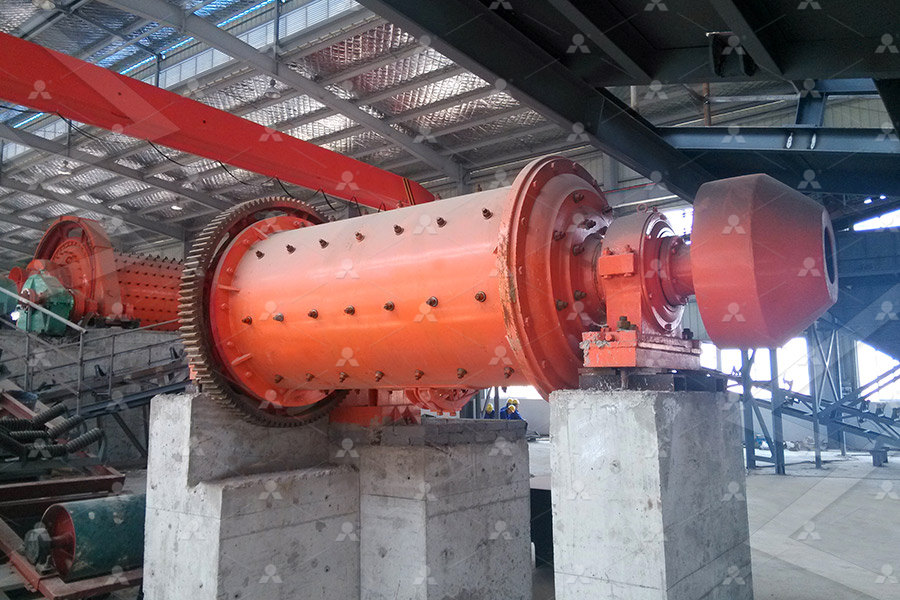

Small ball mill

.jpg)

05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

Data based on:—Wet grinding, single stage, closed circuit operation: feed:—(½” one way dimension); Class III ore All mills:—free discharge, grated type, rapid pulp flow N B—for overflow type mills: capacity 80%—power 83% Dimensions :—“diameters” inside shell without liners—“lengths” working length shell between end 展开The mini ball mill is a type of smallscale ball mill, suitable for trial production and small batch production AGICO offers highefficiency mini ball mills at a competitive price If you are interested, please contact usMini Ball Mill – Mineral Grinding Small Ball Mill For Sale Aside from common ball mills, there is a second type of ball mill called a planetary ball mill Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes A Ball mill WikipediaFind here Ball Mills, Laboratory Grinding Mill manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Ball Mills, Laboratory Grinding Mill, Large Roll Ball Mill across IndiaBall Mills Laboratory Grinding Mill Latest Price,

Batch Small Ball Mill JXSC Machine

Unlike a continuous ball mill, the batchtype ball mill grinds powder over time and adopts intermittent operation 【Batch Small Ball Mills】 The batch small ball mill is a horizontal ball mill Its discharge method is overflowing, also called an PTA02 Ball Mill has a compact design, a slightly larger footprint from the PTA01 that is constructed using powdercoated steel for long lasting durability The PTA02 model accommodates two jar from 1liter to 10liters Ball Mill Rack Attachment NIDECSHIMPO’s Ball Mill Rack attachment is for the WHISPER wheel seriesChoosing Your Ball Mill NIDECSHIMPO CERAMICSBall Mills Steel Ball Mill Lined Ball Mill Since the late 1800s, the ball mill has revolutionized industrial grinding processes, establishing itself as the gold standard in particle size reduction The basic construction of a ball mill is a cylindrical container with journals at its axis Inside this cylinder, grinding media – composed of ceramic, metallic balls, or rods – fills the spaceBall Mills Orbis MachineryDOVE Ball Mills are supplied in a wide variety of capacities and specifications DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (03 TPH – 80 TPH)Ball Mill Ball Mills Wet Dry Grinding DOVE

.jpg)

Laboratory Ball Mills Bench and Floor Jar Mills Gilson Co

Jar Mills are available in bench or floor models and have one to six jar capacities in 1, 2 or 3 tiers They are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass, and more Benchtop Labmill is lightweight and compact and easily adjusts to four sizes of milling jars, 16320oz (05–10L) Jars made of HighDensity Polyethylene fit in metal reinforcing Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheelBall Mills: Lab Equipment Grinding Machines, Features PricingIn its simplest form, the ball mill consists of a rotating hollow cylinder, partially filled with balls, with its axis either horizontal or at a small angle to the horizontal The material to be ground may be fed in through a hollow trunnion at one end and the product leaves through a Ball Mill an overview ScienceDirect Topics2016年2月14日 Do you need a quick estimation of a ball mill's capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Small Ball Mill Capacity Small Ball Mill Capacity Sizing Table 911Metallurgist

Ball Mills – MechProTech MPT

Based on the MPT TITAN™ design, the Mills are girth gear dual pinion driven with selfaligned flanged motors, running on hydrodynamic oil lubricated bearings The TITAN design enables you to run full process load 40% Ball charge at Due to its small barrel diameter and lower impact energy, Ball Mills with small diameter barrels such as our 3 Lb or 6 Lb mills are not suitable for grinding Glass or similar hard materials Ceramic media is a good choice when you must Ball Mills : United Nuclear , Scientific EquipmentWe have a wide range of inhouse built and imported ball mills Both batch and continuous feed mills are available with steel, rubber or ceramic replaceable lining Custom builds are available, contact us for more informationBall Mills Armstrong IndustriesBall Mills 12ft 21ft, Two mills available used Manufacturer: Metso Metso Horizontal ball mills 12ft x 21ft, two mills available POWER: 1600 hp 1194 RPM CLUTCH: Eaton Airflex 38VC1200 , Dual wide SPEED REDUCER: Metso Drives D1PSF110 speed reducer Ratio 6111 : Used Ball Mills (mineral processing) for sale in USA Machinio

Planetary Ball Mill PM 100 RETSCH highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg Wet grinding is used to obtain particle sizes below 5 µm, as small particles tend to get charged on their surfaces and agglomerate, The Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions, as well as mixing and homogenisation of emulsions Skip to content 18886677077 GENERATING CREATIVE SOLUTIONSLaboratory Mini Mill Pulverisette 23 LavallabWe also carry highquality laboratory ball mills, mill systems, necessary media, and more Overstock Sale Select Products 10% much smaller in comparison to common ball mills and are largely used in laboratories to grind sample materials to very small sizes For this purpose, there are specific types of equipment as can be seen on our Laboratory Ball Mill, Planetary Ball Mill– MSE Supplies LLC2017年2月13日 Small Ball Mill FOR SALE We have Small Ball Mills for sale coming in at very good prices These ball mills are relatively small, bearing mounted on a steel frame All ball mills are sold with motor, gears, steel liners and optional grinding media charge/loadBall Mills 911Metallurgist

Small Ball Mills 911Metallurgist

2016年5月26日 The CIW is a Small Ball Mill that’s belt driven, rigid bearing, wet grinding, trunnion or grate discharge type mill with friction clutch pulley and welded steel shell The 7 and 8 foot diameter mills are of flange ring construction with It is designed for fine grinding of materials, and it is usually used in laboratory or smallscale production Vertical ball mills are more energyefficient than horizontal ball mills and can operate at higher speeds 3 Industrial Ball Mill An industrial ball mill is a type of ball mill used in largescale production settingsHow to Choose the Right Type of Ball Mill for Your ApplicationMixer mills grind and homogenize small sample volumes quickly and efficiently by impact and friction These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA or protein recovery For Mixer Mills RETSCH efficient grinding of sample Small and efficient Ball Mills are the most effective laboratory mills for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle sizeBall Mills – fritsch

.jpg)

Nova S Ball Mill Bühler Group

The small grinding chamber volume (4 to 6 times smaller than other ball mills) enables a fast cleaning Nova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, Ball mills can be used to further break down or refine a single material, or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial solution for mixing glazes that require the smallest of mesh sizesBall Mills The Ceramic ShopLaboratory ball mills provide fine grinding, homogenization and mixing for small batch production in the mining, ceramics, chemicals and metallurgy sectors Continuous Ball Mill Continuous ball mills provide uninterrupted grinding and mixing, suitable for largescale production in industries such as cement, mining and chemicalsBall Mills Manufacturer JXSCOur ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsBall Mill Grinding William Boulton

.jpg)

Ball Mills Lime Systems

Whether you need a small labscale ball mill for testing or a large industrial ball mill for highcapacity grinding, we can accommodate your needs With our advanced technology and innovative design, our ball mills are designed to enhance your Economy Ball Mill, a division of JSB Industrial Solutions, Inc manufactures Ball Mills that are diverse in applications and uses Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your process Ball Mills Economy Ball Mill/JSB Industrial Solutions IncThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which This is achieved by using a large number of small grinding balls which have a large surface and 行星式球磨仪PM100德国RETSCH(莱驰)研磨仪粉碎仪The Mini Mill is available in three sizes, the smaller Mini Mill4 can process between 50 and 100 lbs/hour of various materials This completely portable unit plugs into a standard wall outlet The middle capacity Mini Mill12 is capable of Schutte Hammermill Mini Mill Schutte Hammermill

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you The small grinding chamber volume (4 to 6 times smaller than other ball mills) enables a fast cleaning Nova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, Nova S Ball Mill Bühler Group2019年8月14日 When the number of steel balls in the ball mill is too small, although the grinding capacity of each steel ball is maximized, the overall grinding capacity is limited, thereby affecting the grinding efficiency of the ball mill Therefore, maintaining a reasonable balance of the amount of steel balls is a very important part when using ball millThe Ultimate Guide to Ball Mills MiningpediaThe lab ball mill is a particularly suitable solution for grinding small quantities of products Working principle Our lab ball mill is designed for grinding and homogenising a wide range of materials BALL MILL LAB SIZE Lessine

A Comprehensive Guide to Ball Mill Manual

A ball mill is a crucial piece of machinery used in grinding and mixing materials in various industries It works by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be groundThe Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml Wet grinding is used to obtain particle sizes below 5 µm, as small particles tend to get charged on their surfaces and agglomerate, Planetary Ball Mill PM 200 RETSCH laboratory equipmentLaboratory ball mills, including benchtop ball mills, are compact and userfriendly, making them ideal for smallscale applications Jar roller mills offer flexibility with different jar sizes and materials, The 6775 Freezer/Mill® is a small cryogenic mill that processes samples ranging from 01 5 gramsIndustrial Ball Mill Grinder Machines Thomas ScientificOur Benchtop Ball Mill LBBMA20 have features like Speed Range of 60 to 570 ± 10 rpm (adjustable), Roller Size of Φ 25 × 260 mm, Mill Mode of Dry and Wet Milling, and more Buy now! It acts as a smallbatch production unit, integrated with Φ 25 × 260 mm long rollerBenchtop Ball Mill LBBMA20 Benchtop Ball Mill Supplier