1 Which type of crusher and powder selection machine is durable

.jpg)

Selecting the right crusher for your operations Quarry

2020年3月19日 FEATURES, COMPONENTS, DURABILITY Crushing is demanding and arduous work, so machines must be durable enough to 2024年6月28日 When buying a primary crusher, consider material characteristics (hardness, moisture, and particle size), production needs, reduction ratio, durability, initial investment, and What Crusher Should You Choose for Primary Crushing?2024年7月17日 Here is an introduction to the different types of crushers used at each stage and their characteristics 1 Primary crushing equipment Primary crushing is the first stage of the stone crushing process At this stage, raw Types of Crushers: Choosing the Right One for Each Industrial crushers reduce large rocks, ore, or waste materials to smaller sizes They are the first level of size reducer; further granularization occurs in grinding mills or pulverizers Crushing Crushers Selection Guide: Types, Features, Applications GlobalSpec

Selecting the Right Crushing Equipment AggNet

2015年10月28日 Types of crushers Most crushers used for aggregate production fall into one of three main categories/types: Compressive crushers – which squeeze the material until it breaks; Impact crushers – which use the 2016年4月7日 Most crushers used for aggregate production can be categorised as one of three main types: Compression crushers – which squeeze the material until it breaks Impact crushers – which use the principle of rapid impact to Selecting the right type of crushing equipment QuarryA crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size They are particularly used in the mining industry to reduce the size of ore Choosing the Right Crusher Buying Guides A crusher is a major investment, so it’s essential to select one with the potential to meet your needs into the future This guide covers a few of the key points to consider before making a MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

.jpg)

Crushing 101 – Different types of crushers for

2020年12月17日 These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each other Horizontal shaft impact Whether the materials are friable or not will affect the type of particle size reduction equipment that’s optimal In addition to material type, the starting and final size of the milled material drives the mill selection process Contact the Size Reduction Equipment Stedman MachineThe plastic crusher is a crucial piece of equipment for the recycling industry, as it is designed to break down solid plastic waste efficiently for further processing By crushing the plastic materials into smaller pieces, they can be easily and The Complete Guide to Plastic Crusher: Essential Tips Cons – Requires finetuning and might not be as durable as other crushers Applications: Often used in the final stages of crushing and sandmaking operations Factors Influencing Crusher Selection Selecting the right crusher Comparing Different Types of Stone Crushers

.jpg)

Crusher Parts Manufacturers and Factory Wholesale Wujing Machine

A: Choosing the right crusher parts for your machine will depend on the specific application and the type of machine you are using Q: What is the most common type of jaw crusher? A: Blake Jaw Crusher: This type of jaw crusher is the most commonly used 2022年11月19日 There are two types of fine crushing equipment: impact crusher, VSI sand maker and double roller crusher 1 The impact crusher is a commonly used secondary crusher, which is generally used to crush marble stones again after the jaw crusher Using the deep cavity crushing method, the stones falling into the crushing cavity are crushed by the friction and Correct Selection Of marble Crushing Equipment Eastman Rock Crusher2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER 2018年9月10日 As a compression crusher, this type of machine generally produces the coarsest material because it breaks the rock along its natural lines of weakness Jaw crushers are an excellent primary stage solution to prepare rock for subsequent processing stages, such as washing, classifying or secondary crushingUnderstanding the Different Types of Crushers AggNet

.jpg)

Design and Development of Plastic Crusher for a More Efficient

2020年8月31日 The machine, being a medium sized crusher, has the capacity of crushing half a ton of plastic in a day depending on the type of recyclable plastic crushed Material Selection Machine Selected2019年12月10日 What is a crusher? A crusher is a machine that is designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size of materials, or change the form of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials so that pieces of different Type of crushers and their difference JXSC MiningThe cagetype powder separator of the HGM ultrafine crusher adopts German technology, which effectively improves the precision of powder selection In addition, according to the user’s requirements for output, fineness, and sieving rate, a multihead cage type powder concentrator can be configuredUltrafine Glass Powder Making Machine2020年8月25日 The machine, bein g a medium sized crusher, has the capaci ty of crushing half a ton of plastic in a day depending on the type of recyclable plastic crushed The degree of linear correlation, r Design and Development of Plastic Crusher for a More

Which Type of Crusher is Best?qindaojixie

2024年11月13日 In industrial manufacturing, the demand for efficient and reliable crushing equipment has never been higher One of the most crucial tools in this domain is the powerful crusher, which utilizes mechanical force to reduce materials into smaller particles Our article explores the working principles, core components, and applications of powerful crushers, 2023年6月30日 Adequate selection should be interpreted as the use of a specific crusher to achieve a particular task It has been found that the shape characteristics of the end product play anModeling and Improving the Efficiency of Crushing 2024年7月31日 Sandstone crushing and grinding machines can reduce large sandstone rocks into smaller particles or fine powder They include jaw crusher, impact crusher, Raymond mill, ultrafine mill, and so on +29 Determines the type of crusher and grinder Production capacity: The scale of production impacts machine selectionSandstone Crushing And Grinding Machines2023年2月28日 The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1 The secondary crusher can be a cone crusher, impact crusher, or gyratory crusher, depending on the hardness, abrasiveness, and size of the materials The cone crusher is the most common type of secondary crusher used in mining and quarrying operationsPrimary and Secondary Crushing: Understanding the Basics A

Research and Design of High Efficiency Superfine Crusher using

crusher is 3608%, which improves the efficiency by 28197% In this paper the parametric design technology is adopted in the CAD system of crusher The optimal design of the high efficiency ultrafine crusher with the combination of impact type and hammer type is carried out, which greatly improves the design efficiency and quality2022年4月12日 11, the transfer machine, crusher at the roadway support must be intact, solid Caution Test run 1, turn on the power grid switch 2、Hand press the ignition button for the test run of the machine 3, to start, idle; 4, the combined operation of the transfer machine and crusher; 5, check that there is no abnormality, send a startup signalWhat is a plastic crusher Machine? Industrial Shredders2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceCrushing in Mineral Processing 911Metallurgist2016年1月16日 In the history of crushers, both chronologically, and by virtue of its standing in the field of heavyduty crushing, the Blake jaw crusher stands first in the list All of the large, heavyduty primary crushers of the jaw type are built around the Blake principle which, for simplicity and brute strength, is unsurpassed by any mechanism thus far devised for rock and Blake Jaw Crusher 911Metallurgist

Selecting the right crusher for your operations Quarry

2020年3月19日 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)machines are always helping in the organic waste management thus to provide agricultural improvements and also for a better cleaning practices of organic waste by using lower power consumption concepts 11 Crusher: A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces CrushersDesign and Analysis of Organic Waste Crushing Machine Paper 2024年6月28日 This blog post will explore the different types of crusher rock machines, their functions, and their advantages Crusher Rock: Key Takeaways Crusher rock machines are designed to break down rocks into smaller, more Crusher Rock: Exploring the Types of Rock CrushersHandbook of Conveying and Handling of Particulate Solids G Lodewijks, A Newman, in Handbook of Powder Technology, 2001 21 The primary crusher The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour) The driving flywheel has a diameter of 25 meters and is motor driven through six v Primary Crusher an overview ScienceDirect Topics

.jpg)

1 Comparison of measures of rock crushability ResearchGate

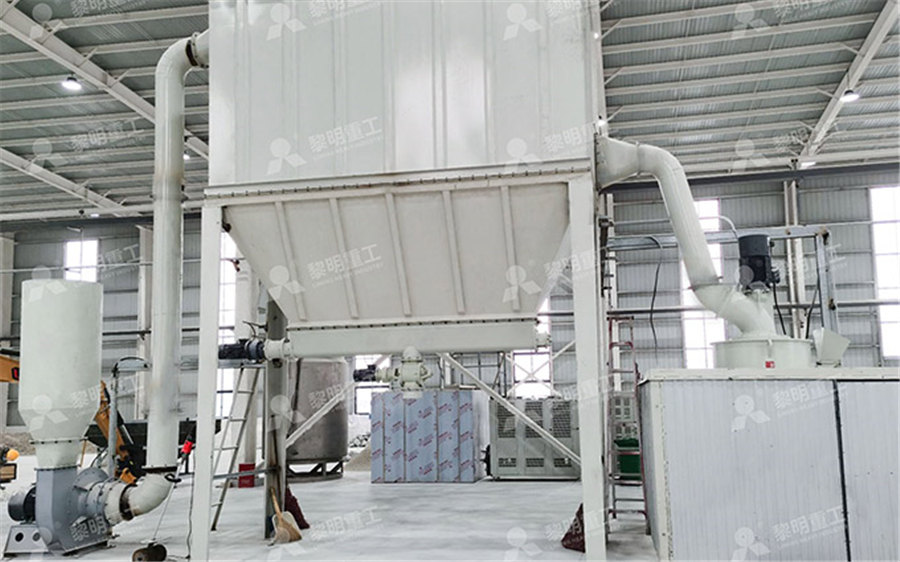

following information for each particular crusher and crushing condition of interest: 1 crusher capacity 2 crusher power consumption 3 level of stresses withstand by the machine during operation 42017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and Pulverizers2019年12月23日 The actual capacity was obtained to be 301 kg/h after the performance evaluation of the machine, and it has a 98 % material recovery rate and 7525 % machine efficiency The machine has a DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER 1 ① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill system, and it can be arranged in the open air, greatly reducing investment costsStone Powder Making Machine

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 1 Type and Hardness of Materials The type and hardness of materials are the first factors to be considered in the selection of crushing equipment Different types of materials will have different hardness and structure, which will have the primary limit on the selection of In this study, the effects of three different choke feed level (1/1, 1/2, and 1/4) and four different effective reduction ratios (25, 5, 10, and 20) depend on the capacity of the crusher of the Performance Parameters of Jaw Crushers Download Table2021年8月1日 A can crusher machine is used to crush the cans for storing in bin efficiently The crushing of cans plays a significant role in economy and ultimately helps to society(PDF) DESIGN AND FABRICATION OF A PORTABLE ELECTRICALLY PDF On Sep 20, 2020, Ekin Koken and others published COMPARISON OF SECONDARY CRUSHING OPERATIONS THROUGH CONE AND HORIZONTAL SHAFT IMPACT CRUSHERS Find, read and cite all the (PDF) COMPARISON OF SECONDARY CRUSHING

.jpg)

Five Common Questions About Roller Compaction/ Dry Granulation

physical changes that transform a powder can be described as follows: Raw material powder in the form of a single component or homogenous powder blend is fed into a roller compactor and delivered by means of a feedscrew to two counter rotating rollers for compaction The rollers will apply hydraulic pressure to the powder that comes between them2019年12月10日 Modeling and simulation is a tool to explore and increase the understanding of a phenomenon This thesis focuses on developing models of crushers and equipment used in the mining industry(PDF) Efficient Modeling and Control of CrushingSelecting a powder blender can appear to be a simple task, the importance of which is often underestimated Although there are a few common varieties that seem to work well for powders and other solids, hastily choosing any blender can result in process inefficiencies or poor product quality In a competitive market, gains in processSelecting the Appropriate Powder Blender Industrial Mixers A Review on the Technology of Size Reduction Equipment A Kumar1,3* and R Yedhu Krishnan2,3 1Department of Chemical Engineering, 2Department of Biomedical Engineering, 3Saveetha Engineering College, Thandalam, Chennai – , India Abstract : Size reduction or comminution is among the most comprehensively used unit operation of widespread International Journal of ChemTech Research

.jpg)

(PDF) Optimum design and analysis of (the) swinging jaw plate

2010年4月30日 PDF A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields The performance of jaw 1) Blake Type Jaw Crusher 2023年7月10日 Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc)Thus, its price is higher than other kinds of jaw crushers Why choose Fote jaw crusher manufacturer? The various types of jaw crushers designed by Fote are widely used in many fields including Characteristics and Comparison of Four Types of Jaw Crushers2010年10月26日 Jaw crusher selection is also heavily influenced by the subjective judgment/experience of individuals, which can result in the conservative selection and operation of jaw crushers The prediction of crusher performance is typically concerned with the size distribution of the product exiting the crusher, the machine’s power draw, and the capacityJAW CRUSHER SELECTION AND PERFORMANCE PRIDICTING2015年4月3日 Crushers and Their Types satyendra; April 3, 2015; 22 Comments ; compression, cone crusher, crusher, gyratory crusher, hammer crusher, jaw crusher, material, Ore, roller crusher,; Crushers and Their Types A crusher is a multi dimensional machine which is designed to reduce large size materials into smaller size materialsCrushers and Their Types IspatGuru

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution