Replacement of the mortar wall of the barite grinding machine

Guidance for Cone Crusher Replacement of Crushed

After the newly installed or newly replaced cone crushing wall has been working for 68 hours, its fastening condition should be checked, and if looseness is found, it should be repaired immediately fasten Replacement method of 2021年2月15日 Gallala et al (2017) replaced natural sand by baritefluorspar mines waste (BFMW) which is the tailings and processing waste from the barite and fluorite mines The Radiation Shielding Concrete with alternate ScienceDirectManfredini Schianchi proposes solutions for the processing and milling of barytes Thanks to technology based on the combined use of leadingedge Manfredini Schianchi machines, it is Barite grinding plants Manfredini and Schianchi2019年8月22日 In many cases, the waste on the hanging wall of the ore must be removed first Removal allows the mining equipment to mine the ore cleaner and with less waste Barium Processing Equipment, Flow, Cases JXSC Machine

Mechanical and radioactivity shielding performances of mortars

2014年1月15日 The compressive strength experiments performed on the mortars in which colemanite, barite, ground basaltic pumice and ground blast furnace slag were used as fine The joint surface between the rolling mortar wall and the cone is stable and firm It could be quick replacement of vulnerable parts without more filling supplements The replacement time of Singlecylinder Hydraulic Cone Crusher BaichyThis research looks at the change in physical properties of concrete when cement is replaced by lime with respect to compressive strength in concrete and shear bond strength in mortar The (PDF) Partial Replacement of Cement by Barites and Lime Powder Barite Roller Mill Our Roller Mills are highly efficient in the grinding of Barite Designed to provide completely automatic operation, the Williams Roller Mill includes micrometer control of the Barite Grinding Mills Barite Crushers Williams Crusher

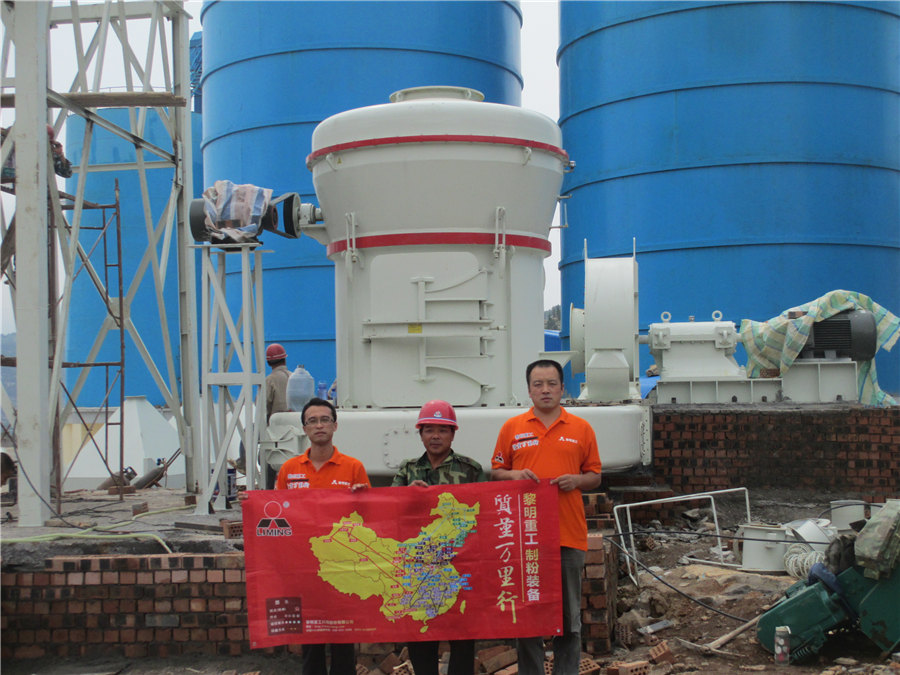

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line processes raw barite ore into fine barite powder through a series of technological processes It has the advantages of simple configuration, stable These machines play a significant role in the production of barite by efficiently processing the raw ore into the desired particle size In this article, we will explore the importance of barite Barite Grinding Plant and Crusher Machine: An Integral Part of the 2021年12月1日 Design concept of the compact grinding machine as shown in (a) SolidWorks CAD model and (b) part of the structural body of the system (PDF) Design of a compact grinding machine ResearchGate2022年10月22日 Conclusions: From the experimental investigation and analysis in software , following conclusions are made when cement is partially replaced by ceramic waste powder and barite powder in cement mortar : Compressive Study on the Thermal Properties of Mortars with

Barite Grinding Mills Barite Crushers Williams

With barite being used for a multitude of industries, our Sales Managers and Agents will help find you the barite grinding machine that will be most suitable for your application Learn more about our barite grinding mills below or contact 2021年1月16日 Your Single Disc Surface Grinding Machine will look like a horizontal spindle surface grinding machine albeit smaller in size since it does not need a reciprocating or circular table The grinding action in your machine takes place by the abrasive particles on the face of the grinding wheel You will be able to give the feed (depth of cut) by moving the wheel headSurface Grinder Types of Grinders How They Work Fine 2014年12月1日 Recently, Petrakis and Komnitsas [15] used the PBM as partial case and developed a nonlinear framework for the prediction of the particle size distribution of the grinding productsThe effects of ball types on breakage parameters of barite2011年12月13日 Control mortar without any replacement of cement and also mortar with 5%, 10%, 15%, 20% and 25% of OPC replaced by MIRHA were studied with different bindersand ratio of 1:3, 1:4 1:5 and 1:6The effects of partial replacement of cement in cement mortar

.jpg)

Concave / Crushing Wall / Rolling Mortar Wall / Mantle and

The frequency of replacement of the mortar wall and the crushing wall will directly determine the operating cost of the cone crusher The superrolling mortar wall independently developed by Nile Company uses lowcost high manganese steel or ultrahigh manganese steel as the base material for large wear parts, which enhances the wear resistance and service life of the rolling 2023年8月14日 21 Model description The deep hole internal grinding (DHIG) machine’s main components include a machine base consisting of two beds, a working table, a workpiece spindle headstock, a grinding shaft mechanism, a feed axis arrangement (Xaxis), and a workbench axis arrangement (Zaxis) displayed in Fig 1Mainly, the machine base structural elements are Structural behavior of the deep hole internal grinding machine 2014, Construction and Building Materials All building materials contain more or less natural radioactivity The present paper reports the results of an experimental study on the mechanical and radiological aspect of the use of colemanite, barite, ground basaltic pumice and ground blast furnace slag as additives in the production of special mortarsMechanical and radioactivity shielding performances of mortars 2018年9月20日 The effect of barite (BaSO4) aggregate rate on the physical and mechanical properties such as the ultrasound pulse velocity (UV), Schmidt hardness (SH) and unit weight (UW) of heavyweight concrete (PDF) The effect of barite dust on the mechanical and physical

.jpg)

MECHANICAL BEHAVIOUR OF MORTAR USING

2022年9月25日 Wall is part of the room divider that influence the structural aspects of weight and rigidity Based on these reasons we need wall that has some characters such as light but also environmentally 2023年11月6日 The influence of the GAs incorporation in cement grinding on properties such as workability and setting times of the placed concrete and/or mortar has been covered in this review(PDF) Review of the Effect of Grinding Aids and Admixtures on the 2021年6月30日 Cement mortars are one of the popular composite materials that are used for various purposes in construction industries Many investigations were conducted over the past few decades with the aim A Review of Cement Mortars Exposed to Elevated 2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest fineness can reach 3000 mesh SBM is a professional manufacturer of milling equipment for the ore industryBarite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder

PERFORMANCE OF MORTAR INCORPORATING CERAMIC WASTE POWDER AS

2020年2月8日 In this study, ceramic waste powder (CWP) from residual ceramic tile was used as a partial replacement of cement in mortars to understand the effect of CWP on the mechanical properties The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERY2018年1月30日 This paper presents a study on alkali activated cement (AAC) mortar produced with waste sodalimesilica glass The waste glass was used simultaneously as a precursor and fine aggregates in the Use of waste glass in alkali activated cement mortarMachines for Mixing Mortar: Power Mixer or Concrete Mixer: A machine that mixes large batches of mortar more efficiently than hand mixing Mortar Mixer: A stationary mixer that can combine the mortar ingredients at a consistent speed, which is crucial for larger projects Protective Gear: Gloves: To protect hands from acidic materials in the Mastering the Art of Mortar: A StepbyStep Guide on How to Mix Mortar

International Journal of ChemTech Research

lime replacement is 296 N/mm 2, for 15% barites and 15% lime replacement is 2483 N/mm After 14th day testing, When compared to control mix, the compressive strength (fig 7) obtained for control mix is 2508 N/mm 2 , for 5% barites and 5% lime replacement is 2582 N/mm , 2023年9月26日 Although the use of primary aluminum dross as cement replacement has shown promising results in mortars and concretes, there is a knowledge gap between the effect of the secondary dross (PDF) Mechanical Performance of Mortars with Partial Replacement 2020年12月14日 DOI: 1033640/2405609x2149 Corpus ID: ; The impact of grinding time on properties of cement mortar incorporated high volume waste paper sludge ash @article{Shubbar2020TheIO, title={The impact of grinding time on properties of cement mortar incorporated high volume waste paper sludge ash}, author={Ali Abdulhussein Shubbar and [PDF] The impact of grinding time on properties of cement mortar June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

.jpg)

Mechanical and radioactivity shielding performances of mortars

2014年1月15日 They used NES as a cement replacement by 2%, 4% and 6% in cement mortar and found that compressive strength slightly increases when ESPs are added to the mortar at all levels compared with control thermal performance analysis of a building wall is done using COMSOL software wherein plastering material for wall is the cement mortar that was developed with partial replacement of cement by ceramic waste powder and barite powder XRD test is conducted to know the phases developed after hydrationStudy on the Thermal Properties of Mortars with Partial Cement 2013年1月1日 Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, machine design, highspeed grinding technology, cost optimization, ultra Principles of Modern Grinding Technology ResearchGate2023年6月8日 The exterior coatings of old buildings were mostly made with limebased mortars As coverings for the external facades of buildings, they are elements that are highly exposed to several actions (PDF) Characterization of Old Mortars for the Formulation of

.jpg)

Surface Grinding Machine: Diagram, Parts, Working, Types, Uses

2023年8月23日 A Surface Grinding Machine is a versatile and essential tool used in the manufacturing and metalworking industries to achieve precise and smooth surfaces on workpieces It is capable of removing material from the surface of a workpiece to create a flat, smooth, and accurately finished product The machine uses an abrasive wheel or grinding 2020年1月20日 Mortar specimens containing limestone aggregate with 109% WSA replacement level showed an average increase in compressive, tensile, and flexural strength by 87%, 67%, and 71%, respectively Durability of concrete made by partial replacement of fine 2023年3月29日 Effect of grinding time and dosage of waste glass powder on the consistency of cement mortar Effect of different grinding times on compressive strength of mortarC15 groupStudying the Effects of Varied Dosages and Grinding Times on the 2023年1月25日 The mortars underwent a wet curing period of 56 days with five observation days The standard mortar properties, such as pH, carbonation depth, compressive strength, and sorptivity, were investigatedThe Effects of Chicken Eggshell Powder as Fine Aggregate Replacement

The Formation of Barite and Celestite through the

2020年2月19日 Barite (BaSO4) and celestite (SrSO4) are the endmembers of a nearly ideal solid solution Most of the exploitable deposits of celestite occur associated with evaporitic sediments which consist of gypsum (CaSO42H2O) 2019年9月1日 The release of gases to the air also causes wall corrosion (linear corrosion rate up to 85 mm 10⁻³ year⁻¹), which produces gypsum replacement crusts above the water tableBarite replacement boxwork in the Frasassi caves (Italy)2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Intro to Grinding Methods, Machines and Tools2020年1月1日 A mortar spaying machine was designed, manufactured and tested, using locally available materials It improved the surface finish and protected the wall from moisture weakening the structureConceptualization, development and design of a mortar spraying machine

.jpg)

Investigation of mechanical behavior of mortar using slag as

2023年12月20日 Since sand replacement by GGBFS aggregate in mortar could affect the strength of the mortar, it is essential to develop an accurate prediction model In this study, Artificial Neural Network (ANN) is established using the test data presented in " Experimental results and discussions " section, to forecast the compressive and tensile strengths of slag 2017年1月1日 Different types of mechanical machine elements such aspulley systems are used for lifting mechanisms, a chainsprocket mechanism for power transmission, and conveyor mechanism for feeding mortar Design and Fabrication of Wall Plastering Machine2021年9月1日 the closed end uppermost in the wall to provide a good bed for the next layer of mortar It offer a lower weight alternative to solid block with improved thermal propertiesEffects of Hollow Sizes on the Properties of Sandcrete Blocksa project report on “partial replacement of aggregate with ceramic tile in concrete” submitted to jawaharlal nehru technological university kakinada in partial fullfillment of the requirement for the award of the degree master of technology in structural engineering by gsai chand (15kq1d8705) under the esteemed guidance of mr pravi kumar, mtech asstprofessor, dept of ce" PARTIAL REPLACEMENT OF AGGREGATE WITH CERAMIC

.jpg)

Xray radiation shielding properties of cement mortars

2013年7月1日 The results showed that mortars prepared with barite and leadladen recycled cathode ray tube funnel glass provided better shielding properties than mortars prepared with natural sand, natural The treatment of full grinding of ball mill is briefly introduced The ball mill liner has 3 functions, 8 classifications and 10 installation requirements Factors Affecting The Life Of The Crushing Wall And Rolling Mortar Wall And Their Replacement Methods 14:21:39 In a Factors Affecting The Life Of The Crushing Wall And Rolling Mortar Wall