Cement mill equipment discount new years

Cement Plant Equipments MadeinChina

China Cement Plant Equipments wholesale Select 2024 high quality Cement Plant Equipments products in best price from certified Chinese Cement Mixer manufacturers, China Plant suppliers, wholesalers and factory on MadeinChinaSetting up a cement plant involves numerous components and stages, each contributing significantly to the overall cost This detailed guide will break down the costs associated with each component and stage of a cement factory, The Comprehensive Guide to Cement Plant Costs: An For a new plant, this approach delivers many relevant savings With more than 80+ years of experience working with the world’s leading cement producers, we have the deep application knowhow you can count on to tailor plantwide Cement processing equipment QlarChina Cement Plant wholesale Select 2024 high quality Cement Plant products in best price from certified Chinese Building Plant manufacturers, Crushing Plant suppliers, wholesalers and factory on MadeinChinaCement Plant MadeinChina

.jpg)

Roller Press KHD Humboldt Wedag

Grind cement raw materials, clinker, and slag, as well as minerals, with a roller press from the technical leader The machine frame – open or closed? We offer both open and closed frame layouts But what’s the difference? Open frames We at Pfeiffer can provide the whole range of grinding, separating, and drying equipment as needed to make your cement line work economically: for example, with our proven vertical PFEIFFER MILLS FOR THE CEMENT INDUSTRYIn recent years, thyssenkrupp Polysius has successfully continued step by step the development process for the quadropol® vertical roller mill concept This compact and modular concept includes the latest market requirements quadropol® thyssenkrupp Polysius Grinding As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO 2BALL MILLS Ball mill optimisation Holzinger Consulting

.jpg)

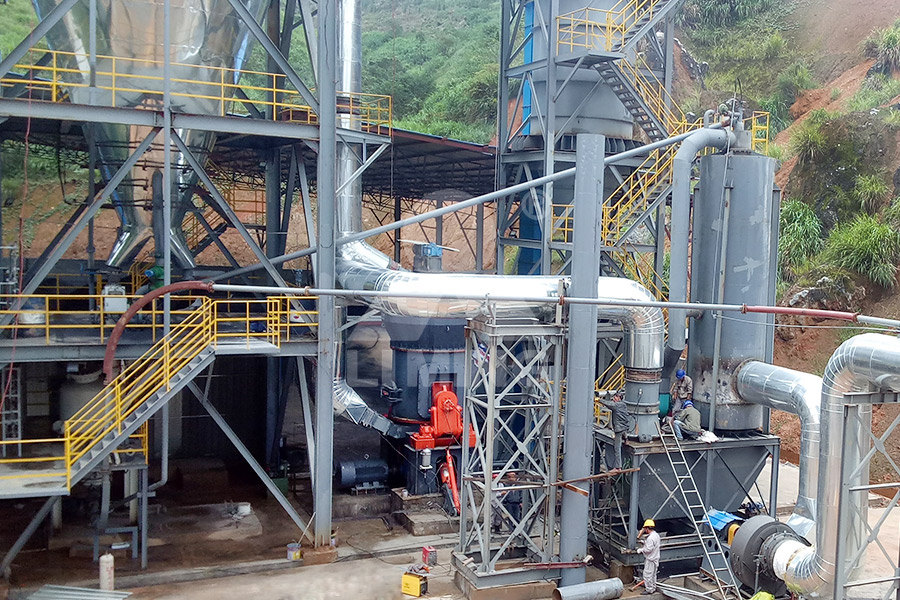

Vertical Cement Mill Magotteaux

Magotteaux’s advanced vertical cement mill technology ensures consistent results by providing precise control over the grinding process, enabling the production of highquality cement with minimal variations in finenessChina Cement Equipment cement Mill wholesale Select 2024 high quality Cement Equipment cement Mill products in best price from certified Chinese Machine Equipment Control Cement Equipment cement Mill MadeinChinaBall mill Ball mill is the key equipment for material crushing Tongli ball mill is widely used in cement clinker, Portland cement, new building materials, refractory materials, fertilizers, ferrous and nonferrous metal beneficiation, glass and ceramics and other production industriesBall mill CEMENTLAGICO is specialized in design and supply equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD,main equipments:Rotary Kiln, grinding equipment, Jaw Crusher, coolerLeading Supplier of Cement Plant Equipments

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Cement mill

Cement mill A cement mill (or finish mill in North American usage[1]) is the the development of specialized steel led to the development of new forms of grinding equipment, and from this point onward, These have been used for many years for the less exacting rawmilling process, 2018年4月24日 A ccording to CW Research’s recently published “World Cement Equipment Market and Forecast Report,” the market for cement manufacturing related equipment and services is projected to reach $9 billion by 2022 However, as greenfield cement plant projects remain scarce, upgrades to existing cement plants will become relatively more important; Cement Plant Equipment Market To Reach $9 Billion By 2022China Cement Equipment cement Mill wholesale Aftersales Service: 1 Year Warranty: Machine Is 6 Months Certification: SGS Standard: AISI, ASME, GB Surface Treatment: Polishing Stay updated to what's new and popular on Cement Equipment cement Mill MadeinChinaIf hardfacing is not applied the cost is as for the ball mill, ie 015020 EUR per ton of cement If hardfacing is applied, the corresponding figure will be 010015 EUR per ton of cement Costs of equipment and civil works The total specific costs associated with a new mill system can be broken into the following sections: 1 Equipment 2 Cement grinding Vertical roller mills VS ball mills

.jpg)

OK™ Raw and Cement Mill

Vertical roller mill with peak raw, cement and slag grinding performance Our costsaving Vertical Roller Mill (VRM) Common parts increase equipment availability, After 140+ years of pioneering new innovations, The thickness of the mill liners depends upon the mill diameter as well as on the size of the grinding media and generally fluctuates within limits of 30 63 mm Shape of the mill liners is usually rectangular; dimensions are approximately 300400 x 450 650 mm Corresponding weights are 50125 kgThe mill shell Optimum dimensions INFINITY FOR CEMENT EQUIPMENTA cement ball mill has the capacity typically ranging from 10 to 300 tons per hour And it has a high efficiency typically reaching up to 90%Cement ball mill DARKOAGICO CEMENT is a cement plant manufacturer supplies cement equipment with high quality and competitive price, including cement mill, cement kiln, cement crusher, and other cement plant equipment any need? Skip to content +86 s about blog contact EN ES Menu MenuCement Equipment, Cement Plant Equipment Cement Plant

Process Training Ball Mill INFINITY FOR CEMENT

Process Training Ball Mill To Download this post + all manuals and books and Excel sheets and all notes I collected over my 23 years of experience in Cement industry click here now INTRODUCTION Comminution is a major unit 2019年11月21日 Cement plant equipment, also known as cement plant machinery, cement production machinery, etcIn a complete cement production line, there is various cement plant equipment to play own roles As we all Cement Plant Equipment Cement Crusher, Cement Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the Cement Mill for Sale Buy Cement Ball Mill Vertical Tamilnadu Cements has announced plans to construct a new grinding mill in Alangulam, Tamil Nadu The new unit will be facilitating the adjacent Arasu cement factory and cost around $523 mn and will quadruple capacity from 028 mtpa to 056 mtpa in Tamilnadu Cements to set up new grinding mill

Drive Systems for Vertical Roller Mills INFINITY FOR CEMENT EQUIPMENT

[5] Baechler, M: Pushing limits Word Cement December 2016 [6] Reichardt, Y: The new PFEIFFER roller mill ZKG International No 112010 [7] Sachse, C O Assmann: Cement grinding with a rollerdriven vertical roller mill Quadorpol RD The coal mill in a cement plant should be reliable and should be operated with great care, or it is easy to cause safety accidents In the In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15% Vertical roller mill is a popular pulverized coal mill in recent yearsCoal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillBALL MILL INSPECTION PROCEDURE source : thecementgrindingoffice Introduction This document is intended to help the staff of the cement plants On a process point of view, a mill inspection is only representative if the grinding mill circuit is in a steady working condition with a representative cement productCement Ball Mill Maintenance INFINITY FOR CEMENT EQUIPMENT2019年9月27日 How much do you know the cement equipment? AGICO offers cement making machines including cement mill, rotary kiln, cement crusher, cyclone preheater, cement dryer, clinker cooler etc any need? Skip to content +86 s about blog contact EN ES MenuCement Euipment Overview Cement Making Machines Cement

.jpg)

Ball mills FLSmidth Cement

Ball mill for cement grinding Heavyduty comminution requires heavyduty equipment – and our Girth Gears are up to the task After 140+ years of pioneering new innovations, we are uniquely positioned to be at the forefront of our industry’s green transitionA new raw mill dassifier is now invariably of the ‘highefficiency’, rotating cagetype: the rotational speed controls product fineness at constant gas flow Raw milling can consume 10 30kWh/t; depending upon the materials and equipment, and developments aim to reduce this figureRaw milling and blending INFINITY FOR CEMENT EQUIPMENT2024年11月4日 global cement milling equipment market size was USD 128 million in 2022 and market is projected to touch USD 18108 million by 2032 Share, Growth, and Industry Analysis, By Type (Cement Ball Mill, Rod Mill, Cement Vertical Mill, and Others), By Application (Raw Material Processing and Clinker Discount on Your Next PurchaseCement Milling Equipment Market Size, Forecast, 2032Why not building a brand new cement plant at a cheaper price? Based on 20 years of experience in cement plant projects and strong production cement ball mill in the cement plant Accessory equipment: except the main part we Cement Plant For Sale Cement Equipment, Cement

.jpg)

Cement ball mill Xinxiang Great Wall Machinery Co, Ltd PDF

CHAENG cement ball mill equipment can reduce energy consumption by 30% and increase the processing amount by 1520% after transformation The cement ball mill can perform dry process production and also wet process production, moreover The installation of liners Length Diameter Ratio The lengthdiameter ratio of the cement ball mill is relatively large For mills of opencircuit grinding system, the lengthdiameter ratio is usually between 35 and 6 to ensure that the product fineness is qualified through single grinding; For ball mills in closedcircuit grind system, in order to increase the material flow rate, the length Cement Ball Mill Cost Effective Cement Grinding Mill from AGICOCement ball mill diaphragm Classification ball mill diaphragm: In recent years, AGICO CEMENT supplies EPC projects for both cement plant and single cement plant equipment CONTACT INFO +86 s 19F, Suite B, Ball mill diaphragm Cement PlantBased on customer needs and years of experience in cement equipment manufacturing, AGICO Cement develops a lowcost and highly efficient EPC solution for cement grinding unit – modular mobile (MMG) cement grinding plant Compared to the traditional grinding station available on the market, the MMG cement grinding plant is more suitable for the small and mediumsized Modular Mobile Cement Grinding Plant For Sale AGICO Cement

Bag Filters in Cement Industry INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents Bag Filters in Cement Industry when you buy the package from here , you will []In the permitting stage for a new cement plant, of water allowed to be withdrawn and consumed Our application to pump 750 liters/minute (LPM) or 38 million liters/year, equivalent to 200 gallons were constructed One tank was located near the cement mill building and one near the kiln drive pier Each pit is equipped with a 2840 LPM Everything you need to know about Water Managementleading mill OEMs and experts in material sciences, to develop hardfacing solutions that deliver optimum performance These solutions have been developed, tested and optimised for wear protection of vertical mill grinding components, setting a new standard in the cement industry MillCarb™ To protect your mill from the daily grind,Innovative Cement Solutions Welding Alloys2020年2月1日 Rather than huge expansion, most industries will focus on maximizing resources for maximum pro tability Consequently, a study of the impact of operational parameters on ball mill energy e ciency Energy and exergy analyses for a cement ball mill of a new

R)8OC`6F[ZIB.jpg)

Cement Manufacturing Equipment for Sale AGICO

Home; About Menu Toggle Project Cases; Solutions Menu Toggle Factory Scales Menu Toggle Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; Cement Types Menu Toggle OPC Ball race mill (Petersmill of the Claudius Peters Joint Stock Company, Hamburg, Germany) The cement industry employs the Petersmill (pre viously called FullerPetersmill) mostly for coal grinding It is a few years now that the shockproof Roller mills INFINITY FOR CEMENT EQUIPMENTThe installation made at a Turkish plant has provided more than a year’s experience of operation in cement grinding and has shown specific energy consumption of 2007 kWh/t with mill output of 147 tph of cement, 17% lower Everything you need to know about cement Materials 2024年8月22日 The cost of investing in a concrete batching plant depends on the scale, ranging from $100,000 to $2,000,000 (about 700,000 to 15 million yuan) for smallscale to largescale concrete mixing plantsequipment Archives AGICO Cement Plant

.jpg)

Cement mill Wikiwand

A 10 MW cement mill, output 270 tonnes per hour Early hydraulic cements, such as those of James Parker, James Frost and Joseph Aspdin were relatively soft and readily ground by the primitive technology of the day, using flat millstonesThe emergence of Portland cement in the 1840s made grinding considerably more difficult, because the clinker produced by the kiln is AGICO Cement is specialized in design and supplies equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD;Spare Part for Cement Machinery and EquipmentThe gearless drive synchronous motor accelerates the mill from standstill up to operating speed Within the range of 80 100 0/o of the nominal speed, the best power factor can be obtained The mill can for a limited time be operated at very low speeds for positioning the manholes of the mill shell; and no extra equipment is neededMill drives INFINITY FOR CEMENT EQUIPMENTAGICO Provides comprohensive equipments for Cement Production lines of different output, vibration ball mill Introduction 2ZM series of two roll vibrating ball mill is a new type of efficient grinding equipment in grinding fine and super fine powder With more than 20 years of exporting experience in concrete and cement production Cement Equipment Sale Cyclone PreheaterRotary KilnBall Mill

.jpg)

The Comprehensive Guide to Cement Plant Costs: An InDepth

6 Cement Mill The cement mill grinds the clinker to a fine powder, which is then mixed with gypsum to form cement Equipment: Ball mills, vertical roller mills Technical Specifications: Ball Mills: 1030 tons/hour capacity, 5001500 kW motor power Vertical Roller Mills: 2050 tons/hour capacity, 10003000 kW motor power Example Brands:Vertical Roller Mill Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish cement mills since their history in cement production is no more than 20 years, but they have already become the standard cement equipment in many regions and are getting more and more popular among Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill