Limestone powder production line process flow description equipment

Limestone Grinding Mill Plant TAYMACHINERY

The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing to finished product Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Limestone Quarrying and Processing: A LifeCycle Inventory2023年2月15日 The whole lime production line includes: mining, crushing, screening and calcinating First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are Lime Production Process and Required Equipment2024年8月26日 At present, most of the limestone powder used in the building materials industry is limestone or stone chips generated in the production of aggregates, etc, which are ground Limestone Powder Grinding Process ALPA Powder Equipment

1117 Lime Manufacturing US EPA

11171 Process Description 15 Lime is the hightemperature product of the calcination of limestone Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing To be classified as limestone, the rock must contain at least 50 percent calcium carbonate When the rock contains2022年3月16日 The hydrated lime production line is to crush the qualified hydrated lime blocks to a particle size of about 40mm by the jaw crusher, and send them to the hydrated lime storage tank silo through the bucket elevator Process flow of hydrated lime production line Gaifeng2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other Limestone crushing, sand making and grinding processThe cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition 3 Raw Mill and Kiln: Raw materials and additives areA practical guide to improving cement manufacturing processes

.jpg)

Active Lime Production Line Hongji Mining Machinery

Active Lime Production Line Capacity : 502000t/d Applicable Materials : limestone, dolomite, chalk, etc Applications: steel smelting, chemical industry and power plant desulfurizatiol and other fields Case Description: The active lime production line is a kind of equipment and process used to produce active limeApplication of ball mill in gold ore beneficiation process 1000 tons per day cement crushing production equipment Configuration and process flow of tuff crushing production lineThe Role of Grinding Mills in Limestone Powder Production2020年8月25日 Before you send inquiry Please provide us with project information as much as possible: For a complete project: the material availability, the required output capacity, the process technology, your budgetary and financing status, the estimated starting time, etc For singular machinery: the model, the capacity, your budgetary information, other requirements, etcCement Production Process Cement Manufacturing ProcessLimestone Production Line (Three Line) High Yield Lime Product Line ZK has a firstrate Lime rotary kiln development, research and design team, perfect test and inspection means and excellent large rotary kiln manufacturing equipment and manufacturing technology, and has formed a complete technology and production system integrating Lime rotary kiln design, Limestone Production Line (Three Line) High Yield Lime Product Line

.jpg)

limestone pellets granulating production line CMPP

2024年4月17日 The production of limestone pellets requires specialized equipment to ensure the pellets are of high quality and meet industry standards Here are some of the essential equipment used in the production of limestone pellets Grinding Equipment Before limestone can be turned into pellets, it must first be ground into a fine powder1the introduction of the cement plant equipment We Henan Zhengzhou Mining Machinery Co,ltd,can provide complete set technology solutions and supporting production equipments of cement production line 1)Design capacity:1506000TPD 2)According to client's special requirements to designSupply Cement Production Line Process Flow Chart and MachineIn mine crushing treatment, choosing a complete set of crushing and grinding production line is the top priority, so choosing highefficiency, energysaving and environmentally friendly mine crushing equipment is the preferred standard for mining in the future Dahua Heavy Industry provides you with the following referenceMining production line process flow CM Mining Machinery1977年5月3日 11171 Process Description15 Lime is the hightemperature product of the calcination of limestone Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing To be classified as limestone, the rock must contain at least 50 percent calcium carbonate1117 Lime Manufacturing US EPA

Limestone Powder Production Line Buy Limestone,

Limestone Limestone is a carbonate sedimentary rock that is often composed of the skeletal fragments of marine organisms such as coral, foraminifera, and molluscs Its major materials are the minerals calcite and aragonite, which are Find production technology for making Limestone, and connect directly with leading machine manufacturers worldwide Select your limestone process Limestone milling Limestone grinding Limestone packing Many industries require reliable pelletizing equipment with smaller scale production capacities Limestone Processing Equipment MakingGypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the Gypsum Powder Production Line Hongji Mining Machinery2024年2月23日 The limestone powder making process and its versatile applications highlight the importance of this finely ground material across multiple industries From construction to agriculture, environmental remediation, and various manufacturing sectors, limestone powder plays a crucial role in enhancing products and processes, contributing to sustainable and Introduction of limestone powder making process and application

DESIGNING A PROCESS LINE Dairy Processing Handbook

For a flow rate of 20 000 litres/hour and a pipe size of 25" (635 mm), a velocity of 175 m/s, the graph indicates a pressure drop, or loss of head, of 04 metre over the fully open valve The pressure drop over each of the components in the line 2021年10月22日 This article takes the 1000t/h limestone aggregate line as an example to introduce the equipment selection, process flow, production line layout, The main feature of this combination is that the product particle size is good, the Configuration and design of 1000tph limestone aggregate production 2016年1月20日 Mass flows are formed when the material runs along a cement production line A production line is composed of three processing stages, and each stage is composed of several units (Fig 5) In each unit's material flow structure, the flow rate and flow direction are varied In the production process, material consumption needs to be investigated Analysis of material flow and consumption in cement production process Cement Manufacturing Process by TIZITA MOGES , SELAMU ABULE DEREJE ENDALAMAW IF YOU NEED THIS GUIDE AND ALL OTHER USEFUL EXCEL SHEETS WHICH WILL MAKE YOU MASTER THE PRODUCTION , PROCESS , MAINTENANCE ACTIVITY IN YOUR CEMENT PLANT KINDLY CLICK HERE Raw Material Preparation and Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

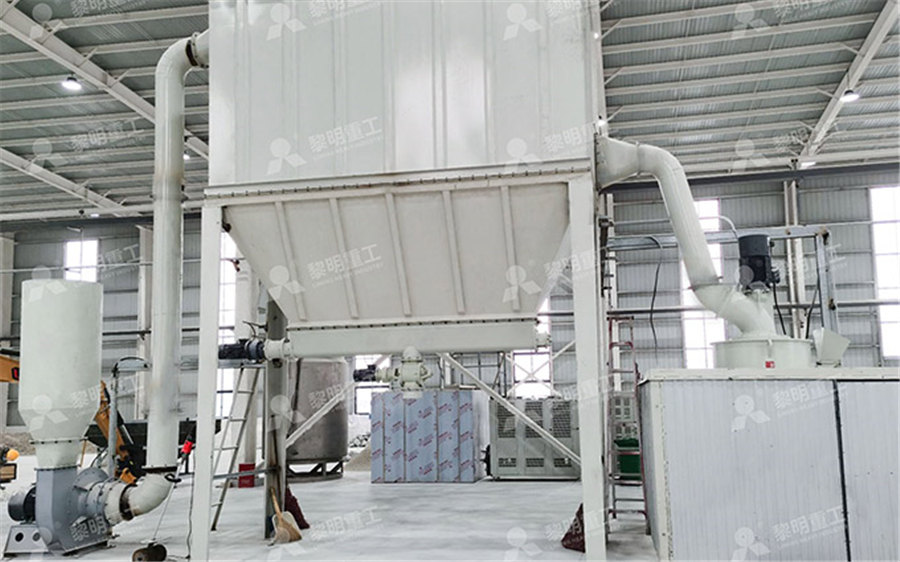

Limestone crushing and grinding production line

2022年4月20日 Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industries Limestone crushing and grinding production line 20/04/2022 2024年2月26日 Pearlite is an acidic karst mineral, nontoxic and odorless, with good fire resistance, sound absorption, chemical stability, etc After the sandmaking equipment process, perlite can applied in various industrial sectors Pearlite Sand Production Line Equipment And StepDescriptionSourcing Limestone PowderLimestone deposits are mined and quarried to extract the raw material for limestone powder productionLimestone Powder Mining and QuarryingSpecialized equipment and techniques are used to extract limestone from natural deposits in The process of making limestone powder is closely watched from start 9 important Uses of limestone powder1971年8月17日 kiln Depending on the process type, kilns have lengthtodiameter ratios in the range of 15:1 to 40:1 While some wet process kilns may be as long as 210 m (700 ft), many wet process kilns and all dry process kilns are shorter Wet process and long dry process pyroprocessing systems consist solely of the simple rotary kiln116 Portland Cement Manufacturing US EPA

Limestone Powder SpringerLink

2017年12月9日 As shown in Fig 42 most of the Portland limestone and composite cements conform to the 325 and 425 strength classes, although “very high strength” 525 Portland limestone cements are also produced Most countries around the world specify similar chemical and physical requirements for the limestone that can be used, including a minimum CaCO 3 Limestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone From its varying composition, to its abrasive nature, limestone requires an engineered process solution, combined with heavyduty equipment That’s why we not only offer limestone processing equipment, but can also help develop a limestone process that works around your unique source of Limestone Processing Equipment FEECO International Inc2024年6月15日 Limestone powder is a key material in the construction world It’s used in making cement, concrete, and for stabilizing soil This makes it vital for many building projects Cement and Concrete Production Limestone powder is a main ingredient in cement It acts as a filler and improves the cement’s qualityLimestone Powder – Essential Mineral for Various Uses

Which Grinding Mill Is Suitable For Processing Limestone?

2022年8月26日 Summary:In recent years, with the rapid development of construction and infrastructure construction, more and more investors consult for limestone powder productionSo what equipment is needed for limestone grinding? What is the process flow? Limestone is the main raw material of cement, concrete aggregate, etc it can also be used as a filler to produce If you want to process it into sand and stone with concrete, that is, machinemade sand with particle size ≤ 475 mm and particle size of 1020 mm, 15 mm 30mm 12/13 stone needs to use limestone production equipment for crushing, sand making, screening and other technological processes 2 Process flow of limestone production line 01What is the technological process of limestone production line?Short Description: The crusher break The qualified gypsum powder will sent to the warehouse or to the board production line Process Flow Diagram Gypsum Powder Factory Equipment; Gypsum Powder Plant; Related Products Hot Gypsum Powder Production Line AmuliteStepDescriptionSourcing Limestone PowderLimestone deposits are mined and quarried to extract the raw material for limestone powder productionLimestone Powder Mining and QuarryingSpecialized equipment and techniques are used to extract limestone from natural deposits in The process of making limestone powder is closely watched from start 9 important Uses of limestone powder

.jpg)

Limestone Quarrying and Processing: A LifeCycle Inventory

depicts the fabrication process Figure 2 Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Figure 2 It should be 2021年5月1日 Process description The milk powder production process is a simple process oxygen and moisture needed to begin deterioration of the equipment The process is accelerated if there is exposure (PDF) Milk Powder Production Food processing ResearchGate2015年8月1日 Cement production, which is highly dependent on the availability of natural resources, will face severe resource constraints in the future This is especially true for the cement industry in ChinaAnalysis of material flow and consumption in cement production process2015年3月1日 This design guideline covers the basic elements of Process Flow Sheets in sufficient detail to allow an engineer to design a flow sheet with the suitable symbols of equipment, line, indicator and PROCESS FLOW SHEET, Kolmetz Handbook of Process Equipment Design

.jpg)

600TPD Vertical Shaft Kiln Lime Production Line

Industrial Grade Hydrated Lime Production Line Equipment for Water Treatment Product Description Low Power Consumption Vertical Shaft Kiln Active Lime Production Line Process Flow of Lime Production Line: 1 Raw Material Conveying: while limestone with particle size less than 10mm will be conveyed to the powder silo 2 Limestone Limestone Rotary Kiln for Clinker Production Line Plant, re grinding; fine powder qualified with gas out flow after grinding and increasing dust mixed wet tower and electric dust collection, through the chute, Dry process cement production line (25200t/d)Configuration Clinker capacity Equipment Parameters: 25t/d:Limestone Rotary Kiln for Clinker Production Line Plant2020年1月9日 Limestone can be directly processed into stones and fired into quicklime Limestone aggregate production lines are very common, with output ranging from hundreds to thousands This article uses a production line of 1000t / h as an example to describe its equipment selection and process flow Selection of main equipmentDetailed Equipment Selection and Process of 1000 Ton Limestone 1 Steel: Steel structures are one of the most popular substrates for powder coating It's durable, strong, and versatile, making it a prime choice for various industries Powdercoated steel is commonly seen in automotive parts, appliances, outdoor furniture, and industrial equipmentPowder Coating Process Explained – A Detailed Breakdown