Limestone plant asphalt coke petroleum coke mill

.jpg)

Full Length ArticleEffect of limestone addition on no emission

2020年6月15日 A dramatically decrease of NO emission from 1200 mg/Nm 3 to 50 ~ 60 mg/Nm 3 was observed when adding limestone for SO 2 capture in the CFBB of a power plant located 2022年10月1日 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is Decarbonising the lime industry: Stateoftheart ScienceDirectZhejiang calcitelimestone ultrafine powder production line with annual output of 100,000 tons Raw material: calcite, limestone Feeding particle size: ≤20mm Finished powder fineness: Petroleum coke processing plant, Petroleum coke grinding 2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready The History and Future Challenges of Calcined Petroleum Coke

.jpg)

CFD Analysis of Cofiring of Coke and Biomass in a Parallel Flow

2022年6月24日 In this paper, a numerical tool is presented, which simulates a largescale Parallel Flow Regenerative (PFR) kiln that currently uses coke as main fuel The developed 2019年5月8日 Petroleum coke is a hard carbon product obtained by compaction and polycondensation in the thermal processing of highboiling petroleum residues (heavy oil tars, Influence of Pressure in the Coking of Heavy Oil Tar and Asphalt 2014年12月20日 This article provides a review of the history and use of calcined petroleum coke for anode production and describes the different calcining technologies used by the industry(PDF) The History and Future Challenges of Calcined Petroleum Products are widely used in power plant desulfurization, large nonmetallic mineral milling and building materials and chemicals Applications: It is maily used for grinding of limestone, Limestone mill Hengtu Machinery

Petroleum Coke an overview ScienceDirect Topics

Petroleum coke is a byproduct produced from heavy crude oil residues by thermal cracking processes, most commonly in an oil refinery coker unit Approximately 31 kg of petroleum New mixing technologies have led to the development of colloidal fuel dispersions using coal, petroleum coke, and asphaltite These nonsettling liquid fuels have the handling characteristicsColloidal Fuel Dispersions using Coal, Petroleum Coke and Asphaltite2013年10月2日 ASPHALT COKE Asphalt coke is the carbonaceous, friable dry residue resulting when asphalt is overheated or distilled to dryness Coking is an inherent property of asphalt, as asphalt itself contains approximately 01% coke before heating Coke is more dense than asphalt, and will therefore collect at the bottom of a tanker or tankASPHALT COKE IKO2014年12月20日 Calcined petroleum coke is obtained by calcining petroleum coke at high temperatures under the condition of 1250 • C to 1350 • C Because of its low cost, high carbon content, and easy (PDF) The History and Future Challenges of Calcined Petroleum Coke

.jpg)

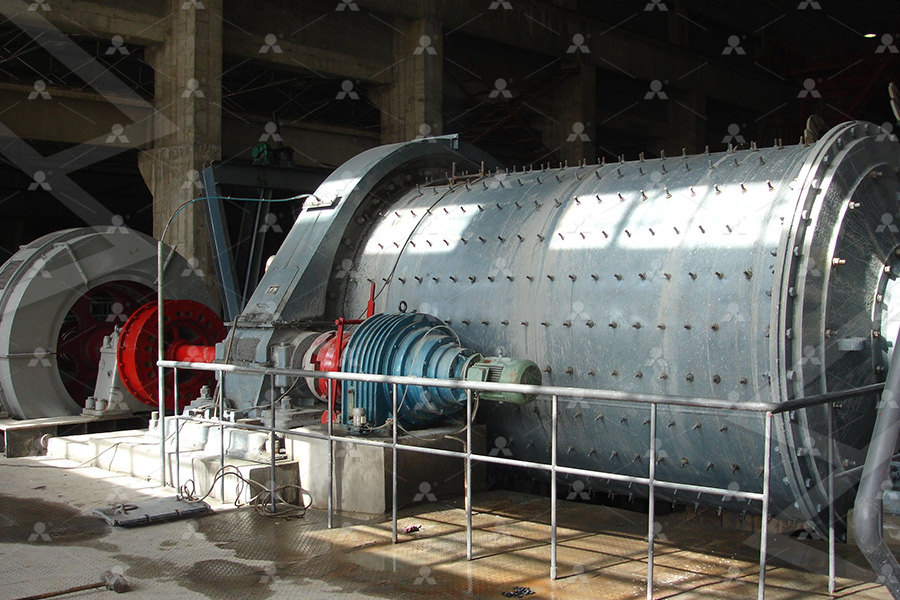

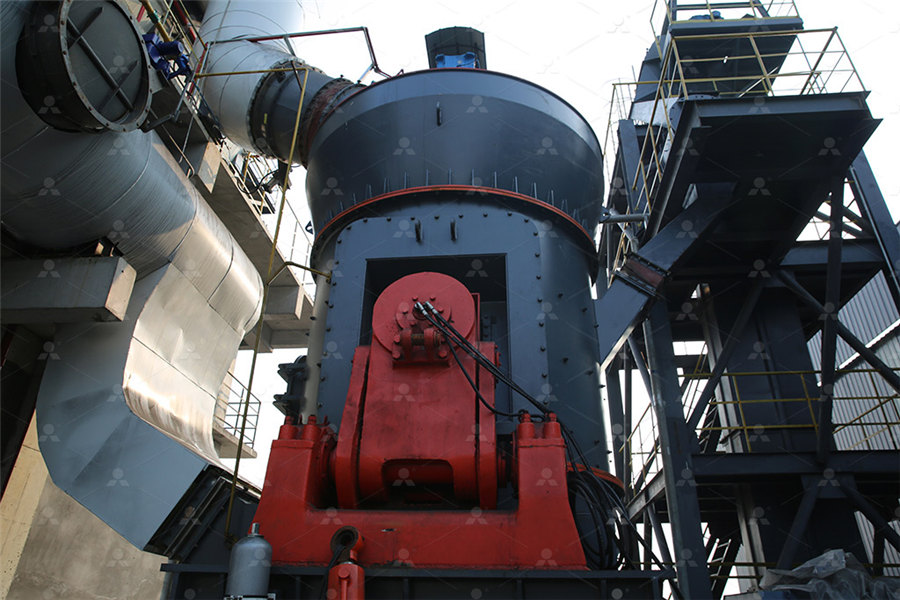

Petroleum coke processing plant, Petroleum coke grinding

In Petroleum coke project, the Petroleum coke grinding machine, which is very popular with customers, has MTW trapezoid mill and singlechip micro grinder Zhejiang calcitelimestone ultrafine powder production line with annual output of 100,000 tons2023年10月27日 The asphalt coke and calcined petroleum coke particles underwent multistage crushing and screening Second, they were mixed according to a speci fi c ratio and sent for the preheating treatment (PDF) Prebaked anode based on petroleum coke used as lithium The gasification of petroleum coke allows the plant to be independent of the volatility of natural gas prices The Selexol solvent is sent to the rod mill for slurry preparation The chilled by heat exchange with ammonia refrigera clean water is sent back to the quench chamber tion to either 0 oF (18 °C) or 15 oF (9 °C)Petroleum Coke Gasification Based Ammonia Plant DocsLib2012年10月14日 This paper presents the results of a detailed experimental study on rheological behaviour of coal water slurry (CWS) In contrast to earlier rheological studies at shear rates of rather narrow Colloidal Fuel Dispersions using Coal, Petroleum Coke and

What grinding equipment is needed for petroleum coke

2022年3月29日 Petroleum coke can be used in ceramics, glass, carbon products, steelmaking and other industries after being processed and ground into powder by industrial grinding mill +17 [ protected]The ground petroleum coke can be used as an important fuel in the chemical and metallurgical sectors instead of petroleum The recycling and reuse of petroleum resources can be realized after the petroleum coke is superfine pulverized by the petroleum coke ball mill On the basis of saving energy, it can also save energy usage costs for customersPetroleum Coke Ball Mill2013年7月18日 Petroleum Coke Crusher Plant We supply Petroleum Coke Ball Mill for Petroleum Coke processing,our Petroleum Coke grinding mill is used to process coal In the plants, petroleum coke is combined with limestone and Petroleum coke processing plant Mining Quarry Plant2009年12月1日 Petroleum coke, a byproduct of the petroleum refining process, is considered to be an attractive primary or supple mentary fuel for power generation (Swain 1997)Fly ashes from coal and petroleum coke combustion: Current and

.jpg)

(PDF) Optimizing Utilization of Petroleum Coke in

2011年1月1日 Moreover, because petroleum coke is the byproduct in the process of refining and commercializing crude oils [7][8][9] [10] [11], refineries can provide longterm stable supplies of petroleum coke 2024年10月31日 See all 13 Petroleum Coke power plants nationwide including their emissions and production Savannah River Mill GeorgiaPacific Consr Prods LPSavannah These 12 month periods may vary from provider to provider and from power plant to power plant, The Largest Petroleum Coke Power Plants in the US FindEnergy2001年9月1日 A kind of petroleum coke was burnt in a bubbling fluidized bed combustor (BFBC) The effect of limestone batch feed for SO2 removal on NOx emission was evaluatedEffect of Batch Feeding of Limestone on NO x and SO 2Petroleum coke is a process that involves steps such as thermal decomposition, polymerizationion and condensation The Petroleum Coke category consists of two substances; green cokeCalcinations of Petroleum coke ResearchGate

.jpg)

Petroleum coke processing plant, Petroleum coke grinding

In Petroleum coke project, the Petroleum coke grinding machine, which is very popular with customers, has MTW trapezoid mill and singlechip micro grinder Zhejiang calcitelimestone ultrafine powder production line with annual output of 100,000 tonsIn Petroleum coke project, the Petroleum coke grinding machine, which is very popular with customers, has MTW trapezoid mill and singlechip micro grinder Zhejiang calcitelimestone ultrafine powder production line with annual output of 100,000 tonsPetroleum coke processing plant, Petroleum coke grinding petroleum coke industry; Bituminous coal powder making plant 15 TPH bituminous coal; 200 mesh D65; asphalt mixture; 200 mesh D90; coal powder processing; Bituminous coal powder making plant 200,000 TPY bituminous coal; Calcium Carbonate Plant; Limestone Mill; Gypsum Plant; SOLUTION Ground Calcium Carbonate(GCC) Grinding Mill;cases2013年5月15日 The objective of this study was to analyze dry grinding kinetics of three different solid fuels in terms of selection and breakage distribution functions values using a batch laboratory ball parisons of Dry Grinding Kinetics of Lignite, Bituminous

The History and Future Challenges of Calcined Petroleum Coke Production

2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low cost This article provides a review of the history and use of calcined petroleum coke for anode production and describes the different calcining technologies used Petroleum coke is a product of crude oil that is distilled to separate light and heavy oils, and the heavy oils are then thermally cracked From the appearance point of view, the coke has an irregular shape and different size black lumps (or particles), with metallic luster, the coke particles have a porous structure, the main element is carbon, which occupies more than 80% by uses of petroleum coke petroleum coke grinding mill hcmPetroleum coke crushers are designed for primary crushing of crude petroleum coke Crawler type mobile crusher plant is high efficient crushing equipment with the selfdriving manner, Producing a modern mobile crusher, stationery crusher, grinding mill, screening and washing plant facilities over the years in Asia and abroad Product Petroleum Coke Crusher CM Mining MachineryThe base of the blends used in this industry is petroleum coke A sketch of a typical plant is shown in figure 1 [1] The delayed coker unit processes the vacuum residue A typical specification of asphalt for coke production is presented in table 4 [9] Table 4FOUNDRY COKE WITHOUT COAL: MORE THAN HALFCENTURY

Petroleum Coke: Industry and Environmental Issues CRS Reports

2013年10月29日 Source: US Environmental Protection Agency, ScreeningLevel Hazard Characterization, Petroleum Coke Category, June 2011; and HW Nelson, Petroleum Coke Handling Problems, 1970 Notes: The process of “calcining” converts green coke to almost pure carbon, with a defined structure to produce carbon anodes for the aluminum industryFigure 24: Colloid mill used in manufacturing asphalt emulsion Some flasher bottoms, such as those at the US Oil and Refining Co can be used immediately as asphalt In this case, the residuum from the vacuum flasher tests as a PG 6422, but this is not true for all refineriesAsphalt Production and Oil Refining Pavement Interactive2009年5月16日 Raw Petroleum Coke (RPC) was utilized in all three sinter plants of Tata Steel, Jamshedpur works since November 2005 RPC usage went as high as 50% of total carbonaceous fuel used for sinter makingUse of Raw Petroleum Coke in Sinter Plants ResearchGate2020年6月15日 Nevertheless, in a power plant located in eastern China, interesting phenomenon that diametrically opposed to the results obtained in the authors’ previous work [13] was observed by the operators In this plant, petroleum coke was combusted in a circulating fluidzed bed boiler (CFBB) and limestone was employed to capture SO 2 to meet the emission Effect of limestone addition on no emission during petroleum coke

Effect of limestone on the emission of NO during petroleum coke

2018年7月15日 In order to investigate the effect of limestone on NO emission during petroleum coke combustion, experiments were conducted in a horizontal fixedbed reactor connected with an online FTIR gas 2002年3月5日 First, limestone added to the CFB boiler will remove the bulk of the sulphur during combustion Then, a secondary “polishing” step will follow – the first petroleum cokeapplication of the FDA system – to further reduce the plant’s SO2 emissionsGenerating clean power from petroleum cokeEnergy Fuels 2005, 19, 453458 453 Coal Blending with Petroleum Coke in a PulverizedFuel Power Plant Katia S Milenkova, Angeles G Borrego,* Diego Alvarez, and Rosa Menéndez Instituto Nacional del Carbón, CSIC, Apartado 73, 33080 Oviedo, Spain Henrik I Petersen and Per Rosenberg Geological Survey of Denmark and Greenland (GEUS), Øster Voldgade 10, Coal Blending with Petroleum Coke in a PulverizedFuel Power Plant2021年8月23日 Petroleum coke is a solid, carbonaceous byproduct of oil refining and is normally used for heating or as an anode in aluminum and steel production These applications contribute to carbon Sustainable production of graphene from petroleum coke

.jpg)

Limestone Coal Plant in Jewett, TX GridInfo

Power plant details for Limestone, a coal plant located in Jewett, TX View the monthly generation and consumption, generator details, and more for Limestone Subbituminous Coal / Natural Gas / Lignite Coal / Petroleum Coke: Startup Source: Natural Gas: Solid Fuel Gasification : No: Carbon Capture Technology: No: Time From Cold Shutdown To forming materials The chromite ore, mill scale, and petroleum coke were dried in an oven at around 473K for 24h Then the materials were ground by a ball mill into various particle sizes Direct Alloying Steel with Chromium by Briquettes Made from Board Plant POP and gypsum board plant 7TPH MTW145G Limestone Grinding Mill In Sichuan, China Output size:180 mesh 15TPH LM1300 Petroleum Coke Grinding Mill; 10 Microns 4TPH Limestone Micro Powder Pr; Contact Us Tel: 0086371; WhatsApp Solution Grinding Mill, mineral mill, limestone mill, calcite mill New developments of Anode Coke Grinding using a vertical Mill Technology, TMS 2015 3 Stefan A Gosau, Andreas Wolf; “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, Germany 4Changing the Fineness of Calcined Petroleum Coke with Ball Race

36.jpg)

Crushing Equipment for Petroleum Coke Plant by feng li

2016年12月12日 1 Application Material: Petroleum Coke 2 Feed size: ≤200mm Moisture ≤5% 3 out size: 325mesh(D97), particle size can be adjusted 4 Output: shot coke 3t/h4t/h ; sponge coke 4t/h5t/h 5 2002年1月1日 The grinding systems of a cement plant still account for more than 50% of the total electric energy consumption of the plant Moreover, in new plants they are responsible for a major portion of Drying and grinding petroleum coke in a roller mill at the Usje In Petroleum coke project, the Petroleum coke grinding machine, which is very popular with customers, has MTW trapezoid mill and singlechip micro grinder Zhejiang calcitelimestone ultrafine powder production line with annual output of 100,000 tonsPetroleum coke processing plant, Petroleum coke grinding Petroleum coke is a byproduct produced in the process of refining petroleum ( Fig 1Fig 1) distillation plant Vacuum distillation plant Asphalt LP gas Naphtha Gasoline Kerosene Heavy oil Diesel oil Residue oil Coking machinePC VR 34893 99~13 21 PC combustion technology with Direct Mill System One method of stably burning solid Operation results of power station with petroleum coke firing boiler

Construction Materials FInal Flashcards Quizlet

Study with Quizlet and memorize flashcards containing terms like The type of "grading" of asphalt binder that involves plunging a needle with a mass of 100 grams into the The raw materials needed to produce iron are A iron ore, coal (coke), and limestone B iron ore, silica, and limestone C iron ore, coal (coke), and sandstone D scrap 2021年6月11日 First, the petroleum coke is crushed and processed by a jaw crusher, and then the crushed petroleum coke enters the dryer for drying and dehydration, and then is subjected to strong grinding processing by the Raymond mill to make the petroleum coke into petroleum coke powder, the petcoke powder is continuously and uniformly sent to the rotary kiln for calcination Types of grinding mills for petcoke grindingNewsultramill