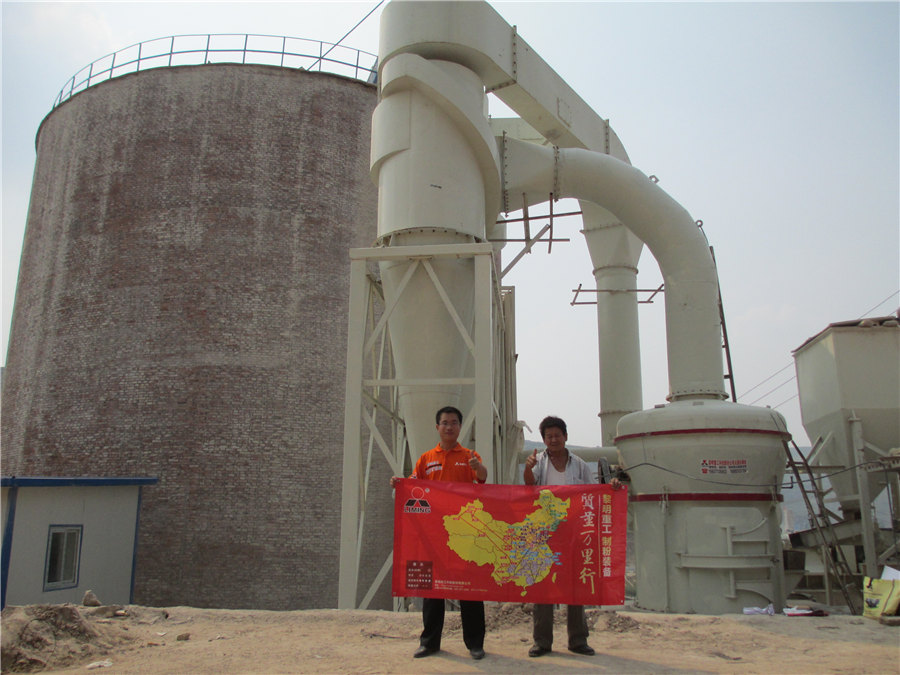

1 hour 35 cubic meters of calcium carbide mud mill Raymond mill has a lower price

.jpg)

Recycling and utilization of calcium carbide slag ScienceDirect

2022年5月1日 CCS is physically purified by hydrocyclone and chemically separated by NH 4 Cl treatment to obtain 999% calcium chloride solution During lowtemperature carbonization, the Coal is the dominant fuel in China to provide primary energy, and 70% of current status and new oppo2023年5月1日 A low carbon geopolymer (RCFG) was developed from the 100% solid wastes including red mud (RM), calcium carbide slag (CS), GGBS and FA in this study The effect of Preparation and curing method of red mudcalcium carbide slag 2023年10月19日 Industrial solid wastes red mud and calcium carbide slag are used to prepare lightweight aggregate ceramsite by coldbonded pelletizing technology in this study The Investigation of various curing methods on the properties of red

.jpg)

Production of a new type of cemented paste backfill with

2023年8月14日 To solve the disposal problems of carbide slag (CS), soda residue (SR), and red mud (RM) solid wastes, a new type of cemented paste backfill (CPB) was prepared with CS, 2022年10月3日 This research aims to investigate the durability of ground granulated blast furnace slag (S) and calcium carbide residue (CCR), two industrial byproducts, solidified Study on Compressive Strength and Microstructure of Using the solid waste carbide slag produced by the calcium carbide industry to absorb CO 2 and convert it into useful products not only improves the utilization value of carbide slag but also Resource utilization of solid waste carbide slag: a brief review of In this paper, carbide slag is used as the calcium source of the calcification process to treat bauxite residue, which Mudslag, discharged from the hydrolysis of calcium carbide to ANALYSIS OF MUDSLAG OF CALCIUM CARBIDE Semantic Scholar

Mechanical, microstructure and reaction process of calcium

2022年1月10日 Compressive strength tests, reaction process and microstructural analysis were performed including Fourier transform infrared, Xray diffraction, scanning electron microscope To control eutrophication and recover phosphate from wastewater, a calcium carbide slag and red mud composite material (CRLDH) was prepared using industrial waste as raw material forXRD pattern of calcium carbide slag, red mud, and CRLDHThis paper focuses on summarizing the traditional and emerging high valueadded utilization technologies of carbide slag, and then introduces the application research of carbide slag in Resource utilization of solid waste carbide slag: a brief review of 2014年1月31日 Owing to the thermodynamic and kinetics restrictions, traditional electric arc method for calcium carbide (CaC2) synthesis is operated at very high temperature (∼2200 oC), which is an energy Thermodynamic Analysis of Calcium Carbide

Solved 115 The mud logger places a sample of

The calcium carbide reacts with the mud to form acetylene gas The acetylene is detected by a gas detector at the shale shaker after pumping 4,500 strokes The drillstring is composed of 9,500 ft of 5 in, 195lbm/ft drill pipe and 500 ft of 2022年4月27日 The fruit samples ripened with technical grade calcium carbide showed the presence of 3,5dimethyl1,2,4trithiolane isomers, which can be used as markers to identify sapota fruits ripened with (PDF) The Use of Calcium Carbide in Fruit Ripening: Download Citation On Oct 1, 2023, Qingxin Zhao and others published Investigation of various curing methods on the properties of red mudcalcium carbide slagbased artificial lightweight Investigation of various curing methods on the properties of red mud 2024年4月25日 Synthesis of calcium cyanamide: This exothermic reaction (ΔH 298 = 289 kJ/mol) converts calcium carbide and nitrogen gas into calcium cyanamide and carbon: CaC 2 + N 2 → CaCN 2 + C Hydrolysis to acetylene: Reaction with water readily produces acetylene, calcium hydroxide, and heat (ΔH 298 = 1284 kJ/mol): CaC 2 + 2 H 2 O → C 2 H 2 + Ca(OH) 2 Calcium Carbide: Properties, Production and Uses

Calcium Carbide an overview ScienceDirect Topics

Calcium carbide has the nominal formula of CaC 2 and the molecular weight of 640992 g/mol The pure material is colorless, but most samples have a color ranging from black to grayishwhite, depending on the grade Its density is 222 g/cc and it melts at 2160 °C with a boiling point (under an inert atmosphere) of 2300 °C, where it decomposesIts main use industrially is in the 2023年10月19日 Industrial solid wastes red mud and calcium carbide slag are used to prepare lightweight aggregate ceramsite by coldbonded pelletizing technology in this study The effects of mixing water and curing method on the physical properties of ceramsite were investigated, including natural curing (in air at 20 °C), sealed curing, water curing, hot air oven curing, Investigation of various curing methods on the properties of red mud 2013年4月1日 Lime mud, a kind of industrial waste that produced in paper mill, was proposed as CO2 sorbent in calcium looping process The carbonation performance of the lime mud was investigated in a dual Utilization of lime mud from paper mill as CO2 sorbent in calcium 2016年2月17日 On the basis of the chemical reaction balance, the hydrolyzing reaction of one ton of calcium carbide can produce 1156 t (tons) of Ca(OH) 2However, in the actual production, the reaction conversion is less than 100 % and the reactant is not 100 % pure, so the hydrolyzing reaction of one ton of calcium carbide can produce 145 t of residue with a number of Preparation of feed grade calcium formate from calcium carbide residue

Calcium Sulfite Oxidation and Crystal Growth in the Process of Calcium

2014年2月1日 Calcium carbide residue mainly composed of Ca(OH)2 can be used in wet flue gas desulfurization (FGD) Different from the traditional limestone–gypsum wet FGD, calcium carbide residue rapidly O serviço do Google, oferecido sem custo financeiro, traduz instantaneamente palavras, frases e páginas da Web do português para mais de cem outros idiomasGoogle Tradutornumber of waste byproducts and waste mud from landfills Keywords Mud solidification Calcium carbide residue Slag Wetting–drying cycles Durability B Qiang Wang wangqiang0711@163 Huangrui Xu xuhrui98@163 Wenjun Zhou @Man Li @Guojun Cai focuscai@163 1 School of Civil Engineering and Study on Compressive Strength and Microstructure of Slag–Calcium Figure 1 31 CaC 2 Reactor Think about what components you need in order to get energy from calcium carbide into the liquid sodium Since you have an inexhaustible supply of CaC 2, let’s start with that Looking up typical reactions for calcium carbide, we can find one that is used in carbide lamps (and many other CaC 2 devices)Calculations for Calcium Carbide / Acetylene Reactor Block

Precarbonation of calcium carbide slag for the preparation of

Download Citation On Oct 1, 2023, Peiyuan Chen and others published Precarbonation of calcium carbide slag for the preparation of ecofriendly mortars Find, read and cite all the research you 2022年2月1日 Calcium carbide can be used as the basic raw material of organic synthetic chemical industry, and many organic compounds, such as polyethylene (PE), ethyne, polyvinyl chloride(PVC), etc, can be produced or synthesized by using calcium carbide [1, 2]As a result, CaC 2 has become an important chemical platform for sustainable development because of its Energy and exergy analysis of a new calcium carbideRequest PDF On Sep 1, 2011, Xiaoyu Liu and others published CO2 emissions in calcium carbide industry: An analysis of China's mitigation potential Find, read and cite all the research you need CO2 emissions in calcium carbide industry: An analysis of EMISSION FACTORS FOR CALCIUM CARBIDE MANUFACTURINGa EMISSION FACTOR RATING: E (except as noted) Condensable Inorganic PMc (kg/Mg feed) Sulfur Oxides (kg/Mg feed) CO2 (kg/Mg feed) ND 15f ND 032g 037g ND Negh Electric arc furnace main stack with scrubber (SCC 30500401)d 025e ND ND ND Electric arc furnace and calcium carbide (PDF) 14 Calcium Carbide Manufacturing Academia

.jpg)

The use of calcium carbide in food and fruit ripening: Potential

2022年1月29日 The global increase in the demand for ripe fruits has induced unhealthy use of toxic chemicals in fruit ripening One of such chemicals in common use is calcium carbide (CaC2)2022年10月3日 The high water content and viscosity make construction mud extremely difficult to manage, causing land occupation and environmental pollution problems This research aims to investigate the durability of ground granulated blast furnace slag (S) and calcium carbide residue (CCR), two industrial byproducts, solidified waste mud under wetting–drying cycles, and Study on Compressive Strength and Microstructure of Slag–Calcium 2021年10月1日 DOI: 101016/jconbuildmat2021 Corpus ID: ; Recycling sediment, calcium carbide slag and ground granulated blastfurnace slag into novel and sustainable cementitious binder for production of ecofriendly mortarRecycling sediment, calcium carbide slag and ground granulated 2024年5月2日 A cubic phase of molybdenum carbide (αMo 2 C) can convert carbon dioxide to carbon monoxide (CO) at 100% conversion at 600°C Although other phases of αMo 2 C have been used for this reverse water gas shift An active, stable cubic molybdenum carbide catalyst

.jpg)

Study on Compressive Strength and Microstructure of Slag–Calcium

2022年10月3日 Download Citation Study on Compressive Strength and Microstructure of Slag–Calcium Carbide Residue Solidified Mud Under Wetting–Drying Cycles The high water content and viscosity make 2022年2月28日 The global increase in the demand for ripe fruits has induced unhealthy use of toxic chemicals in fruit ripening One of such chemicals in common use is calcium carbide (CaC 2)Due to its nature, commercial CaC 2 is consistently found to contain impurities such as Arsenic and other toxic and carcinogenic chemicals Few studies have only reported acute associative The use of calcium carbide in food and fruit ripening: Potential 2024年1月5日 A mixture of calcium carbide residue and coal fly ash with a Ca/(SiO2 + Al2O3) ratio of 15 resulted in the highest compressive strength at long curing periods in both pastes and mortarsEvaluation of calcium carbide residue and fly ash as sustainable 2024年10月25日 Carbide residue is generated during the production of acetylene through calcium carbide hydrolysis, and it mainly 39 hours, and 27 hours when the red mud content was 10 wt%, 20 wt%, and 30 wt%, respectively Download: Download highres It is found that with lower dosage of carbide slag (less than 15 wt Performances enhancing of supersulfated cement (SSC) using

Raymond mill, Raymond grinding mill All industrial

Output: 100 kg/h 180 kg/h Motor power: 30 kWFineness of the final powder is welldistributed, 99% of them can pass through the screen, other milling machines are hard to approachRaymond mill conmission equipment adopt 2022年11月1日 From three (3) industrial coproducts, namely blast furnace slag, red mud and calcium carbide residue, (COPR) and silicon dioxide were homogenized in ethanol and fired at 1200 ℃ for 2 hoursStrength development and microstructure of sustainable The production flow chart for wet calcium carbide slag, 1# and dry calcium carbide slag, 2# are described in Figures 1 and 2 respectively In a general, the processes mainly include measures to stabilize the composition of the raw material feeding into the kiln, optimization of the raw meal grinding system, research on the development of key technologies regarding firing systems Application technology of calcium carbide slag: a case study2024年11月8日 Comparing with C 3 S (tricalcium silicate), lowcalcium calcium silicate minerals, such as βC 2 S (dicalcium silicate) and γC 2 S have lower sintering temperature, lower demand for calcareous raw material and much benefits for reducing CO 2 emission [21], [22], [23]Among them, βC 2 S has the lowest apparent carbonation activation energy during the phase An all solid waste CO2 sequestration material consist of multiple

.jpg)

Optimizing carbonation reaction parameters of calcium carbide

2024年10月15日 Carbide slag (CS) is a typical alkaline solid waste with Ca(OH) 2 as its main component, exhibiting a high capacity for CO 2 mineralization Currently, the methods for CS mineralization of CO 2 include direct and indirect mineralization which the initial pH of the reaction system plays a crucial role in the mineralization process In this study, we explored the effects 2022年11月1日 Approaches for coping with the current challenges of energy shortages and environmental pollution are urgently needed (Li et al, 2018, Wang et al, 2019)Particularly, the production of calcium carbide (CaC 2) involves high reaction temperature (2473 K) and high power consumption (approximately 3500 kWh/t CaC 2)In 2020, the CaC 2 production Comparison of new twostep calcium carbide production process 2023年9月15日 Current developments of the cement industry in China have focused on reducing its environmental impact through techniques With the increasing use of ecofriendly building materials, attention has been placed on increasing the proportion of waste in raw materials while removing impurities (Zuo and Nie, 2003)The use of industrial and domestic waste as raw Life cycle assessment of beneficial use of calcium carbide sludge 2015年12月11日 During the period following the 1973 escalation of fuel prices, the growth rate of emissions has been less than half what it was during the 1950s and 1960s (15%/year since 1973 as opposed to 45% National carbon emissions from the industry

[PDF] THE MANUFACTURE OF CALCIUM CARBIDE Semantic

THE MANUFACTURE OF CALCIUM CARBIDE @article{Morehead1896THEMO, title={THE MANUFACTURE OF CALCIUM CARBIDE}, author={Jarred Morehead and G de Chalmot} Ca and C interdiffused at a lower temperature, but at a higher temperature, the formed calcium carbide crystals would have a negative effect on Ca diffusion to carbonSjoqvistet al [1] have made a detailed study of the benefits of using calcium carbide to control inclusions in case of steels for critical applications such as rail steel and rail wheel With Use of Calcium Carbide and Alumina based Slag ResearchGate2023年10月15日 Key lowcarbon technologies such as raw material substitution and carbon capture in industrial processes are important means to reduce carbon emissions in the industrial sector and support China's “double carbon” goal (Bakshi et al, 2021; Cai et al, 2020; Castilho et al, 2013)CCS is a good lowcarbon calciumbased material for flue gas carbon sequestration Carbon emission free preparation of calcium hydroxide with calcium 2022年8月1日 The utilization of such solid wastes as red mud (RM), carbide slag (CS), and fly ash (FA) in the production of environmentally friendly and cheap construction materials is a challenging taskPreparation of nonsintered lightweight aggregate ceramsite

.jpg)

Investigation of various curing methods on the properties of red mud

2023年10月19日 It was found that the total carbon uptake of RMALCBAs was about 3058–3306 kg/tons, indicating that RMALCBAs show the obvious carboncapturing potential, and when the biochar dosage was increased from 0% to 15%, its compressive strength was 128 MPa198 MPa, and the water absorption rate and apparent density of RMALCBAs before 2024年8月9日 Utilizing MSC composite materials (MMetakaolin(MK)), SSlag, CCalcium carbide residue (CCR)), the waste engineering mud produced through the drilling and grouting pile construction method was solidifiedThrough the analysis of unconfined compressive strength (UCS), Xray diffraction (XRD), and scanning electron microscope (SEM) on solidified Study on mechanical properties and microstructure of metakaolin 2022年12月1日 At present, calcium carbide production includes electrothermal method (ETM) and oxythermal method (OTM) Electrothermal method (ETM) originated early, and calcium carbide is formed by the reaction of calcium oxide and coke at a high temperature about 2000 °C produced by electric arc [10], [11]Generally, the power consumption of producing 1 ton of Carboncalcium composite conversion of calcium carbide