Calcium carbonate test limestone crusher smelting waste slag crusher

.jpg)

Wet carbonation of MSWI fly ash for sustainable limestone

Municipal solid waste incineration (MSWI) is vital in modern urban waste management systems, offering a solution for waste disposal and energy recovery [3] However, the residual byproduct 2014年12月1日 An alternative PCC production method named Slag2PCC, where steel converter slag is used as a calcium source instead of limestone, has been recently developed at Finnish Cradletogate life cycle assessment of precipitated calcium Mineral limestone, carbide slag, and white mud were evaluated for their CO 2 sorption activity, with the latter two being industrial wastes retrieved from chloralkali and paper pulp plants, Evaluation of CalciumBased Sorbents Derived from Natural Ores 2022年1月6日 This study explores the effect of steam addition during carbonation on the multicyclic performance of limestone under calcium looping conditions compatible with (i) CO 2 Effect of Steam Injection during Carbonation on the Multicyclic

Suitability of rocks, minerals, and cement waste for CO

2024年11月20日 A wide variety of rocks and minerals have been proposed to provide benefits for CO 2 removal when introduced into soil systems using Enhanced Rock Weathering (ERW) 2021年1月3日 Calcium oxide constituted the greatest composition of major oxide components of between 72 and 82% The presence of CaO facilitated the transformation of carbon dioxide Geochemical and mineralogical assessment of sedimentary 2014年12月1日 An alternative PCC production method named Slag2PCC, where steel converter slag is used as a calcium source instead of limestone, has been recently developed at Finnish Cradletogate life cycle assessment of precipitated calcium 2022年6月1日 We here propose a new type of mineral carbonation process for concrete sludge comprising filtration and bubbling to obtain highpurity calcium carbonate We examined the Preparation of HighPurity Calcium Carbonate by Mineral

.jpg)

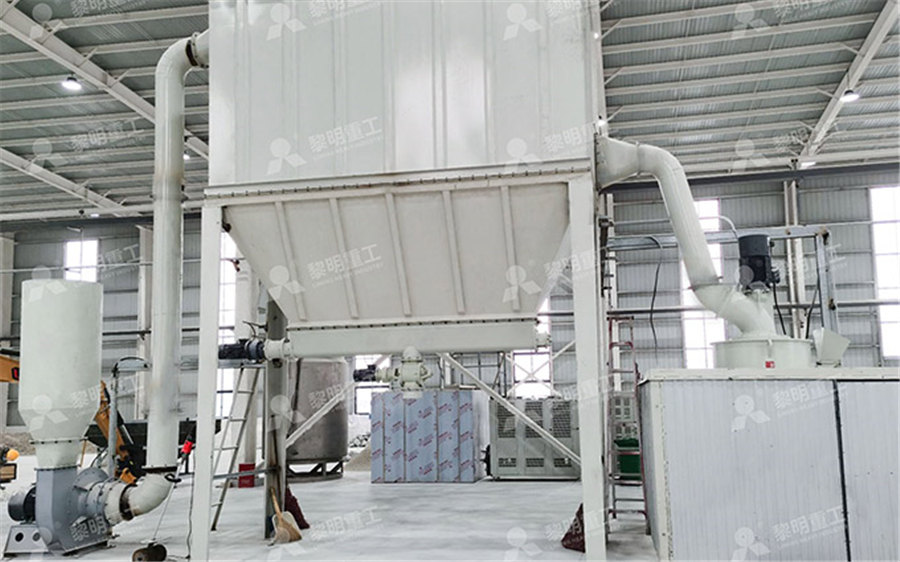

Industrial Ore, Mineral, Slag Crusher Stedman

Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction 2016年2月22日 In this work, different separation processes, including washing, filtering, and drying, were tested on two calcium carbonate slurries produced from steel converter slag and CO2 by a laboratory Performance of Separation Processes for 2024年1月19日 In the following sections, we will review the existing literature on the effects of different calcium carbonate forms on the cement properties (section “Cements with different calcium carbonate Maximising the benefits of calcium carbonate in sustainable 2023年3月2日 Discover the benefits, types, and applications of Slag Crusher Machines in the steel industry Learn how these machines work, the types of slag they can crush, and the maintenance required for optimal performance Maximize the benefits of steel recycling and contribute to a more sustainable future with this comprehensive guideWhat is a Slag Crusher Machine and How Does it Work?

Chapter Ten – Production of Precipitated Calcium Carbonate

2013年12月25日 Precipitated calcium carbonate, a widely used filler material, is nowadays mainly produced by the socalled carbonation process Natural limestone is first calcined and then contacted with carbon Taking into account that the slag contained more copper than ore, a series of flotation tests was conducted on copper smelting slag produced in an electric furnace of a copper plant in China Based on the mineralogical analyses of slag, the tested copper smelting slag was composed of fine particles with complex associaThe Recovery of Copper from Smelting Slag by Flotation Process2014年3月1日 The concept uses steelmaking slag as raw material and has potential to fix CO2 emissions and utilize steelmaking slag, simultaneously As calcium carbonate is precipitated in a solution containing Design of a Continuous Process Setup for Precipitated Calcium Carbonate 2023年2月24日 Limestone is a sedimentary rock composed mainly of calcium carbonate (CaCO3) It is widely used as a building material and is used in the production of cement, concrete, and mortar Limestone has a wide range of uses, including in Limestone Crusher Machine: The Key to Construction Efficiency

.jpg)

Shells and Other Calcium CarbonateBased Waste

2021年10月23日 Calcium carbonatebased shells represent another large group of agro/biowaste The overview of highenergy milling processing of eggshells, oyster shells, shrimp shells, other shells (eg nacre or scallop shells) and bones employing mechanochemical processes is provided in this chapter2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone Mining andCalcium carbonate is a common mineral that is widely used in various industries such as construction, paper, plastics, and agriculture Calcium carbonate crusher is a specialized equipment used to crush calcium carbonate into small particles to facilitate its use in various applications This paper will discuss the importance of calciumCalcium Carbonate Crusher CM Mining Machinery2024年9月15日 Copper smelting slag (CSS) are waste slag obtained from smelters after reusing sulphur smelting slag This study explores the potential of CSS to serve as a resource in cement mortar construction Specifically, the study investigates the use of mechanical and chemical methods to enhance the volcanic ash activity of CSS, enabling them to replace up to 30 % of Cement from Copper smelting slag: Compressive strength,

.jpg)

Slag Wikipedia

Molten slag is carried outside and poured into a dump The general term slag may be a byproduct or coproduct of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced [1] Slag is mainly a 2015年7月1日 With a spirt of that and the resulting of these two mixtures, it seemed that CaCO 3 affected the increase in the early compressive strength of the concrete at the age of seven days, while a drop (PDF) Effect of Calcium Carbonate Replacement on Workability and The processing of limestone is mainly crushing, grading and producing quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, etc Limestone generally adopts dry crushing process For metallurgical and construction use limestone, only the ore needs to be crushed and screened If you want to Limestone Crushing Solution Eastman Rock Crusher2024年10月26日 Calcium carbonate (CaCO3), chemical compound consisting of one atom of calcium, one of carbon, and three of oxygen that is the major constituent of limestone, marble, chalk, eggshells, bivalve shells, and corals Calcium carbonate is either a white powder or a colorless crystal When heated, itCalcium carbonate Formula, Uses, Names, Facts Britannica

.jpg)

limestone, quicklime and slaked lime chemguide

Uses of limestone Limestone is mined in vast amounts An estimate in The Essential Chemical Industry suggests it could be 15 billion tonnes a year worldwide It is used in the construction industry: as a building material; to make cement, which in turn is used to make mortar and (in huge quantities) concrete;Limestone is primarily calcium carbonate When we add limestone to a blast furnace, the calcium carbonate decomposes to form calcium oxide and carbon dioxide The calcium oxide then reacts with silicon dioxide in the charge mixture This silicon dioxide is present as sandy impurities, which exist in the hematite oreLesson Explainer: Extracting Iron NagwaRecycling and utilizing slag instead of treating it as waste enable cutting costs and generating new revenue Solutions for companies processing and recycling slag Menu CloseSlag crushing Metso2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on Precipitated Calcium carbonate production, synthesis and properties

Feasible Utilization of Waste Limestone as a Calcium

2023年3月21日 The specific material used for solidification was soluble calcium ions generated by the reaction of limestone waste, a kind of calciumrich industrial waste from a quarry, and acetic acidKey words: high lead slag; gypsum sludge; calcium sulfate; bath smelting; metal distribution Cite this article as: RUAN Bowen, JIAO Fen, LIU Wei, PAN Zuchao, QIN Wenqing Utilization and detoxification of gypsum sludge by replacing limestone in reduction smelting of high lead slag [J] Journal of Central South University, 2023, 30(4): 1145 Utilization and detoxification of gypsum sludge by replacing limestone because when it ends up in the slag it can lead to failure of the TCLP Barium produces a deep green flame over the slag and matte, a stony appearance, and a large amount of matte Too much alkaline earths or too much zinc can “freeze” a blast furnace [2] A low silica highlime slag is a dangerous sign that the furnace is about to freezeA REVIEW OF SLAG CHEMISTRY IN LEAD RECYCLING2024年11月4日 The calcium carbonate in the limestone thermally decomposes to form calcium oxide calcium carbonate → calcium oxide + carbon dioxide The calcium oxide formed reacts with the silicon dioxide, which is an impurity in the iron ore, to form calcium silicate This melts and collects as a molten slag floating on top of the molten iron, which is Extraction of iron IGCSE Chemistry Revision Notes Save My Exams

.jpg)

Performance of Separation Processes for Precipitated Calcium Carbonate

2016年2月21日 One challenge of the concept presented in Figure 1 is that the produced calcium carbonate is precipitated in a solution of ammonia and ammonium chloride, which raises concern that chloride may be embedded in the product and hinders its commercial use However, the maximum chloride content that can be allowed in a PCC product is not clear as there does not 2021年3月16日 The SPL is impregnated with cell bath salts, with the major fluoride components being cryolite (Na 3 AlF 6), sodium fluoride (NaF), and calcium fluoride (CaF 2) The average sodium concentration is 12–15% in the SPL The major components that contain 10–15% aluminum are cryolite (Na 3 AlF 6) and alumina (Al 2 O 3) Hazardous Waste The SPL Waste Management Challenge in Primary AluminumThe choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will provide you with some suggestions Production method of calcium carbonate powderHow to Choose a Calcium Carbonate Grinding Mill DASWELL2013年12月1日 Calcination of the limestone is energy intensive as it requires high temperatures (∼1000 °C) the objective of this study is to evaluate the feasibility of production of precipitated calcium carbonate from steel converter slag Calcium was extracted selectively from the slag with an aqueous solution of ammonium salt (NH 4 NO 3, CH 3 COONH 4 Production of precipitated calcium carbonate (PCC) from steelmaking

.jpg)

Technoeconomic and environmental evaluation of nano calcium carbonate

2020年4月1日 A new process recently proposed by researchers at the Korea Institute of Science and Technology (KIST) produces calcium carbonate by using steel slag [19]The process named the KIST process not only utilizes steel slag as a feedstock of calcium but also exploits pH differences to increase metal ion extraction efficiency and selectivity In the carbonation 2018年2月10日 Human activities are releasing carbon dioxide (CO 2) into the atmosphere at a rate with no natural parallel over the last 300 million years of Earth's history (Hönisch et al, 2012)To mitigate the negative effects of anthropogenic climate change, a reduction in CO 2 concentrations is necessary Furthermore, preferential warming in the Arctic is expected to Recovery and carbonation of 100% of calcium in waste concrete 2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating Sustainable Approaches for LD Slag Waste 2022年2月26日 Blast furnace slag is a solid waste formed by gangue in ore, ash in fuel and nonvolatile components in solvent (generally limestone) in the process of blast furnace ironmakingIt mainly contains oxides of calcium, silicon, What is Blast Furnace Slag and How to Process It

.jpg)

Crushing and Screening Calcium Carbonate CM Mining

2023年12月7日 Calcium carbonate is a common mineral found in nature It is often used in a variety of applications, including construction, agriculture, and manufacturing Crushing and screening is a process used to break down calcium carbonate into smaller particles This can be done using a variety of methods, including jaw crushers,2023年1月1日 So far, carbon dioxide sequestration by steel slag carbonization has been widely studied by many scholars Ding et al [8] proposed a new linear programming model to evaluate the economic cost of carbon dioxide capture and storage in Chinese steel plants, and believed that the adoption of carbon capture and storage technology in steel plants could obtain Carbon capture and storage technology by steelmaking slags: 2013年3月1日 Steel slag is produced as a byproduct during the oxidation of steel pellets in an electric arc furnace This byproduct that mainly consists of calcium carbonate is broken down to smaller sizes (PDF) Evaluation of steel slag and crushed limestone mixtures as 2014年12月1日 Precipitated calcium carbonate (PCC) is widely used as a filler and a pigment in various applications, eg in paper, plastics and pharmaceutics (Roskill Information Services, 2012, Stratton, 2012)The main PCC production method is the socalled carbonation process, in which limestone (CaCO 3) is first calcined in a lime kiln to calcium oxide, slaked with water to Cradletogate life cycle assessment of precipitated calcium carbonate

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and The Centerfeed Hammermill is a secondary crusher designed to accept feed from a primary with controlled top size ranging from 3" to 5" (75mm to 125mm) Industrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, limestoneHammermill Crushers McLanahan2014年6月7日 The carbonation of steel converter slag features a negative CO 2 emission of 03 kg CO 2eq per kg of calcium carbonate, as compared to 104 kg CO 2eq per kg of calcium carbonate that is produced Cradletogate life cycle assessment of precipitated calcium carbonate 2017年3月3日 PDF Beneficiation and Mineral Processing of Calcium Carbonate and Calcium Sulphate Find, read and cite all the research you need on ResearchGateBeneficiation and Mineral Processing of Calcium Carbonate and Calcium