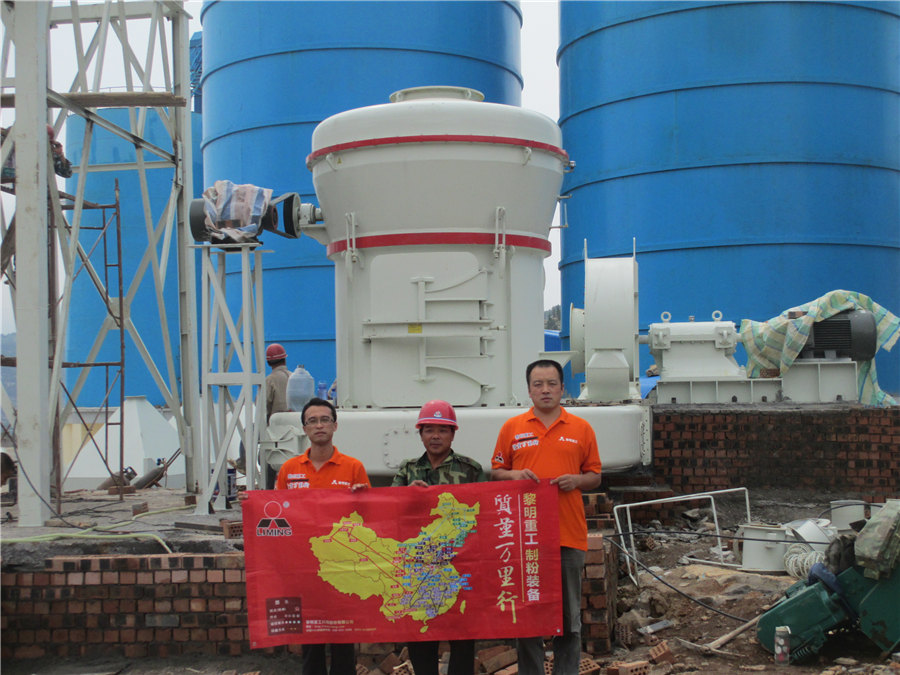

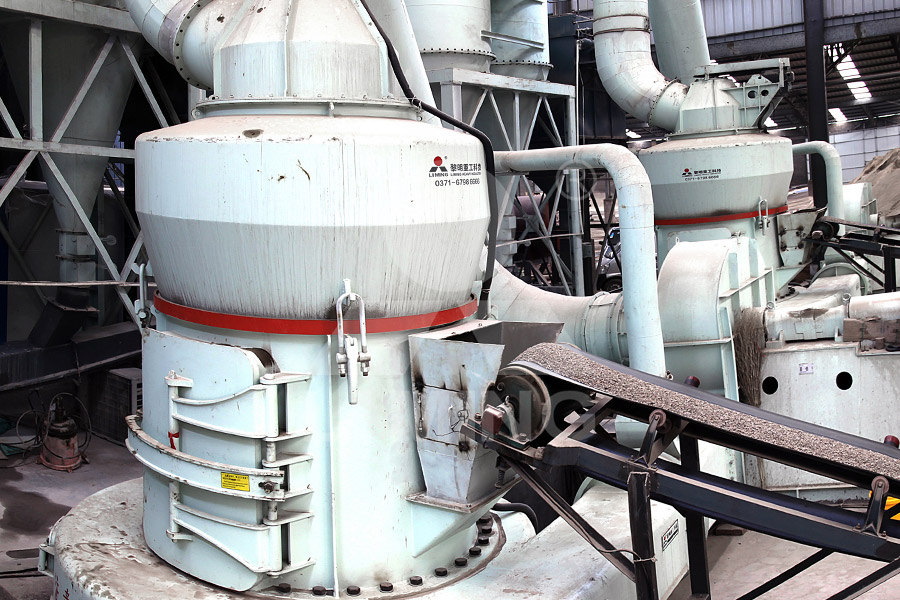

Kaolin refining equipment

Kaolinite Process Equipment

2024年10月24日 This article provides an overview of the typical equipment used in kaolinite processing, from extraction to refining 1 Extraction Equipment Kaolinite mining usually 2021年8月27日 Related: Mining Kaolin? Here are 10+ Kaolin Mining Equipment to Use 2 The Processing Stages After the mining stage, the kaolin will go through further processing stages, This phase also uses the chemically All Steps in Kaolin Production Mining and Processing In the present technological proposal, a kaolin refining plant was designed to remove impurities from the natural state of kaolin, whose raw material comes from the province of Morona Diseño de una planta piloto refinadora de caolín proveniente de 2024年10月8日 The depletion of conventional light petroleum reserves has intensified the search for alternative sources, notably, lowquality heavy oils and byproducts from heavy crude processing, to meet the global demand for fuels, Transforming Petrochemical Processes: CuttingEdge

industrial uses of kaolin: Applications and Benefits

2023年10月1日 Kaolin in the Energy Sector Fracking Fluids Kaolin is used in hydraulic fracturing (fracking) fluids to control fluid loss and improve wellbore stability during drilling operations Catalysts for Refining In the energy sector, 1991年9月1日 Kaolin stiffens the compound and reinforces it when cured It is also used as a lowcost pigment Kaolin is normally used in nonblack rubber goods such as toys and floor Kaolin: processing, properties and applications ScienceDirectof kaolin was used in the United States, more than onehalf of which was consumed by the paper industry The relationships between physical and chemical properties are discussed in the INDUSTRIAL APPLICATIONS OF KAOLIN SpringerKaolin to HPA processing technologies are achieving 9999% purity Besides lower production costs, these disruptive processing technologies have a big advantage in using lowcost low Kaolin to HPA processing technologies InterGroup Mining

The traditional refining technology of kaolin (a)

The iron reduction is an important process in kaolin refining, The physical process is ineffective in purifying heavily contaminated kaolin clay, relying on heavy equipment, trained personnel We have been making full use of our extra lab space and all of our equipment in numerous experimental projects, including two large kaolin refining projects and a sulphide regrind optimisation study In addition, we have carried out several SMD signature plot tests and Ball Mill Bond Work Index TestsKaolin, Sulphides and Bond Work Index Tests GSL2023年1月12日 Kaolin is an important nonmetallic mineral resource with abundant domestic reserves After beneficiation and processing, kaolin can realize its application value and is widely used in ceramics, paper making, Introduction: What is Kaolin Processing and How Does KAOLIN MINING REFINING : Kaolin mining and refining involve several different procedures First, meritoriously over the past years so that we meet our daytoday needs of the desired material usage starting from the equipments that are Kaolin mining techniques rotary core, auger drilling

.jpg)

Kaolinite Process Equipment

2024年10月24日 This article provides an overview of the typical equipment used in kaolinite processing, from extraction to refining 1 Extraction Equipment Kaolinite mining usually begins with the extraction of raw kaolin ore from openpit mines The extraction process involves breaking up the ore and removing it from the deposit using:The major reason that kaolin is used in rubber compounds is its whiteness and low cost Although kaolin costs less than most other rubber pigments, it haR excellent functional properties Ceramics Kaolin is used in ceramic whiteware products, insulators, and refractories (Smoot, this Volume) In whitewares, kaolin aids accurate control of moldINDUSTRIAL APPLICATIONS OF KAOLIN SpringerKaolin processing equipment helps grind kaolin to a suitable particle size This controls low and high shear viscosities of adhesives Wide range of applications requires different processing methods Kaolin products are widely used in cosmetology because of their fine size particles, which makes them safe and smooth on skinKaolin making equipment Making2023年8月1日 Kaolin's size and dimensional aspects make it a good filler for coatings and other materials [5] Its small particles help to improve the wettability, smoothness, and durability of these materials Kaolin chemical structure and element composition give it An overview of kaolin and its potential application in

Material Development Potential of Nigeria’s Kaolin

2023年3月22日 Nigeria possesses a multitude of solid mineral reserves strewn throughout its geographical space in incredible economic numbers, yet they remain mostly unexploited One such solid mineral is kaolin Nigeria has a resource of around three billion metric tons of kaolin deposits spread across the country Kaolin’s distinct mineralogy and physical, morphological, Our equipment is best used in smallscale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics We supply gold mining equipment as well as processing equipment applicable to most base metals such as copper, lead, zinc, etc,Small Scale Gold Mining Equipment JXSC Mineral2019年9月7日 MINE SITE — This is a panoramic view showing the north cut of the Sonoma kaolin mine that operated in Bethel from 1916 until the mid1920s Note the tunnel, vertical shaft, and minecarts on rails that were used to transport the excavated raw kaolin to a nearby water flume (from the Plott collection held by the Bethel Rural Community The Sonoma Kaolin Mine News themountaineerKeywords: Transformer oils, kaolin, Refining unit 1 INTRODUCTION: Kaolin is a In order to increase the equipment lifetime, oilsare usually replaced with fresh ones at regularReclamation of Old Transformer Oil Using kaolin clay

.jpg)

Kaolin: processing, properties and applications ScienceDirect

1991年9月1日 Kaolin, while not having all of these properties, does have perhaps the best selection of properties of any filler available The use of kaolin in fiberglass is further facilitated by an unusual chemical characteristic Kaolin remains chemically stable when heated to about 1000 (537 ) at which point it begins to dehydroxylate losing its water2004年12月31日 CaO–MgO–Al2O3–SiO2 glassceramics were prepared from mixtures of waste generated from refining of kaolin clay (called Kira) and dolomite (CaMg(CO3)2) Kira was mixed with dolomite in mass Preparation and Properties of CaO–MgO–Al2O3–SiO2PRECIOUS METALS REFINING EQUIPMENT, PLANTS , KNOW HOW AND TECHNOLOGY The Refining is a chemical process by which it is possible to recover and refine the precious metals coming from the goldsmiths’ and silversmiths’ scraps and from mines gold bars We supply Gold refining equipment worldwidePRECIOUS METALS REFINING EQUIPMENT PLANTSLearn how to make pottery at home in this guide outlining the materials, equipment, and tools to get started Skip to content Guides To Industrial Art Guides To Industrial Art Toggle Navigation Earth Working With Earth Working With EarthHow To Make Pottery At Home: Materials, Equipment, Steps

Properties of glassceramics prepared from Kira (waste by

kaolin clay refining) and various additives K Okada, T Toya, Y Kameshima A Nakajima Department of Metallurgy and Ceramics Science, Tokyo Institute of Technology, Japan Abstract Five different glassceramics were prepared from Kira (waste byproducts from processing of silica sand and kaolin clay) with various additives Mixtures of2023年5月6日 The rerefining of used oils has been developed over several decades The acidclay rerefining process was the first commercial approach This was the firstgeneration process commercialised in the 1960s by many companies in the United States, and it used a large amount of sulphuric acid and clay to treat waste oils []However, considering the main drawback of Comprehensive investigation of various rerefining technologies 2023年7月27日 Separating kaolin particles from the treated water can be timeconsuming and require additional equipment Overall, kaolin is a valuable tool in wastewater treatment because it can effectively remove various contaminants Its use can help achieve cleaner and safer discharge or reuse of waterExploring the Properties and Applications of Kaolin2002年12月1日 Kaolin have been used as a catalyst in oil and gas refining process to aid in the catalytic cracking and breaking of heavier hydrocarbon molecules into lighter products (Rong and Xiao, 2002 The catalytic cracking activity of the kaolingroup minerals

.jpg)

Influence of organic acids, complexing agents and heavy metals

2011年3月1日 The results of white measurements of treated kaolin samples showed that kaolin powder treated with A niger pistachio skin isolate at 25 °C and 30 °C and A niger NCIM 548 with fungal cells at 2018年4月1日 Riyanto et al 2018 found the best results in waste oil treatment with kaolin (2 grams) Kaolin adsorbed the Cr, Fe, Pb, Mg, Ca metals and other contaminants present in the waste oil (Riyanto et al (PDF) Treatment of Waste Lubricating Oil by Chemical KAOLIN QBBK Kaolin (Kaolin) in Bac Ly, Quang Binh Province is widely used in many industrial fields such as: ceramic industry, paper, paint, rubber, fiberglass, plastics, construction materials, resistant bricks fire, as a catalyst for oil refining technology, fertilizerKaolin Quang Binh Bohemia QBBKAbercrombie Resources is a critical mineral explorer with a 28 billion tonne Kaolin resource in Cape York Kaolin can be used as a replacement for cement in "green" concrete which a has a lower carbon footprint than standard concrete Abercrombie Resources is also exploring for ionic clay rare earth deposits, heavy mineral sands and silicaAbercrombie Resource I Critical Mineral Exploration Kaolin and

Bioleaching of iron from kaolin using Fe(III)reducing bacteria with

2010年4月1日 The conventional kaolin refining technology can be divided into three The physical process is ineffective in purifying heavily contaminated kaolin clay, relying on heavy equipment, 2023年5月6日 Further the work elaborates on the various conventional techniques of rerefining of waste lubricating oil like acid clay, vacuum distillation, hydrotreating, solvent extraction, extraction (PDF) Comprehensive investigation of various rerefining 2020年4月14日 A new largescale suspension calcination process and key equipment suitable for dehydration and calcination of kaolin clay are introduced The pretreatment process can be designed to meet various raw materials with different moisture contents, and the burning system has high heat transfer efficiency with a fivestage cyclone preheater, a suspension calciner Research and Design of Suspension Calcining Technology and Equipment REFINED KAOLIN Kaolen, also known as "China Clay", The refining process for kaolen is carried out to increase the purity and casting performance of kaolin For more information CONTACT US I would like to be notified of Esan by registering to the Refined Kaolin Esan

Lab Kaolin Separating Purification Equipment And Process

2023年9月28日 3 Slurry magnetic separator (kaolin) A wet magnetic separator is an equipment used in the mining industry, that performs magnetic separation on metal minerals, improves the ore grade, and removes iron from nonmetallic minerals It is popular in the mining industry Purpose: To separate magnetic minerals on graded kaolin2021年12月10日 B Transport Equipment Another important part of kaolin mining equipment is the transporting phase From the hydraulic or dredging processes, the resulting sedimentwater slurry will go to the sluice boxes channel to remove the kaolin Some kaolin companies also use a long pipeline to transport the dense slurry to the next or closer processing Mining Kaolin? Here are 10+ Kaolin Mining Equipment to Use2021年5月21日 Recently, microbialbased iron reduction has been considered as a viable alternative to typical chemicalbased treatments The iron reduction is an important process in kaolin refining, where ironbearing impurities in kaolin clay affects the whiteness, refractory properties, and its commercial value In recent years, Gramnegative bacteria has been in the Elucidation of GramPositive Bacterial Iron(III) Reduction for PDF On Aug 10, 2018, Adebowale Adeluola and others published Processing and Evaluation of Locally Sourced Kaolin for Pharmaceutical Production Find, read and cite all the research you need on (PDF) Processing and Evaluation of Locally Sourced Kaolin for

.jpg)

Gold Melting Furnaces JXSC Mineral

Gold melting furnaces are specialized equipment designed to heat gold to its melting point, allowing it to change from solid to liquid These furnaces are employed in various industries, including jewelry making, gold smithing, HUMAN EXPOSURE: Kaolin is a natural component in soil and found in ambient air Kaolin mining and refining involve considerable exposure and significant exposure is expected in paper, rubber and plastics production Long term Kaolin Al2H4O9Si2 CID PubChemMain office 600Richchya Street, Vinnytsia, 21000, office 018 +38 068 nAbout Turbiv Kaolin FactoryKaolin 1 INTRODUCTION Kaolin is a commercial term used to describe white clay composed essentially of kaolinite, Al010(OH)g The term is typically used to refer to both the raw clay and the refined commercial product This manual describes the laboratory assessment of British Geological Survey cna4

.jpg)

PreFeasibility Study of Kaolin Beneficiation Plant

refining, and purification processes, including thermal treatments like drying and calcining, to create different grades of the mineral Kaolin (commonly referred to as China Clay) is used in number of different applications, depending on its subsequent processing Kaolin is used in a variety of different products, in a number of sectors2021年5月21日 The conventional kaolin refining technology can be divided into three approaches: physical (Figure 1 a), chemical (Figure 1 b), and microbial methods; but each approach presents many limitations The physical process is ineffective in purifying heavily contaminated kaolin clay, relying on heavy equipment, trained personnel, Elucidation of GramPositive Bacterial Iron(III) Reduction for 2010年3月16日 Patent No US 7,494,541 B2 BASF Corporation has received a patent for a method of processing kaolin comprised sequentially: providing a kaolin crude comprising higher amount of gray kaolin and a lower amount of white kaolin; degritting the kaolin crude; subject the degritted kaolin crude to flotation to provide a kaolin having reduced titania content; ozonating BASF patents kaolin pigments Coatings World2018年12月1日 The effect of different refining techniques on the oil quality (flash point, pour point, viscosity, metal content, TAN, etc), chemical composition of refined lubricating oil (by GC–MS, FTIR A review on treatment methods of used lubricating oil

Ghana Industrial Minerals Workshop Project KAOLINWG/93/1

further refining, subsequent processing principally being dedicated to improving the brightness and particlesize distribution of the clay 32 Refining The two principle objectives of kaolin refining are the removal of impurities and the production of the desired particlesize distribution