Highquality material removal equipment

Material Removal PAR Systems

PAR’s milling systems perform cutting and material removal operations precisely, cleaning and virtually dustfree for a higher quality cut and safer operations Our automated milling machines typically include automatic tool change capacities, integrated vacuum dust collection systems, Our automated material removal capabilities include solutions for metals, plastics, and composite materials Preengineered product lines are available for finishing, sawing, and routing with Material Removal Lincoln ElectricKongskilde’s industrial separation equipment is expertly designed to remove light impurities or dust from reprocessed materials, such as granulated plastics Essential for recycling processes, our separators ensure that materials are Industrial Material Separation Equipment KongskildeOur versatile, efficient and reliable milling technologies deliver optimized productivity and superior results in a range of material removal applications Whether you’re interested in vertical High precision material removal technologies Fives Group

.jpg)

Advancements in material removal mechanism and surface

2021年7月1日 Through comparing with conventional machining (or called as normal speed machining), the advantages of HSMC are elaborated from the aspects of high material All materials: aluminum, steel, titanium, composites, and more Fully supported, endtoend material removal solutions customized to your application Vertical milling: highrail, gantries, profilers Mill/turn, turning, boring mills, extrusion Material removal solutions from Fives GroupOur versatile, efficient and reliable milling technologies deliver optimized productivity and superior results in a range of material removal applications Whether you’re interested in vertical High precision material removal technologiesOur tools are available in all sizes and power outputs Whether it's a small, onehanded angle grinder or a 45 kW machine, both ofer you superior productivity Our range of grinders Material Removal Tools Catalog Atlas Copco

Robotic Deburring Automated Material Removal

In fact, a robot paired with a PushCorp force compliance device and servo spindle is just what you need to automate your materialremoval application This video showcases an AFD3102 and an STC1503BT30 Together, this equipment is Material removal solutions from Atlas Copco offer excellent ergonomics, durability, and usability Built to last, our grinders, sanders, and percussive tools – among many other products – offer operators powerful, accurate results with Material Removal Tools Atlas Copco USATherefore, it is necessary to use reasonable dust removal equipment to separate dust particles from gas, improve dust removal efficiency of ultrafine powder, protect the atmosphere, protect the health of workers and collect valuable dust particles After powders passes through mill and classifier, they are collected by cyclone or dust collectorDust Removal Collection ALPA Powder Equipment2021年8月5日 Schematic of the dynamic process of the laserinduced plasma assisted ablation The process consists of laser heating, plasma generation, absorption enhancement and material removalHybrid laser precision engineering of transparent hard materials

Multi nuclide Removal Equipment (“ALPS”) (Existing/ Improved/ High

1 Multi‐nuclide Removal Equipment (“ALPS”) (Existing/ Improved/ High‐performance) In order to realize the quickest processing of RO concentrated salt water* currently stored at Fukushima Daiichi Nuclear Power Plant, the full scale operation of High integrity containers (HIC) Transported to the temporary storage facility to be stored 14 towers (adsorbent replacement type) 2 towers At hot testing, the capabilities of the multinuclide removal equipment to “remove radioactive materials” and to “maintain its capability to remove radioactive materials while in operation”areOverview of the Multinuclide Removal Equipment (ALPS) at 2023年10月14日 To investigate the machining mechanism of silicon carbide (SiC) ceramic materials, this study utilized sintered diamond tools to perform drilling and grinding simulations on the material and developed a drilling model for SiC ceramic materials By analyzing parameters such as surface morphology, stress, and cutting force, the material removal mechanism of SiC Simulation experimental investigations into material removal 2021年11月8日 Highprecision optical component manufacturing by ion beam machining tools with ultrahigh material removal resolution and dynamically adjustable removal efficiency is important in various industriesLowEnergy Pulsed Ion Beam Technology with UltraHigh Material Removal

Robotic Material Removal Midwest Engineered Systems

Robotic material removal systems can be customengineered to make this application safe, consistent and economical for businesses both large and small Automating metal removal, degating, and deflashing of castings, and even material handling applications can overcome a shortage of workers that many foundry and casting firms struggle with2024年9月13日 VIA MERCHANT There’s nothing quite like waking up to a fresh snow blanketing everything outside your house However, the luster quickly fades when you realize that you’ll have to get out there and shovel the driveway—but only if you don’t own the best snow removal equipment Many homeowners underestimate the hidden dangers and demanding The Best Snow Removal Equipment for Your Home2023年9月27日 With the development of technology in aerospace, medical devices and other fields, highperformance difficulttomachine materials have been widely used in these fields due to their good comprehensive mechanical properties However, when using traditional machining methods, it is difficult to ensure the machining accuracy and surface quality, and at the same A review of research on material removal mechanisms for2024年9月15日 Composite material curved shell components are key parts of the new generation of highspeed aircraft and missile systems; grinding quality of these components directly affects service performance of the equipment Optimizing processing process parameters with material removal depth and surface roughness as quality targets is an effective means to Study on material removal and process optimization of

Waste Separating Contaminant Removal

Waste Material Separating and Contaminant Removal When you’re processing waste, the right separation equipment is critical in removing unwanted materials like rock, metal, and plastic to improve efficiency and provide a betterfinished The high level of repeatability of material removal robots results in uniform, high quality products for consumers Material removal robots are not only increasing product quality for manufacturers, but also helping eliminate the headache of high turnover and labor costs Many material removal applications require the use of highly skilled workersMaterial Removal Robots Robots Done Right2023年9月25日 Figure 3 shows the experimental scheme for the variedload nanoscratches used in this study The material removal characteristics under different planes (Si and Cplane), indenter directions (edge, face, and side face forward), normal loading rate v p (5, 7, 10 mN/s), and scratch intervals d (3, 5, 8, 11, 14 μm) were discussed, and the mechanism of material Material Removal Characteristics of SingleCrystal 4HSiC Based High Quality Aftermarket Wear Parts for Construction Snow Removal Eastern Wear Parts provides aftermarket wear parts for earth moving, construction, and snow removal equipment We have the resources to identify the parts you need by part number or measurements of the edge and bolt patternsSnow Removal Heavy Equipment Parts Eastern Wear Parts

.jpg)

Transition of material removal mechanism in cutting of

2024年5月14日 SiCf/SiC composites are difficulttomachine materials with high hardness, high brittleness, and anisotropy Exploring the material removal mechanism in depth is the key basic research to achieve highquality machining of ceramic matrix composites The results of orthogonal cutting experiments indicated that the brittle regime of ceramic matrix composites 2021年7月1日 Although some emerging manufacturing processes, such as additive manufacturing, have advanced beyond rapid prototyping to the manufacture of structural and functional components, the dominant role of machining is still irreplaceable owing to its flexibility [1], good surface quality [2], high material removal rate [3], and the capability to machine Advancements in material removal mechanism and surface integrity 2020年11月25日 MAF process is defined as a technology by material removal, in such a way that workpiece’s precision machining is performed through relative motion between magnetic abrasive and workpiece with the presence of a magnetic field in the finishing zone []Magnetic abrasive is mainly composed of ferromagnetic particles and abrasive particles, in which a A review on magnetic abrasive finishing The International Robotic material removal can provide a more uniform finish due to consistent and precise movement, speed, and pressure Automated systems can be programmed to adjust parameters to accommodate variations in material properties or product dimensions This results in increased efficiency and improved product qualityMaterial Removal Robots Sanding, Deburring, Polishing

.jpg)

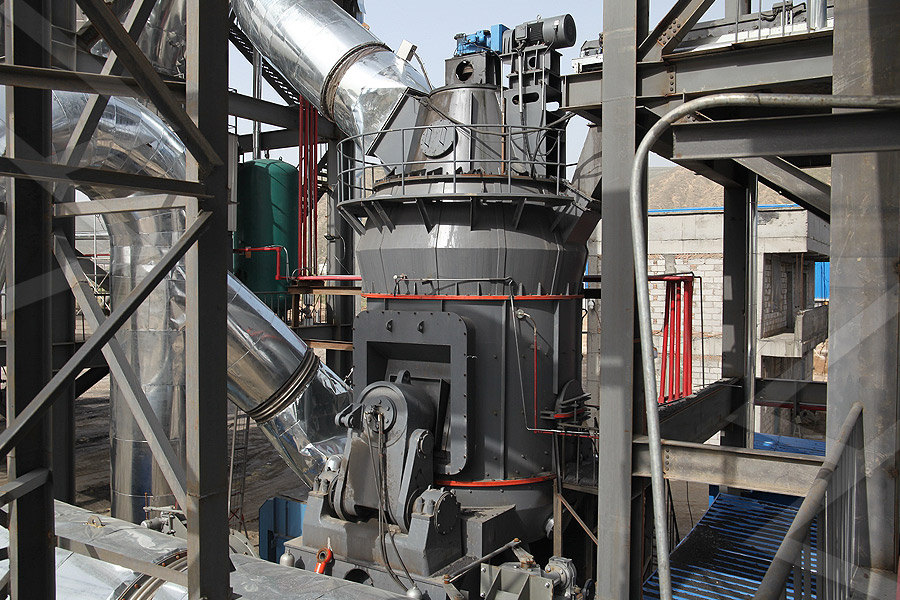

Industrial Dust Removal Equipment MadeinChina

China Industrial Dust Removal Equipment wholesale Select 2024 high quality Industrial Dust Removal Equipment products in best price from certified Chinese Medical Equipment Products manufacturers, Medium Material: Nano Flame Retardant Filter 2023年6月24日 The process eliminates the need for expensive tooling, as the chemical etchants selectively remove material without requiring physical contact This reduces tooling costs, setup time, and material waste, making it an attractive option for largescale production runs or prototyping 5 Surface Quality:Chemical Machining Process: Precise Material Removal2024年6月13日 Electrical discharge grinding technology (EDGT) is an efficient and high precision method for machining RBSiC ceramic materials In this paper, the mechanism of material removal in EDGT is deeply analyzed, and the formation mechanism of surface topography under different material removal regimes affected by grinding depth is discussed Study on material removal mechanism and surface formation An impingement angle (θ) between 70º – 80º provides better result in terms of material removal rate in abrasive jet machining Effects of impingement angle on AJM performance Material removal rate and its estimation Knowledge of Abrasive Jet Machining – Process, Parameters,

Dust Removal Equipment MadeinChina

China Dust Removal Equipment wholesale Select 2024 high quality Dust Removal Equipment products in best price from certified Chinese Gas Generator manufacturers, Stainless Steel Material Dust Removal Equipment US$ 2000 / pieces 1 pieces (MOQ) QIANGHAN MACHINERY (CHANGZHOU) CO,LTD2024年9月19日 The material removal process and the contact state of abrasive particles with Al matrix and SiCreinforced particles were analyzed systematically This study provides a theoretical basis for the highquality and efficient removal of Al matrix composites and facilitates their wider engineering applications The main conclusions are as follows: (1)Material removal characterization during axial ultrasonic vibration Manual material removal equipment, and is only needed when a new part or processes are plagued by output while maintaining quality In automated material removal applications, training time is iARobotics pioneers a robotic system for highprecision, automotive wheel deburring Innovations in RoboticThe Automated Future of Material RemovalLower price point without sacrificing the quality, accuracy and reliability of renowned Fives material removal equipment Linear guideways feature zero clearance and fullyloaded carrying capacity in all directions The ways consume less power and require no adjustments The linear guideways outperform all other types of ways used todayFlexible machining centers for efficient material removal Fives

Material removal model for describing the plasma discharge

2024年3月1日 Magneticelectrolytic plasma polishing is a method employed for achieving metal surface planarization through the synergistic effects of electrochemical dissolution and plasma discharge While numerous studies have focused on elucidating the electrochemical reaction mechanism, there exists a notable gap in understanding and modeling the impact of plasma 2022年6月1日 Request PDF Surface integrity and material removal mechanisms in highspeed grinding of Al/SiCp metal matrix composites SiC particle reinforced Al metal matrix composites (Al/SiCp MMCs) are Surface integrity and material removal mechanisms in high 2023年10月1日 To explore the advantages of highfrequency and the change of material removal mode, this work focused on the micro/nano material removal mechanisms during highfrequency ultrasonic vibrationassisted cutting (HFUVAC) of 316 L stainless steel based on a comprehensive analysis of machinability advantages and microstructure featuresMicro/nano incremental material removal mechanisms in high Gu 'an county yue filter technology co LTDIs the production of filter, oil filter, purify dust removal equipment filter professional manufacturers, mainly engaged in gas filtration and separation technology, fluid pollution control filtering products research and development and manufacturing of hightech enterprises, has more than ten years production experience, strong technical force Dust Removal Equipment

Optimizing Material Removal Rate in CNC Turning: A

2 Use highperformance cutting tools: Investing in highquality cutting tools with advanced coatings and geometries can significantly improve the MRR These tools are designed to withstand higher cutting speeds, reduce friction, and facilitate efficient chip evacuation 3Material Assembly and Processing These custom systems are designed for material handling, material removal, robotic assembly, and dispensing processes Mechanized Automation Custom equipment includes seam tracking, welding positioners, manipulators, jaw chucks, motorized slides, manual slides, pipe support stands, turning Idle rolls, and accessories for various Material Removal Lincoln ElectricIn fact, a robot paired with a PushCorp force compliance device and servo spindle is just what you need to automate your materialremoval application This video showcases an AFD3102 and an STC1503BT30 Together, this equipment is Robotic Deburring Automated Material Removal 2022年9月2日 Reactionbonded silicon carbide (RBSiC) is a high hardness ceramic material with twophase Si matrix and SiC particles so it is very difficult to machine due to their different electrochemical and mechanical properties Electrical discharge machining (EDM) provides an effective alternative regardless of its hardness However, the relationship between machining Material removal mechanism of RBSiC ceramics in dry impulse

.jpg)

LowEnergy Pulsed Ion Beam Technology with UltraHigh Material Removal

2021年11月8日 Highprecision optical component manufacturing by ion beam machining tools with ultrahigh material removal resolution and dynamically adjustable removal efficiency is important in various industries In this paper, we propose a lowenergy pulsed ion beam (LPIB) technology that can obtain a single pulse with highresolution material removal by adjusting In fact, a robot paired with a PushCorp force compliance device and servo spindle is just what you need to automate your materialremoval process This video showcases an AFD3102 and an STC0605BT30 Together, this equipment is able to quickly and efficiently remove welds and blend them with the parent material STC0605BT30; AFD310Robotic Grinding Automated Material Removal Applications 2024年11月1日 Grinding wheel wear is crucial for grinding processes directly affecting surface quality and processing efficiency To achieve efficient, highquality, and stable grinding, it is necessary to closely monitor the forms and mechanisms of grain wear 22, 23, 24 UVAG has advantages in reducing grinding wheel wear 25, 26 Yang et al 27 found that applying Material removal mechanisms in ultrasonic vibrationassisted high 2024年5月8日 According to Eq (), for a given relative speed, the pressure distribution is the main factor affecting the TIF and the quantity of material removedTo ensure that the inclusion of pad grooves increases contact pressure, finiteelement simulations were conducted using the Static Structural Module of ANSYS Workbench 19 in Fig 4First, a model of the polishing head Material removal and tool path ripple error of bonnet polishing

An overview of material removal processes and its importance

An overview of material removal processes and its importance Henry Omietimi1, Sunday A Afolalu1,2 Joseph F Kayode2**, Stella I Monye1, Sunday L Lawal2, and Moses E Emetere2,3 1Department of Mechanical and Mechatronics Engineering, Afe Babalola University, AdoEkiti, PMB 5454, Nigeria 2Department of Mechanical Engineering Science, University of Kongskilde’s industrial separation equipment is expertly designed to remove light impurities or dust from reprocessed materials, such as granulated plastics Separation equipment is crucial in the recycling industry as it enhances the purity of recycled materials, ensuring they are of high quality and suitable for production useIndustrial Material Separation Equipment Kongskilde