Lithium Ore Crushing Green Mineral Grinding Machine Manufacturer, Spodumene

.jpg)

Lithium processing technology Complete solutions that FLSmidth

Spodumene ores are typically consolidated from ore comprising 1–15% Li20 to a concentrate of about 6–65% Li20 To achieve this, the ore passes through a typical concentratortype plant, SGS supports the minerals and chemical industries in the design and operation of efficient crushing and grinding circuits using both power and modelbased methods We can design Hard Rock Lithium Processing SGS2023年12月27日 Two process pathways to achieve batterygrade chemical production from spodumene are summarized herein, with a focus on improving process yields and costs in the saline water circuit Lithium (Li) is essential to Hard Rock Spodumene Lithium Processing Saltworks 2023年1月1日 This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination Lithium extraction from hard rock lithium ores (spodumene,

Lithium Shakeup: An alternative crushing and grinding circuit for

There is an opportunity to develop and operate spodumene flotation circuits based on the “wholeore” flotation flowsheet This flowsheet emphasizes the need for Dense Media Separation as a crushing and grinding to liberate the lithium minerals from the ore matrix followed by beneficiation processes such as dense media separation, (DMS) froth flotation, and magnetic separation to LESSONS LEARNED FROM NEW HARDROCK LITHIUM PROJECTS2021年5月1日 The present study provides a thorough review of technologies of Li production from such industrial sources, as spodumene, lepidolite, petalite, and micaProcessing of lithium ores: Industrial technologies and case studies 2019年5月29日 This process starts with the crushing of spodumene ore The cause behind the grinding of the spodumene is an acceleration of the heat transfer between the surrounding atmosphere and the mineral The crushed Spodumene: The Lithium Market, Resources and

Spodumene: The key lithium mineral in giant lithium

2022年1月1日 Nowadays, lithium (Li) has become an important element in many industries (eg, energy storage), especially in the energy industry Li can be found in many minerals, such as spodumene, lepidolite Spodumene has a theoretical Li2O content of 803% Due to its high lithium content, spodumene is the most important lithium ore mineral A typical run of mine ore can contain 12% Li2O, while a typical spodumene concentrate Lithium Ore Mining Process JXSC Mineral2020年4月12日 Among lithiumbearing ores, spodumene is the most com mon mineral that has been co mmercially mined and processed to produc e lithium compounds a round the world T he world production of lithiu m via(PDF) Lithium Extraction from Spodumene Ore5 天之前 Only after grinding the lithium ore to achieve monomer cleavage can the mineral processing flow effectively extract lithium resources Lithium ore ball mill In the grinding and grading stage of lithium ore, in order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and grading process can be usedBall Mill Is The Key To Grinding Lithium Ore JXSC Machinery

.jpg)

Spodumene Wikipedia

Spodumene is a pyroxene mineral consisting of lithium aluminium inosilicate, Li Al(Si O 3) 2, and is a commercially important source of lithiumIt occurs as colorless to yellowish, purplish, or lilac kunzite (see below), yellowishgreen or emeraldgreen hiddenite, prismatic crystals, often of great sizeSingle crystals of 143 m (47 ft) in size are reported from the Black Hills of South Dakota 2022年12月15日 Three methods of lithium ore beneficiation: Hand selection method: according to the difference of mineral color and mineral shape to hand selection, obtain high purity lithium concentrate Magnetic separation method: For lithium ore with high iron content, magnetic separation method is usually used to screen out the iron ore andlithium ore beneficiation and crushing and milling processGrinding Classifying: In order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and classifying process can be adopted, using ball mill + classifying machine According to the ore properties of different lithium ores, some lithium ores may need to be deslimed after the grinding stageLithium Processing Plant, Equipment JXSC Machinery2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?

.jpg)

Geochemistry and mineralogy of a spodumenepegmatite lithium ore

2023年11月1日 Drill core halves or quarters from mineral exploration campaigns were sampled at the Whabouchi site Identification of the lithological units was previously done by Nemaska Lithium's geologists Two units were sampled: the spodumenepegmatite (SP) ore and the minor spodumenepoor (barren) pegmatite (considered as wasterock, BP)2020年9月30日 This review adds to the public domain literature on the extraction of lithium from mineral ores The focus is on the pyrometallurgical pretreatment of spodumene(PDF) Literature Review and Thermodynamic Modelling of 2022年7月5日 The three minerals, spodumene, petalite, and lepidolite, can be used for various purposes after beneficiation and concentrationThe cutoff grade and industrial grade of lithium deposits are divided into manual beneficiation Lithium Processing Plant JXSC Machine2024年11月21日 In 1962, the world’s beryl concentrate production was 7,400 tons, of which handselected concentrate accounted for 91% This is mainly because most of the lithium ore comes from pegmatite deposits, and the main Progress of Five Spodumene Beneficiation Methods

spodumene processing machine manufacturer Capabuild

Spodumene is a pyroxene mineral consisting of lithium aluminium inosilicate, Li Al(Si O 3) 2, Gulin is a professional gold ore crushing machine Spodumene Ball Mill For Sale , spodumene stone crusher mill lineghai, spodumene grinding machine manufacturer Spodumene, Spodumene Suppliers and, Grinding Machines 2023年10月9日 It's important to note that the specific equipment and processes can vary depending on the type of lithium ore (eg, spodumene, brine, or clay) and the desired end product (eg, lithium Lithium ore processing plant machinery and equipment LinkedIn2024年7月9日 SBM's lithium ore grinding machines are mainly divided into four categories: Raymond mill, (F,OH) It is a lithiumcontaining phosphate mineral, usually light yellow or green Lithium ore is mainly used to extract lithium, which is widely used in batteries Crushing and screening 3 Grinding 4 Ore dressing 5 Calcination Lithium Ore Grinding Mills SBM Ultrafine Powder Technology2016年5月9日 Extracting Lithium from its Ore The problems of spodumene mineral dressing depend on the amount of ore deposit, weathering and presence of associated gangue minerals Weathered mineral surfaces must be thoroughly cleaned for selective flotation Slimes interfere with selective flotation and also consume expensive reagentsProcessing Spodumene by Froth Flotation for Lithium Extraction

.jpg)

Lithium Ore Processing – an Overview of the Current and New

the spodumene crystals present in the ore The coarser the spodumene, the coarser the particle size at which physical separation can be used, thus reducing energy consumption during crushing and grinding Dense medium separation (DMS) will typically be used down to ~05 mm, but ~1 mm is a more suitable size for efficient DMS processing2021年5月1日 In this case, at 180–200 °C (pressure 10–15 atm) from concentrates containing 5–6% Li 2 O, over 95% lithium is extracted into the solution within 1 h, when ground to 015 mm Detailed analysis showed that lithium extraction is not a result of mineral decomposition, but replacement in the βspodumene with sodium with the formation of a new mineral with a cubic Processing of lithium ores: Industrial technologies and case 2024年10月28日 The escalating demand for lithium has intensified the need to process critical lithium ores into batterygrade materials efficiently This review paper overviews the transformation processes and cost of converting critical lithium ores, primarily spodumene and brine, into highpurity batterygrade precursors We systematically examine the study findings Transformations of Critical Lithium Ores to BatteryGrade MDPI2023年1月15日 Lithium production in China mainly depends on hard rock lithium ores, which has a defect in resources, environment, and economy compared with extracting lithium from brine This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination methods, and analyzes Lithium extraction from hard rock lithium ores (spodumene,

.jpg)

How to mine lithium ore, mineral processing, crushing, grinding

2022年12月13日 Plus powder grinding lithium ore Xiaobian recommend LM large vertical mill, LM vertical mill using modern technology, has a national patent, set drying, grinding, powder selection, transportation in one; Single machine output, high efficiency, small metal pollution, stable operation, concentrated particle size distribution, skilled in the field of nonmetallic 2022年7月28日 Processing of spodumene ores requires calcination as a compulsory pretreatment to convert αspodumene to a more reactive βspodumene phase This transformation takes place at an elevated Effect of calcination on coarse gangue rejection of hard rock lithium oresThe largest concentrations of lithiumcontaining minerals are found in granitic pegmatites The most important of these minerals are spodumene (Li2O, Al2O3 4SiO2) and petalite (Li2O, Al2O3 8SiO2) Spodumene has a theoretical Li2O Lithium Ore Flotation Plant Pineer Mining Machinery2024年7月1日 Spodumene is a pyroxene member of inosilicate mineral with chemical formula is LiAl(SiO3)2, lithium aluminium It can also be pink, lilac, or green Crystals are prismatic, flattened, and typically striated along their length Gem varieties of the mineral usually exhibit strong pleochroism Spodumene is an important ore of lithiumSpodumene Mineral Properties, Varieties, Uses, Occurrence

A novel approach for flotation recovery of spodumene, mica and

2017年10月1日 The current review focuses on the existing worldwide resources of lithium ore, along with the production, demand, and mineralogy of lithiumbearing minerals, in addition to lithium recovery from This review adds to the public domain literature on the extraction of lithium from mineral ores The focus is on the pyrometallurgical pretreatment of spodumene Information on the phase transformation from α to β, the heat treatment methods as well as the behavior of various compounds in the roasting processes are evaluated Insight into the chemical thermodynamics Literature Review and Thermodynamic Modelling of Roasting 2024年9月19日 With the rapid development of new energy fields and the current shortage of lithium supply, an efficient, clean, and stable lithium resource extraction process is urgently necessary In this paper, various advanced detection methods were utilized to conduct a mineralogical analysis of the raw ore and systematically study the occurrence state of lithium; Sintering Mechanism and Leaching Kinetics of LowGrade Mixed Lithium 2023年12月27日 In step 1, to convert spodumene into lithium sulfate (Li 2 SO 4), the raw ore is crushed and separated both mechanically and via floatationNext, the concentrate undergoes energy and chemically intensive hot acidroasting This process (as shown in Figure 1 below) sees concentrated spodumene powder roasted at 1050°C, cooled, mixed with sulfuric acid, Hard Rock Spodumene Lithium Processing Saltworks

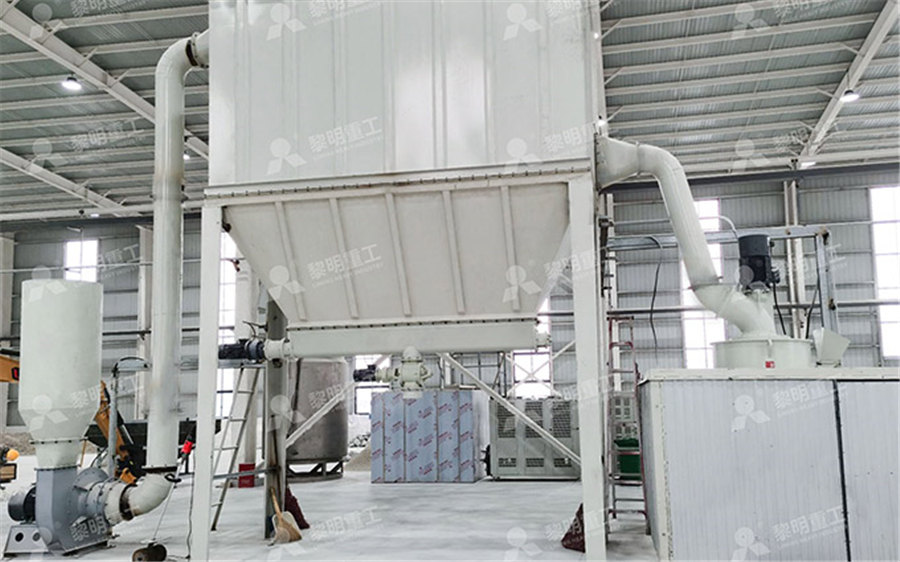

Complete Spodumene Lithium Ore Crushing Grinding

Mobile Rotary Screen Drum Mini GT1015 Small Trommel Screen For Sale hot sale cheap price cross belt overband magnetic separator for conveyor Rock Gold Trommel Screen Alluvial Gold Wash Trommel Gold Plant Good Supply Rotary Drum Dryer Dryers Principle For Garnet Sand tomato paste processing line fruit chips production line production line dates Malachite Copper In the grinding and classifying stage of lithium ore, in order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and grading process can be adopted, and the firststage grinding equipment can use wet grid ball mills, rod mills, etcA Comprehensive Guide to Lithium Processing EquipmentSuccessful cases 300TPD(12TPH) Rock Gold CIP Processing Plant in Kenya Eastman has provided a successful 300TPD(12TPH) rock gold CIP processing plant in Kenya We design the CIP gold plant process flowchart plant layout Mineral Processing Line Mining Plant Spodumene 2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car Aspects of Spodumene Lithium Extraction Techniques

.jpg)

Ball Mill Is Indispensable For Lithium Ore Processing

2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common 2023年2月11日 In the case of Länttä, spodumene is the main lithium mineral and a grade of 520 % Li2O is the maximum obtained in the concentrates, whilst lepidolite is the lithiumbearing mineral in Gonçalo (PDF) Characterization and Beneficiation of Nigerian Lithium Ore: Lithium MinRes is a leading diversified resources company, with extensive operations in lithium, iron ore, energy and mining services across WA MIN $3358 (084%) Contact Suppliers About us About us MinRes is an innovative and leading mining services Lithium Mineral Resources2022年1月1日 Lithium extraction from hard rock lithium ores (Spodumene, Lepidolite, Zinnwaldite, Petalite): Technology, resources, environment and cost Tianming Gao, Na Fan, Wu Chen, Tao Dai(PDF) Lithium extraction from hard rock lithium ores: technology

.jpg)

Copper Introduction And Ore Crushing JXSC Mineral

2024年6月13日 The second stage: grinding – twostage oneclosed grinding The 012mm copper ore powder after the vibrating screen is evenly fed into the grinding machine for grinding The ground material is screened by a spiral classifier, and the material that does not meet the requirements is returned to the grinding machine for further grinding2019年1月15日 There are two economic sources of lithium; brines and hard rock ores The majority of the global lithium production, greater than 60%, is produced from brines while lithium ores accounted for the remaining production (Ebensperger et al, 2005)Table 1 summarises the world’s major lithium producers from ores and brines, and the total reservesThe beneficiation of lithium minerals from hard rock ores: A 2023年12月9日 Minerals crushing and grinding machines are essential for a variety of industries, including mining, metallurgy, and chemical processing These machines are used to reduce the size of raw materials, making them easier to transport, store, and process There are a variety of different types of minerals crushing and grinding machinesMinerals Crushing and Grinding Machines ManufacturersRegarding reserves, the globally confirmed lithium resources have significantly increased, totaling approximately 98 million tons Bolivia boasts the highest reserves, accounting for 2157 % of the global total, followed closely by Argentina and Chile (Fig 1 d) [6]Among these, salt lake brine resources make up 723 % of the reserves, while ores account for 203 %, with nearly 50 % of Advances and promotion strategies of processes for extracting lithium