HOME→Mineral powder grinding central control operation Mineral powder grinding central control operation Mineral powder grinding central control operation

Mineral powder grinding central control operation Mineral powder grinding central control operation Mineral powder grinding central control operation

Operational Control of Mineral Grinding Processes Using Adaptive

In this paper, a datadriven method is proposed for the operational control design of mineral grinding processes with input constraints A reference governor is introduced to take into 2019年4月1日 In this article, a modelfree extremumseeking control (ESC) design is proposed for the operational control of mineral grinding, where both operational indices regulation and Operational Control of Mineral Grinding Processes Using Adaptive 2006年1月1日 In this paper an integrated approach to grinding process monitoring and control is formulated and the components of the integrated automation for typical grinding processes are (PDF) Integrated approach to monitoring and control of mineral 2009年1月1日 The processes to be controlled in MP can thus be classified into three different categories: Minerals liberation processes (crushing, grinding and size classification) Automatic Control in Mineral Processing Plants: an Overview

.jpg)

Survey on higherlevel advanced control for grinding circuits

2016年1月1日 Grinding circuit (GC) is the most critical production unit and it also has the highest energy consumption in mineral processing operations The control and optimization of GC are 1995年8月1日 The GRINDCON system for the control of the grinding circuit at the Pyhasalmi concentrator includes the maximizing control of throughput, the strategies for the control of Design of the Integrated Control Systems for Mineral2009年4月24日 In this paper, an intelligent optimalsetting control (IOSC) approach is developed for a typical twostage GC so as to optimize the production indices by autoadjusting on line Intelligent OptimalSetting Control for Grinding Circuits of Mineral Assess your improvement potential based on current plant operation, stabilize and optimize performance with advanced process control, automate maintenance and performance reportingAdvanced Process Control of grinding flotation in mineral

.jpg)

Intelligent optimalsetting control for grinding circuits of mineral

During the operation of a grinding circuit (GC) in mineral processing plant the main purpose of control and optimal operation is to control the product quality index, namely the product 2001年9月1日 The objective of process control in the mineral industry is to optimise the recovery of the valuable minerals, while maintaining the quality of the concentrates delivered to the State of the art and challenges in mineral processing control2013年3月1日 Crushing is more energyefficient than grinding, but grinding is becoming an increasingly essential operation in mineral processing to liberate valuable minerals from host rocks (Fuerstenau and Energy Use of Fine Grinding in Mineral Processing2016年5月17日 A fourfactor (stirrer speed, grinding time, pulp density, and media filling) and a fivelevel Central Composite Design matrix (CCD) was applied to investigate the stirred mill performance in Mineral Processing Design and Operations: An ResearchGate

.jpg)

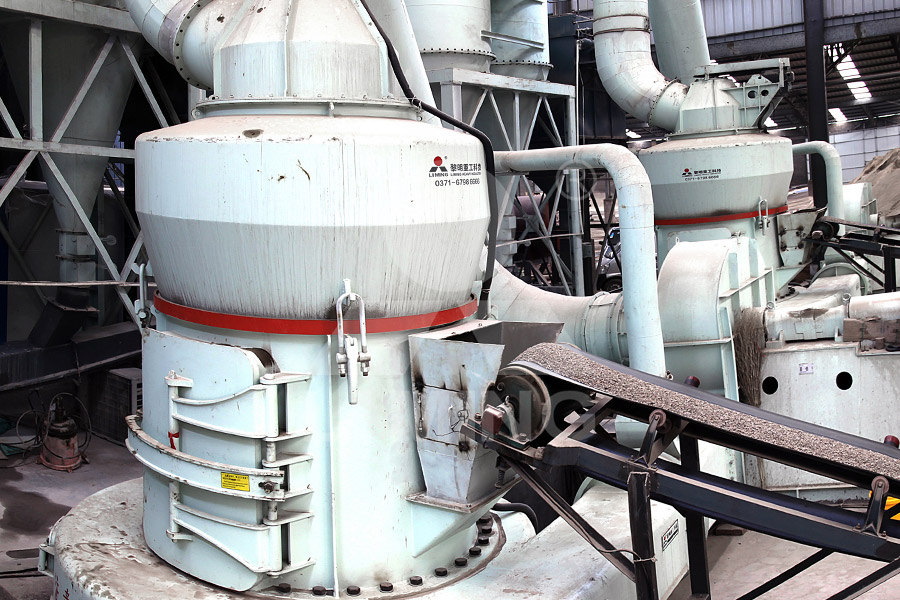

Phosphate Mineral Powder Grinding Mill SBM

2021年11月3日 Phosphate mineral powder grinding mills includes ultrafine mills, vertical roller mills, highpressure mills, etc can grind ores into a fine powder +17 [ protected]Optimization of the precision gear grinding operation based on integrated information system, 2021 In accordance with the principles of hierarchical management, a comprehensive twolevel management system is presented for the development and manufacturing of products for the stages of preproduction (the upper level of the management hierarchy) and for the actual Survey on higherlevel advanced control for grinding circuits operation2015年5月1日 Reference [9] proposes a grinding particle size prediction algorithm using neural networks, and a datadriven optimization control approach to guarantee safe operation and overload fault DataDriven Optimization Control for Safety Operation of 2017年3月4日 The objective of this lesson is to provide the details of size reduction methods involved in mineral processing using grinding no pollution for the powder I t is similar in operation to SIZE REDUCTION BY GRINDING METHODS ResearchGate

.jpg)

Improved Disturbance Observer (DOB) Based Advanced Feedback Control

2012年12月1日 PROCESS ESTIMATION AND SOFT SENSOR Chinese Journal of Chemical Engineering, 20(6) 1206—1212 (2012) Improved Disturbance Observer (DOB) Based Advanced Feedback Control for Optimal Operation of a Mineral Grinding Process * ZHOU Ping (周平) 1, ** , XIANG Bo (å ‘æ³¢) 2 and CHAI Tianyou (柴天佑) 1 1 State Key Laboratory of Synthetical 2007年9月1日 Many advanced control schemes, including model predictive control (MPC), adaptive control, neurocontrol, robust control, optimal control, etc, have been reported in the field of grinding process However, these control schemes including the MPC scheme usually cannot achieve satisfying effects in the presence of strong disturbancesApplication of model predictive control in ball mill grinding circuit2012年6月1日 An overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills is The paper presents advanced technologies and equipment for metal powder production by grinding in planetary and drum ball Abstract To enhance the operation of mineral grinding processes, Grinding in Ball Mills: Modeling and Process Control Semantic 2024年1月23日 This process can be used to create flat, cylindrical, or conical surfaces Key components of a grinding operation include the grinding machine, the workpiece, Enables the operator to control the grinding process, adjusting parameters like speed and Minerals and Ores Grinding plays a critical role in mineral processing and What is Grinding: Definition, Process, Types Specifications

Operational Control of Mineral Grinding Processes Using

2019年4月1日 Operation performance of mineral grinding processes is measured by grinding product particle size and circulating load, as two of the most crucial operational indices that measure the product 2001年9月1日 All content in this area was uploaded by SirkkaLiisa JamsaJounela on Jun 09, 2019State of the art and challenges in mineral processing 2012年2月6日 Human Factors in Control Room Operations in Mineral Processing: Elevating Control From Reactive to Proactive February 2012 Journal of Cognitive Engineering and Decision Making 6(1):88111Human Factors in Control Room Operations in 2023年8月11日 Mineral processing plants have embraced advanced systems to efficiently manage their operations A crucial component of these systems is instrumentation, which aids in enabling realtime data pertaining to various processes The gathered data is then utilized within control loops, allowing for precise control over operationsProcess control in the grinding circuit Rhosonics

IntelligenceBased Supervisory Control for Optimal Operation

2013年1月1日 Request PDF IntelligenceBased Supervisory Control for Optimal Operation of a DCSControlled Grinding System Optimizing the final grinding production indices (GPIs), which include the product Simulation results comparing performances of a mineral grinding process with and without the reference governor show the effectiveness of the proposed datadriven method for operational control design of mineral grinding processes with input constraints Operation performance of mineral grinding processes is measured by the grinding product particle size and the Operational Control of Mineral Grinding Processes Using 2007年9月1日 Despite the actual efforts of utilizing advanced control techniques in the mineral industry, much work has been carried out mainly on just two operations: grinding and flotation (Bergh, Yianatos Application of model predictive control in ball mill grinding DOI: 101016/S10049541(12)606090 Corpus ID: ; Improved Disturbance Observer (DOB) Based Advanced Feedback Control for Optimal Operation of a Mineral Grinding ProcessImproved Disturbance Observer (DOB) Based Advanced Feedback Control

.jpg)

Energy conservation and consumption reduction in grinding operations

2023年11月1日 Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is also an important factor to determine the 2022年6月24日 A Grinding Wheel of SelfLubrication with Solid Powder Lubricant and Centrifugal Impeller for Green Grinding Process of TC4 Alloy InKey Eng Mater 2017; 748: 269–274 Trans Tech Publications LtdA comprehensive review on the grinding process: Advancements 2020年6月15日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding bead size (20 mm Effect of operation parameters and formulation on the 2021年7月6日 dimension, and ends with grinding the reduced materials into powder Be it minetomill In the crushing operation, the valuable mineral is liberated to a certain minution a Heart of Mineral Processing

Intelligent optimal control system for ball mill grinding process

2013年7月4日 Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while guaranteeing producing safely and stably The grinding process is essentially a multiinput multioutput system (MIMO) with large inertia, strong coupling and uncertainty characteristics Furthermore, being unable to Overflow control classification; In the first stage of grinding, very fine final products must be obtained, or in the first stage of grinding, when stage separation is to be carried out, or classification is to be used, overflow control classification operation must be adopted first when too coarse particles are removed in the mechanical classifierFive classification methods of grinding and classification operation 2014年5月15日 10 Comminution Communiation is one of the primary operations in mineral dressing ;takes place in a sequence of crushing and grinding processes COMMINUTION The whole operation of reducing the raw ore to the size required for mechanical separation or metallurgical processingMineral Processing PPT SlideShare2009年1月1日 Sbarbaro D, Ascencio P, Espinoza P, Mujica F, Cortes G, (2008) Adaptive softsensors for online particle size estimation in wet grinding circuits Control Engineering Practice, Vol 16 Issue 2, p171178 Sbarbaro, D, del Villar, R (2009) Advanced control and supervision of mineral processing plants, in print, SpringerVerlagAutomatic Control in Mineral Processing Plants: an Overview

Advanced Grinding Circuit Control Strategies for Mining Operations

2019年1月9日 The digital control system was installed in October 1974 Results tabulated below show how performance was improved Duval Grinding Circuit Control Duval Corporation is implementing computer control of its singlestage ball mill grinding operation in the Sierrita mill using a hierarchical approachOverview of cement clinker grinding Vipin Kant Singh, in The Science and Technology of Cement and Other Hydraulic Binders, 2023 91 Introduction Grinding is understood as a process of size reduction of materials to a fine powder The final grinding operation of clinker with gypsum is often termed finish grinding The terms pulverizing and milling are basically synonymous with Grinding Operation an overview ScienceDirect Topics2012年12月1日 Advanced feedback control for optimal operation of mineral grinding process is usually based on the model predictive control (MPC) dynamic optimizationImproved Disturbance Observer (DOB) Based Advanced Feedback Control 2016年1月1日 As a crucial component of the beneficiation process, mineral grinding process (MGP) is used to grind the runofmine ore into suitable particle size such that the valuable mineral constituent can be exposed to be recovered in the subsequent classification process [1], [2]In the past, the process control research of the MGP was focused on the basic loop control Hardwareintheloop simulation platform for supervisory control

.jpg)

Survey on higherlevel advanced control for grinding circuits operation

2016年1月1日 Introduction of mineral grinding process and its advanced control problem is presented • Different approaches on advanced control for grinding system operation are reviewed , ), the Fundamental Research Funds for the Central Universities (N, N), 2023年10月11日 Grinding Safety Tips Control measures must be put in place to manage the risks posed by grinding to the health and safety of workers One of the main causes of harm while grinding is improper operation of machinery Grinding Safety Precautions Hazards Control 2007年9月1日 Much work has been done on the study and implementation of control strategies in grinding circuits (Herbst and Rajamani, 1979, Najim et al, 1995, Duarte et al, 1999, Yianatos et al, 2002, Bouche et al, 2005)Conventionally, the grinding circuits are controlled by multiloop PID controllers which are usually decoupled to avoid multivariable interactions, but these Application of model predictive control in ball mill grinding circuitHuman Factors in Control Room Operations in Mineral Processing: Elevating Control From Reactive to Proactive semiautogenous grinding (SAG) mills, ball mills, cyclones, and flotation cellsHuman Factors in Control Room Operations in Mineral

.jpg)

Constrained model predictive control in ball mill grinding process

2008年8月1日 Stable control of grinding process is of great importance for improvements of operation efficiency, the recovery of the valuable minerals, and significant reductions of production costs in Because of the scale of equipment in mineral grinding processes, multiple control actuations and control loops have been used Cascade control is widely used in mineral grinding processes, which allocates different control tasks for two loops In the inner loop, the control objective is to design regulators forOperational Control of Mineral Grinding Processes Using 2020年11月1日 Dynamic simulation of industrial grinding circuits – Mineral liberation, advanced process control, and realtime optimisationDynamic simulation of industrial grinding circuits – Mineral 2014年3月1日 Analysis of ball mill grinding operation using mill power specific kinetic parameters Application of the population balance model to the grinding of mixtures of minerals Powder Technology (1984) PC Kapur et al This work is useful for providing essential references to control the quality of milled riceAnalysis of ball mill grinding operation using mill power specific

Grinding an overview ScienceDirect Topics

Grinding for food powder production ED Baudelaire, in Handbook of Food Powders, 2013 61 Introduction Grinding is a unit operation widely used in the food industry and designed to reduce the size of materials to give a usable form or to separate their components In developing countries, it is the common method for food powder processing In general, grinding is part of 2015年8月3日 reduction and size control all minerals are f ree to be Pb concentrations surrounding the central mine of size reduction methods involved in mineral processing using grinding methods Overview of Mineral Processing Methods ResearchGate