Limestone processing equipment without mining quicklime

.jpg)

Impact of Limestone Surface Impurities on Quicklime

2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the bulk concentration of 2024年6月13日 Quicklime, rich in CaO (s), is generated by calcining limestone at high temperatures Parallelflow regenerative lime kilns are the most energyeffective industrial method available today To prevent major disruptions in Characterization of Limestone Surface Impurities and Hydrated lime is a important industrial chemical, mainly composed of calcium dihydroxide CO(OH) 2 It is produced by hydrating quicklime, essentially calcium oxide, using a specific Developing a modular lime plant CimprogettiProcess flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Limestone Quarrying and Processing: A LifeCycle Inventory

.jpg)

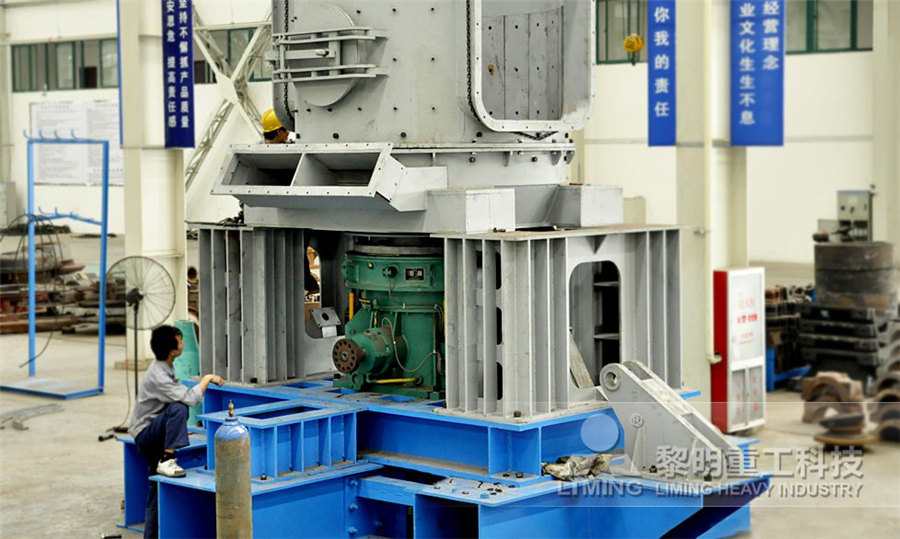

10 Types of Equipment Every Industrial Lime Plant Needs

2022年2月3日 Procuring the right equipment is one of the most critical steps in getting a new lime plant up and running Here are the top ten types of equipment every lime plant needs to compete 1 Limestone Bin Limestone bins are 2021年10月4日 Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO 3) into quicklime (CaO) and carbon dioxide (CO 2), also called calcination Controlled reaction with water is used Natural and enhanced carbonation of lime in its 2022年10月15日 For limestone without ash, the quicklime showed enhanced sintering and reduced porosity at the higher temperature, in agreement with previous studies Interface Solid biofuel combustion or electrification for limestone Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated lime The main component of hydrated lime is calcium hydroxide Limestone Crushing Process JXSC Mineral

Processing Storage and Transport of Quicklime Lime and

1998年5月14日 Processing Storage and Transport of Quicklime JAH Oates (BSc, CChem, FRSC, FIQ, MIQA), Lime and Limestone: Chemistry and Technology, Production and Uses 2017年7月7日 calcining, endothermic reaction, exothermic reaction, hydrated lime, hydration, lime, limestone, quicklime, slaking kiln, Limestone – Its Processing and Application in Iron and Steel Industry Limestone is a naturally occurring and abundant sedimentary rock consisting of high levels of calcium carbonate (CaCO3) in the form of the mineral Limestone – Its Processing and Application in Iron andQuicklime (CaO) was produced from limestone by calcination process Effects of temperature, particle size and time on quicklime yield were determined 10g of the limestone sample (80 m particle size) was weighed into preweighed empty crucible plates The preweighed crucible plates with the limestone were set into laboratory furnace and heatedProduction of quicklime from Ashaka limestone through 2023年2月15日 The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, Lime Production Process and Required Equipment

.jpg)

Quicklime Preparation, Properties, and Applications with FAQs

It can also be noted that quicklime is insoluble in methanol It is also insoluble in octanol and diethyl ether Applications of Quicklime Quicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industry2021年7月15日 Thus, it is evident that the cost of limestone mining operation is variable from mine to mine and from organization to organizations, but it can be kept in check by the local mine management 361 Marginal Cost of Production Limestone mining is a very competitive (throatcutting) industrial businessLimestone Mining, Industry, and Society SpringerLinkLimestone mining involves underground mining techniques that This method is the easiest way to remove limestone without causing much destruction In surface mining or openpit mining, the topsoil and overburden The extracted rocks are then sent for further processing Underground mining is considered to be the most efficient Limestone extraction – underground mining techniques, Without mining limestone, it would be difficult or impossible for these industries to find substances that could do the job instead of limestone Next, many limestone mines are in rural areas where work is harder to come byLesson Video: Limestone Nagwa

(PDF) The Effects of Limestone Characteristics and Calcination

2001年4月1日 This study has examined the effects of limestone characteristics (microstructure and texture) and calcination temperature on the reactivity of the produced quicklime Two types of limestone have Limestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcLimestone Crushing Equipment and Production LineFind production technology for making Limestone, In industries such as mining and chemical processing, There is currently no equipment listed with your specified properties, but we are sure we can help you Try us!Contact us Let's talk about your project!Limestone Processing Equipment Making(English units) include emission factors for the mechanical processing (crushing, screening, and grinding) of limestone and for some materials handling operations Section 1119, Construction Aggregate Processing, also includes stone processing emission factors that are based on more recent testing, and, therefore, may be1117 Lime Manufacturing US EPA

.jpg)

(Slaked and Hydraulic) Do Business Jamaica

1 Quicklime, produced after calcination of limestone, can be hydrated to form Slaked Lime Therefore, generation of Quicklime is a prerequisite for Slaked Lime production In case of Hydraulic Lime, the production process and equipment are similar with the difference being in raw material used and kiln / calcination temperature2021年3月3日 Lime is the least expensive and one of the most heavily used alkali in the world, being essential to our society It is a nonhydraulic binder, excepting the socalled hydraulic lime, meaning that it will not set under waterFor this reason, lime is sometimes called air lime since it hardens on exposure to air It was used for thousands of years in masonry mortars to bind the Lime SpringerLink2021年9月15日 Quicklime is produced by the thermal processing of naturally occurring limestone in industrial kilns Limestone is an abundant rock that contains high concentrations of CaCO 3 , and during thermal processing the carbonate decomposes, resulting in a highly reactive, solid, CaOrich product, quicklime, and gaseous CO 2 Coal ash and limestone interactions in quicklime productionmining operations depend on lime to help them comply with environmental regulations Lime is also used as a neutralizing agent in many scrubbers, resulting in a sludge high in moisture This waste product can be dried for additional use Limestone’s Characteristics Limestone has several characteristics that distinguish is from other materials:PROCESSING • CHARACTERISTICS • PRODUCTION • KILNS • SOLUTIONS

.jpg)

Quicklime Manufacturer, Burntlime, Calcium Oxide Supplier

We are highquality quicklime as well as limestone supplier based in Shanghai We are running a 50millionton highquality limestone mine in Anhui as well as a rotary kiln and a twinshaft kiln there Both our company in Shanghai and facilities in Anhui are certified of ISO9001: 2008High calcium quicklime (CaO) is produced when limestone, or calcium carbonate (CaCO 3), is heated in a kiln through the process of calcination CaCo 3 + heat > Cao = CO 2 After limestone with high calcium content is sourced from our quarries and underground mines, it is transported and processed through a series of crushers to reach a desired sizeHigh Calcium Quicklime Carmeuse2017年7月1日 The limestone mined is used chiefly for the manufacturing of cement, lime and edible lime etc Scientific studies revealed that loss of forest cover, pollution of water, soil and air, depletion of (PDF) LIMESTONE MINING AND ITS ENVIRONMENTAL2019年8月3日 Lime has strong water absorption, and reacts with water to become calcium hydroxide (Ca(OH)2), commonly known as slaked lime or slaked lime It has little solubility in aqueous solution, but it can further ionize calcium ions (Ca2+) and hydroxide ions (OH) in aqueous solution, making the solution more alkalineLime in Gold Ore Mining Process Flotation, Cyanidation JXSC

NonFerrous Mining Metals Carmeuse

Carmeuse lime and limestone products are essential for the nonferrous and ore processing industries Our products provide a source of calcium for many processes, and are often used as an alkali source, desiccant, causticizing agent, saponifying agent, bonding agent, flocculant, precipitant, and fluxing agent We also provide advanced lime handling equipment and slakers 2022年10月15日 The production of quicklime, which is achieved by thermal processing of limestone, results in a highly reactive solid CaOrich product and CO 2 In industrial processes the temperature reaches 900–1200 °C, or higher for special applications [2] and the heat needed for the decomposition of limestone originates from direct firing of a fuel in a rotary kiln or in a shaft Solid biofuel combustion or electrification for limestone 2023年12月19日 Limestone machinery typically refers to equipment used in the mining, processing, and manufacturing of limestone products +29 Purpose: Used in the calcination process to produce quicklime Operation: Limestone is heated to high temperatures in a rotating kiln, What Limestone Machinery Is Used In Limestone Processing?Quicklime is made by putting limestone in a furnace while wearing glovesIf the player isn't wearing gloves, the limestone will corrode the player's skin and damage the player for 8 HitpointsQuicklime is used in the Regicide quest for Quicklime OSRS Wiki

Mining and Mineral Processing Equipment FEECO International

FEECO MINING CAPABILITIES Our equipment and solutions are used around the world in a variety of mining and mineral processing operations We’ve worked with everyone from process startups and entrepreneurs, to Fortune 100 companiesThe limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY2022年12月22日 What is quicklime? Quicklime, the main component of which is calcium oxide, is calcined from limestone and is generally used in steel mills, stainless steel plants, furnace charge plants, etc The main processing fineness is less than 3mm, 100 mesh, 200 mesh, 325 mesh, 8001250 mesh, etcType Selection of Quicklime Deep Processing Equipment2022年2月3日 Procuring the right equipment is one of the most critical steps in getting a new lime plant up and running Here are the top ten types of equipment every lime plant needs to compete 1 Limestone Bin Limestone bins are typically square or rectangular in shape and smaller in volume than hoppers or silos10 Types of Equipment Every Industrial Lime Plant Needs

quick lime process flow diagram Mining Quarry Plant

2013年3月25日 mining process flow diagram; mining process flow chart; Cheney Lime and Cement Company is a producer of high calcium quicklime products Manufacturing Process: 1 Processing of limestone Limestone after its mining has to undergo several processing before it can be used in various processes The basic processes in the production of limestone are quarrying of raw limestone, preparing mined limestone for its use by crushing and sizing, calcining of raw limestone,Comparison of lime kiln types BlitzcoQuicklime (with active ingredient CaO), the starting reagent material for all other forms of lime reagent, is produced by calcination of limestone (CaCO 3 ) at temperatures ranging from 900 to Reactivity of quicklime depending on the burning temperature2024年6月13日 Quicklime, rich in CaO(s), is generated by calcining limestone at high temperatures Parallelflow regenerative lime kilns are the most energyeffective industrial method available todayCharacterization of Limestone Surface Impurities and Resulting

Limestone Production via Mining, Crushing, Sizing and Cleaning

This report presents an exhaustive cost evaluation of limestone production via mining, crushing, sizing and cleaning The process involves raw mining limestone from open quarries, drilling, blasting and extracting via power shovels and bulldozers, and crushing and sizing the stones, which are then washed to remove unwanted entities2022年2月28日 Limestone flour is used in a variety of industrial sectors such as power and heat generation, glassmaking, papermaking, the construction industry and construction materials manufacturing, the The Effect of Calcination Temperature on The Quality of Quicklime Calcium oxide (formula: Ca O), commonly known as quicklime or burnt lime, is a widely used chemical compoundIt is a white, caustic, alkaline, crystalline solid at room temperatureThe broadly used term lime connotes calciumcontaining inorganic compounds, in which carbonates, oxides, and hydroxides of calcium, silicon, magnesium, aluminium, and iron predominateCalcium oxide WikipediaThe current plant consists of limestone rock processing, calcining, hydration, blending and packaging departments Three rotary kilns burn sized limestone rock to produce dolomitic quicklime products with excellent reactivity This quicklime is used either as an industrial product or as a raw material for the hydration processesLime Plant Graymont

.jpg)

Mining Graymont

Aside from the many vital uses to which lime itself is put, limestone and quicklime products are used to help extract many of the other minerals the world relies on now and in the future Lime and limestone products are used for various mining applications including coagulation, flotation and recovery, milk of lime or lime slurry solutions, tailings treatment, acid mine drainage and Carmeuse offers a diverse range of limebased products, including high calcium quicklime, high calcium hydrated lime, and lime slurry for use in gold mining operations Lime is a crucial component in gold mining, playing an essential role in various processes necessary for the extraction of this precious metalGold Mining Carmeuse2023年9月13日 Quicklime is not only an important raw material for the steel and nanocalcium carbonate industries but also a key carrier for capturing carbon dioxide in the fight against global warming, and its reaction activity plays a vital role in these processes Recent studies have found that quicklime produced from limestones with similar chemical compositions under the same Effect of the Textures and Particle Sizes of Limestone on the Quicklime About Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated limeLimestone Crushing Process JXSC Mineral

QuickLime 101: Everything About This Super Substance ZME

2024年6月23日 The construction industry benefits from QuickLime in creating mortar, plaster, and various building materials Chemical processes utilize QuickLime for desulfurization, refining metals, and synthesizing various compounds By delving into the world of QuickLime, one can uncover its versatile nature and fundamental role in numerous sectors