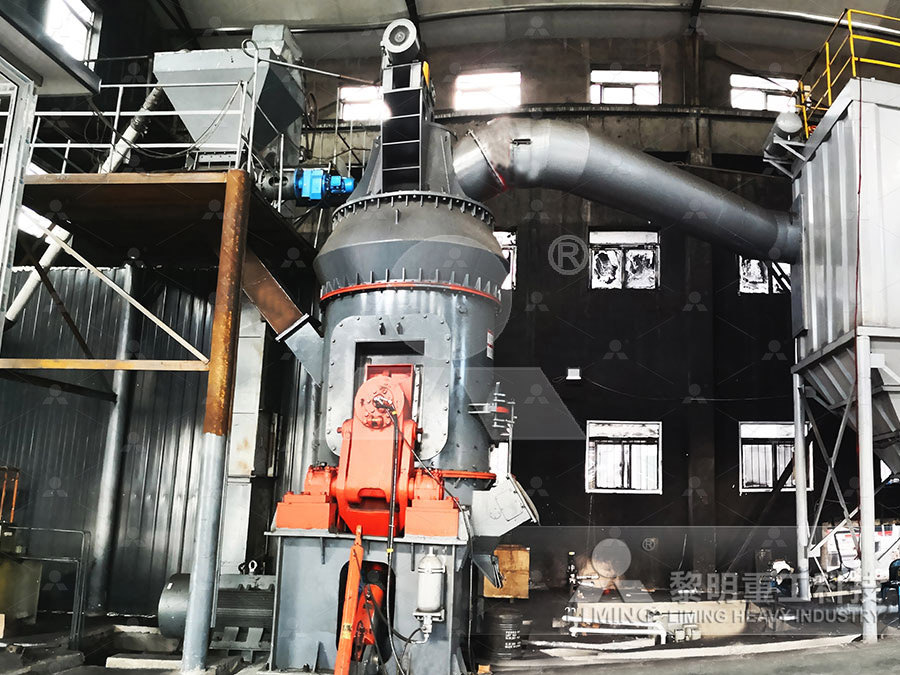

Chemical material calcium carbonate powder making equipment

.jpg)

Calcium Carbonate Manufacturing Process and Equipment

Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years) Chalk 展开Daswell supplies the complete set of equipment for the calcium carbonate plant, from crushing machine, transporting system to grinding mill, classifier, packing machine as well as optional Customize Suitable Calcium Carbonate Plant DASWELLCalcium carbonate powder production line includes several machines such as crushers, dryers, grinding mills, classifiers, coating machines, and packing machines Each stage of the Calcium Carbonate Powder Production Line – Powder EquipmentThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production Calcium Carbonate Grinding Production Line TAYMACHINERY

Calcium Carbonate Ball Mill Plant DASWELL

The ultrafine calcium carbonate ball mill plant is a new energysaving and efficient grinding production line that combines the selfdividing flow micropowder classification technology with the ultrafine ball milling technology2024年10月1日 In this article, we will explore the process of making calcium carbonate, including its sources, methods of production, and applications Understanding Calcium Carbonate Calcium carbonate (CaCO₃) is a white, how to make calcium carbonate Sudarshan GroupIn calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh For processing 4 Steps to Build a Calcium Carbonate Processing PlantPERFECT TOP CUT LIMITATION OF COATED AND UNCOATED GCC THROUGH INTEGRATED HIGH PERFORMANCE CLASSIFIER Pure filler or highquality additive? The CALCIUM CARBONATE (GCC) Hosokawa Alpine

.jpg)

How Calcium Carbonate is

Calcium carbonate is divided into two industrial categories: Ground Calcium Carbonate (GCC) and precipitated calcium carbonate (PCC) The two categories use different manufacturing methods GCC is manufactured by physically We offer a wide range of activated calcium carbonate to our clients Our product's advantages include its ease of application across various uses and its high purity Activated calcium carbonate is produced by coating precipitated calcium Best Calcium Carbonate Powder Manufacturers in Figure 1 Colloidal calcium carbonate with various particle sizes Surface Treatment in Nanoscale Treating the particle surface of calcium carbonate with various chemicals such as fatty acids and resin acids improves affinity with the How Calcium Carbonate is Trusted Filler Masterbatch importers since 1981 supplying highquality materials for multiple industries, Indo Chemicals Pvt Ltd is a leading company in the field of chemicals that has been providing Calcium Carbonate Powder Since 1981 Filler Masterbatch Importers

Precipitated Calcium carbonate production, synthesis and properties

2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on 2022年7月19日 It is a very important chemical raw material, widely used in industry, and is one of the commonly used fillers Raw material for ground calcium carbonate powder production Limestone The calcium carbonate deposited in the lake and sea, after losing water, is compressed and cemented to form a rock called limestoneTo Know Ground Calcium Carbonate from Six Aspects DASWELL2015年6月29日 Our company uses the international advanced technology and production equipment, highquality limestone and big calcite as raw materials to produce the highquality of calcium carbonate products, the main products are Nano (active) calcium carbonate, light (active) calcium carbonate, light (ultra fine )calcium carbonate, heavy (superfine) calcium carbonate, Calcium Carbonate Manufacturer, Calcium Carbonate Granules, With versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate powder of various particle sizes is in great demand around the world As the result, more and more shrewd businessmen want to build or expand their calcium carbonate powder processing plant all over the worldCustomize Suitable Calcium Carbonate Plant DASWELL

.jpg)

Calcium carbonate Wikipedia

Calcium carbonate shares the typical properties of other carbonatesNotably it reacts with acids, releasing carbonic acid which quickly disintegrates into carbon dioxide and water:; CaCO 3 (s) + 2 H + (aq) → Ca 2+ (aq) + CO 2 (g) + H 2 O(l) releases carbon dioxide upon heating, called a thermal decomposition reaction, or calcination (to above 840 °C in the case of CaCO 3), to What is Calcium Carbonate Powder? It's a fine, white powder made from crushed natural sources of calcium carbonate, such as limestone, marble, and chalk Represented by the chemical formula CaCO₃, it marble, and chalk, which are abundant in nature These materials are processed into a fine powder that can be used in various WHAT IS CALCIUM CARBONATE POWDER Global2017年3月9日 The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various Synthesis of precipitated calcium carbonate: a reviewShanghai HySailing Chemical TechCo,LTD is a professional leader China Nano Calcium Carbonate, Talc powder, Zinc Oxide manufacturer with high quality and reasonable price We have helped the customer to build more than 20 Nano Nano Calcium Carbonate, Talc powder, Zinc Oxide,

.jpg)

How to make the calcium carbonate powder?

2019年7月22日 CLUM ultrafine powder vertical grinding mill: 4003000 mesh (D97 less than 3000 mesh, D50 less than 2 micron) calcium carbonate powder making, with capacity 318 t/h The chemical method for calcium carbonate powder making The chemical method includes a carbonization method and a precipitation reaction method2021年8月24日 Heavy calcium carbonate, also known as ground calcium carbonate, or heavy calcium for short, is made by processing natural carbonate minerals as raw materials It has high chemical purity, high inertness, good thermal stability, will not decompose below 400℃, high whiteness, low oil absorption, low refractive index, soft, dry, free of crystal Production and modification process of heavy calcium carbonateCount on us for an unrivaled selection of lab, life sciences, safety, and facility management supplies—including chemicals, consumables, equipment, instruments, diagnostics, and much more—along with exceptional customer care from an industryleading team that’s proud to be part of Thermo Fisher ScientificCalcium carbonate, 98+%, pure, heavy powder, Thermo Scientific Description: Carmeuse is a leading producer of ground calcium carbonate Calcium carbonate (CaCO 3) is a very common chemical compound making up 4% of the earth’s crust and is the primary constituent in limestoneWhile it is abundant, not all limestone is suitable for ground calcium carbonate (GCC) production due to impuritiesGround Calcium Carbonate Carmeuse

46.jpg)

Calcium carbonate Wikiwand

Crystal structure of calcite Calcium carbonate shares the typical properties of other carbonatesNotably it reacts with acids, releasing carbonic acid which quickly disintegrates into carbon dioxide and water:; CaCO 3 (s) + 2 H + (aq) → Ca 2+ (aq) + CO 2 (g) + H 2 O(l) releases carbon dioxide upon heating, called a thermal decomposition reaction, or calcination (to above Dolomite Marble Powder is useful in a size of 100250 microns In the paint industry, calcium carbonate marble powder is a basic material because it is composed of 3040% of the paint components and is preferred over calcium carbonate powder because of its crystallinityMarble Powder Calcium Carbonate BMS FACTORIES2017年3月13日 Use this as early as possible to allow time for tartrate stability and for a reduction in the taste from calcium ions 25 grams of this material will lower acidity by 01% Multiple sizes available Click here to see larger commercial quantities of calcium carbonate Click Here for Acid Reduction InstructionsCalcium Carbonate Powder, USP Wine making SuppliesCalcium Carbonate Powder ( Grade – Light ), especially the light grade, has a wide range of uses and applications in various industries, including paint, construction, composites, and more Here are some of its common applications in these fields: Paint Industry: Filler in Paints: Calcium carbonate is used as a filler in the production of paints to improve opacity, whiteness, and Calcium Carbonate Powder ( GRADE – LIGHT ) Astrra Chemicals

Fine calcium carbonate powder from eggshells Chemistry Stack

2023年5月11日 My goal is to create a very fine calcium carbonate powder using only common materials and ingredients, no specialized chemicals, equipment or tools I start by placing an egg in vinegar, and letting that sit until the eggshell is gone Assuming there's not too much acetic acid, this should give me calcium acetate and water, right?Tailored turnkey solution EPIC Powder specializes in designing and engineering calcium carbonate processing lines We also provide a complete set of equipment to meet customers’ needs in calcium carbonate powder fineness, production capacity, ground calcium carbonate applications, etc Controlled calcium carbonate particle sizeCalcium Carbonate Powder Production Line – Powder EquipmentCalcium Carbonate Classification Equipment Find innovative calcium carbonate classification equipment and connect directly with worldleading technology suppliers For large scale production processes in the chemicals or food industries that require Industrial production of highquality powder materials o Calcium Carbonate Classification Making27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM

Calcium Carbonate – lpowder

Versatile Applications for Various Industries Calcium carbonate, in its various processed forms, serves as a vital filler material in numerous industries, offering a multitude of benefits Its applications span across sectors such as PVC, paint, plastic, paper, rubber, medicine, packaging, food, glass, cable, building and construction, textile, ink, and moreCalcium carbonate is a chemical inorganic compound having the chemical formula CaCO 3It is also one of the most popular chemicals which is encountered first in school classrooms, where the use of chalk (which is a form of CaCO 3) is foundIt is found in the crust of the earth It is available in various forms, such as limestone, marble, and moreCalcium Carbonate Formula, Structure, Properties and UsesUse this as early as possible to allow time for tartrate stability and for a reduction in the taste from calcium ions 25 grams of this material will lower acidity by 01% Multiple quantities available Click here to see smaller quantities of Calcium Carbonate Calcium Carbonate Powder, USP: Bulk 50 lbs Commercial Wine making Calcium carbonate nanocomposites Y Lin, CM Chan, in Advances in Polymer Nanocomposites, 2012 31 Introduction: applications of calcium carbonate nanoparticles Calcium carbonate particles have been used in the plastics industry for many years The original purpose of adding ground calcium carbonate (GCC) particles as filler material for plastics was to Calcium Carbonate an overview ScienceDirect Topics

46.jpg)

Calcium Carbonate (CaCO3) Technical Grade 1Kg Powder

Buy Calcium Carbonate (CaCO3) Technical Grade 1Kg Powder online today! Product details of Calcium Carbonate (CaCO3) Technical Grade 1Kg Powder Calcium Carbonate CaCO3 TECHNICAL GRADE 1 Kilogram Ready to use Expiry Date: October 11, 2026 Lot #: 71210 TECHNICAL GRADE QUALITY Calcium carbonate is a chemical compound with the chemical Range of application: Raw material for making toothpaste, tooth powder, etc in daily chemical industry; Raw material for making face powder, puff cakes, liquid powder, rouge, etc; Essence mixture for making powder cosmetics, and hard abrasive for making toothpaste; in agriculture, it’s used as dairy cow feed additive, antibacterial agent and feed nutrition enhancerShanghai Calcium Carbonate Factory Co, LtdPowder Manufacturing Equipment Find innovative production technology for making powder and connect directly with worldleading specialists Tell us about your production challenge Widely used in the construction industry as filling Powder Manufacturing Equipment MakingKaolin, magnesium carbonate, starch, and calcium carbonate are used for this property Adhesiveness is about how well the powder sticks to the skin Magnesium, zinc or aluminum stearates are commonly used to keep the Face powder making equipment Making

.jpg)

Calcium Carbonate Dickson Chemical

Identification CaCO3 M = 100,09 g/mol CAS [471341] EC number: 2074399 Taric code: 2836 50 00 Synonyms Lime, Chalk, Marblecalcium carbonate shandong alpa powder technology co, ltd ©2022 calcium carbonate powder 02 grinding classifying 10 surface modification 17 project sites 19 application 22 alpa profile dry grinding / classifying / surface modificationCALCIUM CARBONATE POWDERCoated calcium carbonate refers to a form of calcium carbonate in which the individual particles of the mineral are coated or encapsulated with a layer of a different material This layer can be composed of various substances, such as stearic acid, fatty acids, or other polymers The purpose of the coating is to modify the surface properties of the calcium carbonate particles, Coated Calcium carbonate 25kg Amaris Chemical Solutions2023年12月26日 Chemical Properties of CaCO 3 The chemical properties of calcium carbonate can be visualized in terms of chemical reaction it undergoes Let's have glance on the chemical reactions of CaCO 3 Reaction of CaCO 3 with Hydrochloric Acid (HCl) Calcium Carbonate on reacting with HCl gives calcium chloride salt and carbon dioxide gas which causes effervesenceCalcium Carbonate(CaCO3) Limestone Formula, Structure, Uses

.jpg)

Highend calcium oxide ultrafine powder making equipment

2023年11月8日 News/Industry News/Highend calcium oxide ultrafine powder making equipmentHGM series 125 model production line Highend Processing materials: calcium oxide: Finished product particle size: 200600 mesh: China Hubei heavy calcium carbonate HGM100P ultrafine grinding mill production line Hot News Take some Calcium carbonate powder from the original chemical container with a spatula Add little by little to the beaker until 11 g is reached (11 g for 1 Liter, 165 g for a 15 Liter bottle) • Dissolving of the Calcium Carbonate in the mineral water Pour about 400 ml of the mineral water into the 500 ml glass beakerPREPARATION OF CALCIUM BICARBONATE USING MINERAL WATER Chemicals Overview: Calcium carbonate (CaCO 3) is one of the most widely used minerals todayAlso known as limestone, limestone flour, or powdered limestone, it is used in a variety of industrial and commercial applications such as the manufacture of plastics, paints, and adhesives, as well as in environmental applicationsCalcium Carbonate Materials Handled Flexicon Corporation2024年8月23日 However, the heavy calcium carbonate powder products produced by the ball mill plus classifier process have problems such as excessive volume fraction of 2μm fine powder and excessive specific surface area, easy agglomeration of particles, poor product dispersion performance, and excessively high energy consumption per ton of productHeavy calcium carbonate dry production process and equipment EPIC Powder