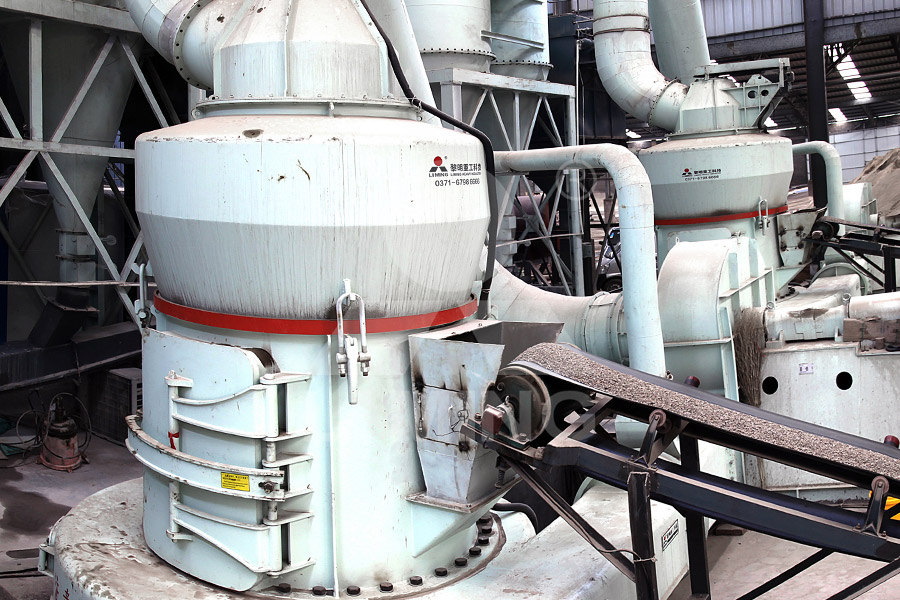

Ring roller mill GSZ200

Ring Rolling Mill Mitsubishi Nagasaki Machinery MfgCo,Ltd

Mitsubishi Ring Rolling Mill can be available from small to extra large diameter for various applications with stand alone unit or fully automated forging line We manufacture two types of Mitsubishi Ring Rolling Mill can be available from small to extra large diameter for various applications with stand alone unit or fully automated forging line The MRX small class can roll Small and Medium size Ring Rolling Mill Mitsubishi Nagasaki We adopted the forced driven method for top and bottom edge rolls to prevent swelling or rolling up generated in rolling with ring rolling mill and lifting often generated in initial stage of rolling KOJIMA IRON WORKS CO,LTD|PRODUCTS|Products Medium diameter ring rolling mills Our medium MRB Series mills provide a stable supply of rings for various fields, mainly slewing rings for mediumsize and small construction equipment, Ring rolling mills|Industrial facilities equipment|Product

Banning new and used forging machines

Banning® is a leading European supplier of new forging machines and ring rolling mills Furthermore, we are an independent supplier of service and spare parts for used forging 磨轮在公转和自转的过程中产生强大的离心力,与定子发生强烈的辊研作用,被粉碎的物料在离心力及磨轮旋转力场的带动下,进入磨轮与定子组成的研磨区中,在强大的挤压力和研磨力作用 辊压磨 埃尔派粉体科技有限公司The ring rolling mill with maximum radial and axial pressing forces of 6,300 kN each manufactures rings with an external diameter of up to 2,500 mm and a height of up to 600 mm Siempelkamp RingRolling Mill本 機では上下エッジロー ルをそれぞれ駆動し、さらに独立制御方式により適正な回転速度に制御することが可能になりました。 これにより、よ り安定したワーク の成形が出来ます。 リングローリングミル

.jpg)

Banning electromechanical ring roll ERW

The electromechanical ring rolling mills offer the possibility of a temporary overload (turbo) of 140% related to 5% of the utilization time All our rolling mills include all potential options as a 2024年4月12日 RadialAxial Ring Rolling (RARR) is an industrial forging process for making strong, seamless metal rings Conventionally, rings are made circular with constant crosssectionRolling Eccentric Steel Rings on an Industrial 2023年12月4日 The simulation was performed by changing the mill speed from 20 to 30 rpm, the gap between the roller and table from 60 to 100 mm, and the dam ring height from 140 to 200 mm The duration of each simulation is 10 s, and the steadystate is reached after 5 sNumerical Investigation of Vertical Roller Mill Operation Using 2017年4月26日 The ring roller mill adopts the principle of impact, Get a server with 24 GB RAM + 4 CPU + 200 GB Storage + Always Free Oct 26 73 In DataDrivenInvestor by Austin StarksThe application of ring roller mill in the processing of non

* 태웅 홈 >설비>RING ROLLING MILL TAEWOONG

Φ9500mm Ring Rolling Mill Φ9500 링 롤링 밀은 직경 9m, 높이 28m 중량 60 톤의 대형 링 단조품을 생산할 수 있는 세계 최대의 링 단조설비 입니다 자유형 단조품 시장의 50% 이상을 차지하는 링 단조품 시장에서 최고의 경쟁력을 갖춘 생산성이 우수한 장비입니다new forging machines and ring rolling mills Furthermore, we are an independent supplier of service and spare parts for used forging machines and ring rolling mills of other brands, especially JBanning and Wagner With our comprehensive range of products and our many years experience in the industry, we design the tailormade solution forBanning new and used forging machinesRing Roller Grinding Mill Benefits 1 High powder fineness process, the powder fineness can be adjusted between 3002500 mesh; 2 High capacity, there are 5 models dolomite powder making machine in Shanghai Clirik, the highest capacity can up to 45 t/h; 3 Environment friend, Clirik HGM dolomite powder making machine id environment friendly, it was popularity by our Ring Roller Grinding MillΦ9500mm Ring Rolling Mill The Φ9500 ring rolling mill is the world’s largest ring forging equipment capable of manufacturing 9 meters wide, 28 meters tall and 60 tons large ring forging products It has an extraordinary productivity for ring forging products that account for over 50% of the opendie forging market SCM태웅 홈 >FACILITIES>RING ROLLING MILL TAEWOONG

.jpg)

Angle Rolls Ring Rollers Roll Benders KAAST Machine Tools

KAAST Machine Tools angle rolls (also referred to as pipe rollers, hydraulic tube benders, ring rollers, bending rolls, profile rolls as well as simply roll benders) are specifically designed for fast and easy circular rolling of a variety of metal bar, angle, tube, pipe, and extrusions Key Features The shafts are hardened and ground from hightensile strength steel and come with modular The ultrafine roller mill drives the main shaft to rotate through the transmission device D97: 815micron heavy calcium carbonate ring roller mill ultrafine grinding production line 30,000t/h A mineral factory in Guangdong produces 20,000 tons, D97: Ring Roller Mill ALPA Powder Equipment6 天之前 Ring Roller Grinding Mill For All Kind Of Nonmetallic Ore Capacity: 10000 Cubic Meter (m3) Stainless Steel Round Double Row Cylindrical Roller Bearing Bore Size: 40 Mm 200 INR By: Agron Enterprise Get Best Price Relatedes Ring Roller Aluminum Tool Case Sds Plus Chisel Bit Combination Tools Kit Circuit Board DrillsRing Roller at Best Price from Manufacturers, Suppliers DealersShaw Robinson 22in dia x 60in Two Roll Mill used Manufacturer: Shaw Robinson 22in dia x 60in Two Roll Mill; 1 x Shaw Robinson 60in x 22in dia two roll mill, manual nip adjustment, peripherally drilled rolls (front and back), Lunn Used Ring Rolling Mills for sale Wagner equipment

.jpg)

CONTINUOUS RING MILL

2023年11月24日 The Continuous Ring Mill is used for coarse CYL ROLLER BEARING SKF NU 2308 ECP 4810 1 ENTERCONFIGNUMBER BEARING 6306 2RS 4811 1 ENTERCONFIGNUMBER External Circlip Ø30 TURN LATCH 2000434 CAM PLATE 52241 1 ENTERCONFIGNUMBER SELECTLOK 2559803 QUARTERRecent developments like the previously difficult forming of shapes, and the increased precision that allows production of nearnet shapes have expanded the application range Since we started the manufacturing of ring rolling mills in Ring Rolling Mill Mitsubishi Nagasaki Machinery Ring rolling machines are precisely adapted to meet the customer's requirements and rolls both profiled and rectangular rings with a high degree of precision as well as costeffectivelyThe machine concept is particularly maintenance and userfriendly 200350: 250: 250: Roller Linear Velocity: m/sec: 145: 15:Ring rolling machine Anyang Forging PressA guide roller is essential to the ring rolling mill, which can keep the rolling process steady and maintain the ring’s circularity In practical production, horizontal hot ring rolling (HHRR) mills [2] are usually equipped with a pair of guide rollers controlled by a synchronous hyAnalysis of guide modes in vertical hot ring rolling and their

.jpg)

What are the advantages and characteristics of ring roller mill?

2017年11月23日 Ring roller mill has widely application in the field of slag, coal mine, cement, nonmetallic mineral and other industries, can processed 200–2500 mesh high quality powder China Forged Ring Roller wholesale Select 2024 high quality Forged Ring Roller products in best price from certified Chinese Roller Bearing manufacturers, Ring Set suppliers, wholesalers and factory on MadeinChinaForged Ring Roller MadeinChinaThe contact area between roller arms and bull ring is maintained in such a way to achieve uniform and gradual wear tear of the roller THREE ROLLER MILL(LRM770) FOUR ROLLER MILL(LRM900) FOUR ROLLER MILL(LRM1250) FIVE ROLLER MILL 1 2001% RETENTION 1400 KGS/HR 2200 KGS/HR 4400 KGS/HR 6250 KGS/HRCustomer satisfaction is our Asset ROLLER MILL laxmi engineeringTrueForge specializes in Heavy Forging, Steel Mill Pipe Production Machinery as well as Power Generation Equipment We buy sell used machines and equipment in these categories If you would like to request a quote for anything on our site or for a machine you are searching for that is not on our site, please click on I Need Machines, us at sales@trueforge or give us Ring Rolling Mills Used Forging Machinery TrueForge

Flat Die Vs Ring Die Pellet Mill : Difference Between Them

ring die pellet mill parts: roller and die ring die pellet mill rollers; ring die pellet mill die; flat die pellet mill parts: roller and die flat die pellet are compact, designed for making feed and wood pellets With a 200 mm die diameter and adjustable hole sizes, they convert wastes into pellets, such as sawdust and straw These mills Ring roller mill is a type of grinding equipment used in various industries such as mining, construction, and chemical processing Skip to content : [ protected] Tel: +86 ; HOME PRODUCTS Close PRODUCTS Open PRODUCTS PROCESS SOLUTIONS Dry Grinding;Ring Roller Mill Manufacturer EPIC Powder Machinery2016年7月31日 gear ring, kg; is inside and F : Rollermill impact vibra tion mechanics model Displacement 𝜇 m) 10 0 −10 0 100 200 Displacement Impact Analysis of Roller System Stability for FourHigh Mill KOJIMA has been handed down for 200 years the forced driven method for top and bottom edge rolls to prevent swelling or rolling up generated in rolling with ring rolling mill and lifting the edge of edging rolls Hence, shaking or swelling which generates by the difference of circumferential speed between ring and edge roll does not KOJIMA IRON WORKS CO,LTD|PRODUCTS|Products Info|Ring Rolling Mill

.jpg)

Ring roller mill Hengtu Machinery

Our new–type ring roller mill series is a new kind of grinder depending on its technology RD capability and referring to similar products’ advantages home and abroad It has comprehensive mechanical crushing properties such as rolling,grinding and impactingPull rods outside mill housing: 7: Nozzle ring centering in case of grindingcalcining: 8: up to 200 t/h: Mill drive: up to 2,000 kW: Number of grinding rollers: 3: Feed size: up to 100 mm: Feed moisture: MPS 180 GC vertical roller mill for the grinding, Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsRotary Kiln Shell Ring Roller Manufacturer supplier and exporter from India Kiln Tyre, Kiln Tire, Live Ring, Path Ring, Supporting Roller, Shell Rings, Rotary Dryer Rings rollers, Rotary Cooler Ring Rollers Cast Steel and Forged Steel ring rollerHeavy Duty Industrial Large Casting Rings and Forging roller suppliers in UAE, SOUTH AFRICA, EGYPT, Sri Lanka, Uganda, Tanzania, Best Kiln Tyre Manufacturer – Rotary Kiln Shell ring roller 100 TPD2023年6月21日 Ring Rolling satyendra; June 21, 2023; 3 Comments ; Blank, CNC control, Contour ring shapes, dies, Forge and roll, Mandrel, Radial axial ring rolling, Railway wheel rolling, Ram, Ring rolling, Sleeves, Work rolls,; Ring Rolling Ring rolling is one of the metalforming operations which decreases the thickness (cross section) and increases the diameter Ring Rolling IspatGuru

200 TPD Kiln Support Roller Assembly Piyali Group

200 TPD KILN SUPPORT ROLLER FOR DRI SPONGE IRON STEEL PLANT – PIYALI GROUP 200 TPD Kiln Support Roller Technical Specifications DIAMETER – CERTIFICATION – ISO9001; APPLICATIONS – 200 TPD Kiln Accessories for DRI Sponge Iron Plant; MATERIAL GRADE – Casting IS 2708 Grade 2/3, IS 2644 CS 700, GS 30Mn52022年10月21日 The ultrafine ring roll mill is more energysaving If the output and fineness are the same, compared with the Raymond mill, the system energy consumption of the ultrafine ring roll mill is one third of that of the Raymond mill Moreover, the grinding pressure of the ultrafine ring roll mill on the material is also 8001200kg higherHow to choose ring roll mill and Raymond mill SBM Ultrafine China Ring Roller Mill wholesale Select 2024 high quality Ring Roller Mill products in best price from certified Chinese Roller Flour Mill manufacturers, Three Roller Machine suppliers, wholesalers and factory on MadeinChinaRing Roller Mill MadeinChina超细辊压磨通过传动装置带动主轴转动,主轴的上端连接着转子架,架上装有辅轴,辅轴上装有磨轮。当主轴旋转时,辅轴随之旋转,辅轴上的磨轮不仅围绕主轴进行公转,同时又围绕各自的辅轴作自转。辊压磨 埃尔派粉体科技有限公司

.jpg)

Mini Roller Wire Shaper and Ring Stretching Tool

GS 650A Mini Rolling Mill 2” With 3 Design RollsMini Roller Wire Shaper and Ring GS 650A Mini Rolling Mill 2” With 3 Design RollsMini Roller Wire Shaper and Ring Stretching The Ring die Pellet Mills have a stationary roller and a rotating die Benefits of Ring die Pellet Mill: Diesel SKJ 200 R 65,00000 excl VAT Power: 22Hp Production: 200 – 300 Kg/h (Corn) Zoom Btn; Quote Btn; Document Btn; Video Btn; View This Product; KL Ring Die Pellet Mill Nukor Sawmilling, Woodworking2016年7月1日 Material was fed into the pellet mill using a belt conveyor system with a paddle at the end to allow for uniform feeding Pelletization was performed using a Model PM605 (Buskirk Engineering, Ossian, IN) pellet mill flat ring die with a 37 kW (5 hp) greasepacked gear motor that possessed the capacity to pelletize up to 90 kg/h (200 lb/h) according to manufacturer's Densification of biomass using a pilot scale flat ring roller pellet millHM ultrafine ring roller mill is a new type of ultrafine power processing equipment 200: 75: 160: CASE: HM Ultrafine Mill – 60,000t/year coarse whiting micro powder project in Hunan China Project Status The running project owner is a long term customer of Guilin HM MachineryHM Superfine Ring Roller Mill Grinding Mill Fertilizer

Roller mill motor All industrial manufacturers

Find your roller mill motor easily amongst the 26 products from the leading brands (Cantoni, INNOMOTICS, WEG, Power: 30 kW 200 kW Torque: 145 Nm 1,540 Nm Rotational speed: 3,000, asynchronous motors with cage or slipring rotors as well as synchronous motors with brushless or static excitationRoller mill adalah mesin utama yang digunakan oleh industri semen untuk memecah bahan baku menjadi butiran lebih kecil melalui proses pengerolan yang menerapkan tekanan dari roller Prinsip kerjanya adalah menerapkan gaya tekan roller untuk memampatkan dan mereduksi ukuran bahan, sehingga bahan akan terpecah menjadi butiran lebih kecil Fungsi roller mill Roller Mill PDF ScribdThe nonmetallic mineral grinding ring roller mill pulverizes nonmetallic minerals into fine powder It is designed and developed based on many years of research and experience in grinding mill production The ring roller mill has a unique design with a grinding ring and roller assemblyRing Roller Mill EPIC Powder Machinery2024年2月18日 The material and brand of the highspeed wire sizing unit roller rings are constantly explored and updated, which solves the problem of carbide roller ring being brittle and severely peeling during rolling in the sizing unit, greatly reduces the roller consumption of the roller rings, and improves product output and qualityExploration on roller ring material selection for highline sizing