Crushing equipment installation rate reference table

.jpg)

Metso Nordberg MP Series Technical Reference Manual

011 General This manual, together with specific instruction manuals for individual equipment, has been prepared by Metso Minerals to increase the knowledge and awareness of all The first considerations are at what point in the process the crusher will be used, the type of material, and the output required Use the table below as a guideMASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDEThe flowsheet specifies the nominal design, peak production flow rate, and equipment sizing to handle those capacities Manufacturers provide ratings for their equipment, preferably based Crushing Plant Design and Layout Considerations 911 Metallurgist%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info AusIMM – Leading the way for people in resources

Crusher Efficiency Calculations 911Metallurgist

2014年9月16日 A grid chart or curve for the selected crusher shows that, for a 2½in setting, 54% of the material will pass a 1½in screen, or 46% will be retained (this is like Jaw Crusher thyssenkrupp jaw crushers are mainly designed to crush mediumhard to very hard materials When it comes to the crunch, crushing systems from thyssenkrupp Industrial Solutions offer Industrial Solutions Jaw crushers ThyssenKruppExtensive data are used to estimate the costs of materials, labor, and construction equipment – based upon detailed design calculations for foundations, platforms, piping, instrumentation, Equipment Sizing and Capital Cost Estimation University of 2016年1月11日 The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are easy to calculate The Crusher Operating Costs: How to Optimize and Reduce

VSI Crushers REMco

REMco ST/AR VSI crushers are rockonanvil vertical shaft crushing machines designed to operate as second, third or fourth stage crushers for processing soft to medium/hard rocks, View and Download Dometic Eskimo Ice Remote Ice Crushing System installation and operation manual online Choosing The Correct Voltage Equipment Installing the Condensing Unit Selecting the Site Dometic ice making units are designed to be Required Seawater Flow Rate The Dometic ice maker requires 25 GPM or 150 GPH of seawater flow Dometic Eskimo Ice Remote Ice Crushing System Installation And 2016年3月11日 The crushing action of the Gyradisc crusher results in circulating loads of less than 50 percent of the new feed rate when closed circulating on 3 mesh, to 150 percent when closing the circuit on 6 mesh Screening Crushing Plant Flowsheet DesignLayout2023年6月30日 Research the modelling and automation of crushing equipment Develop a mathematical model of a cone crusher Identify the effect of plant capacity on the crusher’s current and drive powerModeling and Improving the Efficiency of Crushing

.jpg)

SCHEDULE OF RENTAL RATES FOR CONSTRUCTION EQUIPMENT,

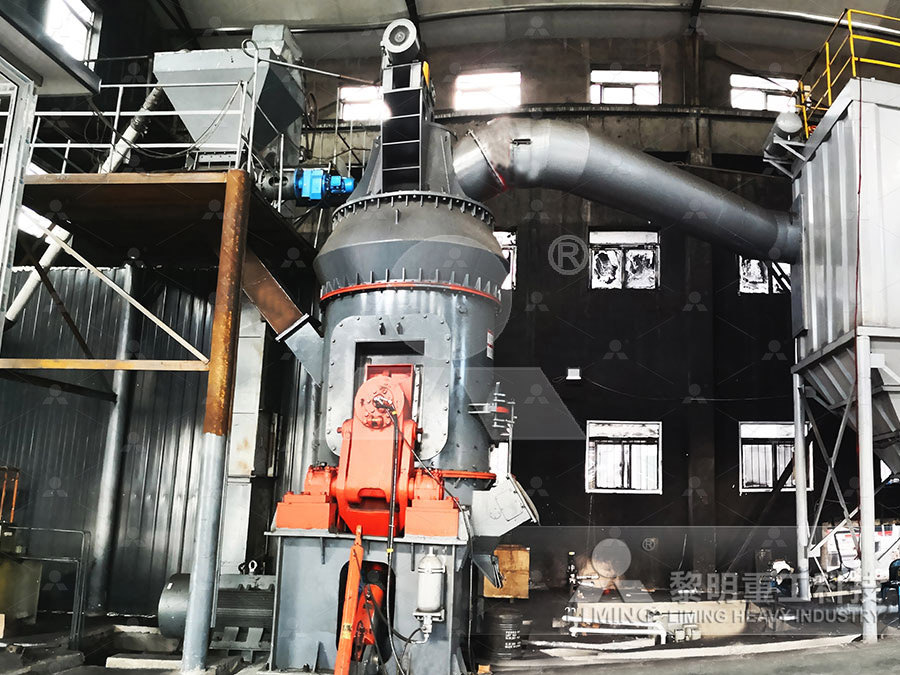

SCHEDULE OF RENTAL RATES FOR CONSTRUCTION EQUIPMENT, INCLUDING MODEL AND SPECIFICATION REFERENCE TABLE OF CONTENTS 12701 SCOPE 12702 SCHEDULE OF RENTAL RATES FOR CONSTRUCTION EQUIPMENT 1270201 Air Equipment 127020101 Air Compressor, Silenced 02 Air Hammer, Including 15 m Hose, 2024年1月1日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for MeasurementControl for Crushing and Screening Process2016年1月18日 It is entirely possible for a crusher to choke at some other point in the crushing chamber than the theoretical chokepoint When the setting of a 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Crusher Performance FactorsCrusher Performance Factors 911MetallurgistBearing parts of crushing equipment is more easily damaged Making sure the service life of bearings needs to add lubricating oil and grease 2 Daily maintenance In order to ensure that the crushing equipment is in good technical condition, to reduce the downtime of failures, and to improve the intact rate and utilization rateCrushing Plant Installation, Operation and Maintain

.jpg)

Metso Nordberg MP Series Technical Reference Manual

011 General This manual, together with specific instruction manuals for individual equipment, has been prepared by Metso Minerals to increase the knowledge and awareness of all persons involved in the operation, supervision, service and maintenance of crushing and screening equipment with regard to safety and operationsA brand of aggregate crushing equipment engineered via the voice of the customer: Liberty™ Jaw Three Cone Crushers we engineer, manufacture, install and service new or expanded plants It's you and us all the way! Close; Ship Loading Conveyors Maximum Production RateCrushing Equipment Superior Industries US ManufacturerTable 3l The results of the PM10 emission tests are presented in Table ll The emission rates determined during both series of tests were low The very low wet stone emission factor results are entirely consistent with the zero visible emissions observed during all of the tests Stone samples obtainedref #5 PM10 Emission Factors for Two Transfer Points at a Granite 2014年1月1日 Conference: Proceedings of the 23rd International Mining Congress and Exhibition of Turkey IMCET 2013; At: Kemer, Antalya, Turkey, April 1619, 2013, pp 293301Factors affecting the performance of crushing plant

.jpg)

Everything you need to know about cement Materials

Such a multistage crushing plant may have an advantage of low wear compared to impactors or hammermill crushers, due to lower differential velocity between material particles and breaker plates However, the installation cost and When designing a new plant, we balance raw material characteristics with the required production rate and the size and shape of the finished product After careful selection of each piece of equipment from final screening to primary crushing your process characteristics are optimum quality, productivity and reliabilitymetsocrushingandscreeninghandbook studylibesThe crusher drive assemblies are to be maintained in good working order with the ability to apply all available horsepower without drive belt slippage Plant installation to ensure the crusher is able to operate continuously consuming the FLA rating of the motor(s) with the equipment able to accept and discharge material freelyCrushing Screening Equipment Product Handbook2023年2月21日 Jaw crushers are popular crushing equipment used for reducing the size of rocks and ores The crushing process is achieved through the use of a jaw crusher plate, which is the fixed or movable component of the crusherJaw crusher plates are crucial to the crushing process because they handle the immense pressure and abrasion caused by the movement of Mastering Jaw Crusher Plates: A Comprehensive Guide

Crushing Plant Design and Layout Considerations studylib

Crusher Installations A summary of previous gyratory crusher installations is shown in Table 3 19 Table 3 Primary crusher plant installations 4 2 quot; (1) Mine Locat i o n Cru sh er M fg Qty Year In st alled Pro d u ct S i ze Bet hlehem Co pper E ndako Gr anisle B C Mo ly Mar co p p er Highland Valley, BC E ndako , BC T o pley, BC Alice Ar m, BC P hillip ines 4 2 x 5 4 AC 1 Previous Post Next Post Contents1 11 Overview the buying criteria for Hammer Crusher2 12Hammer crusher working principle and its application21 122Application of hammer crusher3 13 Types of Hammer Crusher4 14 Characteristics of hammer crusher41 141 Advantages of Hammer Crusher42 142 disadvantage hammer crusher5 Body construction hammer Hammer crusher INFINITY FOR CEMENT EQUIPMENTThe VK series mobile station has 4 configurations, covering all kinds of mining production requirements including coarse crushing, medium fine crushing, threecombination and fourcombination, offering more model types and wider range of applications compared to similar mobile crushing and screening equipment offered domestically and abroadVK Mobile Crushing Station VERTEXprimary crushing stage, secondary crushing stage The primary stage usually has a jaw or a gyratory crusher and screening equipment The secondary have a single or several cone, VSI, HSI crushers and screening equipment In a mining industryCost Analysis for Crushing and Screening – Part II

.jpg)

Schedule of Equipment Rates FEMAgov

Each rate covers all costs eligible under the Robert T Stafford Disaster Relief and Emergency Assistance Act, 42 USC § 5121, et seq, for ownership and operation of equipment, including depreciation, overhead, all maintenance, field repairs, fuel, lubricants, tires, OSHA equipment and other costs incidental to operationbetween the crushing elements (mantle and concaves), finally exiting the crushing chamber at the bottom under the influence of gravity The crushing elements, mantle and concaves are made of high wear resistant material The crushing gap is adjusted by hydraulically lifting or lowering the main shaft by the hydraulic cylinderConstruction, Working and Maintenance of Crushers for Crushing Other machinery and equipment repair and maintenance: Agriculture, construction and mining heavy machinery and equipment repair and maintenance assets: Workshop assets: Welding assets: Weld table s and positioners (including rotary table s) 10 years: 2000%: 1000%: 1 Jul 2015: Work benches and table s: 15 years: 1333%: 667%: 1 Jul 2015 ATO Depreciation Rates 2021 • Tablerefurbishment and repair Where possible, equipment manufacturers should be encouraged to stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steelCrushing Plant Design and Layout Considerations 911

.jpg)

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 It normally highlights a huge crushing rate and high return and is utilized as an essential equipment in primary, secondary, and tertiary stages of crushing Right from hard stones to delicate minerals, stone can incorporate slag, limestone, quartz, rock, iron metal, sandstone, copper metal, marble, concrete and that is just the beginning2016年2月28日 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Crushing Equipment SelectionCrushing Equipment Selection 911Metallurgist2023年2月23日 Each type of equipment is designed to perform a specific function in the crushing and screening process, and may be used in combination with other equipment to achieve the desired results Overall, crushing and screening equipment plays a vital role in the construction industry, enabling the efficient processing of raw materials and ensuring the A Comprehensive Guide To Crushing And Screening EquipmentHow Much Does It Cost To Operate a Crusher? By Chris Nawalaniec Crushing equipment is the heart of an industrial materialprocessing system The size reduction choice you make will have a profound impact on the profitability of your business When the right choice is made, you should expect many years of profitable operation How do you make the right crusher choice? How Much Does It Cost To Operate a Crusher? Resource Center

Overview of the soybean process in the crushing industry

1 Desmet Ballestra, Buenos Aires, Argentina 2 Desmet Ballestra, Zaventem, Belgium * Correspondence: vgibon@desmetballestra Received: 11 February 2020 Accepted: 7 September 2020 Abstract A minimal residual oil content in the meal coming out of the hexane extractor is a clear benefit for a crushing plant; the more oil yield the better revenue for the 2023年7月1日 Understanding the dynamic crushing process of sugarcane is very important to improve the juice extraction rate In this work, we prove the feasibility of using the Smooth Particle Hydrodynamics (PDF) Numerical calculation of sugarcane crushing process based 2023年6月21日 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable The movable jaw plate approaches the fixed jaw plate periodically to realize the functions of crushing, splitting, breaking, and impacting, thus to coarsely or mediumly crush materials with various hardnessJaw Crusher SpringerLink2023年6月3日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for MeasurementControl for Crushing and Screening Process

.jpg)

Primary Jaw Crusher – Everything You Need to Know

2023年2月28日 Learn everything you need to know about primary jaw crushers in this comprehensive guide Discover how they work, their applications, and where to buy them from reputable sources Whether you're in the mining or Look no further than AF Minerals Equipment in Rowland Heights, CA for topoftheline vertical VSI and GS series crushers enable you to achieve a higher reduction rate with fewer crushing stages, lowering your capital costs Vertical Shaft Impact Crusher AF Minerals Equipment2015年10月28日 Selecting the Right Crushing Equipment 28 October, 2015 First published in the September 2015 issue of Quarry Management and on to the centre of a rotating table or rotor The material is then accelerated to high velocity and thrown into the anvil ring or outer shellSelecting the Right Crushing Equipment AggNet2020年10月2日 Chapter #12 – HVAC Equipment Labor There are several sources for equipment labor values But none is better than the contractors own historical data of the actual time required to set a piece of HVAC equipment in place Below is a list of published data on equipment rigging and setting time Read carefully the information []HVAC Equipment Labor MEP Academy

MODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING

back to the same crusher for further crushing Comminution Generic name referring to any minerals processing operation used to achieve size reduction of minerals and ores Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoingnew fine crushing technology can promote our country's comprehensive utilization of straw In China, mill has several decades of development time, because of hammer type crusher advantages of simple structure, good versatility and strong adaptability, at present, straw fine crushing equipment widely used hammer type crushing structureThe research progress of agricultural straw crushing machinery 2019年9月27日 Crushing Screening Equipment held the largest share in the global crushing, screening, and mineral processing equipment market in 2021 The Asia Pacific accounted for the majority of the share in terms of revenue in 2021 owing to increased investments by key players operating in this region coupled with rising demand from enduse industries such as the Global Crushing, Screening, and Mineral Processing Equipment 3 Ensuring processing steps are carried out efficiently by introducing checks and loops after crushing and grinding equipment 4 Providing filtering equipment for ecologically safe discharge whilst following government norms for air pollution 5 Calculation of key specifications and selection of appropriate equipmentDesign of Dolomite Crushing and Grinding Plant JETIR

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processes