Water loss of lignite during crushing

Chapter 7 Physical properties of lignites ScienceDirect

1995年1月1日 The loss of moisture at this stage weakens the physical structure of the lignite, by one or both of two processes: the introduction of stresses in particles by shrinkage during drying, or weakening the macromolecular 354 coal matrix by removal of water molecules which may The lignite structure may be analogous to reinforced concrete, in that dehydrated Chapter 7 Physical propertie2023年5月1日 During evaporative drying, lignite exhibits weak thermal stability, in which its particles undergo shrinkage resulting in the cracking or extended fragmentation and Structural changes mechanism of lignite during drying: Correlation 2022年5月15日 Lignite fragmentation during drying can significantly impair the operation of a drying system Volume shrinkage is the main factor that causes lignite fragmentation during Hotair drying shrinkage process of lignite and its ScienceDirect

.jpg)

Experimental Study of the Volume Drying Shrinkage

2022年3月3日 When the rapid loss of external water decreased to less than 128%, the water adsorbed on the external surfaces, the movable water between large particles was completely 2022年3月16日 The moisture content and volume variations of lignite during lowtemperature drying were measured to analyze the change in the water content and volume drying Experimental Study of the Volume Drying Shrinkage 2024年1月4日 The lignite exhibited elevated levels of moisture, and the continuous water molecules resulted in the formation of a stable gel with the carboxyl and hydroxyl groups Influence of Composition on Differential Evolution of To sum up, during lignite drying under lowtemperature conditions, the moisture evaporated and dissipated, and volume shrinkage occurred, leading to the desiccation crack emergence and Experimental Study on the Variation of Surface Widths of Lignite

The relevance between water release behavior and pore evolution

2019年12月1日 As known, the shrinkage of coal and the pore collapsed during the drying process due to water removal The relevance between water release behavior and pore 2017年12月11日 The results showed that the drying of lignite could be classified into two stages, namely, a fast upgrading stage where surface moisture was lost, and a slower moderating Drying and Moisture Readsorption Characteristics of Lignite2022年3月16日 When the rapid loss of external water decreased to less than 128%, the water adsorbed on the external surfaces, the movable water between large particles was completely Experimental Study of the Volume Drying Shrinkage 2024年1月4日 The cracking behavior of lignite during drying–wetting cycles impacts the efficiency of coal mining, underground coal gasification, and coalbed methane development Lignite is known to have high water content, and it exhibits strong hydrophilic properties, resulting in a weak and rigid gel structure caused by water interactions with coal matrix molecules Even Influence of Composition on Differential Evolution of

.jpg)

A DSC study on the impact of lowtemperature oxidation on

instrument to investigate the behavior of water in porous materials such as lignite coal [27, 28] Lignite coals need to be predried due to their high water content in order to increase the efficiency of their combustion The changes in the interaction of water with lignite during oxidation may have a profound influence on its2018年3月1日 Coplot of the two approaches to quantifying drug loss during crushing Drug concentration was measured by UV (% paracetamol loss = 100% recovered) and tablet weight was measured using a balance (PDF) Drug loss while crushing tablets: Comparison 2024年9月3日 The residual coal is prone to oxidation in different degrees after being immerseddried in waterlogged goafs, but the reignition characteristics of waterimmersion coal by lowtemperature preoxidation remain unclear Herein, lignite was preoxidized to 40 °C, 80 °C, 120 °C, 160 °C, 200 °C, and 230 °C after 60 days of immersion Moreover, the microstructure Effect of lowtemperature preoxidation on microstructure and 2016年3月10日 crushing costs and are preferable for industrial formation The shrinkage, due to the loss of water and other elucidated the pumping effect during microwave irradiation of lignite, Elucidation of the Pumping Effect during Microwave Drying of Lignite

.jpg)

Structural changes mechanism of lignite during drying:

2023年5月1日 The macrostructural changes affecting the characteristics of lignite during drying have been extensively studied He et al [16] investigated the fragmentation and pulverization characteristics of lignite particles during drying They concluded that the fragmentation index exhibited a linear relationship with water loss2019年12月1日 As known, the shrinkage of coal and the pore collapsed during the drying process due to water removal The relevance between water release behavior and pore evolution of lignite during the thermal (PDF) The Relevance between Water Release Behavior and Pore 2020年6月1日 The Na2CO3treated lignite showed two distinct weightloss Spontaneous combustion of the loneterm water soaked coal has been frequently taken place during air drying after water Experimental investigation on using ionic liquid to control 2019年7月1日 The objectives of this work were (1) to investigate the drying behavior of single lignite particle in hot air, (2) to analyze the development of cracks both on the surface and within the interior of single lignite particle under different drying conditions, and (3) to determine the relationships among crushing strength, drying temperature, and moisture content of single Hotair drying behavior and fragmentation characteristic of

Classification of water forms in lignite and analysis of energy

2019年10月1日 The moisture content in NM lignite is 43% db, but the weight loss of NM lignite is 53% db in 500–600 W microwave field under N 2 Even if the microwave power is 450 W, the weight loss of NM lignite exceeds 50% db This shows that when the moisture in the NM lignite was removed, volatiles were also removed2018年7月1日 W/g Li et al [26] observed the removal of different form water in lignite and obtained that the effective diffusion coefficient are ranging from 0371 × 10 −8 to 1672 × 10 −8 m 2 min Kinetic analysis on the microwave drying of different forms of water 2019年10月1日 The ether bond content was greater in the coal samples at 300 and 950°C, which changed the trend of lignite water molecule absorption and the distribution of water (T2) detected in the ¹HNMR Classification of water forms in lignite and analysis of energy 2021年8月8日 Significant volume shrinkage and drying cracking of highwatercontent lignite will occur during lowtemperature drying To determine the variation behaviors of the drying shrinkage rate and desiccation crack surface width in the process of lowtemperature drying, lowtemperature and lowhumidity drying experiments were conducted, and the variations of the Experimental Study on the Variation of Surface Widths of Lignite

.jpg)

Experimental Study on Crushing Characteristics of Lignite under

2022年6月18日 After crushing the lignite under pressure, there was a logarithmic relationship between the height decrease and stress of the 100 mm high lignite after compaction; that is,2024年6月1日 The experimental process is shown in Fig 1Lignite (Fig 1 (a)) sourced from the Inner Mongol Autonomous Region of China underwent experimental analysis in this studyThe coal samples were prepared following the Chinese National Standard GB474–2008 [22]Initial steps involved removing the oxide layer from the sample surface, followed by lowtemperature Dynamic evolution of terahertz permittivity of lignite during Significant volume shrinkage and drying cracking of highwatercontent lignite will occur during lowtemperature drying To determine the variation behaviors of the drying shrinkage rate and desiccation crack surface width in the process of lowtemperature drying, lowtemperature and lowhumidity drying experiments were conducted, and the variations of the surface widths of Experimental Study on the Variation of Surface Widths of Lignite 2019年2月2日 Microwave drying is a promising and effective way to drying and upgrading lignite The influence of temperature (100–140 °C) and microwave power levels (500–800 W) on thinlayer drying Effect of Temperature and Microwave Power Levels on

.jpg)

Effects of LowTemperature Pyrolysis in a Tube Furnace on Water

2021年5月1日 Additionally, ca 008 g of lignite matrix was removed from 1 g of lignite on a dry basis for all the treated samples, indicating that water loss content measured by the mass release observed 2019年12月1日 Water release behavior of lignite during the thermaldrying process311 Moisture content of the lignites products and it was not directly related with the loss of water The structural mechanical characteristics of macropores The relevance between water release behavior and pore evolution 2021年10月1日 In this study, interactions between free radicals during copyrolysis of lignite and biomass were explored Changes in free radical concentrations were investigated using electron spin resonance Interactions between free radicals during copyrolysis of lignite The fresh lignite samples were retrieved from the Xieerta Coal Mine in Inner Mongolia The dried coal samples were sieved to 120–160 mesh and sealed after crushing according to Chinese standard GB474–2008 Coal samples weighing 100 g were completely immersed in water and left for 60 days at room temperature This immersing time wasEffect of lowtemperature preoxidation on microstructure and

.jpg)

Solidstate C13 CP/MAS NMR study of Baganuur coal

2010年5月1日 Request PDF Solidstate C13 CP/MAS NMR study of Baganuur coal, Mongolia: Oxygenloss during coalification from lignite to subbituminous rank The rank of Lower Cretaceous Baganuur coal from 2012年3月1日 Request PDF Mechanical/thermal dewatering of lignite Part 4: Physicochemical properties and pore structure during an acid treatment within the MTE process The Mechanical Thermal Expression Mechanical/thermal dewatering of lignite Part 4: 2019年7月1日 The objectives of this work were (1) to investigate the drying behavior of single lignite particle in hot air, (2) to analyze the development of cracks both on the surface and within the interior of single lignite particle under different drying conditions, and (3) to determine the relationships among crushing strength, drying temperature, and moisture content of single Hotair drying behavior and fragmentation characteristic of single 2003年3月1日 Pressure is applied to prevent the evaporation of water in lignite during dewatering (Bergins et al, 2003; Bergins et al, 2007) would reduce fertiliser N loss from the soil systemKinetics and Mechanisms during Mechanical/Thermal Dewatering of Lignite

Production of Useful Silica Sand from Lignite Overburden

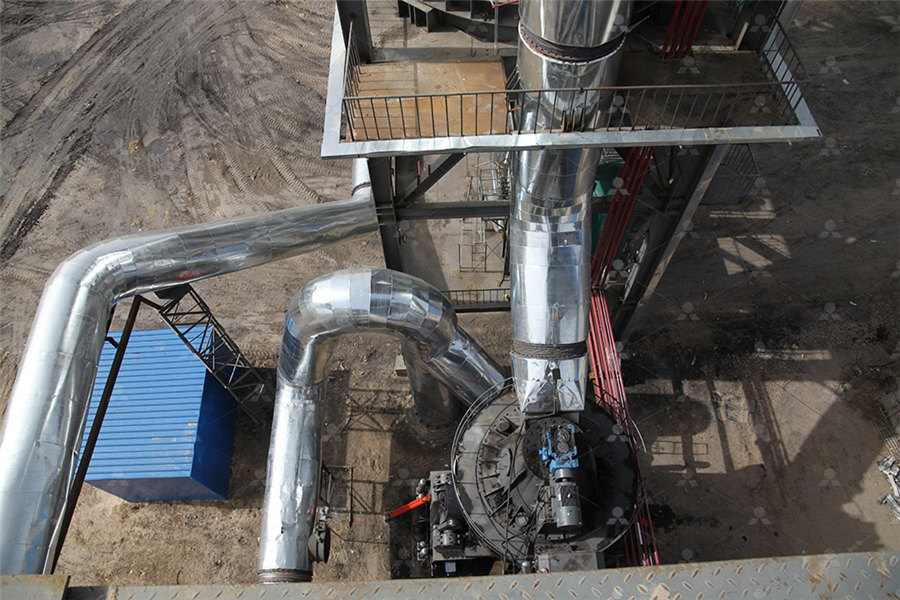

As an environmentally responsible company, CDE washing plant comes with water recycling system as a standard supply to recycle more than 90% of process water CDE Asia has recently completed commissioning of another 50 tons per hour silica sand washing plant for similar application, eg Lignite overburden sand processing at Neyveli, Tamil Nadu2015年1月23日 During the pyrolysis of the coal samples studied, gradual and continuous weight loss over the entire temperature range was observed The weight loss below 210°C is related to the removal of moistureThermal decomposition and evolved gas analysis (TGMS) of lignite 2008年1月31日 Type II kerogen and a Type III lignite in order to determine the different sources of the petroleum potential during primary cracking Experiments were carried out in closed system pyrolysis in (PDF) Role of NSO compounds during primary cracking of a Type 2019年8月14日 The effect of temperature and atmosphere on the syngas yields of CO and H2 during gasification of Zhundong lignite (ZD) and waterwashed Zhundong lignite (WWZD) in a fixedbed reactor was investigated The experiments were run over temperatures from 750 to 950 °C, atmospheres of pure steam or with CO2 addition ratios of 25–75% The syngas yield rate, Effect of atmosphere and temperature on syngas production during

.jpg)

Enhanced nitrogen retention by lignite during poultry litter

2020年12月20日 Lignite addition changed moisture variation during composting The moisture content of the mixtures decreased from 640% to 604% for CK and from 636% to 599% for T1, however, the moisture content for T2 and T3 showed an upward trend during composting (Table 1)The higher moisture content in T2 and T3 than that in CK could be attributed to higher 2023年4月27日 Assessment of soil loss using RUSLE around Mongolian mining sites: a case study on soil erosion at the Baganuur lignite and Erdenet copper–molybdenum mines(PDF) Assessment of soil loss using RUSLE around2023年3月27日 Coal has many closed pores that limit fluid escape However, the evolution of these closed pores during pyrolysis has rarely been studied Based on the method of opening closed pores through stepbystep crushing, this study investigated the pore structure of thermallytreated bituminous coal during crushing using lowfield nuclear magnetic resonance, Porosity Changes in ThermallyTreated Bituminous Coal During 2013年1月2日 The aim of this study is to find a biobinder for the production of waterproof or at least waterresistant coal briquettes from the Slater coal slurry of South Africa(PDF) Production of WaterResistant Briquettes from a

Transformation of heavy metals in lignite during supercritical water

2017年2月1日 However, the high moisture content of lignite results in substantial heat loss during gasification [5] Thus, lignite must be dried in advance, which is an energyintensive process Supercritical water gasification (SCWG) of lignite avoids the drying process because it is carried out in water, which saves a great deal of energy2016年5月1日 Conversion of Xiaolongtan lignite in sub and supercritical water (SCW) was studied in an autoclave in the temperature range of 350–550 °C and water density 0–021 g/cm3 for 0–60 min under Transformation of potassium and sodium in lignite during the 2019年9月5日 Lowrank coals may undergo lowtemperature oxidation and selfheating during mining, freightage, and handling The oxidation of coal changes its structure which will be relected in the behaviour of coal water A differential scanning calorimetry study was conducted to investigate the impact of lowtemperature oxidation on the nature of water in a Chinese lignite A DSC study on the impact of lowtemperature oxidation on2014年11月1日 22 Experimental setup and procedure The coliquefaction experiments were carried out in a 250 ml autoclaveEach time 1000 g JG lignite, wheat straw, plastic waste, or mixtures of the three samples were put into the reactor together with 80 ml deionized waterBefore the liquefaction experiment, the reactor was filled with nitrogen to the desired initial pressure Hydrothermal liquefaction of lignite, wheat straw and plastic

Pore structure evolution and fractal characteristics of Zhaotong

2020年5月1日 Therefore, the aims of this study are to (1) analyze changes in pore structure during drying; (2) calculate the fractal dimensions of the pore structure of Zhaotong lignite during drying based on mercury intrusion porosimetry (MIP) data; (3) study the relationship between fractal dimension and water content of Zhaotong lignite samples during drying2017年5月5日 Loy Yang lignite with a high water content was dewatered by freeze drying (FD) The drying kinetics of FD was calculated using thinlayer drying modelExperimental study on freeze drying of Loy Yang lignite and 2007年1月1日 The Cobham Lignite Bed includes two lignites, one preceding and including the onset of the carbon isotope excursion (CIE) associated with the PaleoceneEocene thermal maximum, the other formed The Cobham Lignite Bed: The palaeobotany of two