How to make the roller seal of Zhejiang 3840 vertical mill

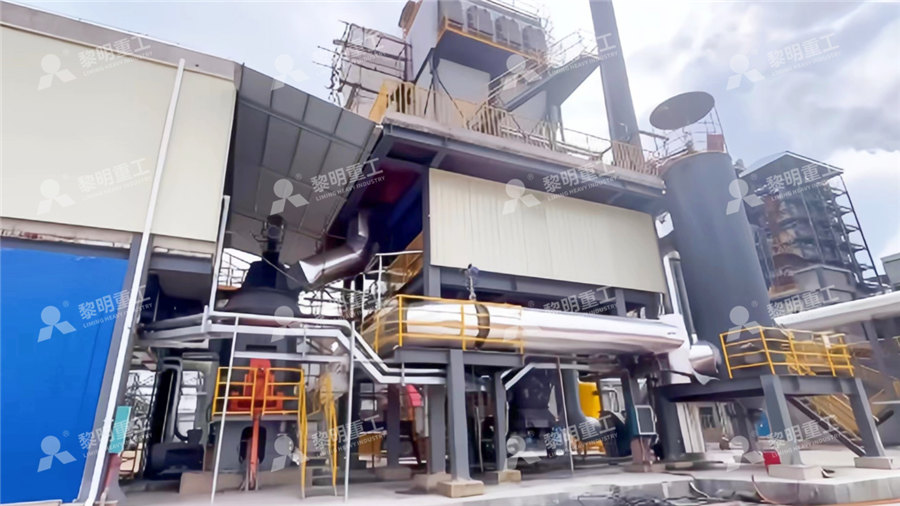

Vertical roller mill for raw Application p rocess materials

The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, the vertical roller mills have been widely adopted A)Structure (1) 2023年8月20日 Here's how it works: The mill's motor powers the rotation of the grinding table, causing materials to descend towards the millstone's center from the feeding inlet How Does a Vertical Roller Mill Work? YouTubeVertical roller mill is used in cement industry for grinding limestone , coal and clinkerTitle: Understanding the Vertical Roller Mill An InDepth AnalysiUnderstanding the Vertical Roller Mill An InDepth Analysis2015年3月25日 The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity Hydraulic system vertical roller mill operation PDF SlideShare

.jpg)

Review on vertical roller mill in cement industry its performance

2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 2023年12月4日 When higher rolling resistance is applied due to particle shape complexity at less mill speed, more vertical force is exerted on the roller, and the roller speed is insensitive to rolling resistance This study provides the basis for further experimental investigations on industrialscale VRM and supports the design optimization of the VRMNumerical Investigation of Vertical Roller Mill Operation Using 04 Vertical Roller Mills Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses vertical roller mills (VRM) which are used to grind raw meal in the 04 Vertical Roller Mills PDF Mill (Grinding) Turbine

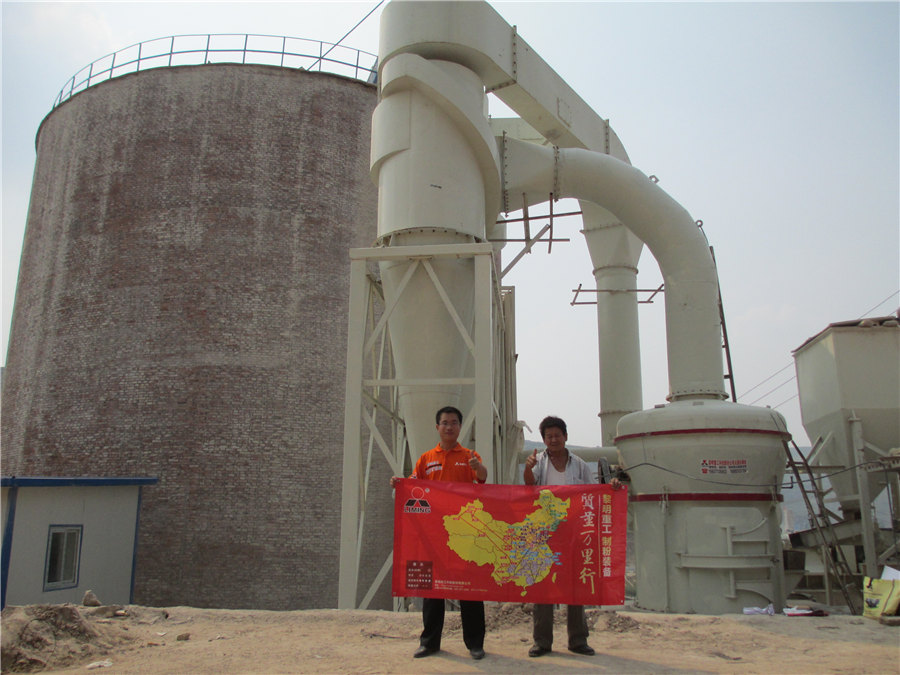

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a 2022年5月31日 Mineral crushing is the main source of energy consumption in mineral processing According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higherIt may also account for 18% of the global electrical energy consumption (NapierMunn, 2015)More efficient crushing equipment needs to be Analysis of vertical roller mill performance with changes in 2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the Performance Evaluation of Vertical Roller Mill in Cement 2016年5月10日 To stabilize the vertical mill grinding table, we must do a good adjustment of dam height , which is the basis of a vertical mill grinding table, the key of vertical mill normal operation Chaeng will introduce you to describe how to establish stable abrasive bed Material thickness can be adjusted to adjust the height of dam, retaining ring material vertical mill is a How to stabilize the vertical roller mill material dam ring?

Increase productivity of vertical roller mill using seven QC tools

2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around The document discusses maintenance and repair of an ATOX Vertical Mill It describes systematic and conditionbased maintenance approaches Systematic maintenance consists of regular cleaning, lubrication and visual inspections Conditionbased maintenance monitors factors like vibration levels and temperatures during operation and performs more thorough inspections Atox Vertical Roller Mill, Maintenance and RepairCoal vertical roller mill also known as vertical grinding mill is an equipment widely used in Tongli coal vertical roller mill is equipped with a highspeed centrifugal blower to send highspeed air into the seal of the roller bearing to form a gas seal to prevent dust from 3840 1400 ≤100 4800~5000 ZJTL4040 170~190 4040 1500 Coal vertical roller millVertical roller millPRODUCTTongli Vertical roller mill is used in cement industry for grinding limestone , coal and clinkerTitle: Understanding the Vertical Roller Mill An InDepth AnalysiUnderstanding the Vertical Roller Mill An InDepth

How a Vertical Form Fill Seal Machine Works PLAN IT

2023年6月26日 This machine comes in two versatile options, the horizontal and vertical assemblies And this is not only used by food manufacturers but also in many other industries Often, manufacturers use vertical form fill seal 2017年4月1日 Separation operation of verticalrollermill will be modelled by application of current models The model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treatedOperational parameters affecting the vertical roller mill The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal MillThere are two main layouts for a vertical roller mill (VRM) system, with product collection in cyclones or a filter The power consumption of a VRM is calculated using factors like the specific grinding pressure, roller dimensions, grinding track speed, and number of rollers The grinding pressure has components from the roller weight and hydraulic system Key internals are the Vertical Mill Calculations PDF Mill (Grinding) Nozzle

Coal Pulverizer Design Upgrades to Meet the Demands of Low

The MPS mill is classified as an airswept, pressurized, vertical spindle, table/roller mill It contains an integral classifier, a grinding section, a windbox (plenum), and auxiliary components (Figure 1) Frequency converted electric drive Turret Louvre Return hopper Pendulum joints Housing Hot air inlet duct Grinding track carrier MotorThe differential pressure of the vertical roller mill is generally controlled at 5000~7000Pa to ensure the proper air volume The change of the pressure difference within the mill is mainly affected by the feed amount when other conditions are constant Therefore, the feed amount should be stabilized Vibration of Verticle Roller MillHow to Improve Grinding Efficiency of Vertical Roller MillThis video explains how to replace bearings of a Roller on a vertical roller mill in detail Following the replacement of the bearing, How to Replace Bearings of a Roller of Verical Roller Mill Vertical 2023年7月4日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore Roller Mill SpringerLink

How to make a rotary kiln riding ring? Medium

2023年10月23日 How to operate a raw material (coal, limestone, rock) vertical roller milla comprehensive guide to Brief description of the process flow of raw material vertical mill system 18 min read Dec vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSOK Vertical Roller Mill Free download as PDF File (pdf), Text File (txt) or read online for free The OK mill is the premier roller mill for finish grinding of portland cement, slag and blended cements It uses a hydropneumatic system to OK Vertical Roller Mill PDF Mill (Grinding)2023年5月31日 Definition of a Rolling Mill Generally, a rolling mill refers to a machine used in metalworking works or projects to shape metal materials by passing them through a pair of rolls Similarly, these machines’ main objective A Definitive Guide to Rolling Mills: All You Need to

.jpg)

Vertical raw mill Cement Plant

Mill drive: The reducer driven by the motor transmits the torque to the grinding table, and the reducer is equipped with a lubricating oil pump station Auxiliary drive: The main engine drive is equipped with an auxiliary drive device, which can make the vertical raw mill start smoothlyThe auxiliary drive is also used for the accurate position required in the inspection of the grinding Vertical roller mills have numerous applications in many different industriesAlthough they are widely used in the cement sector, for example, you are just as likely to find a vertical roller mill being used to handle ores in mining processing plantsThere again, vertical roller mills also have uses within the context of power stations where they are primarily used to pulverize coalVertical Roller Mill MagotteauxCement vertical roller mill also known as vertical grinding mill is an equipment widely used in Tongli cement vertical roller mill is equipped with a highspeed centrifugal blower to send highspeed air into the seal of the roller bearing to form a gas seal to prevent dust 3840 1400(3) ≤100 4800~5000 TL4040 170~190 4040 1500(3 Vertical Roller Mill Cement ManufacturerSupplier Tongli 2022年6月24日 Introduction of vertical roller mill CLUM vertical roller mill series mainly consists of grinding roller assembly, grinding disc assembly, hydraulic station, transmission arm assembly, powder separator, main reducer, motor, body, main reducer lubrication station, hydraulic station, PLC electrical control cabinet and other parts compositionHow to choose between ball mill and vertical roller mill?

How to Solve Excessive Temperature of Vertical Mill Roller

2020年4月2日 The sealing air system one of is the key Raymond Roller Mill Parts that protect the oil seal of the grinding roller The sealed air system consists of a sealed fan and an air duct2020年5月15日 The vertical seal bar, which is hot, moves forward and makes contact with the vertical overlap on the film, bonding the layers of film together On continuous motion VFFS packaging equipment, the vertical sealing mechanism remains in contact with the film continuously so the film does not need to stop to receive its vertical seam Next, a set How do Vertical Form Fill Seal (VFFS) Packaging Machines Work?2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or repairThis type vertical roller Hydraulic system vertical roller mill operation PDF SlideShare2023年8月20日 A vertical mill operates on the principle of material bed grinding, where raw materials undergo a precise grinding process Here's how it works: How Does a Vertical Roller Mill Work? YouTube

.jpg)

Operational parameters affecting the vertical roller mill

2016年9月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industriesVertical Roller Mill for Cement, Clinker, Slag, etc See details Release time 20/10/2017 Superfine Powder Vertical Roller Mill See details Release time 19/01/2015 Carbon black grinding mill, processing line See details Release vertical roller mill clirikultrafine vertical mill, The economic and fast packaging solutions of formfill bags are widely favored in the market HonorPack’s VFFS Machine can operate with various types of heatsealable singlelayer polyethylene films and composite films, such as PE/BOPP, CPP/BOPP, CPP/PET, PE/NYLON, and aluminum foilbased composite filmsVertical Form Fill and Seal Machine VFFS Machine How to Swing Out a Roller from a Vertical Roller Mill StepbyStep TutorialDescription: In this tutorial, we'll show you how to swing out a roller from a vHow to swing out Roller from a vertical roller mill#vrm #roller

.jpg)

How Does The Raymond Roller Mill Work? YouTube

2022年3月30日 Raymond roller mill is used for getting coarse powder It is widely used in grinding calcite, limestone, talc, kaolin and other nonflammable and explosive mAt Magotteaux, we are committed to providing our clients with sustainable products for their vertical roller mill operations Part of this comes down to the fact that we make products that offer a great deal of operational use during their lifespans, of course, but there is more to what we do than simply designing durability into our wear parts because we offer the chance to recycle, tooVertical Roller Mill MagotteauxMill motor speed Classifier speed Material temperature Mill air flow Mill fan speed Material moisture Mill differential pressure Water injection Mixture composition Product transport volume Grinding aid injection Composition of raw material Temperature after the mill Hot gas Grinding roller wear Mill vibrations Fresh air Figure2PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL The vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill

)D`ERF`389RMI4.jpg)

(PDF) Drives for large vertical roller mills ResearchGate

2017年1月1日 Schmitz, T: Quadropol QMCRD World's First Vertical Roller Mill with Driven Rollers Presentation 7 th International VDZ Congress 2013, 2527 September 2013, Düsseldorf/Germany