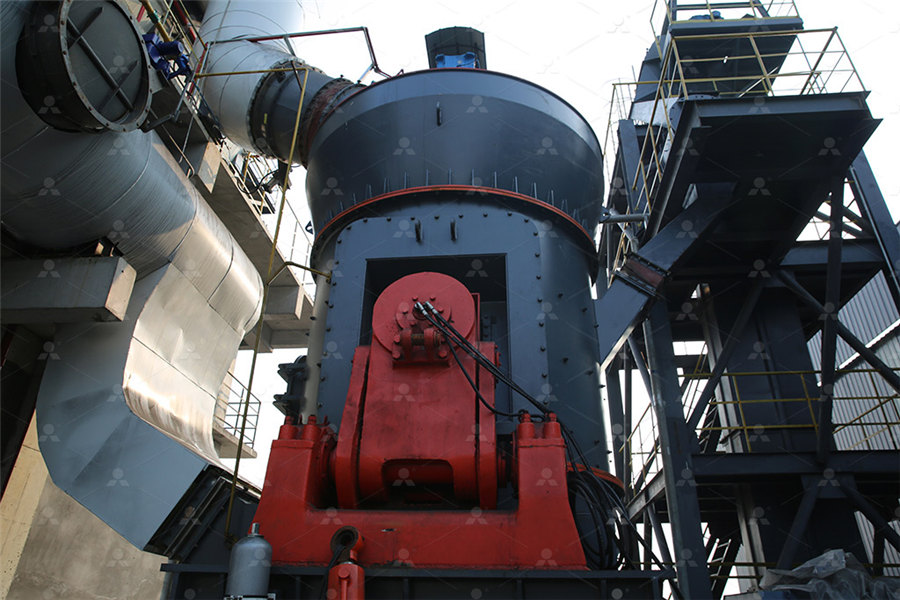

Plan design of environmentally friendly powder making equipment for vanadium plant

.jpg)

industrial powder processing plants and the relevance of design

2024年2月10日 The process design phase examines the specific requirements of a powder processing plant It meticulously selects equipment tailored to the characteristics of the 2023年5月1日 To ensure energy conservation and emission reduction, a quantitative evaluation of V 2 O 5 production from environmental and economic perspectives is crucial for process Life cycle assessment on the vanadium production process: A multi The recovery of metals from byproducts in an environmentally friendly manner is very important for Europe The EU commission has defined vanadium as a critical raw material for the union Sweco Finland assigned to plan Europe´s first production plant 2021年3月7日 In this review, the production of vanadium using primary resources including vanadium titanomagnetite, vanadium slag, vanadium bearing stone coal, and carnotite has Review of Vanadium Production Part I: Primary Resources

Ecofriendly synthesis of vanadium metalorganic frameworks

2022年12月1日 Herein, an ecofriendly strategy is demonstrated to extract toxic vanadium from gasification waste to synthesize various vanadium oxides, which are the essential precursors 2020年7月15日 In this context, the current paper comprehensively addresses the sustainability of vanadium, taking into account the modern stateoftheart, complementing and expanding Vanadium sustainability in the context of innovative recycling and Research on machining vanadium parts has been divided into investigating the properties of vanadium itself and its machining properties Furthermore, the research focused on machining DESIGN AND OPTIMIZATION OF PRODUCTION TECHNOLOGY OF GfE develops and produces highpurity vanadium products such as vanadium oxide (eg vanadium pentoxide) and solutions containing vanadium (eg sodium vanadate solution) for a GfE: Highpurity vanadium chemicals from residues

.jpg)

TOWARDS A GREENER AND MORE SUSTAINABLE VANADIUM

Vanadium can be sustainably recycled from vanadiumcontaining products and vanadiumcontaining steel and steel scrap It can also be recovered from electrolytes used in vanadium 2021年8月1日 Process design engineers and process safety engineers can use the methodology developed in this study to design energyefficient, economically feasible, and environmentally safe chemical process Process Design for Energy efficient, Economically feasible 2021年1月1日 Request PDF Environmentally friendly plant essential oil: Liquid gold for human health Plant essential oil (PEO) is extracted from various parts of plants PEO contains various bioactive Environmentally friendly plant essential oil: Liquid gold for 2018年8月1日 Vanadium is widely used in various industries The prospects for its consumption in the world are considered The relevance of vanadium obtaining from various vanadiumcontaining materials in (PDF) A review of processing technologies for

.jpg)

Novel Environmentally Friendly Leaching Process for Vanadium

2022年2月2日 Cueva Sola AB, Parhi PK, Lee JY, Kang HN, Jyothi RK (2020) Environmentally friendly approach to recover vanadium and tungsten from spent SCR catalyst leach liquors using Aliquat 336 RSC Adv 10(34):19736–19746 Google Scholar Forzatti P (2001) Present status and perspectives in deNOx SCR catalysis2021年6月10日 PDF This technical report presents the conceptual design of a plant that is required to produce 50,000 tonnes of pharmaceuticalgrade starch per annum Find, read and cite all the research (PDF) DESIGN OF A PLANT TO PRODUCE 50,000 TONNES PER 2024年8月30日 4 Detergent Powder Manufacturing Machine Cost of Plant The basic detergent powder manufacturing types of equipment needed are listed below: Reactors; Neutraliser; Pulveriser; Blender; Weighing scale etc The approximate cost to establish a detergent plant is Rs 5 – 10 Lacs on a small scale and Rs 30 lacs to Rs 50 Lacs on a Detergent Powder Manufacturing Business Project Plan GuideAdvantages Of Banana Powder Manufacturing Plant This set of equipment is specially designed for banana powder processing, which can meet the mass production of banana powder The banana powder production line is continuous and smooth and supports customization The banana powder produced is of good quality and can maintain the original color wellBanana Powder Manufacturing Plant Commercial

.jpg)

Design for environment: a stateoftheart review

2010年9月17日 Traditional process design concentrates on process simulation and profitability However, for design for environment one has to extend the simulation framework to include chemical and process synthesis steps and multiple objectives for environmental and societal impacts This article describes the developments in process design for environmental 2019年2月16日 Roasting of Pellets The stone coal powder was mixed with Fe 2 O 3 and carbon powders by using a planetary ball milling The molar ratio of Fe 2 O 3 to carbon powder was unity The content of Fe 2 O 3 relative to the stone coal changed from 50, 80, up to 10% in different experimental runs The mixed powder was pelletized, the diameter of the pellets was A Novel Approach for Preconcentrating Vanadium from Stone Coal2022年2月2日 Request PDF Novel Environmentally Friendly Leaching Process for Vanadium and Tungsten Recovery from Spent SCR Catalyst Selective catalytic reduction (SCR) is the best technology to reduce the Novel Environmentally Friendly Leaching Process for Vanadium 2024年4月22日 Project Highlights Living Room with Fireplace: The design’s boldness comes from removing the walls around the existing, which greatly expanded the kitchen and elevated it to the heart of the home Living Room How to Design an EcoFriendly Home: Top 7

.jpg)

Evolutionary multicriteria optimization aspects for sulfuric acid

2021年3月29日 Acid and greenhouse gaseous emissions as well as the physical exergy are massive challenges associated with sulfuric acid plants Minimizing these critical problems along with maximizing the economic efficiency of the plant is of important concern A selected plant was simulated with Aspen Plus and used for this multiobjective optimization (MOO) study MOO 2021年10月15日 The Design of a Tomato Powder Processing Plant with a Capacity of 75,000 Tonnes Per Annum in Oyo State, Nigeria, West Africa October 2021 European Journal of Engineering and Formal Sciences 4(2):46The Design of a Tomato Powder Processing Plant 2020年11月16日 A considerable amount (more than tens of millions of tons) of slag has been collected as discarded waste in the landfilled site of steelmaking company Recovery of valuable metals and materials to the recycling of slag could be an urgent decision for solving this problem To turn into usable products, slag leaching by hydrochloric acid reduces the slag weight by up An innovative method for recycling vanadium and valuable materials from 2024年3月11日 Business Plan: Develop a comprehensive business plan outlining your goals, strategies, and financial projections Include details about your factory's production capacity, machinery requirements, staffing needs, and marketing strategies A wellstructured business plan will serve as a roadmap for your banana powder venture Raw Material Sourcing:Banana Powder Business Plan In Factory

Detergent Powder Plant (Dry Mixing Process) Qazi Engineering

As a leading provider of plant and machinery OEM(Original Equipment Manufacturer) and spare parts for the Soap and Detergent Industry, Qazi Engineering Private Limited understands the importance of a detergent powder plant in the cleaning industry and is committed to delivering the bestinclass solutions to our clients2024年8月30日 Potato Powder Manufacturing Plant Cost The cost of setting up a potato powder manufacturing plant in India can vary depending on various factors such as the scale of operations, location, machinery and equipment required, labour costs, regulatory expenses, and other overheads Here’s a rough estimate of the potential costs involved:Potato Powder Manufacturing Business Plan Machine, Cost2019年9月1日 Vanadium pentoxide (V2O5) is one of the important compounds of vanadium, which is mainly extracted from titanomagnetite, phosphate rocks, uraniumvanadium deposits, oil residues, and spent catalystsBlank roasting and bioleaching of stone coal for vanadium 2024年1月1日 In the wake of increasing the share of renewable energybased generation systems in the power mix and reducing the risk of global environmental harm caused by fossilbased generation systems Design and development of largescale vanadium redox

Vanadium Powder Additive Manufacturing Material

Vanadium metal has good resistance to radiation induced expansion and damage, high thermal conductivity, lower coefficient of thermal expansion, lower elastic modulus, good creep resistance, low activation characteristics under neutron irradiation conditions, and excellent hightemperature strength performance Vanadium V powder is widely used in fields such as magnetic 2020年8月7日 PDF The vanadium redox‐flow battery is a promising technology for stationary energy storage A reduction in system costs is essential for Find, read and cite all the research you need on (PDF) Preparation of Electrolyte for Vanadium Powder coating offers numerous advantages over traditional liquid painting methods, making it an attractive option for industries seeking durable and environmentally friendly finishes By investing in the right equipment and Surface Pretreatment For Powder Coating Finishing Are you ready to establish your own detergent production? Experienced guidance is crucial for a successful process Design Development Lifetime SupportDetergent Plant Equipment Build Your Own

Nanoengineering of ecofriendly silver nanoparticles using five

2021年11月11日 Silver nanoparticles characterizations Silver nanoparticles formation UV–visible analysis was employed to validate the synthesized silver NPs formation through the surface plasmon resonance (SPR)2024年9月22日 Energy Star Appliances Equipment Using energyefficient appliances and equipment is the easiest of these energyefficient home ideas to achieve As a minimum requirement, use Energy Starrated appliances Your kitchen appliances can use a lot of energy, so look out for those Energy Star labels LED Lighting For Energy Efficient Home Design21 Sustainable House Design Ideas Fontan ArchitecturePLE is a rapid, clean, and environmentally friendly technique for determination of bioactive compounds in plant matrix For this extraction technique, there are commercial systems, and with these kinds of equipment, the extractions can be programmed and automatically run, which is convenient for quality controlEnvironmentally Friendly Methods for Flavonoid Extraction from Plant 2010年4月1日 We have demonstrated an environmentally friendly and efficient route for the reduction of graphene oxide by aluminum powder in only 30 min The highly reduced graphene oxide had been confirmed by X An environmentally friendly and efficient route for the reduction

Powder Coating Conveyor Systems Powder Coating Equipment

Powder coating offers numerous advantages over traditional liquid painting methods, making it an attractive option for industries seeking durable and environmentally friendly finishes By investing in the right equipment and understanding the intricacies of powder coating processes, businesses can enhance their production capabilities and meet the growing demand for highquality 2022年7月21日 By considering wellknown models of the engineering design process, the work focuses on the early design stages that precede the embodiment design of the whole components of the plant,The followed design approach allowed to preliminarily evaluate different alternatives of the process from a functional point of view, thus allowing to identify the preferred conceptual Conceptual design of a small production plant for ecofriendly 2019年5月1日 During the traditional metallurgical process of vanadium (V), an ammonium salt is often employed as the precipitator to form an ammonium vanadate, which converted into V 2 O 5 in the subsequent calcination Due to the restriction of ammonia emissions by the Chinese government, the vanadiumbearing shale industry in China urgently needs to find out a new An environmentally friendly hydrothermal method of vanadium 2020年5月26日 Environmentally friendly approach to recover vanadium and tungsten from spent SCR catalyst leach liquors using Aliquat 336 May 2020 RSC Advances 10(34):1973619746(PDF) Environmentally friendly approach to recover

A critical review on extraction and refining of vanadium metal

2021年12月1日 The total output of vanadium in the world in 2019 was 102,365 tons, surpassing 100,000 tons for the first time [13]However, it is considered a rare element because it is very scattered [14]According to the latest statistics from the US Geological Survey at the end of 2019, the global reserves of vanadium metal were approximately 63 million tons, and concentrated in 2020年9月1日 1 Introduction Vanadium and molybdenum, which has the reputation of “strategic metal” and is active in highend technologies such as aerospace and rockets, respectively, are irreplaceable for their unique properties of high strength, corrosion resistance and abrasion resistance [[1], [2], [3]]Especially in terms of catalysts, containing of A clean and efficient method for separation of vanadium and 2003年1月1日 PDF The IGPC Engineering Department designed basic projects for powder detergent production plant, using technology developed in the IGPC Find, read and cite all the research you need on (PDF) Powder detergents production plant ResearchGate2022年1月1日 Agriculture sector contributes towards one third share in global gross domestic products However, with the increasing trend in human population, world's population has been estimated to rise upto 95 billion by 2050, leading to high food demand (Green et al, 2005; Gerland et al, 2014)Besides availability of limited fertile land, urbanisation, unexpected Biofertilizers: An ecofriendly technology for nutrient recycling

.jpg)

Powder Manufacturing Equipment Making

Powder Manufacturing Equipment Find innovative production technology for making powder and connect directly with worldleading specialists Manual cosmetic powder press The design, manufacture and testing of new cosmetic powder products require a smallscale pressi 2019年8月1日 To develop a method for recovering titanium (Ti), tungsten (W), and vanadium (V) from a spent selective catalytic reduction (SCR) catalyst, leaching of the catalyst after alkaline melting was Leaching of spent selective catalytic reduction catalyst using alkaline Processing flowsheet utilises conventional equipment at atmospheric pressure mild temperatures and nonexotic materials in construction The recovery of metals from byproducts in an environmentally friendly manner is very important for Europe The EU commission has defined vanadium as a critical raw material for the unionSweco Finland assigned to plan Europe´s first production plant 2023年7月30日 Research on energy storage technology is a vital part of realizing the dualcarbon strategy at this stage Aqueous zincion batteries (AZIBs) are favorable competitors in various energy storage devices due to their high energy density, reassuring intrinsic safety, and unique cost advantages The design of cathode materials is crucial for the largescale Review of vanadiumbased oxide cathodes as aqueous zincion

.jpg)

A review of mechanism and technology of vanadium extraction

2024年7月17日 Black shale represents a unique and strategic vanadium resource in China, accounting for ~ 90% of the nation’s vanadium reserves The complex forms of occurrence of vanadium in black shale, particularly its incorporation into aluminosilicate mica via isomorphism, render it tightly bound and challenging to extract Against the backdrop of green metallurgy