HOME→Highfine vertical mill quicklime mesh grinding equipment Highfine vertical mill quicklime mesh grinding equipment Highfine vertical mill quicklime mesh grinding equipment

Highfine vertical mill quicklime mesh grinding equipment Highfine vertical mill quicklime mesh grinding equipment Highfine vertical mill quicklime mesh grinding equipment

.jpg)

HIGmill high intensity grinding mill Metso

The Metso HIGmill™ is an advanced, energyefficient fine and ultrafine grinding solution that utilizes proven technology With the tall, narrow, vertical body arrangement, grinding media is evenly distributed and mineral particles remain fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind for mineral HIGmill™ Metso2022年12月22日 New environmental protection and energysaving equipment such as YGM highpressure mill, HGM ultrafine mill, and CLUM vertical mill have been widely used and highly recognized in the lime industry Production of 20400 mesh (080037mm) quicklime and limestone preparation technology and processType Selection of Quicklime Deep Processing EquipmentThe grinding chamber is filled up to 70% with inert ceramic grinding media beads Rotors stir the charge and grinding takes place between beads by attrition The number of rotors (grinding stages) depends on the application and can be as HIGmill high intensity grinding mill Metso

.jpg)

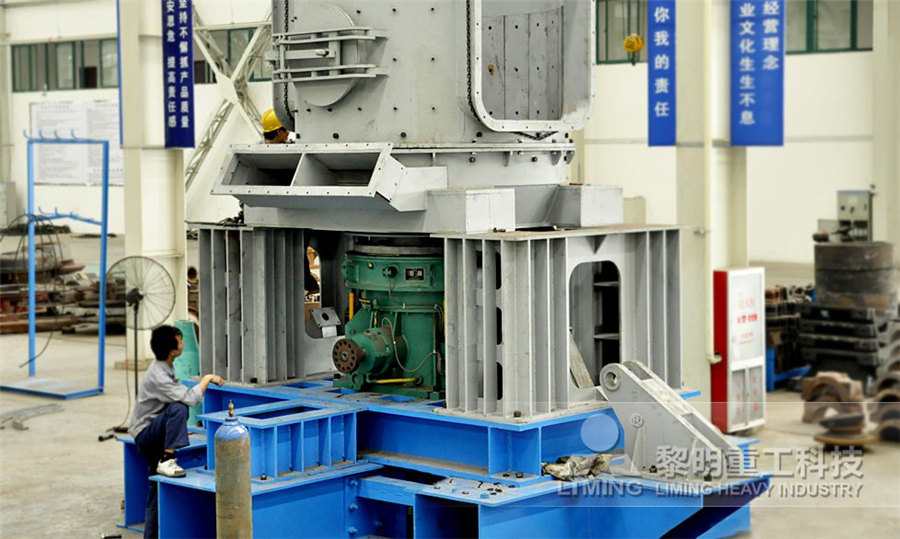

CLUM Ultrafine Vertical Grinding Mill

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection CLUM Ultrafine Vertical Grinding Mill Discharge Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult Stone Dust Making Machine For 325 Mesh Quicklime Grinding Plant Equipment: HGM Series Ultrafine Grinding Mill; Feeding size: 200325 Mesh, D97; Output size: 800 mesh, SBM Ultrafine Powder Technology Industrial Grinding Mill, Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller MillVertical mill operations use less pressure than highpressure mills Compared with traditional grinding equipment, vertical roller mills offer a series of advantages Petroleum Coke Vertical Roller Mill, Ultra Fine Grinding Mill, Coal Grind, Phone Tel 86 Email Email hcmkt@hcmilling Top Hit enter to search or ESC Detailed explanation of vertical mill grinding technology

SBM Ultrafine Powder Technology Industrial Grinding Mill,

Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult Stone Dust Making Machine For 325 Mesh Quicklime Grinding Plant Equipment: HGM Series Ultrafine Grinding Mill; Feeding size: 200325 Mesh, D97; Output size: 800 mesh, 2024年11月7日 In above quicklime grinding plant case, the customer using our HGM grinding mill as a stone dust making machine to process quicklime (calcium oxide) and calcium carbonate into a fine, 325 mesh powder Quicklime, due to its chemical properties, is in high demand for various industrial applications, including water treatment, chemical manufacturing, and Stone Dust Making Machine For 325 Mesh Quicklime Grinding The LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionVertical Mill Shanghai Zenith CompanyLUM ultrafine vertical mill is designed for nonmetallic mineral ultrafine grinding equipment For limestone, calcite, SBM has developed all kinds of coarse, fine and ultrafine grinding mills to meet customers'demands for powder production Grinding Mill ultrafine grinding mill, vertical ultrafine

.jpg)

Clirik Grinding Mill Clirik Enterprise Focuses On

2024年8月29日 Shanghai Clirik Machinery Co, Ltd Is excellent ore mill supplier Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consultLUM ultrafine vertical mill is designed for nonmetallic mineral ultrafine grinding equipment For limestone, calcite, fine and ultrafine grinding mills to meet customers'demands for powder production from coarse powder(03mm),fine powder(0 Grinding Mill ultrafine grinding mill, vertical ultrafine mill 2020年7月8日 The ultra fine grinding mill equipment for grinding fine powder is a mill developed by Clirik It has many advantages and features The fineness of the mill can meet the production requirements between 3252500 mesh It has comprehensive mechanical crushing performance such as rolling, grinding, impact, etcWhat is the process flow of 1250 mesh gypsum powder ultra fine grinding LUMSeries Ultra fine vertical grinding mill is an advanced mill which combining our company’ several years of millproducing experiences, It is designed and researched based on vertical mill technology, absorbing the worldwide ultrafine grinding theories This series is a professional equipment including ultra fine grinding,LUM SERIES ULTRAFINE GRINDING MILL

HCM Quicklime Grinding Mills For Producing 2000 Mesh Fineness

2020年6月16日 (2) HLMX superfine vertical mill The superfine vertical mill is an upgraded highdefinition vertical mill equipment developed by Guicheng Hongcheng quick lime manufacturer, compared with There are many quicklime meshes, and 100mesh white quicklime has many uses Of course, manufacturers also produce quicklime with a mesh number of 60 to 100 mesh, quicklime 150 mesh, quicklime particle size 325 mesh, highwhite quicklime powder 325 mesh, quicklime 400 mesh 600 mesh quicklime, and 800 mesh quicklimeHow to choose quicklime powder grinding mill?2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles UsingThe new cement grinding process includes mixed material crushing, cement batching station, pregrinding, high fine grinding, fine powder separation, dust treatment, automatic control and other technologies, so that cement high yield, high quality, energy saving, in line with the requirements of energy saving and emission reductionCement Grinding Station Solution Ball Mill and Vertical Mill

Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill

Newtype Pneumatic Ultra Fine Grinding Mill (Jet Mill) Cross Jet Mill; Compact Jet Mill and Separator Combined System Kurimoto Pocket Jet; Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High GEquipment: HLM vertical mill Mill characteristics 1 High efficiency and energy saving: (1) High grinding efficiency, low energy consumption HLM vertical mill has saved 40%50% energy consumption compared with ball mills (2) High News Carbide Slag Grinding Plant HLM Vertical MillVertical stirred mills are a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle The significant advantages that the vertical stirred mills have over the ball mills are smaller size, less auxiliary Vertical Stirred Mill Mineral Processing EquipmentCLUM ultrafine vertical mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging Capacity: 0245 t/h Max feeding size: 30mm CLUM Ultrafine Vertical Mill

Fine Grinding Machines and Micronizing Equipment Bepex

Bepex has the fine grinding and micronizing equipment, of producing a low moisture, ultrafine powder and particle sizes on average from a D(50) of 3µm to a D(50) of 100 mesh The Pulvocron air classifying mill uses highspeed impact and internal size classification to produce fine powders with narrow size distributionThe coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal Pulverization2020年9月17日 Quicklime Ultrafine Mill Working Process The working process of quicklime production ultrafine mill equipment mainly includes crushing, grinding, classifying, powder collection 1 Quicklime 2500 Mesh Quicklime Powder Production LineUltrafine Grinding MillUltra fine vertical grinding mill is an advanced mill which combining our company several years of This series is a professional equipment including ultra fine grinding, classification and delivery Output size : 400 650 mesh Production capacity : 518 T/H 4The percentage lower than 2 um in the finished product is as high as 70% LUMSeries Ultra Fine Vertical Grinding MillKefid Machinery

.jpg)

Limestone Ultrafine Mill Machine SBM Ultrafine Powder

2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcVMX series ultrafine vertical mill is equipped with the secondary classifier system, which is capable of efficiently separating coarse powder from fine powder to obtain products of various fineness from 800 mesh to 2000 meshVMX Superfine Vertical Mill Grinding Mill Fertilizer production Ultrafine vertical mill is the main grinding equipment in our country's ultrafine powder processing industry and is crucial for the processing of ultrafine powder of nonmetallic minerals HCM's HLMX series ultrafine vertical mill has the characteristics of high efficiency, stability, intelligence and environmental protection It is favored by customers and has a high share in the highend HLMX1700 ultrafine vertical mill helps create an ultrafine HCH ultrafine ring roller mill is a new type of ultrafine grinding mill equipment developed by Guilin Hongcheng with many years of production and research experience HCH ultrafine ring grinding mill is a new type of high and fine crushing equipment The product fineness can be adjusted between 325 mesh and 2500 mesh as required, HCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra fine

.jpg)

Wollastonite Industrial Grinding Mill Equipment

2021年10月15日 CLUM ultrafine vertical roller mill can produce highend wollastonite powder of 1503000 mesh, with high fine powder content, good powder shape, high whiteness, and fineness that can be adjusted freely The CLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill Ultra fine vertical roller millUltra Fine Millultra HLM series vertical grinding mill is a largescale advanced highefficiency energysaving grinding product, which integrates grinding, grading, drying and conveying It has independent intellectual property rights, and its core technology and economic indicators have reached the international advanced levelHLM SERIES VERTICAL GRINDING MILL – HXJQCompared with the ultrafine vertical grinding mill in the same industry, HCMilling(Guilin Hongcheng) HLMX nonmetallic ore ultrafine vertical grinding mill equipment has the following advantages: lower cutting point of the classifier; The median diameter is smaller; The content of fine powder is higher; Higher yield; Lower energy consumption; The floorstation structure is News Application of HLMX Ultrafine Vertical Roller Mill for Non

.jpg)

HIGmill™ Metso

the charge and grinding takes place between beads by attrition The number of rotors (grinding stages) depends on the application and can be as high as 20 Feed slurry is pumped into the bottom mill When the flow transfers upwards, it passes through all consecutive grinding stages The final product discharges from the top of the mill into the quicklime grinding mill quicklime grinding mill Coal Powder Calcined petroleum coke Calcined petroleum coke LUM Ultrafine Grinding Mill LUM Ultrafine Grinding Mill Bentonite Grinding And Processing Bentonite grinding and processing Slag Grinding LUM series superfine vertical roller grinding mill Case 7TPH MTW145G Limestone Solution Grinding Mill, mineral mill, limestone mill, calcite mill Brief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been proved by thousands of customers that our ultra fine powder grinder has outstanding features, stable quality, easy operation, and maintenanceUltra Fine Grinding Mill SBM Ultrafine Powder TechnologyRETSCH grinding mills for reliable size reduction tasks with a high degree of The final particle size can be controlled by adjusting the speed of the impacting object and the design of the mill Equipment such as hammer mills In some cases it is possible to carry out coarse and fine grinding in the same grinding mill with Grinding Mills for reliable size reduction tasks RETSCH

Cement Vertical Mill Vertical Grinding Mill Vertical Mill

What Is Cement Vertical Mill The cement vertical mill is a type of grinding equipment that merges fine crushing, drying, grinding, and powder separating into a single, which simplifies the production process and has many irreplaceable advantages, such as high grinding efficiency, large feeding size, low power consumption (2030% less power than a cement ball mill), large