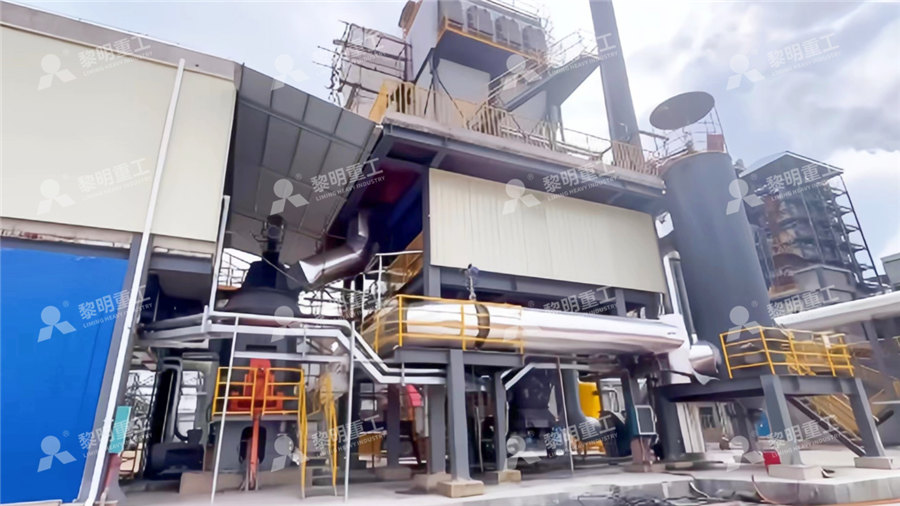

After the quicklime is calcined, the coke is ground finely with a grinding machine.

.jpg)

The Effects of Limestone Characteristics and Calcination

2001年4月1日 Test results indicate that the lower the limestone calcination temperature, the more reactive the produced quicklime The optimum calcination temperature is ∼900°C, which was the temperature2001年4月1日 Samples of limestones were calcined at four different temperatures (900°C, 1000°C, 1100°C, 1200°C) for 24 h for the production of quicklime The quicklime was The effects of limestone characteristics and calcination Quick limes calcined at 900°C show the lower reactivity values This could be related to the low calcination temperature or to the short calcination time of 30 min which was unable to produce (PDF) The effects of limestone characteristics and calcination 2018年11月12日 Results show that the CaO content has slightly increased as temperature increases indicating that the purity of sample increased FTIR shows that all samples have (PDF) Characterization of quicklime as raw material to hydrated

JeanMichel Commandre, Sylvain Salvador, Ange Nzihou To cite

Limestone is calcined to produce quicklime, and the quality of lime is closely linked to the calcination process (Potgieter et al, 2002; Seidel et al, 1980; Zhong and Bjerle, 1993) 2012年1月1日 The low total weight loss even at prolonged calcination times suggests that these samples are not as high in available CaCO 3 as expected, or that calcination resulting in The Effect of Calcination Time upon the Slaking Properties of The aim of this work is to investigate the carbonation resistance of limestone and calcined clay blended cementbased concrete Two limestone and calcined clay concretes with an average Limestone and the resulting quicklime chemical analysis after 2021年3月3日 Quicklime is obtained by calcination of calcium carbonate (CaCO 3) to less than its melting point, resulting in the dissociation of calcium carbonate into calcium oxide (CaO) Lime SpringerLink

.jpg)

The Versatile Chemical Lime

Quicklime is highly reactive with water, generating considerable heat in the hydration process This material will react with the moisture in the air, and as such, it can be used as a desiccant 2021年10月4日 Lime is a product derived from the thermal decomposition of limestone (mainly calcium carbonate, CaCO 3) into quicklime (CaO) and carbon dioxide (CO 2), also called Natural and enhanced carbonation of lime in its different ASTM C 618 classifies pumice as a Class N pozzolan, raw or calcined natural pozzolan, if it meets specific physical and chemical requirements Class N pozzolan should have a minimum of + + content of 70% As shown in the chart below all pozzolans noted fit the description of Class N with the exception of the Handelage calcined clayThe use of finely ground pumice pozzolan in GFRC composites2024年2月27日 Grinding machines play a crucial role in the processing of petroleum coke, transforming it from coarse feedstock into finely ground powder suitable for a myriad of industrial applications These machines are designed to achieve precise particle size distributions, enhance product quality, and optimize process efficiency, thus enabling industries to harness the full Petroleum Coke Grinding Machines

The History and Future Challenges of Calcined

2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively low cost This article 2019年2月16日 Calcined Petroleum CokePetroleum coke CPC of 75% passing 75#160;#181;m is typically mixed with pitchPitch to form the anodes Some paste plants have their reasons to use super fine ground dust, like 75% passing 32#160;#181;m Claudius Peters EMBallRaceMillsChanging the Fineness of Calcined Petroleum Coke with Ball Download Table Limestone and the resulting quicklime chemical analysis after calcination in a kiln from publication: Management of Lime in Steel The EU28 total lime demand in 2017 was Limestone and the resulting quicklime chemical analysis after 2022年2月28日 ① Grinding stage The calcined lime raw material is directly (or once crushed) continuously and uniformly sent to the main machine grinding chamber through the feeder after being cooled in transit, and the ground fine powder is classified by the classifier under the action of the air flow of the fan and then sent to the main machineHow to do a good job of grinding in the lime industry?

.jpg)

Effects of calcination variables on quicklime yield of Nkalagu

removed after 1 hr of holding time, thereafter other samples at the time of 2 , 3, 4 and 5 hours After heating the calcined sample, it was allowed to cool for 515minutes The calcined sample was transferred to desiccators The weight of the quicklime produced was measured The procedure was carried out at temperatures of 800, 850, 900, 9500 Calcium oxide, also known as quicklime, is an alkaline substance that has been in use since the medieval age It is believed that quicklime is one of the oldest chemicals known to the human race It can also be referred to as burnt lime or lime Table of Contents Preparation of Calcium Oxide; Structure of CaO Molecules; Lime Water FormulaCalcium Oxide (CaO) Preparation, Properties Uses of QuicklimeTurning limestone into quicklime industrially The next video shows a modern industrial plant for producing quicklime, calcium oxide It carries far more information than you need, and you really only need to concentrate on what happens in the kiln itself (starting just after 2 minutes) This is where the limestone is heated and quicklime is limestone, quicklime and slaked lime chemguideLearn the chemistry of limestone Compare its reactivity with other metal carbonates, learn the ‘lime cycle’ and the impact of limestone quarryingLimestone [GCSE Chemistry only] The limestone cycle

.jpg)

Factors influencing the reactivity of quicklime

These calcretes were selected in order to assess the characteristics of quicklime, which is calcined in traditional limekilns and most commonly used as a binder CaO C CO2 ðcalcium carbonateÞCheat ðcalcium oxideÞ Cðcarbon dioxideÞ 2 Grinding: After calcining, the coke is cooled and then ground into a fine powder The European version vertical grinding machine, also known as a vertical roller mill, is often used for this process The vertical grinding machine offers several benefits, such as high efficiency, compact design, lower energy consumption, and reduced Calcined coke powder production process European version Download scientific diagram Limestone and the resulting quicklime chemical analysis after calcination in a kiln from publication: Management of Lime in Steel The EU28 total lime demand in Limestone and the resulting quicklime chemical analysis after finelyground (100200 mesh) The smallsized and finelyground lime products are obtained from grinding mediumsized lime particles in a grinder to the desired size All products are either put into packages or transferred directly to transport vehicles that deliver them to customers, branded as ‘Rhinoceros’Business Operation

.jpg)

Calcium oxide CaO Lime Kalkfabrik Netstal AG Firma

We offer three types of quicklime, they differ in grain size: nekafin® 2 and nekasol® 2 as well as the very finely ground nekafin® 0 nekafin® 0: solutions for the chemical industry The finest type of our quicklime is used as a raw material for numerous product solutions of the chemical industryCalcium oxide (formula: Ca O), commonly known as quicklime or burnt lime, is a widely used chemical compoundIt is a white, caustic, alkaline, crystalline solid at room temperatureThe broadly used term lime connotes calciumcontaining inorganic compounds, in which carbonates, oxides, and hydroxides of calcium, silicon, magnesium, aluminium, and iron predominateCalcium oxide Wikipedia2020年7月17日 As early as 4000 BC the ancient Egyptians used quicklime, after mixing it with water, as a construction material for building pyramids Today, quicklime is a widely used chemical compound The use of lime surrounds our everyday life making the water we drink safe, the air we breathe cleaner, our steel purer and construction projects more stableWhat is Lime: Lime vs Limestone Mintek ResourcesChanging the Fineness of Calcined Petroleum Coke with Ball Race Mills JensPeter Thiel, Jan Paepcke, and Arne Hilck Abstract Calcined Petroleum Coke CPC of 75% passing 75 µmis typically mixed with pitch to form the anodes Some paste plants have their reasons to use super fine ground dust, like 75% passing 32 µm Claudius Peters EMBallChanging the Fineness of Calcined Petroleum Coke with Ball Race

Quicklime: what is it and the application, lump and ground slaked

For quicklime, belonging to the second class of hazard used in construction, there is a quality standard GOST №917977, in which the physical and chemical indicators of this material are clearly stated According to the written requirements, the lime particles after grinding should have a Quicklime is an alternate name for the chemical compound known as calcium oxide This compound is represented by the chemical formula CaO and is also known can increase the loadcarrying capabilities of claybased soils by reacting with the alumina and the silica that is finely divided in the soil to produce silicates of aluminium and Quicklime Preparation, Properties, and Applications with FAQsIt can either be crushed or ground, after which, it can be mixed with specific impurities to form composites But the most common treatment is slaking, or addition of water to the quicklime This is an exothermic reaction, which means it results in the evolution of a large quantity of heat to form calcium hydroxide or slaked limeWhat is Quicklime and How is it Made? Science Struck2023年9月13日 Quicklime is not only an important raw material for the steel and nanocalcium carbonate industries but also a key carrier for capturing carbon dioxide in the fight against global warming, and its Effect of the Textures and Particle Sizes of Limestone

THE FUNCTIONS OF QUICKLIME IN WATER

2020年12月18日 Quicklime in all its forms – quicklime and hydrated lime, as well as calcined dolomite are the most effective and cost efficient alkaline products used in the making of drinking water, as well as in the treatment of waste The quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the limestone, as well as operating conditions in the kiln such as temperature, particle size of the limestone, rate of temperature rise, retention time, and CO2 concentration Controlling these Factors Affecting The Quality of QuicklimeIn the more modern precalciner kilns, the feed is calcined prior to entering the kiln Calcining In isolation, decarbonation of calcium carbonate at 1 atmosphere takes place at 894 °C This temperature is reduced to 500 °C 600 °C if the reaction takes place in contact with quartz or the decomposition products of clay minerals, which react with the calcium oxide as it formsReactions in the cement kiln clinkering Understanding CementIn 1990, after 11 years, the compressive strength values were situated between 13 MPa and 34 MPa and therefore above the requirements in aptitude tests for quicklime soilstabilisation schemes (≥ 02 MPa after freezing and thawing) In 2013 results from lime treated layers at nearly similar depths as tested in 1990 showed signifiSoil improvement with quicklime quantification of the

.jpg)

Changing the Fineness of Calcined Petroleum Coke with

2019年1月1日 The use of a vertical mill for the grinding of anode coke is well accepted in the Aluminium industry One of the raw materials, calcined petcoke (CPC), is sourced from different parts of the world 2024年1月14日 Petroleum Coke can be used here in some applications, but others require more processing and are called “Calcined Coke” This process means transferring petroleum coke to a rotary kiln to remove the remaining volatile hydrocarbon residues The calcined petroleum coke can be further processed in an anode baking ovenPetroleum Coke: A Comprehensive Guide to Production, content () + (%) Effect of CO2 Content in Quicklime on Dissolution Rate of Quicklime 2024年4月16日 After you’ve determined what raw source of calcium carbonate you’ll be using, you need to get the right amount of rock to make your quicklime Because whatever rock you’ll be using as a material to make quicklime will not contain 100% calcium carbonate, you’ll need to acquire more rock than you’ll need for the amount of quicklime you want to make [3]How to Make Quicklime: 10 Steps (with Pictures) wikiHow

Calcined Coke – Marlin Energy Group

Calcined petroleum coke is mainly used to produce anodes used in the aluminum industry, steel making and titanium dioxide industries among other niche applications The coke calcining process is a timetemperature function The most significant use of pulverized limestone is in agriculture in a finely ground and dry form or in flue gas desulphurization in slurry form The use of lime in carbonate form is beyond the scope of this paper We will concentrate on lime as calcium oxide and calcium hydroxideAn Overview of Lime Slaking and Factors That Affect the ProcessThe UNE 36001 norm includes the following classification of steel products: Irons, steels, foundry or pigiron, ferroalloys, ferrous aggregates and special ferric alloysEspecially worth highlighting is steel, a very versatile material that Lime, an essential component in the steel industry2023年2月9日 A polishing sequence involves grinding at around 200 rpm on a 320grit silicon carbide disk exposing the CPC particles This is followed by grinding on 500, 1000, and 2000 grit silicon carbide disk at same rpm, using water both as a lubricant and a coolant as shown in Fig 1d The polishing cloth was used for fine polishing by applying 3 µm highperformance Method for Calcined Petroleum Coke Evaluation to Improve the

(PDF) The Effects of Quicklime on the Decomposition Process in a

2022年1月1日 Site Two (End Date) showing the mummified pig carcass still intact except for the ground contact surface after 39 days in La Plata County, Colorado at an elevation of 8,700 feet above sea level 2023年10月11日 What happens when quicklime is added to water Here you will explore the chemical reaction that occurs when quicklime is added to water After reading this topic you will understand the complete process of reaction when quicklime is added to water When a small amount of quicklime is added to water in a beaker, a highly exothermic reaction What happens chemically when quicklime is added to water filled Lime in the form of quicklime (calcium oxide – CaO), hydrated lime (calcium hydroxide – Ca[OH]2), or lime slurry 1 can be used to treat soils Quicklime is manufactured by chemically transforming calcium carbonate (limestone – CaCO3) into calcium oxide Hydrated lime is created when quicklime chemically reacts with waterLime Treated Soil Construction Manual Graymont2023年10月11日 Calcium carbide, the oldest source of acetylene, is formed by mixing quicklime and coke and heating to a temperature of 2000 degrees C Molten carbide is continuously removed from the furnace and, upon solidifying, is crushed and ground to the desired sizeCalcium Oxide (CaO) : Definition, Properties Uses

.jpg)

limestone, quicklime and slaked lime chemguide

Turning limestone into quicklime industrially The next video shows a modern industrial plant for producing quicklime, calcium oxide It carries far more information than you need, and you really only need to concentrate on what happens in the kiln itself (starting just after 2 minutes) This is where the limestone is heated and quicklime is 2022年3月29日 The calcined petroleum coke (or after onetime crushing) is continuously and evenly sent to the main machine grinding room for grinding through the skirt belt feeder The ground fine powder is sent to the classifier for classification under the action of fan air flow, and the fine powder with qualified fineness enters the collection stage through the air outlet pipeWhat grinding equipment is needed for petroleum coke