What are the main components of a coal crusher

Primary Crusher an overview ScienceDirect Topics

In general, coal crushers are categorized into two types and three types of primary crushers, as follows: Primary coal crusher: Used for larger coal size The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal Understanding the main components of a mobile coal crusher can help in selecting the right machine for your needs Here’s a closer look at the key components of these versatile The Main Components of a Mobile Coal Crusher – stone cruxderThe main component of the crusher is a high inertia rotor spinning at over 250 revolutions per minute (rpm) This rotor contains six impact hammers called “blowbars” which are designed to Crusher an overview ScienceDirect Topics2023年10月8日 To ensure that coal is not affected by overcrushing while achieving the required particle size and output requirements, FTM Machinery will help you choose the optimal coal crusher machine 1 Jaw crusher The jaw 6 Types of Coal Crusher: Which Is Best for Crushing My

Impact Crusher an overview ScienceDirect Topics

The crusher can crush the stone into fine particles by extrusion or bending, which is usually divided into fine crushing, medium crushing and coarse crushing Crushers mainly include jaw Coal crushing is an essential part of the coal handling process within the mining and energy sectors The primary goal of coal crushing is to reduce the size of coal particles to enable The Ultimate Guide to Coal Crushing: Understanding the Different The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated)Cone Crushers (Parts of a Cone Crusher) Explained2015年4月3日 Crushers are classified into three types based upon the stage of crushing they accomplish These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher The primary crusher receives material directly from Crushers and Their Types IspatGuru

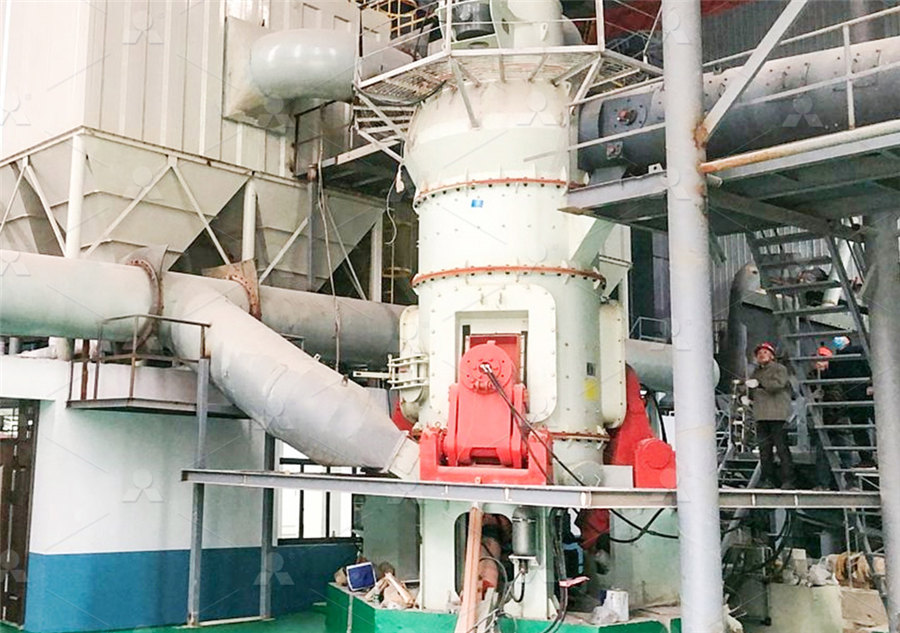

.jpg)

Thermal Power Plant Components, Working and

While combustion of coal in a boiler, the flue gases exhaust the atmosphere from the chimney Related Post: Solar Power Plant – Types, Components, Layout and Operation; Components of Thermal Power Plant In a thermal power plant, The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw What Are Jaw Crushers and How Do They Work?A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to Crusher Wikipedia2023年3月11日 500t/h Coal Gangue Mobile Crushing Plant; Main Menu What is an impact crusher? Crushing Equipment / March 11, 2023 / 5 minutes of reading The components of an impact crusher An impact crusher consists of several components, including the rotor, hammers, What is an impact crusher? AGICO

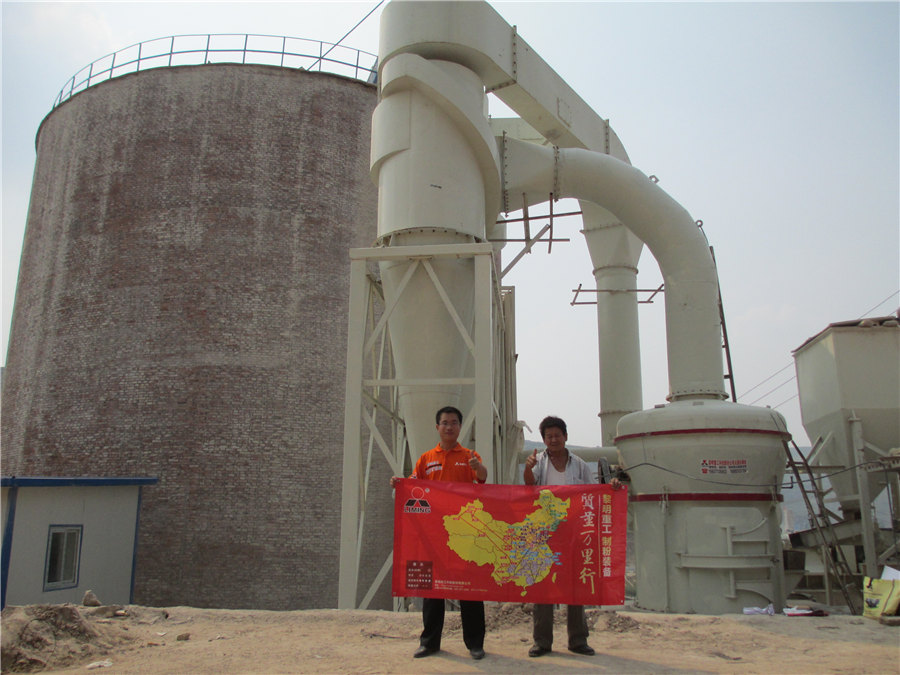

.jpg)

Types of Crushers 911Metallurgist

2015年6月23日 Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This category embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells Impact Crushers: This division is represented chiefly by the various styles of Now, let’s dive in to understand the components of a jaw crusher Crusher Frame Components The structural backbone of a jaw crusher comprises two main parts: the stationary and the movable jaw frames, constructed mainly of highquality steel or iron The stationary or fixed jaw forms the crusher’s side that does not moveWhat Are The Parts Of A Jaw Crusher? Caldas Engineering and 2021年6月14日 The jaw crusher is one of the most admired and most sought after equipment from the house of Propel Industries For the benefit of newcomers in the industry, here is an explainer of the various components of the Jaw crusher A jaw crusher consists of Crusher Body Pitman Jaw plate Rear end frame Eccentric shaftIn depth – Components of a Jaw Crusher PROPEL INDUSTRIESFor example crushed material for road base and fill The main kinds of crushing machines for secondary processing are discussed below Cone crushers Cone crushers are one of the main choices for secondary crushing A cone crusher is a powerful machine that is used in largescale industries for crushing various types of materials into smaller Types of Crushers: What You Need to Know Machinery Partner

What Are The Reasons for The Large Vibration Eastman Rock Crusher

2021年8月16日 The hammer crusher is mainly used in the underground chute of coal mine, which is used together with the transfer machine to crush large pieces of raw coal and gangue passing through the transfer machine The main components of hammer crusher are hammer head, impact plate, central shaft, support ring and other accessoriesThe primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher The primary crusher converts the feed size to one that is acceptable to the secondary crusherPrimary Crusher an overview ScienceDirect Topics6 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance shown in above figure, a closed circuit crushing system is a means of controlling product top size by screening the product Construction, Working and Maintenance of Crushers for Crushing 2023年2月22日 Stone crusher machines are essential tools in the construction industry, used to crush rocks and stones into smaller pieces for a variety of applications This guide provides an overview of stone crusher machines, A Comprehensive Guide to Stone Crusher Machines

Primary and Secondary Crushing: Understanding the

2023年2月28日 The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1 The secondary crusher can be a cone crusher, impact crusher, or gyratory crusher, depending on the hardness, abrasiveness, and size of the 2023年2月23日 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries These machines are designed to crush large rocks and ores into smaller pieces for further processing A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the jaw up and downJaw Crusher Parts And Their Functions AGICO2023年2月23日 As the main shaft rotates, it causes the mantle to move back and forth against the concave, crushing the rocks and ores between them The eccentric motion of the main shaft is a crucial component of the cone crusher working principle It creates a powerful force that allows the machine to crush rocks and ores with precision and efficiencyUnderstanding the Cone Crusher Working Principle: How It 2020年6月3日 In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be exploring in more detail the A Detailed Overview of Cone Crushers and What You Need to

Crusher an overview ScienceDirect Topics

The main component of the crusher is a high inertia rotor spinning at over 250 revolutions per minute (rpm) This rotor contains six impact hammers called “blowbars” which are designed to strike the feedstock In normal operation, 2024年7月17日 The compound crusher, a doublerotor primary impact crusher, is a new type of fine crushing and coarse grinding product launched by FTM Machinery Materials entering the highspeed rotating impeller are centrifugally thrown outward, colliding with other materials, then repeatedly colliding and grinding between the impeller and casing before finally discharging Types of Crushers: Choosing the Right One for Each Stage2020年7月24日 coal belt conveyor enters the main workshop or the coal coal crusher house, especially it is important to optimize the antivibration performance of its key components in order to ensure (PDF) Research on Structural Design of Coal Crusher House in 2021年3月25日 The material and its characteristics, eg, its hardness, density, shape and condition, will affect the type of crusher that needs to be used Knowing the material characteristics as well as the advantages and limitations of the different crusher types will help to determine the best primary crusher for a given applicationWhat Type of Crusher Is Best for Primary Crushing? McLanahan

What are Coal feeders? Principle, components –

2021年8月19日 Coal that has been crushed with a Crusher will be transported by belt conveyor to Coal Yard for stock and also supplied air from the Air Fan which is useful to prevent hot air from the mill not going up to the bunker The main function of breaker plate is to protect the crusher body from wear 7 Tramp Iron Pocket Tramp iron and uncrushables are prevented from continuing around and back into the crushing zone by a heavy metal plate Work Ring Granulator Type Coal Crusher COAL 2023年2月23日 The gyratory crusher operates by means of a gyrating mantle, which gyrates continuously against a stationary concave surface The main components of a gyratory crusher include the mantle, the concave surface, Gyratory Crusher vs Cone Crusher: What's the 2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap between the bowl liner How it Works: Crushers, Grinding Mills and Pulverizers

What is the role of ‘jaw crusher’ in the construction industry

2023年9月30日 Q2: What are the key components of a jaw crusher? The main components of a jaw crusher include the fixed jaw, the movable jaw, the pitman (eccentric shaft), toggle plates, and the motor The movable jaw exerts force on the material by pressing it against the fixed jaw, crushing it in the process Q3: What types of materials can jaw crushers handle?Jaw Crusher with Single Toggle Plate Design Jaw Crusher Classification Jaw crushers are classified based on the position of the pivoting swing jaw There are three main jaw crusher types: Blake crusher – the swing jaw is fixed at the lower position Dodge crusher – the swing jaw is fixed at the upper positionJaw Crusher Explained saVRee2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industryThey are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore some of the key features The Importance of Jaw Crusher Design Features in Crushing working of the crusher is as under The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assembly The spider bearing fixes the position of the upper end of the main shaft Eccentric bearing assembly with inner bushing can be replaced, or in some models turned, to adjust the strokeConstruction, Working and Maintenance of Crushers for Crushing

.jpg)

(PDF) Operation and Maintenance of Coal Handling System in

2011年12月31日 The equipment component of CHF consists of a belt conveyor, supporting equipment that moves continuously and is integrated (Zhao Lin, 2011)With conditions like this, it illustrates that 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing, 2015年7月25日 These are the parts and components that generate the crushing action and provide the energy needed to break the ore Let’s follow the chain of events within a crushing cycle to see how they all go together The first Jaw Crusher Components Parts 911MetallurgistWHAT ARE THE MAIN COMPONENTS OF JAW CRUSHERS? / PARTS AND MAIN PARAMETERS OF JAW CRUSHERS Jaw crushers are generally defined by their opening size For example, a 900x650 mm crusher refers to a crusher What Is A Jaw Crusher MEKA

.jpg)

What Are the Main Parts of a Cone Crusher?

Main Parts of a Cone Crusher Frame: The frame is the primary structure that supports all other components of the cone crusher It is built to be strong and durable, as it absorbs vibrations and impacts that occur during the crushing process A welldesigned frame ensures the crusher operates smoothly and withstands heavy loadscoal crusher house, especially in the areas with high seis ration seam set in the buffer between the main structure components, the components in the device when can haveResearch on Structural Design of Coal Crusher House in Thermal Power 2024年2月6日 Picture this: in a single toggle jaw crusher, the main engine shaft is installed at the very top Now, the swing jaw hangs on this shaft, leading to some fancy jaw movement that’s a bit more complex than what you’d find in double toggle crushers As the swing jaw dances up and down, its path looks like an ellipseUnderstanding Types of Jaw Crusher: A Comprehensive GuideThe impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, The external shell is the supporting component of the crusher, Jaw Crusher The main features of a jaw crusher are large crushing ratio, even granularity, Impact Crusher an overview ScienceDirect Topics

What Are The Components of an Impact Crusher?

An impact crusher is composed of various crucial components such as the rotor, impact plates, and feed hopper, each playing an integral role in the crushing process Understanding these components and their functions can help operators make informed decisions about maintenance, leading to increased efficiency and reduced downtime2013年7月17日 Coal rises from crusher house and reaches the dead storage by passing through transfer point 8 Stages in coal handeling power plant Equipment used in a coal handling plant 1 Pull chord switch A series of such switches are arranged in series at a Coal handling plant in a thermal power generating station EEP2014年9月1日 Coal mine gangue was chosen as the research object, and its particle size and chemical components at various crusher discharge settings were examined through screening, grinding, chemical Assessing the energy efficiency of a jaw crusher Request PDFThis step prevents overloading the crusher and increases its efficiency Fine particles make the crusher less efficient and increase the power draft for crushing such small particles which increases the kWhr per ton crushed Screening and diverting fine particles significantly increases the performance of the crusher 2 Crushing and stock pilingThe six main steps of iron ore processing Multotec