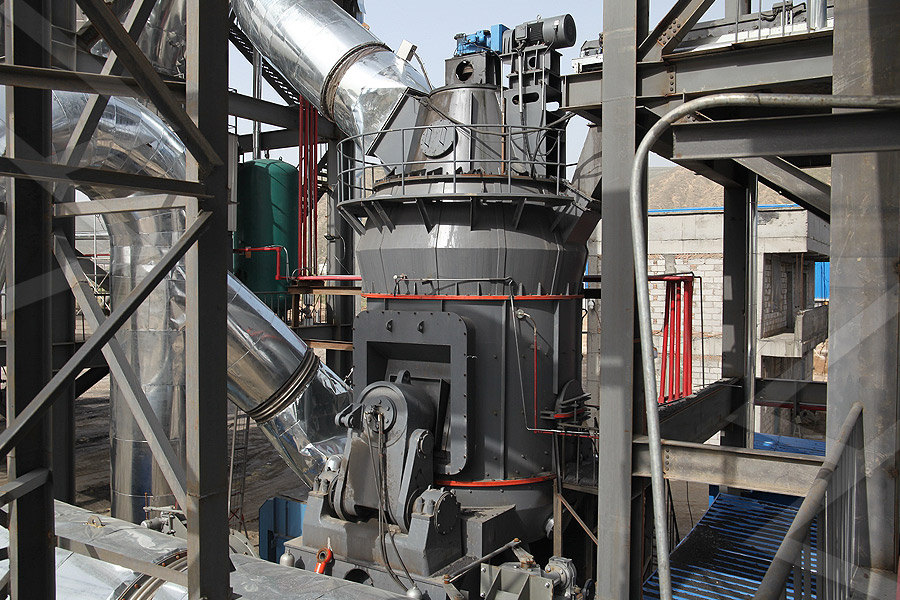

Coal raw coal grinding machine picture

.jpg)

coal grinding machine CHAENG

Vertical Coal Mill is specially used for ultrafine grinding of raw coal and bituminous coal materials in cement, power plants, iron and steel plants and other fields The GRMC coal vertical mill 2024年5月27日 Find Coal Crusher Machines stock images in HD and millions of other royaltyfree stock photos, illustrations and vectors in the Shutterstock collection Thousands of new, Coal Crusher Machines royaltyfree images ShutterstockIt is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, LtdThe airswept coal mill is the main equipment for the cement factory It grinds the coal block into pulverized coal and is used to grind and dry various of hard coal It’s important auxiliary equipment for pulverized coal furnaceAirSwept Coal Mill Grinds the Coal Into Pulverized

.jpg)

Roller mill GMRC Series coal mill Xinxiang Great

It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screen After the iron is removed by the Explore Authentic Coal Mining Machines Stock Photos Images For Your Project Or Campaign Lessing, More Finding With Getty Images1,414 Coal Mining Machines Stock Photos HighRes PicturesOur engineers have designed the most advanced coal pulverizing and crushing systems in the field Are you looking for a directfired coal pulverizer, a lowcapacity coal size reduction machine, or something in between? Williams has Coal Crushers Coal Pulverizers Mills Williams CrusherBrowse 15,221 authentic coal mining equipment stock photos, highres images, and pictures, or explore additional underground mining or pit mining stock images to find the right photo at the 15,221 Coal Mining Equipment Stock Photos HighRes Pictures

LOESCHEMILLS

Loesche designs, plans and constructs everything from individual machines to turnkey drygrinding installations for all solid fuels Loesche is certified in accordance with EN ISO 9001, Find Coal Washing Machine stock images in HD and millions of other royaltyfree Washing and sorting raw coal Grading coal ore Processing ITALY AUGUST 24, 2011: Tanker with water jets for street washing In the picture, the work vehicle in area with fossil coal and dirty asphalt GENOA, ITALY AUGUST 24, 2011: Tanker with water Coal Washing Machine royaltyfree images ShutterstockShuliy Machinery produces all kinds of charcoal processing equipment If you would like to know about our crusher machine, please contact us immediately And you will obtain equipment price and parameter information Type 1: Charcoal Shredder Coal Grinder Machine Shuliy 【Coal Pulverizer Structure】 The coal injection machine mainly comprises coal hopper, shell, main shaft, coal hammer, liner, fan, separator, and motor 【Coal Pulverizer Injection Machine Working Principle】The raw coal enters the Coal Pulverizer Injection Machine JXSC Machine

.jpg)

How Does a Vertical Coal Mill Work Coal Grinding Mill In

2024年3月16日 Ultimately, the finely pulverized coal is transported via a burner pipe to the furnace of a power plant or cement kiln, where it undergoes combustion to generate heat for electricity production or industrial processes, completing the operational cycle of the coal mill The coal grinding mill serves as a versatile grinding machine, adept at Caterpillar bulldozers can be divided into three main groups – small, medium and high power bulldozers The lowpower machines presented by the "K" series have a mass of 75 and up to 135 tons, and a power of 74 and up to 129 hpCoal mining machines2018年11月26日 why doing coal briquetting Coal briquetting is a process which turn the coal dust to briquette Compare to directly use coal dust as fuel, use coal briquette not only helps to reduce the burning cost (reduce 2030% of coal dust usage), but also makes benefit to the environment So, how can we make briquette from Coal briquetting technology process, binder and the briquette machinePerfect quality high capacity coal crusher machine/raw coal crusher Product Description 1Introduction of raw coal crusher The Vertical Complex Crusher is a new type of rough grinding and fine crushing product combineded the domestic and foreign crushing technologies together, developed and designed by our team of highly qualified engineers on main technical parameterPerfect quality high capacity coal crusher machine raw coal

Coal Properties, Formation, Occurrence and Uses Geology Science

2023年8月15日 Coal has a variety of physical properties, including: Color: Coal can range in color from black to brown to grayish; Hardness: Coal can range in hardness from very soft and crumbly, like graphite, to very hard, like anthracite; Density: Coal has a lower density than many rocks and minerals, making it relatively lightweight; Porosity: Coal can be very porous, with The grinding roller is driven by a motor to make the grinding disc rotate in the coal mill shell The coal is placed between the grinding discs, and due to the relative movement of the grinding rollers and the grinding discs, the coal is crushed and ground into fine powderAir Swept Coal Mill Cement Plant Equipment Coal Grinding Millinhouse expertise designing large rotating machinery, FLS was ideally positioned to develop and provide the industry with an improved stateoftheart version of a vertical roller mill And accordingly, in over 30 foreign installations since 1980, FLS has successfully placed in operation their own VRM's, grinding coal or raw meal,A Comparison of Three Types of Coal Pulverizers Babcock PowerOur Pulverized Coal Preparation Production Line is composed of Raw Coal Storage Transportation System, Grinding System, Dust Collecting System, Electrical Instrument Automation System By the consideration of safety Pulverized Coal Preparation Pulverized Coal Grinding

COAL GRINDING IMPS: more than meets the eye Gebr Pfeiffer

Vertical roller mills are not only used for grinding cement raw materials but also find an application in grinding a wide variety of coal types in cement and power plants Gebr Pfeiffer SE (GPSE) describes its vertical roller mills for coal grinding and provides a case study of an MPS225BK installed at CBR’s Lixhe cement works in Belgium Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2535M/sec above the ball it would be seen that the most significant process and types used for raw material grinding operations in modern cement industry are: Process: Dry Closed circuit drygrinding Type of mill: Ball and Raw Material DryingGrinding Cement Plant OptimizationPicture originated at the electron microscope laboratory of BauhausUniversität Weimar T OFTEN UNDERRATED Tobias Korz, Loesche GmbH, Germany, considers coal preparation in gasification plants he coal gasification industry has experienced enormous growth over the last few years, and consequently the demand for coal grinding and dryingOFTEN LoescheProcess introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenCOAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

Henan Mining Machinery and Equipment Manufacturer Bhel Coal Mill Picture

Please feel free to contact us Home Crusher Price babkok coal mill hi res cement mill picture [1030] raw mill to the requirements of major coal mill manufacturers such as BHEL, heating kit for grinding roll of coal mill – SAMAC input and hourly output of tph stone crusher machine; Hot News crushing of ore processing;Coal grinding is a critical process in various industries, particularly in power generation and cement production However, the process involves significant safety risks due to the combustible nature of coal dust and the mechanical hazards posed by grinding machinery Ensuring safety during coal grinding is essential to prevent accidents, explosionSafety Aspects of Coal Grinding Coal Mill Safety, Explosion and Coal is crushed to desired fineness between spheres or cylindrical rollers After that, air from the boiler is heated to around 330°C (650°F) The raw coal is then fed into the pulverizer where it is ground into fine coal particles What are the Advantages of Pulverized Coal? Pulverized coal produces a larger amount of heat than traditional coalCoal Crushers Coal Pulverizers Mills Williams Crusher2015年3月1日 Specific energy consumed by raw coal with a small size was higher when subjected to the same value of t10, with no material in the grinding machine Then, the grinding tests were doneEnergySize Reduction of Coals in the Hardgrove Machine

Indirect Firing Coal Grinding Systems: Enhancing Efficiency and

Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding system is nothing more than a mirageThe raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned Coal ball mills are widely used in the cement industry and thermal Coal Ball Mill Grinding for Different Kinds of Vertical coal mill is the coal milling machine SBM designed for coal grinding process Coal mill operationCoal grinding millCoal milling machine Get Info; Coal MillBall Mill,Ball Mill Supplier,Ball Mill For Sale, Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them grinding process in coal KOOKSPulverized Coal Injection 4 Grinding and Drying of Coal in Inert Conditions Blast Furnace Gas Based Drying Blast Furnace Gas Based Drying, Dilution Air Drying energy supply based on blast furnace gas combustion Inert conditions produced by closed loop circulation of waste drying gas as a dilution gas for drying gas temperature control (selfPulverized Coal Injection Paul Wurth

Ensuring Safety in Coal Grinding Operations Coal Mill Safety

Safe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding 2024年7月9日 Charcoal powder mixer (also known as wheel mill, charcoal mixer machine, charcoal powder grinding machine) is used for mixing and pressurizing charcoal powder, necessary in the coal processing plant It can handle charcoal powder with a capacity of 0310t/h You can choose suitable output to meet your charcoal making line demandsGreat Charcoal Powder Mixer For Grinding In Coal LineDuring operation, the main motor drives the grinding disc through a reducer Hot air enters the vertical mill through the inlet, while the raw coal is fed evenly into the center of the grinding disc via the conveyor The raw coal is crushed by the grinding roller as it moves evenly to the edge under the influence of centrifugal forceHighEfficiency Vertical Coal Mill YingYong Machineryball mill Solutions for coal gangue grinding plant Grinding production solution 1 Equipment configuration: jaw crusher+coal gangue grinding machine (Raymond grinding machine equipment)+auxiliary equipment Production advantages: If the particle size of coal gangue raw materials is relatively large, choosing a combination of jaw crusher and powder mill is more Custom Coal Gangue Crushing And Grinding Plant Machine

Improving the efficiency of the coal grinding process in ball drum

2022年2月24日 Improving the efficiency of the coal grinding process in ball drum mills at thermal power plants February 2022 EasternEuropean Journal of Enterprise Technologies 1(1 (115)):93105Energies 2021, 14, 7300 3 of 15 A = f2(G, B) (2) where G is the coal grindability within the specified system, M means the mechanical properties of the coal, r is the coal porosity, q determines the hard particles mechanical and geometrical characteristics, w is the moisture, T is the temperature, h is the overall efficiency of the grinding system, A is the coal abrasiveness, of Coals in Mineral Processing SystemsMining coal Coal miners use large machines to remove coal from the earth Many US coal deposits, called coal beds or seams, are near the earth's surface, while others are deep undergroundModern mining methods allow coal miners to easily reach most of the nation's coal reserves and to produce about three times more coal in one hour than in 1978coal machines Sebocom ConstructionEnergies 2021, 14, 7300 3 of 15 A = f2(G, B) (2) where G is the coal grindability within the specified system, M means the mechanical properties of the coal, r is the coal porosity, q determines the hard particles mechanical and geometrical characteristics, w is the moisture, T is the temperature, h is the overall efficiency of the grinding system, A is the coal abrasiveness, of Coals in Mineral Processing Systems

Coal mills for all requirements Gebr Pfeiffer

Our machines and products for the coal industry The grinding plant can be inerted The raw coal is dried while being ground in the mill even if feed moisture exceeds 25% The feed size that can be handled is up to 100 mm, making two It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screen After the iron is removed by the Roller mill GMRC Series coal mill Xinxiang Great You will be surprised about what has gone wrong with fire and explosion protection of your system(s) Be sure about that! Evaluation of a coal grinding system’s fire and explosion protection, including the raw coal storage and the fine coal silo storage normally can be done in one day, mostly without having to stop coal grindingEnsuring Safety in Coal Mills – Best Practices and Precautions Coal 2009年9月20日 It contains larger mass of raw and pulverized coal but less grinding heat is generated in this mill Coal mill modeling by machine learning based on onsite measurements Article Jan 2003;Modeling and Parameter Identification of Coal Mill

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 FTM MachineryGreen and Intelligent Mining Machinery Manufacturing and Export Base Based on high quality and perfect aftersales service, our products have been exported to more than 120 countries and regions FTM Machinery has become the first choice for over 2,000,000 customers Our customer service team is here to help you 24/7The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40%Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillCrsine HTML Template For Car Services sbm crushing coal grinding mills at nagpur YouTube Aug 9, 2014 Coal Crushing Plant,Coal Grinding Process,Coal Plant,Coal Powder Even after 8 years, Genco's Odisha coal mine yet to start on a PVC Pipes 23 Apr 2014 spring compression kit for coal mill in india coal processing plant The vendors SBM Machine Coal crushing coal grinding powder compression machine Capabuild2024年10月15日 21 Cashew Nutshell and Raw Coal Analysis As the data shows in Table 3, the raw coal LHV is about 23,500 kJ/kg, the sued cashew nutshell LHV is about 26537 kJ/KG the moisture of the coal is high due to open storage, for CNS is still in the target The mixing percentage is 57% of total raw coalCashew Nutshell and Raw Coal Cogrinding for Sustainability

How does a Coal Mill Work? ball mills supplier

The dried coal powder is then transported to the combustion chamber where it is burned to generate heat The process of generating heat from raw coal is similar to that of pulverizer coal mills How Does a Raw Coal Mill Work? Raw coal is fed into the mill through the raw coal feeder The raw coal is then crushed between the roller and the ring