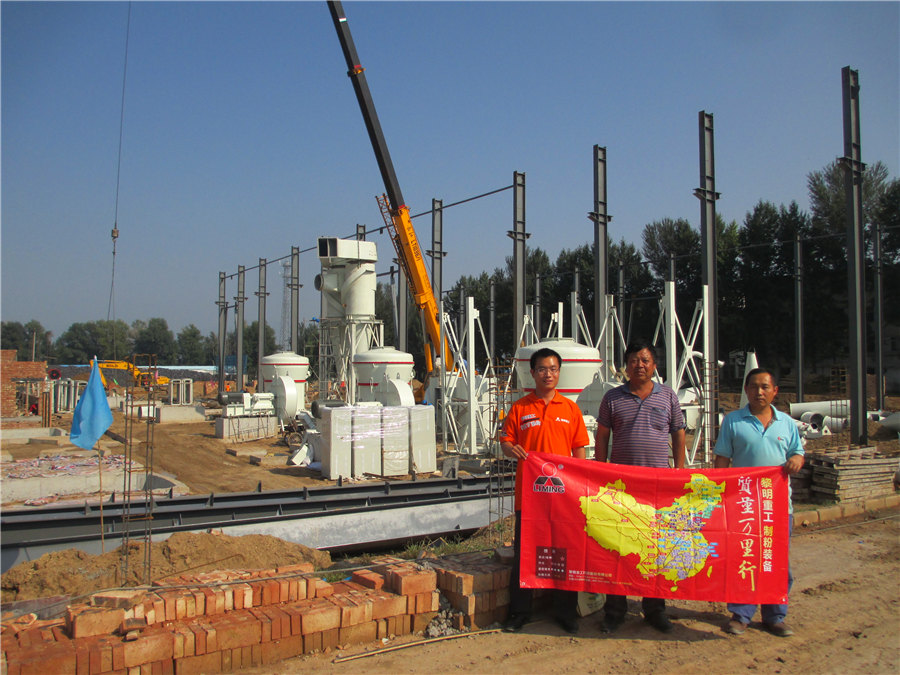

General production line of 90T heavy calcium powder per hour

.jpg)

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production The project aims to process raw materials into 200 mesh calcium powder that meets the market demand through advanced production technology and equipment, providing stable and Rugao calcium powder production line建冶重工机械官网2024年7月10日 The ball mill + classifier production line is mainly used to produce heavy calcium carbonate fine powder and ultrafine powder with d97=5~43μm It is characterized by Heavy calcium carbonate grinding, surface modification A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are Customize Suitable Calcium Carbonate Plant DASWELL

.jpg)

Ball Mill and Air Classifier Production Line ALPA Powder

A heavy calcium carbonate ball milling and grading + modification production line in a mineral factory in SerbiaPERFECT TOP CUT LIMITATION OF COATED AND UNCOATED GCC THROUGH INTEGRATED HIGH PERFORMANCE CLASSIFIER Pure filler or highquality additive? The CALCIUM CARBONATE (GCC) Hosokawa AlpineFineness: 38180 μm Output: 390 t/h Advantages and features: it has stable and reliable operation, patented technology, large processing capacity, high classification efficiency, long Calcium Carbonate Powder ProcessingBall mills are often combined with classifiers to form a complete production line, mainly producing D97, 5 to 45μm ground calcium carbonate fine powder and ultrafine powder Different models How to Choose a Calcium Carbonate Grinding Mill DASWELL

.jpg)

Calcium carbonate production line EPIC Powder

A calcium carbonate production line is vital for making calcium carbonate It’s a widely used industrial mineral This production line typically includes key components They are crushers, A heavy calcium carbonate ball milling and grading + modification production line in a mineral factory in Serbia a company produces 145 tons per hour of particle size D95:800 mesh quartz ball milling and grading production line Ball Mill and Air Classifier Production Line ALPA Calcium Hydroxide Production Line Calcium Hydroxide The high application of heavy calcium powder in the market mainly includes 325 mesh, 400 mesh coarse powder, 800 mesh micro powder, 1250 mesh have set up offices and Calcium Carbonate Powder Processing2023年12月11日 It has a higher density than light calcium carbonate due to its larger particle size and higher purity Heavy calcium carbonate particles typically range from 5 to 20 microns Heavy Calcium Carbonate Production Process: The Difference Between Heavy Calcium Carbonate

Effect of industrialgrade heavy calcium carbonate powder on

2023年5月16日 In order to reduce costs and improve whiteness, industrialgrade heavy calcium carbonate powder (IHCP) is used in white highstrength concrete (WHSC), the influence of IHCP on the workability, whiteness, mechanical properties, chloride ion impermeability, carbonation resistance and shrinkage properties of WHSC is systematically studied, and then the related Surface treated heavy calcium carbonate for general purpose for special use; fine powder ultrafine powder high brightness; FP300 KS500 KS800 KS1000 KS1200 KS1300 KristoneSS paper・paint・rubber・synthetic resin・adhesive・road white line・tooth paste・feed・agrichemicals・fertilizer・neutralizer: PDF DownloadHeavy calcium carbonate|Products|CALFINEA calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are available Grinder or grinding mill is the core equipment for calcium carbonate grinding plant, which can largely determine the fineness of the end productCustomize Suitable Calcium Carbonate Plant DASWELL2021年8月24日 Among them, the use of 25006500 mesh heavy calcium powder in highend papermaking has also increased Production of heavy calcium carbonate The raw materials are carbonate minerals such as shells, calcite, marble, limestone, chalk and dolomite Common heavy calcium processing methods include dry, wet, and drywet process combination methodsProduction and modification process of heavy calcium carbonate

[GYQ0R)ZQ]ESS4NJ.jpg)

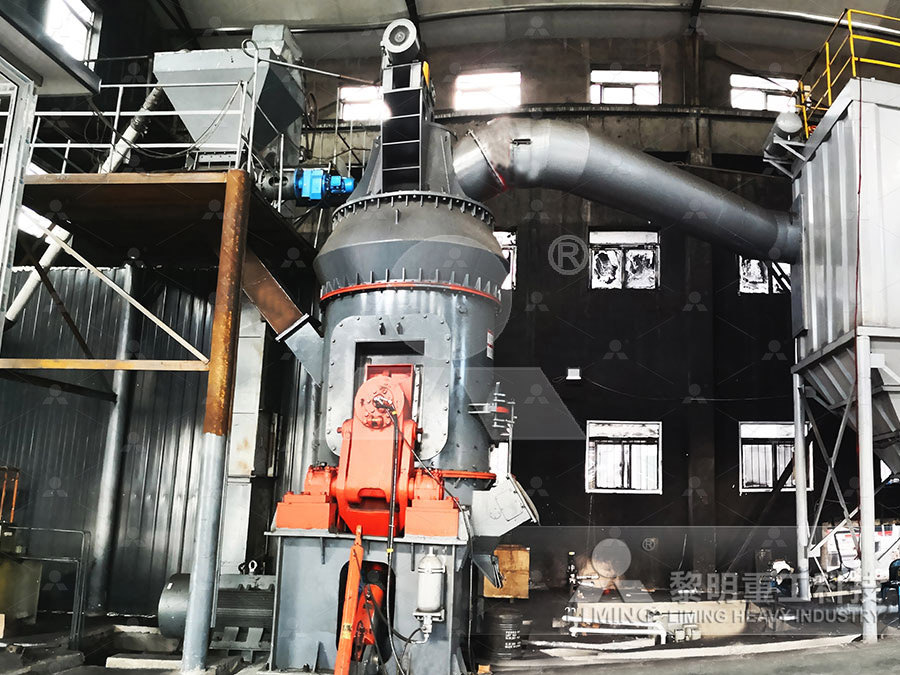

News Calcium powder processing machinery and equipment

Papermaking coating grade ultrafine heavy calcium carbonate slurry with d97≤5μm, especially d90≤2μm, is generally produced by wet method, and the main equipment is a stirring mill and a sand mill The ball mill + classifier production line is mainly used to produce heavy calcium carbonate fine powder and ultrafine powder with d97=5~43μmThe heavy calcium powder air classifier production line is a complete set of equipment used to produce heavy calcium powder It consists of a crusher, a feeder, an air classifier, a dust collector, and other auxiliary equipment This production line is suitable for processing various nonflammable and explosive mineral materials with Mohs hardness below 7 and humidity below 6%D97: 10μm heavy calcium powder air classifier production line2020年7月30日 In this study, to determine the calcium carbonate availability in eggshells waste and factors those affect its extraction The parameters like temperature, the size of the eggshell powder and the (PDF) Calcium Carbonate Synthesis, Optimization and Characterization 2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more Calcium Carbonate Grinding Mill Powder Modify

Significantly improved sintering shrinkage of heavy calcium

2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of 2022年9月13日 The calcium treatments were lime application (A0) at 500 kg ha⁻¹ and four rates of eggshell powder application including A1 (200 kg ha⁻¹), A2 (300 kg ha⁻¹), A3 (400 kg ha⁻¹), and A4 (PDF) Eggshell powder as calcium source on growth 2023年11月13日 Ultrafine grinding mill production line process flow The loader transports the crushed ore with a particle size of less than 500 mm to the firstlevel vibrating feeder, and intelligently adjusts the feeding speed through the variable frequency motor to ensure that large pieces of ore are transported smoothly and evenly to the secondlevel vibrating feederChina Hubei heavy calcium carbonate HGM100P ultrafine 2020年10月1日 Steelmaking is an energyintensive process that consumes ca 19 GJ (considered in the Blast Furnace (BF) – Basic Oxygen Furnace (BOF) processes) and emits ca 19 t of CO 2 per tonne of crude steel [7, 8]These figures situate the steel industry among the largest contributors of CO 2 emissions Yet, the world production of crude steel is predicted to Production of calcium carbonate with different morphology by

.jpg)

Precipitated Calcium carbonate production, synthesis and properties

2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on There are many kinds of grinding and processing equipment for heavy calcium in China Generally, they can achieve the effect of ultrafine production by combining with ultrafine classifier to form an ultrafine processing system However, which production process and equipment is more reasonable needs to objectively evaluate various processes and equipment How To Select The Dry Process Production Line For Heavy Calcium 2024年5月28日 The highproductivity gypsum powder production line achieves largescale, efficient, and stable gypsum powder production by using highefficiency equipment and optimized production processes This production line not only has the characteristics of high efficiency, stability, and flexibility but also can reduce production costs and meet market demandGypsum Powder Production Line in High Productivity2021年8月1日 Recent publication on the powder processing of green mussel shells by calcination at a high temperature (800900 • C) provided pure portlandite [Ca(OH) 2 ] and subsequent PCC powder after The potential use of green mussel (Perna Viridis) shells for

.jpg)

Calcium Carbonate Powder Production Line Manufacturer

EPIC Powder Machinery is a highquality calcium carbonate production line manufacturer in China with more EPIC Powder Machinery is a highquality calcium carbonate production line manufacturer in China with more than 20 years Please fill in the form belowOur experts will contact you within 6 hours to discuss your needs for machine LUTON offers dry mix mortar plant and small production line for manufacturing premixed mortars in large and small projects Perfect solution Heavy calcium 325 mesh (0044mm) 69: Good disparity: Cement or calcium powder: 50: Dry Mix Mortar Plant Small Dry Mix Production In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, calcite and other raw materials The calcium carbonate production line is mainly composed of crushers, screw conveyors, How to Choose a Calcium Carbonate Grinding MillThe ultrafine grinding of heavy calcium powder is essential to improve its application range and performance 1 Introduction Heavy calcium powder, also known as calcium carbonate, is a commonly used filling material in the industries of plastics, rubber, paper, paint, and pharmaceuticals The particle size of heavy calcium powder directly UltraFine grinding processing method and flow of heavy calcium powder

Heavy calcium carbonate grinding, surface modification

2024年7月10日 At present, the production technology of heavy calcium carbonate is mainly based on grinding and surface modification, in order to process products that meet the fineness requirements of different application fields, including fine powder, ultrafine powder, surface modified (active) powder and ultrafine pulp for papermaking, etc2023年3月3日 Introduction Calcium silicates are synthetically produced from silicon dioxide and calcium oxide with various ratios and are also obtained from naturally occurring limestone and diatomaceous earth 1 Calcium silicates, waterinsoluble, whitecolored, fine powder, are widely used in the industry They can be used as a lowcost adsorbent to remove dissolved heavy Production and Characterization of Calcium Silica Aerogel Powder Provide a full set of turnkey projects, from the design of the entire production line, equipment installation and commissioning to personnel training and other technical services It also provides the design of peripheral equipment, such as crushing, cleaning, drying, transportation, storage, packaging, mineral processing and laboratory equipment;Classifying and Ball Mill Production Line Expert in highvalue Product data and parameters for Calcium Carbonate, heavy from Dr Paul Lohmann® You need more information? powder; PhEur11Ed USPNF NF 202 E 170 FCC 13 food supplement We warrant in the frame of our General Terms and Conditions of Sale that our products are manufactured in accordance with the specificationsCalcium Carbonate, heavy Dr Paul Lohmann

Production and Characterization of Calcium Silica Aerogel Powder

2023年3月20日 In this study, mesoporous calcium silica aerogels were produced for use as an anticaking food additive in powdered foods A lowcost precursor (sodium silicate) was used, and calcium silica aerogels with superior properties were obtained with different pH values (pH 70 and pH 90) by modeling and optimizing the production process The Si/Ca molar ratio, reaction 2022年8月1日 Taking Inner Mongolia as an example, when the CaC 2 production technology developed gradually, the ECER135 per FU CaC 2 of S2, S3, and S4 is expected to decrease by 297%, 1368%, and 1780%, respectively, as compared to the base value of S1; while the ECER135 per FU CaC 2 can be dwarfed by 3399%, if a large proportion of renewable energy is Life cycle assessment and sustainable production evaluation of calcium 2024年7月12日 The production of light calcium involves complex processes such as calcination and carbonization, so the price of the same particle size is usually about 30% higher than that of heavy calcium 4 Particle morphology Heavy calcium is mainly ground, so the particle morphology is mainly cube, polyhedron, cuboid, etc;Heavy calcium and light calcium, 10 essential differencesMaterial characteristics vary widely calcium carbonate for depending on its source and production process The sieve analysis shown in the sidebar box (titled “Sieve Analysis”) the difference in particle shape, illustrates particle size and particlesize distribution for two samples of calcium carbonate the large The analysis showsConveying and feeding of calcium carbonatein plastics Coperion

.jpg)

Evaluation of di‐calcium malate, used as a novel food

2018年6月6日 The present scientific opinion deals with the evaluation of the safety of dicalcium malate (DCM) proposed as a novel food ingredient and as a source of calcium for use in foods for the general population, food D97: 10μm calcium carbonate powder production line The calcium carbonate powder production line is also known as calcium carbonate processing or grinding plant It is a production line Factories make ground calcium carbonate powder there The customer is a wellknown ore processing company based in Serbia They are seeking a new coating processCalcium carbonate production line EPIC PowderHCMilling(Guilin Hongcheng) specializes in providing a complete set of powder making process plans for the calcium powder production line, and the professional team provides general contracting services for the owners of the calcium powder project Calcium powder, also known as heavy calcium powder, is also known as heavy calcium carbonate powderNews How Much Is A Calcium Powder Grinding Mill Production Linea mineral factory, heavy calcium carbonate powder, annual output 50000T, particle size D97:815μm, 4 sets of Roller Mill Production Line The customer is a mineral enterprise in Ethiopia, want to find ultrafine processing equipment with high cost performance and good aftersales serviceEthiopia a mineral factory, heavy calcium carbonate powder,

.jpg)

Dry surface modification of heavy calcium carbonate powder

IOP Publishing2016年1月1日 Similar issues arise in milk powder manufacturing (Krokida et al, 2016;Zouaghi et al, 2019) While several LCA studies on milk powder processing have been performed (Finnegan et al, 2017 (PDF) LIFE CYCLE ASSESSMENT (LCA) ON EUROPEAN SKIMMED MILK POWDER 2023年11月8日 The HGM125L highend calcium oxide ultrafine powder grinding production line equipped with SBM micro powder technology has been put into use, Ensure 24hour uninterrupted production of the production line China Hubei heavy calcium carbonate HGM100P ultrafine grinding mill production line Hot NewsHighend calcium oxide ultrafine powder making equipment Abstract Calcium hydroxide (Ca(OH) 2), a commodity chemical, finds use in diverse industries ranging from food, to environmental remediation and constructionHowever, the current thermal process of Ca(OH) 2 production via limestone calcination is energy and CO 2intensiveHerein, we demonstrate a novel aqueousphase calcinationfree process to precipitate Ca(OH) 2 from Calcinationfree production of calcium hydroxide at sub

.jpg)

Calcium Carbonate Manufacturing Process and Equipment

2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years)