Quicklime ore powder processing equipment 18 powder ore

QUICK LIME AND BYPRODUCTS PEC Consulting Group

Dolomitic quicklime is used to produce metallic magnesium by thermal reduction which reduces magnesium oxide Lime is also used in the processing of ores and the subsequent smelting Quicklime or Calcium Oxide (CaO), is an alkaline and crystalline solid utilized in several environmental and industrial applications Graymont can supply various types of quicklime in Quicklime GraymontWe have innovative processes for limestone grinding and separating as well as for lime hydration with Pfeiffer mills, hydrators, high efficiency separators, and distribution table separatorsQuicklime preparation Gebr PfeifferOur Quicklime is refined into three different varieties including lump, powder, and fine powder forms for use in different applications, such as steelmaking, sintering, and preprocessing Quicklime and Mini Pellets JFE Mineral Alloy Company,Ltd

.jpg)

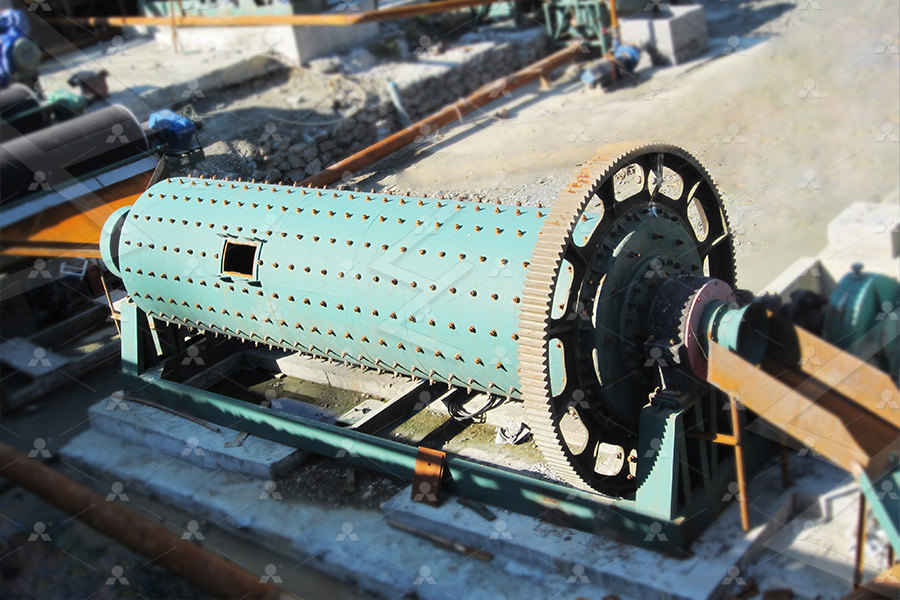

Quick Lime Plant Equipment MadeinChina

China Quick Lime Plant Equipment wholesale Select 2024 high quality Quick Lime Plant Equipment products in best price from certified Chinese Machine Equipment Control 2023年10月11日 Quicklime is offered in a variety of product sizes to fit any application or jobsite Quicklime Fines, generally less than ¼inch in size The small sizing helps accelerate the Quick Lime Preparation, Properties and Uses Hebei Yayang In this study, we present a method to determine the optimum water content using the agitation torque of wet ore powder blended with quicklime First, we investigated the agitation torque for Optimum Water Content Estimation for Wet Granulation of Iron Our CALSAFE lime slurry is a readymade high calcium liquid lime formulated to adjust pH levels or add needed alkalinity for industrial processes CALSAFE is safe and easy to use, requiring CALSAFE® Lime Slurry Carmeuse

Influence of quick lime on pore characteristics of hightemperature

2021年10月1日 Wet granulation plays an important role in the processing of fine ore powder Water content is a critical process parameter that determines the granule properties during wet 2022年9月16日 Numerical Simulation of the Operating Conditions for the Reduction of Iron Ore Powder in a Fluidized Bed Based on the CPFD Method September 2022 Processes 10(9):1870Numerical Simulation of the Operating Conditions for 2023年7月25日 To investigate the feasibility of cosintering of fluxed iron ore with magnetite concentrates, the mineralogical properties of a novel fluxed iron ore were studied using particle size analysis, microscopic morphology characterization, and Xray diffraction Rietveld analysis Following that, the experiments for granulation performance and basic sintering characteristics Mineralogical properties and cosintering characteristics of fluxed 2021年10月31日 3 How to use ecofriendly gold stripping powder to extract gold After the preparation of the ecofriendly gold stripping agent is completed, the specific steps for extracting gold using it are as follows: Step1 The sample Ecofreindly Gold Stripping Powder’s Preparation

.jpg)

Complex processing of oxidized copper and zinc oxide ores with

2020年12月5日 Complex processing of oxidized copper and zinc oxide ores with simultaneous production of several productsInhouse mineral processing laboratory facilities to ensure 100% performance on Industrial scale design; Expertise: Mine development and equipment fleet sizing; Ore Iron Ore (Hematite)43% to 62%+, 195% to 632%; Manganese ore 18% to 38%; KINC’s IOBP plant for iron ore beneficiation is milestone in a journey of excellence Capable to Beneficiation Equipment Plant Machinery Medical Waste 2020年2月1日 In recent years, with the rapid development of the iron and steel industry, the amount of industrial waste gases, wastewater, and waste residues has increased every year [[1], [2], [3], [4]]Among these, the amount of iron ore tailings discharged from concentrators is enormous, and more than 10 billion tons of iron ore tailings and barren rock are discharged A new approach for recovering iron from iron ore tailings using 2019年5月23日 The smelting of manganese ores is mainly performed through electrolysis and reduction to produce pure manganese Electrolysis produces over 95% of total manganese metal products [], and electrolytic manganese (EM) has very high purity and used mainly as deoxidant and desulfurizing agent in iron and steel smelting processesManganese is the element most Resource Utilization of Electrolytic Manganese Residues

.jpg)

(PDF) Industrial Chemistry ResearchGate

PDF On Oct 15, 2007, Wanasolo William and others published Industrial Chemistry Find, read and cite all the research you need on ResearchGate2023年4月8日 Huge amounts of manganeserich solid residues are yearly produced worldwide by industrial electrolysis, calling for advanced methods of recycling in the context of the circular economy Here, we review manganese recycling with focus on ore reserves, electrolytic production, residue stockpiling and environmental impact, reducing the amount of residue and Recyling manganeserich electrolytic residues: a review2021年5月1日 The role of lithium in chemical and nuclear industries could hardly be overestimated (Babenko et al, 2007)World lithium consumption in 2019 was estimated as ~58∙10 3 tons, with an increase of 18% compared with the previous year (National Minerals Information Center, 2020)Nevertheless, excluding the USA, worldwide lithium production in 2019 Processing of lithium ores: Industrial technologies and case 2019年12月24日 Energy Resources, Its Role and Use in Metallurgical Industries RC Gupta, in Treatise on Process Metallurgy: Industrial Processes, 2014 423132 Sinter Making The iron ore fines (− 10 mm) are agglomerated using Dwight Lloyed sintering machine The iron ore fines and coke breeze fines mix with moisture is fed on the sinter bed which is ignited by a gas Sintered Ore an overview ScienceDirect Topics

Decarbonizing lithiumion battery primary raw

2024年11月20日 Lithium, cobalt, nickel, and graphite are essential raw materials for the adoption of electric vehicles (EVs) in line with climate targets, yet their supply chains could become important sources of greenhouse gas (GHG) 2017年9月10日 This review has critically looked into a few authors‘ recent reviews on six major processes of rare earth processing steps and each step is considered as important to produce both high quality (PDF) A Review of Rare Earth Mineral Processing To create CALSAFE lime slurry, it all begins with limestone After being quarried, crushed, and calcined in a kiln, the resulting quicklime can be slaked with water in a hydrator to produce hydrated lime On its own, hydrated lime is a dry powder To achieve a liquid lime product (or slurry), the dry quicklime or hydrated lime is added to waterCALSAFE® Lime Slurry Carmeuse2021年5月1日 The role of lithium in chemical and nuclear industries could hardly be overestimated (Babenko et al, 2007) World lithium consumption in 2019 was estimated as ~58∙10 3 tons, with an increase of 18% compared with the previous year (National Minerals Information Center, 2020) Nevertheless, excluding the USA, worldwide lithium production in Processing of lithium ores: Industrial technologies and case studies

.jpg)

A new enrichment method of medium–low grade phosphate ore

2022年5月15日 Considering that the phosphate ore belongs to a nonrenewable resource, it was predicted to run out around 2033 with the highgrade phosphate ore being constantly consumed (Cordell et al, 2009, Elser, 2012) The medium–low grade phosphate ore is difficult to meet market requirements due to its high content of impurities (Dong et al, 2021)2017年3月4日 The objective of this report is to provide the details of size reduction methods involved in mineral processing using crushing equipments powder pr oducts 2 their ores Mineral SIZE REDUCTION BY CRUSHING METHODS ResearchGate2021年1月15日 The Skorpion zinc processing method demonstrated the viability of the production of zinc from zinc oxide ores, using hydrometallurgical route including the leaching, solvent extraction, and Leaching and solvent extraction purification of zinc from 2024年2月8日 Present investigation includes the magnetizing roasting of lowgrade iron ore fines followed by grinding and beneficiation using magnetic separation The hematite iron ore used in the investigation contains 5317% T Fe, 107% SiO2, and 45% Al2O3 Powdered bituminous coal of 210 μm size with an ash content of 125% and fixed carbon of 5425% was Beneficiation of LowGrade Hematite Iron Ore Fines by

.jpg)

Tungsten extractive metallurgy: A review of processes and their

2019年10月1日 Roasting the mixture of NaNO 3 and tungsten ores, together with carbon and slight NaSiO 3 solution, then leaching to obtain Na 2 WO 4 solutions Na 2 WO 4 solution: 1924: Alkali hydroxide decomposing: Decomposing wolframite or scheelite ore by caustic soda/potash in a digester, then using HCl to precipitate H 2 WO 4: H 2 WO 4, CaWO 4 H 2 O 2021年7月1日 Among the 17 critical metals/materials, copper is classified as “crosscutting”, defined by the World Bank as essential in at least 8 renewable energy and clean storage technologies (WBG, 2020)Copper is used in rechargeable batteries, electric motors, electrical wiring and connectors, charging stations as well as in supporting infrastructures needed to Copper and critical metals production from porphyry ores and E 2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for Crushing in Mineral Processing 911MetallurgistFerroalloys Processing Equipment Isobel Mc Dougall, in Handbook of Ferroalloys, 2013 422 Sintering of Manganese Ore The sintering process employed for manganese ore and the siliceous ores used to produce silicomanganese results in partial reduction of MnO 2, Mn 2 O 3, and Mn 3 O 4 in the ore to MnO by reaction with carbon in addition to agglomerating the fine Manganese Ore an overview ScienceDirect Topics

.jpg)

Process Mineralogy Characteristics and Flotation Optimization of a

2023年9月2日 The beneficiation of lowgrade oxidized lead and zinc ore from the Lanping mine has attracted extensive interest in the mineral processing field due to the extremely rich resource reserves and the challenge in lead and zinc recovery This study’s objective is to analyze the process mineralogy characteristics and to conduct the flotation optimization of this ore 2022年8月1日 Considering the disadvantages of traditional beneficiation methods for processing lowgrade iron ores, such as long process and low iron recovery rate, some researchers proposed using coalbased direct reduction methods to reduce iron minerals in lowgrade iron ores to metallic iron (Srivastava and Kawatra, 2009, Liang et al, 2018)Improved iron recovery from lowgrade iron ore by efficient 2020年8月3日 Manganese alloys are important raw materials for steelmaking However, selective mining of highgrade manganese ore resources has resulted in a scarcity of these highgrade Mn ores (Mn: >42; Mn/Fe: >5) The present research work is carried out to explore a new smelting reduction process to produce highMn/Fe synthetic Mn ore from lowgrade Development of a Smelting Reduction Process for LowGrade 2021年8月5日 Lowgrade vanadiferous titanomagnetite ore (LVTM) is as an important mineral resource for sintering ore manufacturing Furthermore, TiO2 has a significant effect on the sintering process of iron ore fines The effects of TiO2 on the metallurgical properties, microstructure, and mineral composition of LVTM sinter were investigated by sintering pot Effect of TiO2 on the Sintering Behavior of LowGrade MDPI

.jpg)

Innovative utilization of refractory iron ore via suspension

2019年6月15日 Iron ore is an important strategic resource, and it is used extensively in a wide variety of fields The steel and iron industries have developed rapidly in recent years, resulting in the requirement for a large quantity of iron ore [8, 9]However, the decrease in highquality iron ore resources is a serious threat to the sustainable development of the steel industry [21, 25]2020年8月1日 The raw materials for iron ore sintering used in this study came from an iron ore sintering plant in China It mainly consists of iron ores, dolomite, limestone, quicklime, coke breeze, blast furnace return fines and sintering return fine The main characteristics of the sintering raw material were shown in Table 4Resource utilization of municipal solid waste incineration fly ash in 2022年8月19日 Steel is an important industrial raw material and plays an important role in industrial construction Studying the efficient utilization of complex refractory iron ore with large reserves is of great significance to ensure the strategic safety of China’s iron and steel industry Focusing on the typical mixed iron ore of siderite (FeCO3) and hematite (Fe2O3), this paper Efficient Utilization of Siderite and HematiteMixed Ore by MDPI2015年1月1日 Iron ore is the primary raw material from which metallic iron is extracted to make steel The rapid increase in crude steel production in the last decade has seen major expansions in world iron ore production from around 1 billion tonnes (Bt) in 2001 to over 29 Bt in 2012China is the largest iron oreproducing country, producing about 13 Bt in 2012, which accounts for Introduction: overview of the global iron ore industry

.jpg)

Research on MultiDecision Sinter Composition

2023年3月9日 However, it is reasonable to use more highquality ore powder under the condition of ensuring cost performance We use the single product price of sinter ore, that is, the price per 1% of TFe, to measure the cost 2018年10月15日 Enhancing the purity of magnesite ore powder using an ethanolaminebased However, approximately 500,000 tons of waste magnesite powder which during magnesite processing every year could be utilized Hence, with 4000 mg/L BHDA as a collector, the flotation separation of magnesite ore could be realized at pH 418–917Enhancing the purity of magnesite ore powder using an 2014年10月29日 Rare earths are used in the renewable energy technologies such as wind turbines, batteries, catalysts and electric cars Current mining, processing and sustainability aspects have been described in this paper Rare earth availability is undergoing a temporary decline due mainly to quotas being imposed by the Chinese government on export and action Rare Earth Elements: Overview of Mining, Mineralogy, Uses 2021年9月6日 Request PDF Micronsized ore powder production by propulsion and rapid unloading of highpressure gas We describe a micronsized ore powder production by propulsion and rapid unloading of high Micronsized ore powder production by propulsion and rapid

Review on Beneficiation Techniques and Reagents Used for Phosphate Ores

2019年4月25日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to the low grade of P2O5 and high content of impurities In order to obtain a qualified phosphate concentrate, the beneficiation of the lowgrade phosphate ore is, 2023年10月20日 Enhanced iron extraction from highphosphorus waste limonite ore via suspension magnetization HQ Zhang et al, 2019) obtained iron concentrate of 6018% Fe grade with 9017% after SMRstage The behavior of separation and enrichment of valuable metals during the synergistic processing of metallurgical dust and sludge via Enhanced iron extraction from highphosphorus waste limonite ore 2023年11月1日 Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is also an important factor to determine the Powder Technology2020年11月16日 For energy saving and emission reduction in the iron and steel industry, the metallurgical performance of iron ore sinter, including reduction degradation index (RDI), reduction index (RI), and (PDF) Thermodynamic Analysis of Iron Ore Sintering

Extractive Metallurgy of Rhenium: A Review ResearchGate

2013年3月1日 A variety of processing technologies exist for recovery from both primary and secondary sources of rhenium Currently, there are no known primary rhenium deposits; thus, the method in which