Limestone crusher smelting waste slag crushing has red brick

Applicability of gold tailings, waste limestone, red mud, and

2018年12月1日 In the present study, the utilization of smelting byproducts such as red mud and ferronickel slag and mining wastes such as gold tailing and waste limestone were investigated 2023年2月15日 Slag is fully named groundgranulated blastfurnace slag (GGBFs), a byproduct produced by metallurgical smelting plants In addition to iron ore and fuel (coke), appropriate How to Process Slags (with detailed process)? Fote Machinery2023年12月7日 This study investigates the alterations in the ratios of components such as class C fly ash (FA), blast furnace slag (BFS), and waste stone powder (WSP) types of limestone The Effects of Fly Ash, Blast Furnace Slag, and Limestone Powder2021年11月1日 This article aims to recycle industrial slags in brick manufacturing and investigates the performance of fired clay bricks incorporating different kinds of industrial slags Recycling industrial slags in production of fired clay bricks for

(PDF) Recycling and environmental issues of metallurgical slags

2004年1月1日 Using slag as a recycling or renewable resource rather than a waste product has environmental and economic benefits Recycled smelter slags can be used in both in situ and 2015年6月1日 Slag is a waste product from the pyrometallurgical processing of various ores Based on over 150 published studies, this paper provides an overview of mineralogical and Characteristics and environmental aspects of slag: A review2018年12月1日 Increasing concerns about environmental issues have led to more attention being paid to the recycling of mining wastes and smelting byproducts In the present study, the Applicability of gold tailings, waste limestone, red mud, and In this study, the replacement of raw rice husk, fly ash, and hydrated lime for fine aggregate and cement was evaluated in making raw rice husk‑concrete brick This study optimizes Properties of Natural soil and crushed red brick

.jpg)

Microstructure and mechanical properties of ternary mortars with

2022年1月31日 The objective of this research is to study the effects produced by ternary binders which combine the addition of waste brick powder with fly ash, limestone, ground granulated Limestone can be crushed and used to build roads The waste slag from the blast furnace can also be used for this purpose Most limestone is obtained by quarrying, where the rock is Limestone [GCSE Chemistry only] Uses of limestone BBC2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Types of Crushers: Choosing the Right One for Each 2022年1月10日 The paper attends to the utilization and performance improvement of waste red brick powder activated by calcium carbide slag (CCR) Therefore, the improvement of mechanical properties and microstructure of calcium carbide slagwaste red brick powder based alkaliactivated materials (CWAAMs) by silica fume, composite activator and curing temperature was Mechanical, microstructure and reaction process of calcium carbide slag

.jpg)

Comparison of properties of steel slag and crushed limestone aggregate

2003年3月1日 Steel slag, one of the huge industrial waste sources, which has many outstanding advantages (hardness, roughness, angularity, and abrasion resistance) has been used as an aggregate in asphalt 2020年6月3日 Smelting slag is a typical hazardous waste generated in the smelting and metallurgy industry 1,2Slag contains high concentrations of heavy metals, such as Cu, Zn, Cr and Ni, which are harmful if Highpurity recycling of hematite and Zn/Cu mixture from waste smelting 2012年5月23日 Recently, Park and Park investigated the vitrification of red mud using gold tailing and waste limestone to make glass ball by slag atomizing technique (SAT), which is a process where air jets are A new approach to the recycling of gold mine tailings using red 2024年1月11日 3 Hammer Crusher The hammer crusher is a crushing processing equipment for limestone This equipment can replace the rough crushing process of the stone crusher, directly crushing limestone into particles below 25mm The hammer crusher adopts a dual motor operation, consisting of a plate hammer and a rotor to form a crushing powerLimestone Crushing And SandMaking Plant Eastman Rock Crusher

Bond Impact Crushing Work Index Procedure and Table of Crushability

2015年6月16日 Sizing a crusher can be done reliably calculated thanks to the Impact/Crushing Work Index and the testwork research done by Fred Chester Bond and his 1952 paper According to Bond’s Third Theory of Comminution, the work/energy input is proportional to the new crack tip length created during particle breakage and equivalent to the work represented by the product 2023年2月15日 Slag brick is made by mixing, watering, grinding and pressing slag and limestone In the production process of slag brick, the particle size of the slag is generally smaller than 8 mm, and the steam temperature injected into the kiln is about 80 ℃ to 100 ℃, the maintaining time is about 12 hoursHow to Process Slags (with detailed process)? Fote Machinery2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimization2022年11月1日 China has the largest output of steel and iron in the world (Zhang et al, 2022)In 2021, China's average annual pig iron output arrived at about 869 million ton (Stewart et al, 2021) and crude steel arrived at about 103 billion tons (Zhao et al, 2022)Meanwhile, the output of steel solid waste keeps at a high level and generally the production of one ton steel will generate Life cycle assessment of melting reduction treatment for iron and

.jpg)

Applicability of gold tailings, waste limestone, red mud, and

2018年12月1日 Mining wastes; gold tailing and waste limestone, and smelting byproducts; red mud and ferronickel slag, were utilized The mechanical properties of the produced glass fiber were measured Mechanical properties similar to those of basalt fiber were achieved2023年3月2日 Discover the benefits, types, and applications of Slag Crusher Machines in the steel industry Learn how these machines work, the types of slag they can crush, and the maintenance required for optimal performance What is a Slag Crusher Machine and How Does it Work?2019年11月4日 The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performance Limestone Rock Crushing Flow Price JXSC Machine2021年3月16日 By Alton Tabereaux, Contributing Editor Spent potlining (SPL) disposal is one of the largest environmental waste management challenges confronting worldwide primary aluminum smelters due to its toxicity The International Aluminium Institute (IAI) asserts that 16 million tons of SPL were generated from primary aluminum production in 2019,1 making it the The SPL Waste Management Challenge in Primary Aluminum

.jpg)

Limestone crushing, sand making and grinding process

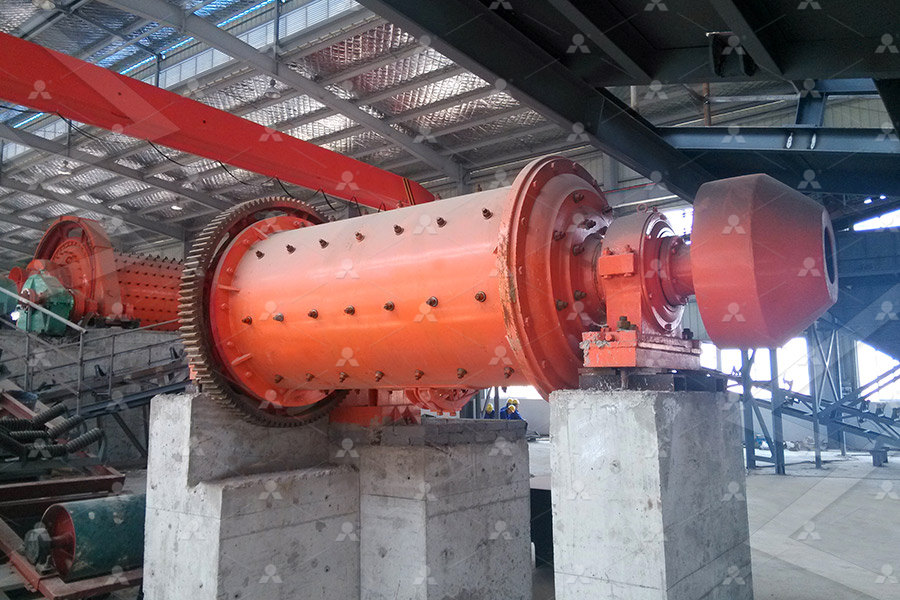

2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished 2021年3月8日 With the acceleration of urbanization, a large amount of construction and demolition waste (CDW) is being produced on a global scale [1], [2], [3]According to reports, the European Union and United States produce approximately 800 and 700 million tons of CDW each year, respectively [4], [5], [6]As the largest developing country in the world, China produces Research progress on recycled clay brick waste as an alternative Steel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentSteel Slag Processing SHANGHAI SANME MINING MACHINERY 2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel

Limestone Crushing Plant, limestone crusher plant, limestone crushing

Limestone is an important raw material of limestone gravel plants, aggregate plants, has a wide range of applications, our company provides the crusher wear parts can increase the life expectancy of 32 times, exports to the United Kingdom, the United States, Canada, Indonesia, the Philippines, India, Australia, 80 countries and regions, including Lafarge, Heidelberg, 2004年1月1日 Laboratory tests have also been carried out for the production of bricks using boron mine tailing, granulated blast furnace slag (GBFS), ferrochromium slag, steel slag, clinker dust, limestone dust, kaolin fine quarry residue, granitebasalt fine quarry residue, red mud, construction and demolition waste and fly ash by mixing or without mixing it with other Characteristics of bricks made from waste steel slagCrushing Limestone to a 1¼" Product A RM 120X crushes limestone in Brazil feeding 2 ft x 2 ft blast rock producing a 1¼" spec product We can crush hard limestone with an impact crusher Occationally, limestone can be very hard Crushing Limestone Impact Jaw Crushers2018年12月1日 Increasing concerns about environmental issues have led to more attention being paid to the recycling of mining wastes and smelting byproducts In the present study, the utilization of gold tailings, waste limestone, red mud, and ferronickel slag was investigated for producing continuous glass fibersTo verify the applicability of the downdrawing process, the Applicability of gold tailings, waste limestone, red mud, and

The compositions of tailing, red mud and waste

Gold mine tailing, red mud and waste limestone cause very serious problems to the environment Due to their abundant amount of waste as well as difficulties with disposal, an appropriate recycling Limestone Crusher Limestone can be directly processed into stone and fired into the quicklime So it has a wide range of applications, such as building materials, Then the materials with qualified sizes will be evenly sent into the Jaw Crusher for the primary crushingLimestone Crusher LIMING (Shanghai)About Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated limeLimestone Crushing Process JXSC MineralLimestone Crusher for Efficient Limestone Crushing Plant Limestone is a versatile nonmetallic mineral with widespread applications in construction, agriculture, environmental protection and more As the primary raw material for cement production, reliable limestone supplies are critical for sustainable infrastructure development globallyLimestone Crusher for Efficient Limestone Crushing Plant

Rock Crusher Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industriesAt present, there are two types of stone crushing machines commonly used: mobile stone crushers and stationary stone crusher equipment Stationary crushers include jaw crushers, impact crushers, hammer crushers, 2015年11月15日 The optimum mix was found to be the one with 7 molar Na + , 045 water to binder ratio and 16 molar ratio [26] investigated on the effect of adding ground red clay brick waste of various Alkaliactivated cements and mortars based on blast furnace slag Stone Crusher,Brick Crusher,Limestone Crusher and more products, see info for all products/services from Shanghai MGThe products have got the international quality Red Rhino Crushers The crusher has been attached to a raft meaning they can move the crusher along the river using just the power of the currentBrick Crusher Crusher Mills, Cone Crusher, Jaw CrushersLaboratory Tests on Compaction and Crushing Behaviors of Construction Waste Slag–Clay Mixtures Xiaoqiang Gu1; Chao Hu2; Jiru Zhang3; and Kai Xu4 Abstract: Construction waste slag–clay mixture Laboratory Tests on Compaction and Crushing Behaviors of

.jpg)

Rock Crushers Pulverizers Williams Crusher

Once in the crusher, the material is broken down using a breaker plate and grinding chamber The reduced rock exits the crusher via a conveyor belt or is discharged into a hopper In some applications, primary crushing alone can 2023年1月1日 Although considerable effort has been done over a long period of time in the exploitation of industrial waste, ferrochrome slag has received surprisingly less investigationUtilization of steel slag waste as construction material: 2018年9月7日 The present study deals with the utilization of waste building bricks, fly ash, RHA, and clay as ingredients for brick manufacturing Figure 1 shows the physical appearance of waste ingredients Most of the industries around the globe use wet method for manufacturing of clay bricks but the present study deals with the use of the semidry method for manufacturing of Manufacturing of green building brick: recycling of waste for 2012年3月1日 Gold mine tailing, red mud and waste limestone cause very serious problems to the environment Due to their abundant amount of waste as well as difficulties with disposal, an appropriate recycling technology of this waste is necessary to mine and smelting industries As a prospective process for treating a large volume of the waste, slag atomizing technology is A new approach to the recycling of gold mine tailings using red

(PDF) Nickel Laterite Smelting Processes and Some

2019年9月3日 red mud addition to ferronickel slag was beneficial for reducing the slag melting temperature For the charge with 125% red mud, melting took place at 1773 K2024年8月15日 Copper smelting slag (CSS) is commonly generated during the smelting process of the copper concentrate, it comprises a range of valuable metals, especially the valuable copper (Cu), possessing the greatest recovery value Currently, direct flotation is commonly used to recover Cu from CSS, but the Cu recovery rate is usually below 90%Efficient recovery of copper from copper smelting slag by gravity Features of Steel Slag Process Steel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable Efficient Steel Slag Processing Senya Crushers Solution1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for fine crushing and then uses a vibrating screen for screening operation, and the qualified materials flow into the next process, and the Limestone Aggregate Crushing JXSC Machine

.jpg)

Resource utilization strategy of Febearing smelting slag in China:

Taking copper slag as an example, copper slag is a solid waste containing iron, lead, and zinc produced in the process of copper smelting, which is a typical nonferrous smelting slag Besides oxides of Ca, Mg, Si, and Al, copper slag also contains 20 %–40 % total iron (TFe) and a certain amount of lead and zinc, which has a high comprehensive utilization value ( Zhang et al, 2020 This project helps a customer complete a slag crusher plant with an output of 100t/h Limestone Crushing Plant; Granite Crushing Plant; Projects Menu Toggle 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; 200t/h River Slag Crushing Plant Track Mounted Mobile Slag Crusher Machine