Magnesium limestone crushing process

11192 Crushed Stone Processing and Pulverized Mineral Processing

Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl, marble, shell, and slateProcessing activities include conveying, screening, secondary and tertiary crushing, and sizing Screening is the single most important part of the processing cycle of crushed stone particles Limestone and Crushed Rock Department of Energy2 Limestone Quarrying and Processing Operations 21 Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Limestone Quarrying and Processing: A LifeCycle Inventory2 Limestone Quarrying and Processing Operations 21 Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium A LifeCycle Inventory of Limestone Dimension Stone Quarrying

.jpg)

How Lime is Made

Quicklime can be processed into hydrated lime by crushing the quicklime, adding water to the crushed lime (water accounts for approximately 1% of raw hydrate), and then classifying the processes in the production of lime are: (1) quarrying raw limestone; (2) preparing limestone for the kilns by crushing and sizing; (3) calcining limestone; (4) processing the lime further by 1117 Lime Manufacturing US EPA2023年2月15日 During the process, the crushed limestone mixed with the coal in a ratio of 4 is to 1 It can also be mixed with petrol coke, but ratio will have to be altered then it is burnt in a Lime Production Process and Required Equipment Fote MachineryCalcination is the thermal process of heating limestone This processed stone is then transferred by conveyors to the lime kilns The lime burning process within the kilns requires enough heat Production European Lime Association

Lime SpringerLink

2021年3月3日 Manufacturing processes are then described, involving quarrying and limestone preparation, calcination process, quicklime processing, and quicklime hydration The most The crushing process of the invention has the advantages of meeting the process requirements of alumina plants on preparation of crushed limestone, increasing a boulder yield to aCNA Limestone crushing process Google Patents2021年3月3日 Lime is the least expensive and one of the most heavily used alkali in the world, being essential to our society It is a nonhydraulic binder, excepting the socalled hydraulic lime, meaning that it will not set under waterFor this reason, lime is sometimes called air lime since it hardens on exposure to air It was used for thousands of years in masonry mortars to bind the Lime SpringerLinkAbout Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone Limestone Crushing Process JXSC Mineral

.jpg)

Process of manufacturing magnesium carbonate Google Patents

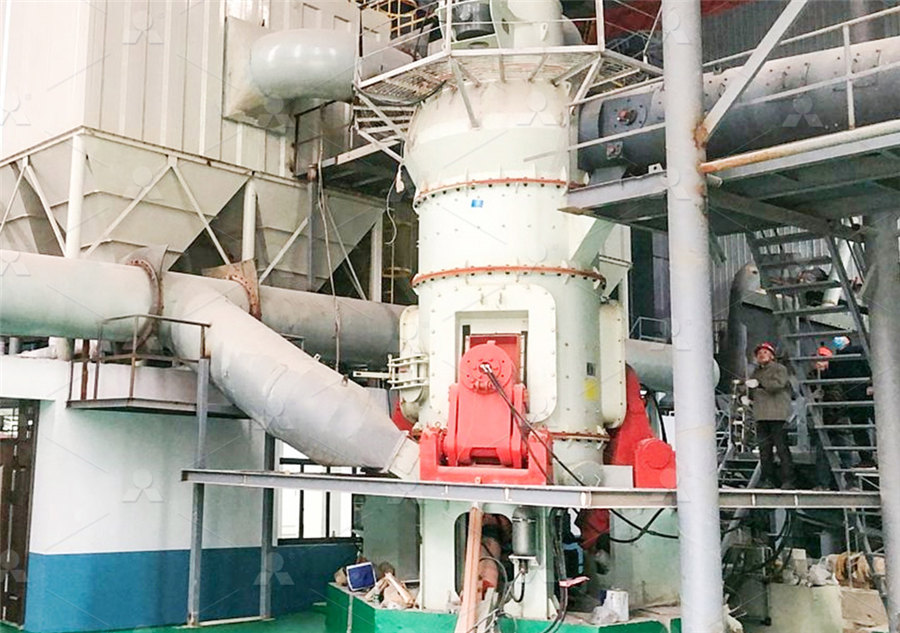

nesium carbonate which comprises crushing dolomitic limestone, heating the crushed stone to a temperature such that a portion of its, magnesium carbonate is dissociated but substantially all of its calcium carbonate remains undissociated, grinding the soheated stone, dissolving out the magnesium carbonate fromthe heated and ground stone by treating said stone with carbon 2023年10月21日 Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO3) in the form of mineral calcite or aragoniteIt is one of the most common and widely distributed rocks on Earth, with a wide range of uses in various industries and natural settings Limestone forms through the accumulation and compaction of marine organisms, primarily the Limestone Types, Properties, Composition, Formation, UsesLimestone is a massive stone material that is mined by a limestone crushing plant through a limestone crusher Its main component is calcium carbonate (CaCO3), and it also contains clay, dolomite, magnesium carbonate, iron oxide, The limestone grinding process will start after the crushed limestone entering the millLimestone Mill for Limestone Powder Grinding Limestone Crushing2023年2月14日 The limestone crushing process is a crucial step in the production of cement, as well as in other industries that utilize limestone as a raw material The process of crushing limestone involves several stages, each of which plays a critical role in ensuring that the final product meets the necessary specifications and standardsOptimized Limestone Crushing Process for Increased Efficiency

.jpg)

Limestone Quarrying and Processing: A LifeCycle Inventory

presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Crushing at Crushing Facility Figure 1 Process flow diagram for limestone quarrying operations 3 As shown in Figure 1, 2022年6月1日 Increasing pore solution pH in a concrete matrix will enhance CO2 dissolution In this study, calcined limestone was used as a replacement of reactive magnesium oxide (MgO) cement (RMC) at 5 and Enhancing carbonation of magnesium oxide (MgO) cement (RMC) 2024年10月14日 Remark: For conversion from millimeter to mesh, please refer to mm to mesh Process 3: Calcinating dolomite rock The crushed dolomite is calcined in a rotary kiln, which is used for producing refractory materials, magnesium alloys, cement, etc Dolomite is calcined at 1500°C to obtain magnesiacalcium raw materials, such as dolomite sand, magnesiacalcium How to Process Dolomite Rock and What Is It Used for?In addition, the type of process (batch or continuous) and the uses of the product(s) must be identified One of the case studies is concerned with the manufacture of magnesium oxide from sea water This process is carried out by Premier Periclase in Drogheda, Co Louth The term periclase refers to natural magnesium oxide In 1979, PremierManufacture of magnesium oxide from sea water by Premier

A MAGNESIUMENHANCED LIME CLEANING PROCESS OF

40 JET JET ol (28) Issue 3 4 Martin Bricl Martin Bricl JET Vol 11 (2018) Issue 3 containing the MgSO4, is transported back to the absorber to help enhance the quality of the slurry and to save the amount of the reagent that is needed for the efficient cleaning of the flue2019年11月4日 After crushing, it is screened by a circular vibrating screen The largergrained limestone is returned to the cone crusher and crushed again; the mediumsized limestone is sent to the next process Third stage: fine Limestone Rock Crushing Flow Price JXSC Machine2022年6月24日 The Australian Magnesium Process developed in Australia involves dissolving pure magnesite ore in hydrochloric acid to produce magnesium chloride The magnesium chloride is then purified, dehydrated to a dry feed and electrolysed in an Alcan cell The molten magnesium is tapped from the cell and cast into ingotsMagnesium Geoscience AustraliaDetailed Process to Make Powder Fertilizer from Limestone Limestone powder is a versatile and useful material that has many applications in different industries It is widely used as a raw material for cement, lime, plaster, paint, paper, rubber, and other productsLimestone Powder Making Process NPK Plant Cost

Magnesium Smelting via the Pidgeon Process SpringerLink

2021年4月30日 At present, there are two main magnesium smelting methods: electrolytic smelting and reduction smelting Compared to electrolytic smelting, reduction smelting has the advantages of having a simple and mature process, requiring a small investment, short construction period, can use various heat sources, produces good quality magnesium, 2021年9月21日 This study describes and demonstrates a carbonnegative process for manufacturing cement from widely abundant seawaterderived magnesium (Mg) feedstocksCarbonNegative Cement Manufacturing from SeawaterDerived Magnesium 2023年2月15日 After the first screening process, the primarily qualified limestone would be sent to the hammer crusher for fine crushing The limestone material discharged from a hammer crusher will be further screened to get qualified material for the next step Best crushing and equipment of Fote ManufacturerLime Production Process and Required Equipment Fote presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Crushing at Crushing Facility Figure 1 Process flow diagram for limestone quarrying operations 3 As shown in Figure 1, A LifeCycle Inventory of Limestone Dimension Stone Quarrying

.jpg)

The Role of Crushed Limestone In Agriculture Pontotoc

2024年11月9日 Dolomitic limecrushing plant or coarse limestone, known by its agricultural term “builder’s lime,” is excellent in providing magnesium, a vital plant nutrient This type of liming material is recommended when soil tests indicate a magnesium deficiency and soil acidityAgain, noncarbonate magnesium compounds (for example, phlogopite) react thus: KMg 3 AlSi 3 O 10 (OH) 2 + 05 SO 2 + 025 O 2 → 05 K 2 SO 4 + 3 MgO + 05 Al 2 O 3 + 3 SiO 2 + H 2 O (vapor) Lowtemperature calcite decomposition Calcium carbonate, present in the rawmix as calcite, produces carbon dioxide, the amount of which exceeds half the mass of the finished Cement Clinker Manufacturing Process with Reactions2013年8月29日 ground magnesium limestone powder – stone crushing ground magnesium limestone powder dolomite crusher for powder making process,grinding (Calcium Magnesium Carbonate) – Quarrying Crusher processing dolomite into magnesium sulfate : calcium magnesium powder crusher Mining Quarry PlantThe cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition 3 Raw Mill and Kiln: Raw materials and additives areA practical guide to improving cement manufacturing processes

.jpg)

Production European Lime Association

Crushing and washing Calcination is the thermal process of heating limestone This processed stone is then transferred by conveyors to the lime kilns The lime burning process within the kilns requires enough heat to be transferred to the limestone in order to decompose the calcium and magnesium carbonates2021年4月30日 111 Properties and Main Uses of Magnesium Metal Human beings discovered magnesium compounds as early as the seventeenth century Antoine Lavosier, a French scientist, theoretically inferred that an ore with unknown composition (ore containing alumina and magnesium oxide) contained a new metal element, but the magnesium could not be extracted Overview of Magnesium Metallurgy SpringerLink2020年7月17日 All refer to the same material, lime Dolomitic lime contains magnesium oxide (MgO) derived from the presence of magnesium carbonate (MgCO3) in the initial stone referred to as dolomitic limestone Dolomitic limestone contains two forms of carbonate, calcium carbonate and magnesium carbonate High calcium lime is almost pure calcium carbonateWhat is Lime: Lime vs Limestone Mintek ResourcesLimestone (calcium carbonate CaCO 3) is a type of carbonate sedimentary rock which is the main source of the material limeIt is composed mostly of the minerals calcite and aragonite, which are different crystal forms of CaCO 3Limestone forms when these minerals precipitate out of water containing dissolved calcium This can take place through both biological and nonbiological Limestone Wikipedia

Overview of Magnesite ResearchGate

magnesium ion can also be bonded with sulphate (MgS04)e These salts can form solid deposits (evaporite), but also occur as a water solution (brines and seawater)2021年10月14日 Limestone, chalk and high magnesium limestone (Mglime) application to (a) permanent and (b) recent grassland for Great Britain, from the annual British Survey of Fertiliser Practice 1994–2019 A spatial analysis of lime resources and their potential for 2023年12月8日 Limestone crushing process Limestone or limestone resources are abundant, and the raw ore grade can generally meet the requirements of various industrial sectors Therefore, generally only simple mineral washing is required, and there is no need to use complex mineral processing processes for purificationLimestone crushing technology and equipment SBM Ultrafine represent the current magnesium market604020 0 20 40 60 80 100 120 140 160 Production Use Phase Vehicle EndofLife Credits for Use of PostConsumer Scrap t Electrolysis QSLM Pidgeon process (CN) Magnesium average world Electrolysis DSM Pidgeon process (CN) best case RIMA process Pidgeon process w/o credits100 80 60 40 20 0 QSLM process Carbon Footprint of Magnesium Production and its Use in

Do’s Don’ts Of Limestone Rock Crushing Mellott

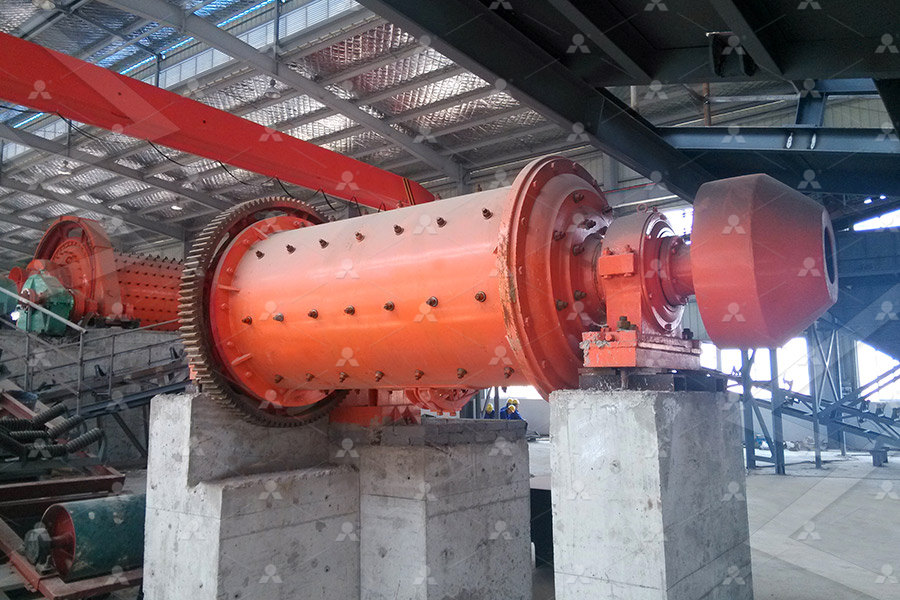

2023年3月27日 Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different applications The limestone crusher is equipment that can crush large limestone gravels about 6001800mm into materials about 25mm or smaller It provides limestone crushed products in the construction industry because limestone is a key ingredient in the production of cement, concrete and other building materialsThe size and type of crushers may vary according to the specific What is Limestone Crusher? AIMIX GROUP2024年1月23日 Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feeder The jaw crusher crushes large limestone blocks into Limestone crushing and screening production line introductionpresence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Crushing at Crushing Facility Figure 1 Process flow diagram for limestone quarrying operations 3 As shown in Figure 1, A LifeCycle Inventory of Limestone Dimension Stone Quarrying

.jpg)

Limestone Crushing And SandMaking Plant Eastman Rock

2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for industries such as airport construction, water conservancy power stations, tall buildings, concrete mixing plants, etcThe higher investment costs require the limestone forced oxidation system, 42 JET Magnesium Enhanced Lime Cleaning Process Of The Flue Gases 7 Magnesium Enhanced Lime Cleaning Process Of The Flue Gases since the reagent preparation system cost €2 million and the desulphurization unit is €4 million higher, corresponding to the proposed systems for the A MagnesiumEnhanced Lime Cleaning Process of Flue Gases2024年3月19日 To process lightburned magnesium oxide into 1500mesh fine powder, you need to configure the following equipment: Crushing equipment: crush the raw magnesite into particles smaller than 20mm to facilitate subsequent processing Commonly used crushing equipment includes jaw crusher, impact crusher, cone crusher, etcHow to process 1500 mesh light burned magnesium oxide fine 2022年5月11日 The basic chemistry of limestone is calcium, magnesium, iron, and silica Calcium and magnesium are essential for glass making, while silica is mainly from sand Iron is the primary impurity found in limestone, and glassmakers need to know what its effects might be before choosing a limestone for their processHow Is The Processing Of Limestone Processed?

Optimal Limestone Content on Hydration Properties of Ordinary

2024年7月2日 In this study, the effect of limestone content on the mechanical performance and the heat of hydration of ordinary Portland cement (OPC) was investigated Changes in the phase assemblage were analyzed through XRD and thermodynamic modeling The purpose of the study was to identify the optimal limestone content in OPC As a result of the experiment, all 2023年2月13日 This article states types of limestone crushing equipment and compares them in production efficiency and other pespectives to help you selecting the best limestone crushing equipment Skip to content Call Us Now: +86 What Is The Best Limestone Crusher Limestone Crushing AGICO