quicklime grinding production line diagram

.jpg)

Quicklime preparation Gebr Pfeiffer

We have innovative processes for limestone grinding and separating as well as for lime hydration with Pfeiffer mills, hydrators, high efficiency separators, and distribution table separatorsIt is produced by hydrating quicklime, essentially calcium oxide, using a specific apparatus Limestone quality Calcium oxide properties (size and reactivity) Chemical properties and Developing a modular lime plant CimprogettiQuicklime When a calcium limestone or chalk rock, that comprises mainly of calcium carbonate (CaCO 3), is heated in a kiln, it changes by a process called calcination into quicklime also Making LimeQuicklime is produced by heating rock or stone containing calcium carbonate (limestone, marble, chalk, seashells, etc,) to a temperature of around 1000°C for several hours In this process, LIME KILN DESIGNS

Quicklime SMA Mineral

Quicklime is produced by heating crushed limestone to around 1,100 degrees Celsius in a shaft furnace or rotary kiln The heating of limestone releases carbon dioxide, leaving calcium oxide ScienceStruck gives you a lot of information about quicklime,and explains how it is industrially madeMilk Powder Processing Facility Development Proposal and Figure 4: Estimated quicklime powder production process flow chartmd2023年2月4日 These highquality lime briquetting machines can be used for highload production and longterm production in harsh working environments, ie afford heavy duty and Lime/quicklime for metallurgy – how producing and briquettingGreat Wall can provide technological solutions and complete production equipment for quicklime (active lime) production line We use the new type, energy saving and environmental system, Lime Production Line

制粉项目-2023.11.17.jpg)

quicklime processing plant, quicklime grinding machine, quicklime

Gansu bituminous coal grinding production line with annual output of 200,000 tons Raw material: bituminous coal Processing capacity: 200,000 tons/year Finished powder fineness: 200 mesh Combining Quicklime (CaO) and water (H20) produces Calcium Hydroxide (Ca(OH)2 slaked lime and heat There are three main ways of slaking the Quicklime: in an excess of water to Lime and its ProductionPDF On Oct 19, 2016, Zeyni Arsoy and others published Optimization of Grinding Parameters of Quicklime CaO at Different Mills Find, read and cite all the research you need on ResearchGateOptimization of Grinding Parameters of Quicklime CaO at2023年10月27日 Quicklime is an alkaline substance produced from heating limestone in specialized kilns Humans have used quicklime since antiquity for construction, agriculture and metalwork applications It is still used in all of Quicklime: A Primer

.jpg)

Lime Production Line for HighOutput Lime Production Plant

Product: Lime Production Plant Capacity: 50 – 1200 TPD FUEL: Coal Gas, Natural Gas, and Pulverized Coal Application: Active Lime Production Line/ Quicklime Production Line/ Hydrated Lime Production Line Main Equipment for Lime Production Line: Rotary Lime Kiln / Vertical Lime Kiln, Raymond Mill, Jaw Crusher, Bucket Elevator, Separator, Dust Collector, etc2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the bulk concentration of impurities in limestone products During thermal processing in a kiln, impurities such as Si, Mg, Al, Fe, and Mn react with Ca, reducing quicklime product qualityImpact of Limestone Surface Impurities on Quicklime Product 2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is Lime/quicklime for metallurgy – how producing and briquettingLower Oxford Clay (LOC) used in this study was supplied by Hanson Brick Company Ltd, from their Stewartby brick plant in Bedfordshire, UK The chemical and physical properties of the LOC are shown Chemical and physical properties of Lower Oxford Clay, Quicklime

.jpg)

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and If you just throw a stack of peat and a stack of lime into a fire pit and walk away, you end up with like 7 or 8 quicklime in exchange for that entire stack of peat There is a method that is far more efficient, if you are okay with babysitting the fire, and you can scale it up to about 10x productionQuicklime mass production? : r/VintageStory Reddit2022年2月1日 Decomposing limestone (CaCO 3) into quicklime (burnt limestone; CaO) releases significant CO 2 emissions, both from the combustion of fuel needed to heat the kiln to temperatures over 1,000°C, and by the release of CO 2 from the reaction itself (CaCO 3 → CaO + CO 2)Because quicklime is a key ingredient in the production of cement, as well as being Reducing the carbon footprint of quicklime productionGreat Wall can provide technological solutions and complete production equipment for quicklime (active lime) production line We use the new type, energy saving and environmental system, through which fuel consumption can be reduced 40%, output capacity increased 30%Lime Production Line

.jpg)

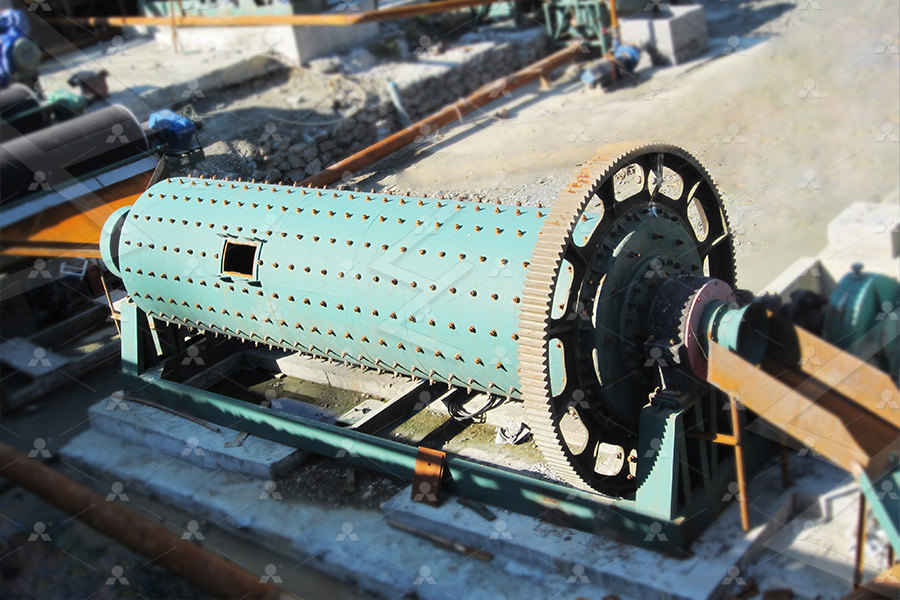

2001000tpd Quicklime CNBMSINOMA cement grinding plant s

Customize your quickLime production line Rotary kilns for lime calcination grinding equipment cement ball mill vertical roller mill roller press cement separator bucket elevator Cement Bag Filter Cement Packing Machine Conveyor Steel Silo In quicklime project, the quicklime grinding machine, which is very popular with customers, has MTW trapezoid mill and singlechip micro grinder Gansu bituminous coal grinding production line with annual output of 200,000 tons Raw material: bituminous coal Processing capacity: 200,000 tons/yearquicklime processing plant, quicklime grinding machine, quicklime Download scientific diagram Particle size distribution of sieved quicklime sample from publication: Optimization of Grinding Parameters of Quicklime CaO at Different Mills Grinding, Milling Particle size distribution of sieved quicklime sampleTurning limestone into quicklime industrially The next video shows a modern industrial plant for producing quicklime, calcium oxide It carries far more information than you need, and you really only need to concentrate on what happens in the kiln itself (starting just after 2 minutes) This is where the limestone is heated and quicklime is limestone, quicklime and slaked lime chemguide

.jpg)

33 PROFILE ON LIME PRODUCTION

production and Customs Authorities External Trade Statistics for imports As can be seen from Table 31, the average local production in the period under review is 4,9825 tonnes, while import stands at 164 tonnes Information obtained from CSA may refer to production of a single plant2021年9月15日 The microstructure of the quicklime product is connected to the reactivity of the product, where a denser product generally results in a lower reactivity [20]While there is an agreement that a CO 2rich atmospheres and/or high temperature promotes the densification of CaO, literature on the effects of (specific) impurities on quicklime densification is scarce and Coal ash and limestone interactions in quicklime production%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources2020年9月17日 Quicklime Powder Production Line To reach the required fineness and capacity of quicklime powder, the key point is to choose the right grinding mill with proper configuration, HCH ultrafine ring 2500 Mesh Quicklime Powder Production LineUltrafine Grinding

Reactivity of quicklime depending on the burning temperature

Download scientific diagram Reactivity of quicklime depending on the burning temperature from publication: Lime Shaft Kilns The annual world lime production amounts to approximately 350 2021年3月3日 Lime is the least expensive and one of the most heavily used alkali in the world, being essential to our society It is a nonhydraulic binder, excepting the socalled hydraulic lime, meaning that it will not set under waterFor this reason, lime is sometimes called air lime since it hardens on exposure to air It was used for thousands of years in masonry mortars to bind the Lime SpringerLinkQuicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, mediumburnt lime, and hardburnt lime In the construction industry, quicklime is added to mortar It can also be used as a drying or Quicklime preparation Gebr Pfeiffer2021年7月6日 So many production factories in Africa are still using manual production methods A few of them have introduced a semiautomated production process, wasting lots of time trying to balance the production line As a result, it is essential to investigate the production line balance problem and optimize the production line layoutBalancing of the Production Line Process in the Manufacturing

Calcium oxide Wikipedia

Calcium oxide (formula: Ca O), commonly known as quicklime or burnt lime, is a widely used chemical compoundIt is a white, caustic, alkaline, crystalline solid at room temperatureThe broadly used term lime connotes calciumcontaining Flowchart Maker and Online Diagram Software drawio is free online diagram software You can use it as a flowchart maker, network diagram software, to create UML online, as an ER diagram tool, to design database schema, to build BPMN online, as a circuit diagram maker, and more drawio can import vsdx, Gliffy™ and Lucidchart™ files Flowchart Maker Online Diagram Software2013年3月7日 Limestone Today, limestone production in West Virginia exceeds 10 million tons per year, with much of that coming from Greer Limestone, a highly advanced mining production of lime from limestone Mining Quarry PlantDownload scientific diagram Corncob (a) before grinding (b) after grinding from publication: Evaluation of particle board from sugarcane bagasse and corn cob This article evaluates particle Corncob (a) before grinding (b) after grinding ResearchGate

.jpg)

How to choose quicklime powder grinding mill?

Process flow of quicklime grinding production line First, the calcite and other materials transported from the quarry are evenly sent to the jaw crusher under the action of the vibrating feeder, and crushed to the feed fineness (15mm50mm) that can enter the mill; Under the combined action of bucket elevator and electromagnetic vibrating feeder, the material is evenly sent to the Download scientific diagram Scanning electron microscopy for (a) quicklime and (b) hydrated lime from from publication: Technical and Environmental Performance of Eggshell Lime for Soil Scanning electron microscopy for (a) quicklime and (b) hydrated Download scientific diagram Schematic diagram of a rotary lime kiln from publication: Computer Simulation of Heat Transfer in a Rotary Lime Kiln In the present work, a steadystate, finite Schematic diagram of a rotary lime kiln ResearchGate2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are not suitable for putting in a kilnLime Production Process and Required Equipment Fote

Limestone crushing and screening production line introduction

2024年1月23日 Cement Production: Crucial raw material in cement preparation, obtained through the calcination process to produce quicklime Chemical Industry: Utilized in fertilizer production, industrial wastewater treatment, and the purification of flue gas Agriculture: Used as a soil amendment to adjust soil acidity and enhance soil fertility2023年5月28日 The dotted line denotes the setting time diagram of SPB and SPF, and the solid line represents the setting time diagr am of SPCB and SPCF following the addition of quicklime(PDF) Unveiling the Effects of Quicklime on the 2022年10月1日 The term “lime” is usually used to refer to all those products deriving from the calcination of limestone and/or chalk, although they may be classified as: quicklime CaO, hardburnt lime CaO, slaked/hydrated lime Ca(OH) 2, and dolomitic lime (eg, 30 wt% CaO, 21 wt% MgO, and 45 wt% CO 2 in the original limestone [1])CaO, the main product of the calcination Decarbonising the lime industry: Stateoftheart ScienceDirect2023年5月12日 They are used in the primary crushing process or secondary crushing process of the sand making line Applicable materials: Hammer crushers are suitable for crushing mediumhard to soft materials like quicklime, dolomite, gypsum, brick, limestone, coal, compound fertilizer, and glass Details you may concern Maximum feed size: 250mm6 Sand Making Machines and How to Choose the Best One

.jpg)

Grinding Machine: Definition, Parts, Working Principle, Operation

2021年5月5日 A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the unwanted material to get the desired surface finish, correct size, and accurate shape of the workpiecepebble quicklime is used Once the slaking tank is emptied, the water for the next batch is added to the slaking tank and the system goes to a standby mode waiting for an operator to start the next batch cycle Figure 4 shows a batch slaker for use with pulverized quicklime Batch slakers are used where only a few small batches are neededAn Overview of Lime Slaking and Factors That Affect the Processboth trials, the grinding process started with an efficient grinding period which ended after 125 s Figure 3: RMS acceleration signal assessed during 20 s grinding of 350 g of quicklime in the HPM 1500 disc mill The trials A F showed efficient grinding periods of at least 17 s duration (green dots) In C, D and E short periods ofRealtime monitoring of efficiency in quicklime grindingcontent () + (%) Effect of CO2 Content in Quicklime on Dissolution Rate of Quicklime

.jpg)

quick lime manufacturing process flow chart Mining Quarry

2013年3月25日 hydrated lime manufacturing process,hydrated lime grinding dog roll manufacturing process flow diagram Process Flowchart quicklime process flow chart FLOW CHART OF PRODUCTION/ASSEMBLY LINE : 1 The plastic face is cut to shape on a band saw or jig saw Commercial sales accounted for 91% of total lime consumption and 92% of domestic production Captive lime accounted for the remainder of consumption and was used in the production of steel in basic oxygen furnaces (BOF), magnesia production, precipitated calcium carbonate production, sugar refining, and refractories (deadburned dolomite)QUICK LIME AND BYPRODUCTS PEC Consulting Group