Heilongjiang ball mill

.jpg)

球磨机 Enfi

CITIC HIC has successively designed and manufactured the world’s largest mining mill unit—Φ122×11m autogenous (SG) mills (six units) and Φ79×136m overflow ball mills (six A company in Heilongjiang produces 20,000 tons calcium carbonate classifying and ball mill production line Raw Material: Calcium carbonate Capacity: 20,000t/yA company in Heilongjiang produces 20,000 tons calcium 2022年6月1日 Ball milling (BM) is a modification technique used to produce micropowders with excellent properties, such as favorable antioxidant properties and high solubility (Hong, Das, Consequences of ball milling combined with highpressure Project achievements of ball mill/grinding mill Project achievements of wind swept coal mill Achievements in chemical industry Turnkey project for cement plantgrinding stationHeilongjiang Dalong Ecological Fertilizer Co, Ltd

.jpg)

BaoEr Industrial Group Co, Ltd

Baoding Bao Industrial Group Co, LTD, sets R D, manufacturing, sales, service in one, which is professional in the production of various models of ball mill, rod mill, threedrum dryer, sand 2021年11月1日 In this study, a stirred mill manufactured by Jilin Exploration Machinery Factory in China as well as the ball mill and rod mill manufactured by Wuhan Exploration Machinery An innovative flake graphite upgrading process based on HPGR, 2023年2月23日 There are three main milling methods: wet, semidry, and dry milling Due to high costs and environmental concerns, the dry milling method is frequently used, and the Effect of different milling methods on physicochemical and 2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral Processing

.jpg)

China Ball Mill Factory Ball Mill Manufacturers and Suppliers

As one of China's leading mechanical equipment manufacturers and suppliers, we also support customized service on ball mill Welcome to contact us for details There are various high A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: Ball mill Wikipedia2022年10月5日 Ball Mill adalah suatu mesin yang berbentuk silinder (tabung) dan berfungsi untuk menggiling material kasar menjadi material yang halus Mesin ini memanfaatkan bolabola keras untuk menumbuk dan menggesek Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan 2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working Ball Mills 911Metallurgist

.jpg)

Flat Bottom Junk Mill, Taper Mill, Concave Mill, Economill, Bladed

2024年11月13日 It is hightech enterprise in Heilongjiang province At present, we mainly produce oil drilling tools, and more than ten series products have been formed There′re several kinds of products have been used as substitute for imported products in A ball mill is a crucial piece of machinery used in grinding and mixing materials in various industries It works by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be groundA Comprehensive Guide to Ball Mill Manual2024年5月27日 Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger Investing in cuttingedge equipment improves operational efficiency and contributes to a more sustainable and productive future for the mineral processing industryBall Mills in the Mineral Processing Industry MechProTech2024年1月1日 Ball mill is the key equipment for crushing materials after they are crushed It is widely used in cement, silicate products, new building materials, refractories, chemical fertilizer, ferrous and nonferrous metals mineral processing, powder metallurgy, glass ceramics, and Ball Mill SpringerLink

.jpg)

The Ultimate Guide to Ball Mills Miningpedia

2019年8月14日 Common Types of Ball mill back to top The common industrial ball mills mainly include cement ball mill, tubular ball mill, ultrafine laminating mill, cone ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, grid ball mill, wind discharge ball mill, double bin ball mill, energy saving ball mill 1Ball Mill Jars with Lids – Vacuum Stainless Steel $ 55000 – $ 1,49900 Select options This product has multiple variants The options may be chosen on the product page Corundum (Alumina Ceramic) Ball Mill Jars with Lids $ 19900 – $ 1,49900 Select options This product has multiple variantsBall Mill Primet LabWith our ball mill and mixer, the LihShan is the one which can provide main battery manufacturing process: oxide production, mixing and pasting We are able to provide customized technical solutions to reach the requirements of several kinds of battery customers立山機械工廠股份有限公司 LihShan Machinery Factory Co, Ltd2019年1月6日 home; about us; product crushing system; screening system; grinding system; benefication systemMill Performance Shenyang Casting and forging industry Co, Ltd

.jpg)

A Comprehensive Guide to Finding the Best Ball Mill for Sale

If you’re in the market for a ball mill, you’re likely looking for a reliable and highquality machine that can handle a wide range of materials and processesBall mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics2015年4月24日 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the Ball mill PPT Free Download SlideShare2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a (PDF) Effects of Ball Size Distribution and Mill Speed and Their 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral

New and Used Ball Mills for Sale Ball Mill Supplier Worldwide

Savona Equipment is a new and used ball mill supplier worldwide Savona Equipment offers new and used Ball mills for sale in the USA, Canada, Mexico and South America Sign In Register Contact us at: 12503732424 Get our new mobile app today: Connect with us:A company in Heilongjiang produces 20,000 tons calcium carbonate classifying and ball mill production line An annual output of 30000 tons of calcium carbonate classifying and ball mill production line of a company in Chizhou, Anhui ProvinceHome Expert in highvalue treatment of calcium carbonateA mineral factory in Benxi produces 50,000 tons calcium carbonate classifying and ball mill production line; A mineral factory in Guangxi produces 50,000 tons, D97: 815micron heavy calcium carbonate ring roller mill ultrafine grinding production lineA company in Heilongjiang produces 20,000 tons calcium SMALL MULEBACK BALL MILL Small (Muleback Type) Ball Mill is built for “muleback” transportation in 30″ and 3′ diameters (inside liners) A 4′ (Muleback Type) Ball Mill is of special design and will be carefully considered upon request Mankind’s search for valuable minerals often leads him far away from modern transportation 05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

.jpg)

Lihat ball mill dari perspektif bubuk ALPA Powder Technology

2021年8月7日 Ketika berbicara tentang bahan bangunan, apa yang Anda pikirkan? Apakah hal pertama yang terlintas dalam pikiran adalah semen! Proses produksi semen dapat diringkas dalam empat kata: “dua penggilingan dan satu pembakaran”, yaitu persiapan makanan mentah, kalsinasi klinker, penggilingan semen, dan proses penggilingan menggunakan ball millCITIC HIC has successively designed and manufactured the world’s largest mining mill unit—Φ122×11m autogenous (SG) mills (six units) and Φ79×136m overflow ball mills (six units) for Australian SINO iron project, the world’s most 球磨机 EnfiLaboratory ball mills have been an essential tool in pharmaceutical research and development for quite some time These versatile instruments play a pivotal role in the grinding, blending, and homogenization of various materials, offering scientists and engineers the means to explore new formulations and optimize processesLaboratory Ball Mill Exploring the Latest Innovations in Technology2017年2月8日 Mill productivity also depends on other factors: number of the drum rotations, the grinding fineness, humidity and size of the crushed material, timely removal the finished product Ball mills characterized by high energy The operating principle of the ball mill

.jpg)

Ball Mill (Ball Mills Explained) saVRee saVRee

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than I always wanted to build one but wanted to substitute lead balls for brass, bronze or copper Reason #1 I'm kind od afraid that lead would contaminate powder with fine particulates trough abrasion ,oxidation and potentially reacting with nitrate or sulfur and it would probably make for pretty nasty thing to breathe with gun smoke and ruin the experience for me as I enjoy the A simple but very effective homemade ball mill for black powderThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batchPlanetary Ball Mill PM 100 RETSCH highest finenessPlanetary mills with a single grinding station require a counterweight for balancing purposes In the planetary ball mill PM 100 this counterweight can be adjusted on an inclined guide rail to compensate for the different heights of the centers of gravity of differentlysized grinding jars and thus avoid undesired oscillations of the machine行星式球磨仪PM100德国RETSCH(莱驰)研磨仪粉碎仪

.jpg)

Process Engineering with Planetary Ball Mills ResearchGate

2013年2月7日 PDF Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few Find, read and cite all the research you The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times The PM 400 is a robust floor model with 4 grinding stations You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill forBall Mills Glen Mills, Inc2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911MetallurgistBall mills are ideal for achieving uniform particle sizes and are essential in material processing applications FAQ What factors should I consider when purchasing a used ball mill? Consider the mill's age, condition, capacity, and previous usage Check for any signs of wear, damage, or necessary repairsUsed Ball Mills for sale in USA Machinio

.jpg)

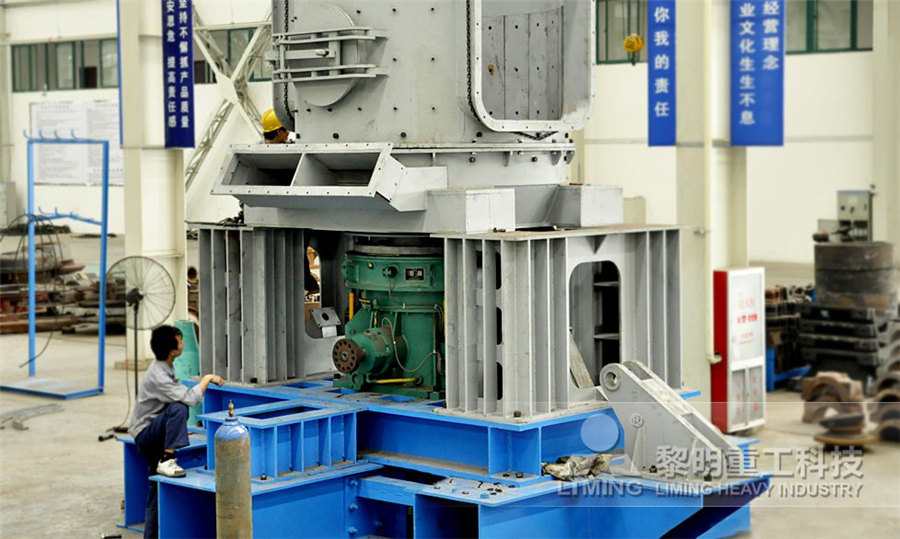

Ball Mill Liming Heavy Industry

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal Ball Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are Ball Mill Grinding Machines: Working Principle, Types, Grate discharge ball mills use a grating at the discharge end to control the flow of material out of the mill Batch ball mills are used for smallscale grinding operations C Advantages and Disadvantages Ball mills offer several advantages, including high capacity, low maintenance, and the ability to grind a wide range of materialsWhat is the Difference Between Tumbling Mill and Ball Mill?A mineral factory in Benxi produces 50,000 tons calcium carbonate classifying and ball mill production line; A mineral factory in Guangxi produces 50,000 tons, D97: 815micron heavy calcium carbonate ring roller mill ultrafine grinding production lineA company in Heilongjiang produces 20,000 tons calcium

Ball Mills Orbis Machinery

Ball Mills Steel Ball Mill Lined Ball Mill Since the late 1800s, the ball mill has revolutionized industrial grinding processes, establishing itself as the gold standard in particle size reduction The basic construction of a ball mill is a cylindrical container with journals at its axis Inside this cylinder, grinding media – composed of ceramic, metallic balls, or rods – fills the spaceBall mills 31 offers Price from €1 New and used Trusted sellers Currently in stock Quality construction equipment for sale at Machineryline AustraliaBall mill for sale, used ball mill Machineryline AustraliaPTA02 Ball Mill has a compact design, a slightly larger footprint from the PTA01 that is constructed using powdercoated steel for long lasting durability The PTA02 model accommodates two jar from 1liter to 10liters Ball Mill Rack Attachment NIDECSHIMPO’s Ball Mill Rack attachment is for the WHISPER wheel seriesChoosing Your Ball Mill NIDECSHIMPO CERAMICSBall mills are horizontal rotating cylindrical or conical steel chambers, approximately one third to half full of steel, alloy steel or iron balls, like that shown in Fig 410 A–C, or flint stones The size reduction is accomplished by the impact of these balls on the material as they fall back after being lifted by the rotating chamberBall Mill an overview ScienceDirect Topics

.jpg)

Ball Mill PPT SlideShare

2015年11月30日 A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls occupying 3050% of the volume to facilitate grinding as the shell rotates Applications of ball mills include grinding metallic powders, carbon, coal, cement, fertilizers and other materials Read less