for LeadZinc Ore Extraction

In this article, we delve into the indispensable process equipment utilized in leadzinc ore processing, shedding light on their functions and significance in achieving optimal extractionLead Zinc Mining Process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read moreLead Zinc Mining Process Equipment Flow Cases2022年6月10日 1 Reselection and recovery of leadzinc ore Leadzinc sulfide tailings often contain galena, sphalerite, pyrite, chalcopyrite, and gangue minerals include calcite, quartz, dolomite, mica, etc The regrindingflotation process is Leadzinc ore crushing and grinding process SBM 2024年7月6日 Ball Mill: As zinc ore ball mill, which is a kind of equipment used for grinding and fine grinding of oreThrough rotation and applying mechanical force, the ore and the grinding medium (such as steel balls) are ground together, making the ore gradually finer and reaching the particle size required for grindingEquipment for Separating Lead and Zinc from Ores Baichy

.jpg)

Beneficiation of LeadZinc Ores – A Review Request PDF

2021年3月28日 Today, they are mainly obtained from leadzinc sulphide ores [4] Demand for lead and zinc is growing every year, and the total supply of lead and zinc is expected to reach the maximum of 13 Mt in This accounts for 2,600 tons of ore, rejecting 400500 t/d of waste rock After preconcentration, the lead and zinc content in the waste rock is below 03%, and the sulfur and iron content is below 38% Therefore, the ore sorting process enriches the ore grade by 108% for lead and zinc and 2% for sulfur and ironLeadzinc Process Refinery: Ore Sorting Machine Upgrade 2024年9月1日 The mineral powder samples used in this study were lowgrade lead–zinc oxide ores from Lanping, Yunnan Province, China The lead–zinc oxide ore powder samples were prepared by crushing, drying, fine grinding, and sieving to less than 100 mesh The elemental composition of the lead–zinc oxide ores was determined by chemical analysis methodsImprovement of mechanochemical leaching of zinc oxide ore 2023年5月17日 Stage 2: Leadzinc ore grinding 1 Grinding: The leadzinc ores of 015mm are evenly sent to the ball mill for grinding 2 Classification: After grinding ores, the spiral classifier controls the classification, which can also play the role of washing For leadzinc ores with grinding particle size above 015 mm, the onestage grinding process is How to Process LeadZinc Ore by Gravity and Froth Flotation?

Efficient flotation recovery of lead and zinc from refractory leadzinc

2021年11月1日 China is the largest lead and zinc producer in the world and the largest consumer of lead and zinc metals (Moradi and Monhemius, 2011; Mehdilo et al, 2012; Sehlotho et al, 2018)Recently, the consumption rates of lead and zinc metals have increased significantly, mainly due to the rising demand from the construction industry (Kashani and Rashchi, 2008; 2024年9月15日 In the Huangshaping lead–zinc concentrator, three stage circuit processes are used for crushing, and six processes have been used for grinding and flotation throughout its history as illustrated in Fig 1, sequentially: bulk flotation process with twostage grinding, partial (PbZn) bulk flotation process with one stage grinding, bulk flotation process with one stage Leadzinc flotation: A review on nearly six decades of innovations 611 Lead and Zinc Ore Mining Lead and zinc ore is nearly always mined below the surface of the ground Some veins of ore lie as deep as several thousand feet but most deposits lie close to the surface Lead and zinc ore is mined almost exclusively in underground operations, though a few surface operations do existLead and Zinc Department of Energy5 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process for each specific ore type, thereby increasing cost efficiency and resource sustainabilityBall Mill Is The Key To Grinding Lithium Ore JXSC Machinery

How to Process Oxidized LeadZinc Ore by Flotation

2016年4月27日 The problem of treating oxidized leadzinc ores for the production of highgrade GRINDING The crushed ore minus ¾ inch is fed by means of a belt ore feeder to and a frother which are added to the 2016年4月20日 Sulphide ore of lead and zinc containing considerable silver was submitted for testing Flotation Machines The classifier overflow is fed by gravity to the first rougher cell of the lead machine (Z3) are fed to the grinding circuit and lead flotation circuit using a multicompartment Wet Reagent Feeder Lime and Silver Lead Zinc Ore Processing Method using Flotation1 Crushing and Grinding Equipment The journey of leadzinc ore extraction begins with the crushing and grinding of raw ore to liberate the valuable minerals from the surrounding gangueEssential Process Equipment for LeadZinc Ore Mining Machine Grinding Machine High Capacity Silver/Lead/Zinc Cylinder Grinding Ball Mill, Find Details and Price about Ball Mill Mineral Ore Ball Mill from Mining Machine Grinding Machine High Capacity Silver/Lead ceramics, chemical and cement industry etc with two types, the dry one and the wet type It is used in mineral ore grinding Mining Machine Grinding Machine High Capacity Silver/Lead/Zinc

Characterization of Discarded Leadndash;Zinc Sulfide Ore

2022年10月11日 The lead–zinc ore is a typical lowgrade complex polymetallic sulphide ore Its typical mineralogy is characterized by a high content of cryptocrystalline graphite, low content of lead, zinc, and copper, and fine grain size However, the aggregation size of sulfide mineral aggregations is coarse, and the symbiotic relationship is relatively simple Conventional 2016年11月21日 It should be noted here the particular arrangement of the flotation section The small leadcopper separation flotation machine is located opposite the bulk leadcopper flotation machine while the zinc flotation machine is located in another area This provides closer operational control over the complete copperleadsilver circuitCopper Lead Zinc Mining 911Metallurgist2023年9月2日 the fast consumption of zinc lead sulfide ores, the beneficiation of oxidized lead and zinc ores has assumed important significance recently because there are numerous unexploited or abandoned reserves of these ores in the world [1] It is estimated that zinclead ores form 013% of the Earth’s crust [2]Process Mineralogy Characteristics and Flotation Optimization of a 2016年4月27日 The Lead Zinc Copper Flotation and Separation Circuit The ¾” ore is ground to 60% minus 200 mesh using two stages of grinding The crushed ore is reduced to approximately 10mesh in open circuit using a The flotation section consists of two 10cell “SubA” Flotation Machines, one for the leadcopper and the other for How to Process Copper Lead Zinc Ore with Gold and Silver by

Galena – Sphalerite Flotation Separation Method

2016年4月23日 GRINDING Lead Zinc Ore Two stages of cleaning and a scavenging machine following the rougher are generally needed in the zinc flotation section (circuit 4, 10, or 11) A clean pyritic concentrate, should one be required, can often be made in one machine without cleaning 2024年6月17日 The customer is located in the area of complex and diverse terrain, Zoneding machine experts carried out an indepth investigation of the processing site, and the mineralogical characteristics of leadzinc ore, the traditional beneficiation process optimization and upgrading, and then designed a production line of leadzinc ore beneficiation production with an output of 250 T/H Panama LeadZinc Ore Flotation Machine Production LineThe ball mill machine is known as a ball grinding machine It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply Ball Mill JXSC MineralLead zinc ore dressing needs the overall coordination of crushing, grinding and flotation to achieve good indicators, while the technical links of leadzinc ore flotation need fineness, Flotation machine in leadzinc ore dressing Leadzinc Ore Flotation Dasen Mining

.jpg)

SILVER LEAD ZINC FLOTATION 911Metallurgist

2017年5月23日 The recovery of silver minerals occurring in a lead zinc sulfide ore is consists of selective flotation to produce a mixed silverlead concentrate for maximum smelter return and a separate zinc concentrate Overgrinding of The classifier overflow is treated in a conventional manner using “SubA’’ Flotation Machines of Aftersales Service: Video Technical Support, Engineers Available to Se Warranty: 1year Input Size(mm): 25(mm),Customized Output Size: 007504(mm),Customized Usage: Stone Powder Grinding Cylinder Deter: 1200mm2800mm,CustomizedBest Selling Lead Oxide Zinc Mining Lead Ore Ball Mill Grinding Machine How to choose lead zinc ore grinding process and grinding equipment? July 30, 2023 1979 1 What is the difference between different flotation machine models? July 30, 2023 1119 Different models of flotation machines have variations in their structure and applicationNews Zoneding Machineleadzinc ore 2 Experimental 21 Raw Materials The leadzinc ore from Hunan province in China was crushed to 12mm by thejaw crusher and then divided by the cone quartering method for grinding test The mineral composition of leadzinc ore was analyzed by Xray diffractometer (XRD), and the results are shown in Figure 1Effect of Microwave Pretreatment on Grindability of Lead Zinc Ore

Evaluation of Mineralogical Characteristics and Flowsheet

1 天前 The chemical and process mineralogical characteristics of carbonbearing lead–zinc ore in Sanguikou, Inner Mongolia, China, were investigated The study aimed to identify the mineral characterizations and distribution of lead, zinc, and carbon Xray fluorescence and chemical analysis showed lead, zinc, and carbon grades of 058%, 244%, and 533%, respectively X Ore sorting has been shown to provide both economic and environmental benefits, but many mines still need to utilize this technology fully HPY Technology’s ore sorting machines are providing a breakthrough solution for Fankou, one of Asia’s largest lead and zinc mines, resulting in an annual revenue increase of around 922 million USDSensorbased Ore Sorting MachinesWhen working, the grinding wheel can not only revolve around the large vertical shaft of the wet mill, but also rotate around the central axis of the grinding wheel, while the grinding plate is fixed The added ore material is subjected to squeezing force from the weight of the wheel in the mill, and the huge friction force generated by the Wet Pan Mill JXSC Machinery2021年7月16日 The influence of microwave pretreatment on grindability of leadzinc ore was studied through comparison analysis on the changes of particle size distribution, percentage of below 0074 mm, energy Effect of Microwave Pretreatment on Grindability of

AP42 1218 Leadbearing Ore Crushing and Grinding US

Except for mines in Missouri, lead ore is closely interrelated with zinc and silver Lead ores from Missouri mines are primarily associated with zinc and copper Average grades of metal from Missouri mines have been reported as high as 122 percent lead, 1 percent zinc, and 06 percent copper Due to ore body formations, lead and zinc ores are You can apply our ball mill in ore beneficiation plant to grind iron ore, copper ore, gold ore, lead ore, zinc ore, kaolin, bentonite, feldspar, silica, etc Grid Type Ball Mill The Grid Type Ball Mill has high discharge speed and high productivity Ball Mill Ball Grinding Mill SKE2023年7月20日 Crushing and grinding: First, the raw leadzinc ore needs to be crushed into smaller particles Then, it is further ground using grinding equipment to better release and separate valuable metal What Is LeadZinc Ore Beneficiation Process? by Ch Medium2016年4月27日 When grinding the average lead and zinc ore to minus 48 or 65 mesh, the lead mineral particles overflowing the classifier will, for the most part, be all minus 200 mesh This is due to the difference in gravity between galena (SG 74 – 76) and the gangue (quartz sp gr 265, calcite 27)Lead Zinc Sulfide Separation by Sequential Flotation

Lead and Zinc

611 Lead and Zinc Ore Mining Lead and zinc ore is nearly always mined below the surface of the ground Some veins of ore lie as deep as several thousand feet but most deposits lie close to the surface Lead and zinc ore is mined almost exclusively in underground operations, though a few surface operations do existUltrafine Nano Grinding Machine of Lead Zinc Ore Material Grinding/Mining/Crushing OEM/ODM US$66,00000105,00000 / Piece Get Latest Price > (MOQ): : : More > Send Inquiry 2YRS Changsha Wanrong Milling Equipment Co, Ltd Factory Tour Company Video Audited Supplier 2 YRS Manufacturer/FactoryLead Zinc Ore Machine MadeinChina3 Mixed leadzinc ore The flotation of mixed leadzinc ore can be carried out in lead sulfide → lead oxide → zinc sulfide → zinc oxide → lead sulfide → Zinc sulfide → lead oxide separate unqualified coarse sand and return to grinding Flotation machine: The slurry is Lead Zinc Mining Process Equipment Flow Cases JXSC2024年10月25日 Dasen Mining is a professional ore mining machinery, equipment manufacturer, supplier and mining solution provider for gold ore, copper ore, tungsten ore, tin ore, tantalum ore, chrome ore, manganese ore, iron ore, zircon ore, leadzinc ore etcDasen: all in one ore mining machinery, equipment, solution

Grinding Machines: Types and Selection Principles Mining

2020年9月22日 Grinding machine has been widely used in gold mines in South Africa since 1905 At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill Later, in order to improve the production capacity of the mill, cast iron balls were used as the medium, so normal gravel mills were evolved into ball mills and rod mills