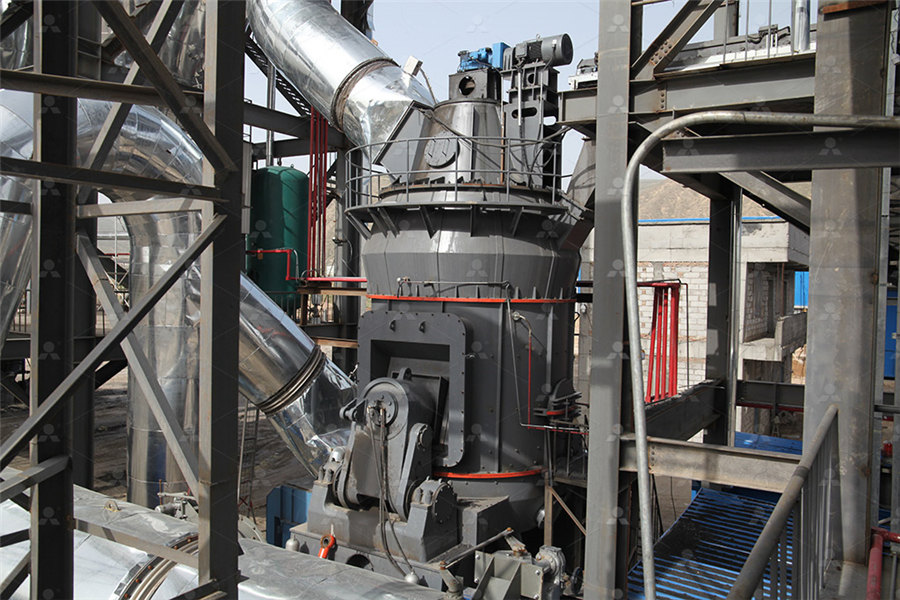

Urumqi ore mill, reliable work

.jpg)

Distribution and geological profile of northern and southern

In recent years, the rockburst induced by steeply inclined coal seam mining in the Urumqi mining area has become seriousDownload scientific diagram Profiles of the Urumqi mining area from publication: Spatial and temporal microseismic evolution before rock burst in steeply dipping thick coal seams under Profiles of the Urumqi mining area Download Scientific Diagram2014年10月15日 The goal of ore sorting is to reduce the total amount of material sent to the high energy milling circuit, while not significantly impacting total metal recovery In general, ore Development of ore sorting and its impact on mineral processing 2018年12月1日 Geometallurgy does not end with the delivery of ore to the plant Ore feed passes to the crushers, mills, and concentrator or leach pad, and ultimately smelters and Geometallurgy—A Route to More Resilient Mine Operations MDPI

Innovation in the Mining Industry: Technological Trends and a

2020年7月23日 Improving productivity to overcome natural factors such as decreasing ore grades, deeper deposits, and harder rock mass, combined with an increasing environmental 2019年8月16日 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital Future of Mining, Mineral Processing and Metal Extraction Industry 2021年10月15日 We explore challenges, opportunities, and enabling approaches to integrate renewable energy technologies into mining operations by examining the literature, including Integrating renewable energy into mining operations: Therefore, a number of chemical and physical separation processes are required to convert uranium ore into optimized nuclear fuel elements through the stages of mining, milling, MINING, MILLING, CONVERSION, AND ENRICHMENT OF

A Study on the Water Mill Industry in Urumqi During the ISCCAC

2024年7月2日 Urumqi's water mill industry mainly engaged in four types of business: incoming material processing, selfgrinding and selfsales, outsource processing, and consigned The fast growth of the Urumqi International Land Port Area in northwestern China's Xinjiang Uygur autonomous region will further enrich the Belt and Road Initiative and fuel the region's Urumqi a key hub on Belt and Road 2022年10月1日 The ball mill grindability test is used for describing ore hardness and it is so widespread that the Bond Work Index generated from the test is often referred to as an ore characteristic The ore resistance to grinding and energy consumption can be expressed using the work index and Bond’s Third TheoryA new methodology to obtain a corrected Bond ball mill work 2021年9月8日 The Bond Work Test was run in duplicate on each mill for each material The Bond Work Indices from Dr Usman’s material were calculated to be, 1339 kWh/mt and 1487 kWh/mt for the BICO and A Statistical Comparison of Bond Ball Mill

.jpg)

Monitoring ore loss and dilution for minetomill

Despite the interest in investigating minetomill integration at individual gold mines (Bamber, 2008, p 5; Grundstrom et al, 2001), information on ore loss and dilution is relatively scarce as few reliable works have been documented that 2016年3月21日 where R represents the ratio: % Pb in crude ore/% Cu in crude ore Formula (32) is very convenient for milling calculations on ores of this type Example: An ore contains 5% lead and 1% copper The ratio of perfect concentration for a concentrate of maximum grade and 100% recoveries of lead and copper would be:Common Basic Formulas for Mineral Processing CalculationsThe Ore Sawmill is a Reborntier utility upgrader added in the Reincarnation Update It was first revealed in a screenshot on Foxy's Twitter The Ore Sawmill has a unique hybrid function that duplicates ore, but also halves both their value and size Ores may be duplicated again with the Ore Replicator The description is a parody of a nowinfamous infomercial for Flex Tape, a Ore Sawmill The Miner's Haven Wikiaimperfect and ore hardness can vary with size, grindability tests are designed to best represent the size reduction of the industrial equipment analysed For that reason, it is preferable to design a primary ball mill from a rod mill work index rather than a ball mill index, because the industrial mill will operate over a coarser size reductionSAG Mill Testing Test Procedures to Characterize Ore

.jpg)

What Ore Testing is Required For Mill Selection

2015年4月15日 If 50 mm x 75 mm (2″ x 3″) ore lumps are available an impact crushing Work Index test If 30 mm x 20 mm (11/4″ x 3/4″) ore is available an abrasion index test For regrind ball milling or ball milling of rougher concentrates produced in the grinding circuit run ball mill grindability tests as outlined in B abovegeous for being based on the Bond work indexes that are determinable in any wellfitted ore pretreatment laboratory (it is UDC 622732 O I SKARIN (RIVS Science and Production Association) N O TIKHONOV (JV “IVS”) CALCULATION OF THE REQUIRED SEMIAUTOGENOUS MILL POWER BASED ON THE BOND WORK INDEXES O I SKARIN, CALCULATION OF THE REQUIRED SEMIAUTOGENOUS MILL 2005年8月5日 mill, such as the Denver lab ball mill, to determine work index The experimental tests were carried out with samples picked up in the plant, from different ores but similar chemical propertiesDetermination of work index in a common laboratory millUnlike more traditional ringgeared mill drives – where a ringshaped gear encircles the mill and drives it through one or two pinions followed by conventional motors – GMDs work by mounting rotor poles directly to the mill Making remote mines and low ore grades economical

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

2019年4月16日 This paper will highlight key benchmarks of mineralogical work from ore characterization to advanced process mineralogy including the increasing importance of mineralogical mine site laboratories2018年12月1日 Geometallurgy is an important addition to any evaluation project or mining operation As an integrated approach, it establishes 3D models which enable the optimisation of net present value and effective orebody Geometallurgy—A Route to More Resilient Mine 2019年3月1日 Kansanshi mine, located in northwestern Zambia, uses conventional openpit mining to produce primarily copper, with gold as a byproduct The ore is extracted from a deposit with highly complex (PDF) Application of geometallurgical modelling to mine planning 2021年3月23日 Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational massesEnergy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

(PDF) i) Direct Reduced Iron: Production ResearchGate

2016年3月30日 In book: Encyclopedia of Iron, Steel, and Their Alloys (pppp 10821108) Chapter: i) Direct Reduced Iron: Production; Publisher: CRC Press, Taylor and Francis Group, New York2001年1月1日 Mine monitoring and reconciliation must take a multidisciplinary approach across geology, mining engineering, operations, survey and metallurgy to deliver benefits throughout the mining value A strategy to minimise ore grade reconciliation problems between the 2015年6月19日 This Table of Ball Mill Bond Work Index of Minerals is a summary as tested on 'around the world sample' You can find the SG of each mineral samples on the 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Table of Bond Work Index by Table of Bond Work Index by Minerals 911MetallurgistChe ora è a Urumqi in questo momento? Su questo sito web è possibile trovare l'ora e la data attuali in qualsiasi Paese e città del mondo È inoltre possibile visualizzare la differenza di orario tra la propria posizione e quella di un'altra cittàOra esatta Urumqi, Cina SvegliaOnline

v116n2a6 Monitoring ore loss and dilution for minetomill

more tonnage to the mill in mining operations has resulted in loss of focus in this area There is a need to close this gap The primary objective of this study was to understand how ore loss and dilution affect the MCF and to subsequently improve the quality of ore mined and fed to the mill On the basis of this objective, the basic research 2024年11月9日 Ora legale: Urumqi, Cina al momento non osserva l'ora legale; Settimana del calendario: La settimana del calendario per oggi, Sabato, 09 Novembre 2024, è la settimana del calendario 45Ci sono 52 settimane nell'anno 2024Sono rimaste 7 settimane prima della fine dell'anno 2024; Numero del giorno: Oggi Sabato, 09 Novembre 2024 è il giorno 314 dell'anno Ora esatta a Urumqi, Cina2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common Ball Mill Is Indispensable For Lithium Ore Processing2015年7月29日 The single most common reason for an increase or drop in the production of fines is the WORK INDEX of the ore If you remember, the work index of the ore is a method of measuring the degree of hardness As the ore Ore Feed Size * Work Index Hardness: Crushing

.jpg)

(PDF) Sensor‐Based Ore Sorting Technology in Mining—Past,

2019年8月29日 separation of gold ores showed that the association of gold with certain c olor features is not reliable, and equipment installed was taken out of operation [65]2012年12月1日 A mineral processing plant with three semiautogenous (SAG) mills, 97m in diameter and 4m in width, produces iron concentrates using Chadormalo ore Each SAG mill has about 400t/h capacity which (PDF) A Methodology to Estimate Ores Work Index Values, 2005年9月19日 Reconciliation at large iron ore operations is a complex and timeconsuming process Often the volume of data and the large range of different stakeholders makes the process almost impossibleIron Ore Mine Reconciliation—A Case Study From Sishen Iron Ore 2017年1月1日 The Bond work index is a measure of ore resistance to crushing and grinding and is determined using the Bond grindability test Its value constitutes ore characteristic and is used for industrial A quick method for bond work index approximate value determination

.jpg)

Mining 101: The mill (from ore to finished product)

2023年11月5日 Mining 101: The mill (from ore to finished product) Last updated: 14:30 05 Nov 2023 GMT, First published: 14:24 05 Nov 2023 GMT In the heart of the mining industry, the mill is where the alchemy Consolidated Virginia Mill and Hoisting Works, Virginia City, Nevada 1876 There are many different techniques to process the vast variety of ores that came out of western mines, It is almost impossible to describe, let alone do justice to, the variety of processes that have been used to mill oreWinning the Metal: Ore Mills of the West Western Mining History2013年4月1日 A simple and novel nonlinear model of a runofmine ore grinding mill circuit, developed for process control and estimation purposes, is validatedAnalysis and validation of a runofmine ore grinding mill circuit 2016年1月1日 For the past 100 years, the key element in the processing of gold ore has been the cyanidation processOver the years, steady improvements have occurred in equipment design; milling has evolved from stamp mills, through tube mills and ball mills to the large semiautogenous grinding (SAG) and fully autogenous grinding (FAG) circuits in modern gold Metallurgical Test Work: Gold Processing Options, Physical Ore

.jpg)

SCALEUP OF TOWER MILL PERFORMANCE USING MODELLING

Fine Particle Breakage Characterisation Single particle breakage tests are often used to study breakage properties of materials (Schönert, 1979; Whiten, 1987)2013年7月15日 What is the Bond Work Index FormulaEquation? In case you had forgotten, here is a classic: You can read all the details of this now “Biblical” grinding power requirement calculation formula in Fred Bond’s original paper Bond Work Index FormulaEquation 911Metallurgist2022年1月1日 Ore that is less than 40 mm but greater than 8 mm is conveyed to the lump stockpile Ore that is finer than 8 mm, but greater than 1 mm is conveyed to the fines stockpile Any ore that is finer than 1 mm in size is conveyed to a desanding plant consisting of cyclones, upper current classifiers and two stages of spirals for further minution and classification technologies of iron ore2008年1月1日 Predicting the Overall Specific Energy Requirements of AG/SAG, Ball Mill and HPGR Circuits on the Basis of SmallScale Laboratory Ore Characterisation Tests January 2008 Conference: Proc Procemin (PDF) Predicting the Overall Specific Energy ResearchGate

.jpg)

Reliable equipment for iron ore mines FLSmidth

For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, digitalization and use of the latest technology in everything from bulk materials handling stockyard machines to crushers, screens and samplers give you the highest throughput with less manpowerThe chromite ore, mill scale, and petroleum coke were dried in an oven at around 473K for 24h Then the materials were ground by a ball mill into various particle sizes (chromite ore: D 80¼147mm Direct Alloying Steel with Chromium by Briquettes Made from 3 天之前 Non c’è l’ora legale al momento Ora legale 2024 Non noto l’adeguamento all’ora legale per quest’anno Aeroporti Aeroporto IATA ICAO Distanza da Ürümqi; Urumqi Diwopu International Airport: URC: ZWWW: 15 km Ürümqi orologio per il tuo sito Online orologio html Orologio Ürümqi ora esatta, fuso orario, differenza oraria, Download scientific diagram Classification of common materials according to work index (911 metallurgist, 2017) from publication: The effects of ore blending on comminution behaviour and product Classification of common materials according to work index

MAGNITOGORSK IRON STEEL WORKS AnnualReports

2015 Mill 5000 set a new output record for finished products – 953,300 tonnes This is the most outstanding achievement of the past five years In July 2015 Mill 5000 surpassed the production milestone of 5 million tonnes of finished metal products Today the products of