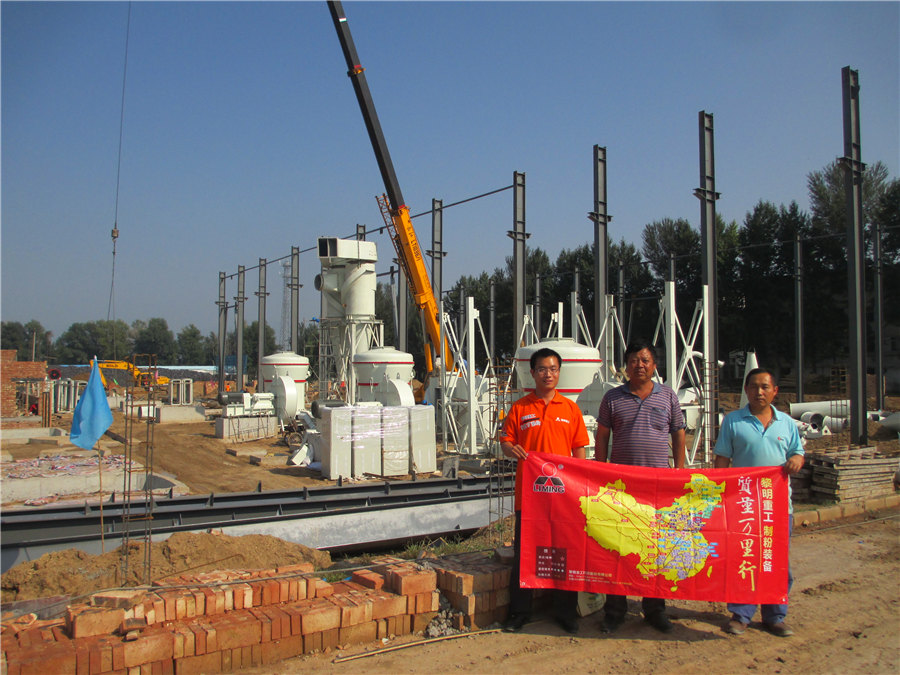

Largescale raw calcined coke grinding machine

Calcined petroleum coke grinding machine Clirik

Clirik Calcined petroleum coke powder grinding machine and Calcined petroleum coke micro powder grinder mill can grind noninflammable, nonexplosive and brittle materials with Mohs’ hardness under six Such as calcite, chalk, Petroleum coke calcining is a three step process, including drying, devolatization and densification The coke calcining process is a timetemperature function, conducted in an Petroleum Coke Calcining Systems MetsoCoke calcining systems Proven experience Metso Outotec is the world’s leading supplier of coke calcining systems and equipment, having furnished 50 plants representing approximately 70 Calcination solutions Coke calcining systemsArtificial synthetic anode material grinding shapemaking machine (1) Meet client's requirements for different fineness powder, finished powder fineness is adjustable and at stable quality (2) Longyi Calcined Coke Powder Grinding Mill

.jpg)

China Calcined Coke Grinder Manufacturer, Supplier JINGHUA

Weifang Jinghua Powder Engineering Equipment Co, Ltd offers a reliable and highperformance solution for grinding and pulverizing calcined coke particles to your desired fineness, Our We are building the most modern and largest plants in the world including our inhouse developed ROTAFAST® Coke Cooling System to produce a top quality calcined coke for the aluminum Calciner / ROTAFAST® MTP Mannesmann GmbH ROTAFASTThe main equipment for processing calcined petroleum coke is European type grinding mill and vertical millCalcined petroleum coke mill Kefid Shanghai MachineryWith over a century of experience in the mining and chemical processing industries around the world, Metso offers equipment, parts and services to supply complete coke calcining and Calcination Metso

.jpg)

Petroleum Coke Grinding Machines

2024年2月27日 Petroleum coke grinding machines encompass a variety of specialized equipment tailored to meet the unique requirements of petroleum coke processing These Energy efficient With over 80 years of successful experience in serving the minerals and chemical processing industries, Metso has the proprietary technology and knowhow to design and build Coke Calcining Systems Metso Automation PDF Catalogs2020年6月5日 Replacing a large proportion of Portland cement by calcined clays and limestone reduces the total alkali content, which may affect the hydration reactions as the reactivity of the SCM is dependent Limestone calcined clay cements (LC3): raw materialCALCINED PETROLEUM COKE [3595] Coke is a fuel with few impurities and high carbon content, usually made from coal It is the solid carbonaceous material derived from destructive distillation of lowash, lowsulphur bituminous coal Coke made from coal are grey, hard, and porous While coke cDetailed Project Report on calcined petroleum coke

.jpg)

Petroleum coke grinding mill Milling Equipment

2020年4月6日 Petroleum coke grinding mill is an largescale petroleum coke processing equipment for large production, widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore and 2023年2月9日 A polishing sequence involves grinding at around 200 rpm on a 320grit silicon carbide disk exposing the CPC particles This is followed by grinding on 500, 1000, and 2000 grit silicon carbide disk at same rpm, using water both as a lubricant and a coolant as shown in Fig 1d The polishing cloth was used for fine polishing by applying 3 µm highperformance Method for Calcined Petroleum Coke Evaluation to Improve the New developments of Anode Coke Grinding using a vertical Mill Technology, TMS 2015 3 Stefan A Gosau, Andreas Wolf; “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, Germany 4Changing the Fineness of Calcined Petroleum Coke with Ball Race Calcined Petroleum Coke(CPC) is a kind a petrochemical product, whose raw material is green petroleum coke This coke is the product of the coker unit in a crude oil refinery The combination of energy recycling with calcining therefore achieves the simultaneous benefits of CPC production and energy conservationCalcined Petroleum Coke/CPC Carburizing Machine

Green Petroleum Coke and Calcined Petroleum Coke Market

2024年11月4日 Green Petroleum Coke and Calcined Petroleum Coke Market Report Overview The global green petroleum coke and calcined petroleum coke market size was valued at USD 3055 billion in 2023 and is projected to grow from USD 3202 billion in 2024 to USD 4677 billion by 2032, exhibiting a CAGR of 48% during the forecast period2019年2月16日 Calcined Petroleum CokePetroleum coke CPC of 75% passing 75#160;#181;m is typically mixed with pitchPitch to form the anodes Some paste plants have their reasons to use super fine ground dust, like 75% passing 32#160;#181;m Claudius Peters EMBallRaceMillsChanging the Fineness of Calcined Petroleum Coke with Ball 2024年11月20日 The demand for raw materials for lithiumion battery (LIB) manufacturing is projected to increase substantially, driven by the largescale adoption of electric vehicles (EVs) To fully realize the climate benefits of EVs, the production of these materials must scale up while simultaneously reducing greenhouse gas (GHG) emissions across their supply chainDecarbonizing lithiumion battery primary raw materials supply 2023年5月25日 Semicoke is a product of lowtemperature pyrolysis by lowrank coal, with a composition similar to that of anthracite for pulverized coal injection (PCI)Impacts of Blending Semicoke in PCI Coal on Grinding Efficiency

Grinding Cement Raw Meal Powder

Stage I: Crushing of raw materials The large c ement raw meal material is crushed by the crusher to the feed fineness (15mm50mm) that can enter the grinding mill Stage II: Grinding The crushed cement raw meal small S V Ispat Private Limited is a trusted Manufacturer and Supplier of Metallurgical Coke Fines, Calcined Petroleum Coke, Raw Petroleum Coke, Raw Anthracite Coal, Calcined Anthracite Coal, Amorphous Graphite at best price in Pune, Metallurgical Coke Lumps Manufacturer, Raw Size : CP Coke derived from the Kiln is in size of 0 mm to 30 mm The same can be further supplied in any size required by the Customer Packing : In 25/50kg PP bags Or in Jumbo Bags packing as per Customer’s requirement Certification : We are an ISO 9001:2015 Certified Division Customers Profile : We specialize in supplying Calcined Petroleum Coke to Steel, Calcined Petroleum Coke Graphite India LimitedCALCINED PETROLEUM COKE (CP COKE) (30 MT/Day )[CODE NO4457] Calcined Petroleum Coke (CPC) is manufactured from Raw Petroleum Coke (RPC) by the process known as high temperature pyrolysis The process is carried out in a rotary or vertical kiln at temperatures exceeding 1300 deg C Calcincalcined petroleum coke (cp coke) (30 mt/day )

.jpg)

Calcined Petroleum Coke Large Production Capacity

We take qualified green petroleum coke into calcination furnace under the temperature of 12501350℃ The calcination process could exclude volatile matter in raw materials, improve the density and oxidation resistance So that we can get 2017年10月28日 LC 3 is a new family of ternary cements that is being developed in a large international collaboration []The cement provides several benefits such as improved durability along with lower emissions and a better utilisation of resources While pilot productions of LC 3 have been carried out earlier in Cuba and India [2, 3], the first worldwide production of LC 3 by Pilot Scale Production of Limestone Calcined Clay CementAO HUI Carbon specializes in screening various particle size calcined coke, 13mm, 15mm, 110mm, 120mm, etc, customized according to the needs, screening various types of spongelike calcined coke, of which after calcination The coke mainly produces lowsulfur calcined postcoke and mediumsulphur calcined postcoke The stock is large, with China Calcined Petroleum Coke Manufacturer and Factory AO HUIInformation on Surface Grinding Machines from Sumitomo Heavy Industries We are a comprehensive heavy machinery manufacturer with a diverse range of businesses, including standard and massproduction machines, such as reducers and injection molding machines, as well as environmental plants, industrial machinery, construction machinery, shipbuilding, and Surface Grinding Machines Sumitomo Heavy Industries, Ltd

.jpg)

Calcined Petroleum Coke Market Global Industry Size

Calcined petroleum coke, with its high carbon content and low impurities, serves as a key raw material in the manufacturing of anode and cathode components in aluminum smelting Furthermore, it finds widespread application in the production of steel, where it aids in maintaining appropriate carbon levels+ In midOctober 2024, Chinese synthetic graphite project developer, Shandong Houwei Chemical (Shandong Houwei), announced that its precalcined pet needle coke plant, with a nameplate capacity of 200,000 tpa located in Shaanxi, China entered trial production + The plant, which was constructed by the Chinese petrochemical company, Shaanxi Chemical Shandong Houwei’s large scale precalcined pet needle coke Grinding disc diameter: 180 mm; Grinding disc material: The need for frequent replacement is gone with discs made of wearresistant steel Fine to coarse grinding: Grind anything from espresso to French press coffee with this 5 Best Industrial Coffee Grinders for Large Scale Calcined petroleum coke is widely used in carburizing and recarburizing process, owing to its lower grade of coke and high carbon content Demand for calcined coke rapidly growing across the globe, due to the increasing steel industry, development in the cement and power generation industries, growth in the supply of heavy oils and favorable government initiatives regarding Calcined Petroleum Coke Market Size, Industry Share, Forecast

Guide of coke making, briquetting system, briquette

Why make coke briquette Coke powder is a byproduct produced by metallurgical calcium carbide and chemical manufacturing enterprises when coke is crushed, transported and used Due to the small size of the powder, it does not meet Ball mill for pet coke grinding with good grinding effect is at a discount today Skip to content Home; Highsulfur and ordinary raw petroleum coke are used in chemical production, The reducer set in the traditional ball mill machine is transformed Petroleum Coke Ball Mill Buy Ball Mill for Pet Coke Superfine Grinding2024年4月1日 SFGDA is calcined under different conditions: (a) The XRD of SFGDA mixed with different proportions of coke powder and calcined at 1100 °C for 1 hour under N 2; (b) XRD of SFGDA mixed with different proportions of coke powder, calcined at 1100 °C for 1 hour in air atmosphere; (c) Effect of calcination time; (d) Calcination time effect on the desulfurization Resource utilization of semidry flue gas desulfurization ash by The quality of calcined petroleum coke used in primary aluminum production is affected by each of the Hume, SM, “Influence of Raw Material Properties on the Reactivity of Carbon Anodes Used in the “The Effects of Feedstock and Coke Calcination Degree on the Properties of BenchScale Anodes,” Light Metals, p 511 (1990 Calcined Coke from Crude Oil to Customer Silo SpringerLink

Calcined Petroleum Coke Market Research Report 2032

The global calcined petroleum coke market size in 2023 was estimated to be USD 82 billion and is forecasted to reach USD 125 billion by 2032, The cost of green petroleum coke, the raw material used to produce CPC, The presence of large players in the market makes it difficult for new entrants to gain a foothold in the market2015年4月15日 The typical molecularscale (∼70 atoms) models, latticescale (3990 atoms) 3D model, and nanoscale (31909 atoms) 3D model of the calcined coke were constructed via the imageguided construction Modeling the Change of Green Coke to Calcined Coke Using Qingdao High Thiel, JensPeter; “Results of Grinding Tests with Calcined petcoke”; unpublished report 2017; Claudius Peters Projects GmbH, Buxtehude, Germany 2 Stefan A Gosau, Andreas Wolf; “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”;Superfine Grinding of CPC with Ball Race Mills Challenges and 2013年10月24日 The Flow of Raw Materials The production of steel requires various raw materials such as coal, coke, iron ore, flux, mill scale, sinter etc and they undergo processes like unloading, stacking, reclaiming, blending, crushing, grinding and screening and are finally conveyed to the sinter plant, coke oven battery and blast furnaceLargescale Raw Materials Handling at Bushan Steel's

5 Types of Briquette Machines (With Budget Analysis)

2023年7月4日 Generally, briquette machines can range in price from a few hundred dollars to several thousand dollars Smallscale machines (15 t/h): Prices typically start around $1,000 These machines are suitable for 2024年7月17日 Fine crushing: Utilize sand making machines, roll crushers, fine crushers or compound crushers in tertiary crushing to produce fine sand or powder 4 Capacity requirements Determine the hourly capacity needed Types of Crushers: Choosing the Right One for Each 2024年10月28日 Green Petroleum Coke and Calcined Petroleum Coke Market Report Overview The global green petroleum coke and calcined petroleum coke market size was valued at USD 3055 billion in 2023 and is projected to grow from USD 3202 billion in 2024 to USD 4677 billion by 2032, exhibiting a CAGR of 48% during the forecast periodGreen Petroleum Coke and Calcined Petroleum Coke MarketLongyi Newtype grinding roller mill series is a new grinder pulverizer depending on its technology RDcapability and referring to similar products advantages home and abroad It has comprehensive mechanical crushing propertiessuch as rollinggrinding and impactingAccording to clients' different requirements to finished powder,our companycan provide diverse and Longyi Calcined Coke Powder Grinding Mill

.jpg)

Importance of granulometry in calcined petroleum coke

2003年1月1日 The samples of calcined coke, coal tar pitch and butt were provided by Deschambault aluminum plant (Alcoa, Canada) The coke and butt particles were crushed and sieved through seven different USA 2021年12月20日 Thin section images of calcined clay mixtures after largescale calcination processing in a rotary kiln; maximum material temperature in the rotary kiln: 750 °C (a) and 930 °C (b) [41]Clay calcination technology: stateoftheart review by the 2019年9月4日 Particles of large fractions (about 10%) have an irregular shape, since they were formed outside the arc zone in the absence of phase transitions Such dust contains particles of charge materials (ore raw materials, fluxes, and coke) The size of almost 90% of the dust particles of gas cleaning of ferroalloy furnaces does not exceed 10 µBriquetting SpringerLinkBall Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement Kiln, Lime Kiln SupplierHenan ZK Corp already has been growing up to a comprehensive company with strong ability of the whole system researching and designing on process technology and equipment manufacturing in the fields of building materials, mining, metallurgy, environmental protection etcBall Mill, Cement Mill, Grinding Mill, Rotary Kiln, Cement Kiln, Lime

.jpg)

Bulk calcined pitch Coke Sasol

A solid carbonaceous product from the Coal Tar Filtration plant is fed into a coker unit at high temperature and pressure The light products produced in the cracking process in the coker drums are routed back to our refining units A solid black substance form in the coker drums The solid black substance (also known as green coke or raw coke) consist of around 90% fixed Graphite Grinding Shaping System Technical Feature 1High yield rate with lower power consumption 2With shaping function to make better shape 3Designed for ultrafine grinding work 4Final product is adjustable between 5300 μm 5Hard alloy and ceramic wearing parts available 6High efficiency classifier make narrow PSDGrinding Shaping System Anode Material