Measures for openpit coal powder vertical mill to pass highvoltage line

.jpg)

Performance optimisation of vertical spindle coal pulverisers

this dissertation was to investigate the effect of coal feedstock property variation on the vertical spindle coal pulverising mill’s performance to facilitate optimal plant performance Plant design and mill’s acceptance test data was analysed to understand the design and subsequent 2023年6月1日 Based on the Kriging surrogate model, a multiobjective optimization framework for large vertical mills is proposed Finally, the multiobjective optimization design of LGM large Advanced Powder Technology2024年2月23日 Taking the illustrative case of an idealized smallscale inclined coal seam openpit mine, adjustments to the boundary closely track variations in coal prices, further enhancing Midlong term boundary dynamic optimization of openpit coal 2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate An investigation of performance characteristics and energetic

.jpg)

Research on production capacity planning method of openpit

2023年5月29日 Aiming at the capacity target of 30–35 Mt/a in Baorixile openpit coal mine, this research studies the influence of working face length and annual advancing speed on 2023年5月1日 The strategy entails assessing the significant ecological costs associated with openpit coal mining, floating cone exclusion method, and iterative optimization algorithm The Ultimate pit optimization with environmental problem for open Open pit mine planning is a decisionmaking process that leads to a realistic and actionable plan to profitably extract mineral resources Planning can be carried out for a wide range of periods ValueOptimal design of ramps in open pit mining2021年6月1日 Pulverized coal fineness (PCF) is a key parameter in coalfired power plants, demanding accurate and online monitoring This study presents online measurement of PCF Online measurement of pulverized coal fineness on a 300 MWe

.jpg)

Investigation on flow field characteristics in an openpit coal mine

2022年1月4日 This paper offers an effective way to study the flow field characteristics in an openpit coal mine, which is essential to the dust pollution control of openpit mine In this e addresses the open pit mining of lightly pitching coal below different surface topography Based on the analysis of the effect exerted by highwall angle on the current stripping ratio, Effect of Highwall Parameters on the Open Pit Operation and Limits2021年2月17日 Open pit mining method is one of the surface mining methods that has a traditional coneshaped excavation and is usually employed to exploit a nearsurface, nonselective and lowgrade zones deposits It often results in Open Pit Mining IntechOpen2022年5月1日 It has been observed that worldwide explosion has occurred due to the following reasons, viz sealing works, reopening of sealedoff area, spontaneous combustion, the buildup of methane in an unventilated area, explosion in working face due to sluggish ventilation, etc Table 1 depicts the mine gas explosion tragedies that have occurred worldwide in the last twenty Review of preventive and constructive measures for coal mine

.jpg)

An investigation of performance characteristics and

2020年8月12日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining PDF On Oct 7, 2015, F Ferrari and others published A new qualitative rockfall hazard methodology for openpit coal mines Find, read and cite all the research you need on ResearchGateA new qualitative rockfall hazard methodology for openpit coal 2020年12月30日 UAV PhotogrammetryBased for Open Pit Coal Mine Large Scale Mapping, Case Studies in Cam Pha city, Vietnam December 2020 International Journal of Sustainable Development 12(4):501509(PDF) UAV PhotogrammetryBased for Open Pit Coal Mine Vertical mill is widely used for pulverized coal preparation system in power plant, cement plant, metallurgy industry, chemical plant, etc It could be used to grind bituminite, meagre coal, and anthracite lignite with high moisture under some conditions Vertical mill adopts low speed, big roller diameter, high loading force designVertical mill for coal pulverizing in power plant Geckointech

.jpg)

DeepL翻译:全世界最准确的翻译 DeepL Translate

即时翻译文本完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVReehigh angle conveyor installations including vertical continuous haulage from underground mining and direct haulage from open pit mines, yard handling and prep plant feed, coal prep refuse disposal, and coal transfer, to market, domestic and export Also, this writing places special emphasis on noting the systems suitability for handling large sizeSandwich Belt High Angle Conveyors Coal Mine to Prep Plant2016年1月1日 To understand the influence of spontaneous combustion of the residual coal in open pit coal mine slope on slope stability, code PFC3D was used to model certain slope Coal MineDiscussion and exploration of management measures for slope

.jpg)

Mining MethodsPart II: Surface MiningPlanning and Design of Open Pit

2010年3月1日 Figures shows: In order to keep the pit dry, There are 40 dewatering pumps around the Cortez pit pumping water out of the ground at a total rate of 30,000 gallons per minuteThe coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is Coal Mill – Coal Mill In Cement Plant AGICO Cement 2020年4月2日 The different mill has different PC pipe corners, and with different length and high level This case indicates and measures the changes of boiler parameters due to different mill in serviceAnalysis of the Coal Milling Operations to the Boiler The project is to build a highefficiency clean coal powder production line with an annual output of 300,000 tons for customers in Vietnam Customers specialize in the coal powder products business, processing coal into highefficiency clean coal 20tph Coal Ball Mill for Clean Coal Powder Production Line in

What is a Coal Grinding Mill

To convert raw coal into fine coal powder, coal grinding mills are essential Coal grinding mills are specialized equipment designed to break down coal into fine particles suitable for combustion The coal grinding process involves crushing and grinding coal into small particles, which are then heated to high temperatures in a furnace, producing steam that drives a turbine to generate rocks) from a vertical or subvertical cliff, followed by a rapid motion downward characterised by free falling, bouncing, rolling and sliding phases (Varnes, 1978) Due to the high motion velocities, which render any warning equipment useless, rockfalls are A new rockfall hazard assessment methodology for openpit coal 2023年12月9日 The shape of the adsorption isotherm of the soil pavement particles of the openpit mine shows that the adsorption isotherm of the soil pavement particles in openpit mine belongs to type II This also reveals that the soil pavement particles in openpit mine have a relatively complete pore structure, which ranged from micropores to infinite pores (Chen and Microstructure and adhesion force of dust on soil pavement in openpit 2003年10月1日 Flow visualisation and velocity measurements in a vertical spindle coal mill static classifier☆Flow visualisation and velocity measurements in a vertical spindle coal

.jpg)

Vertical roller mill for raw Application p rocess materials

Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation2021年5月7日 The particulate pollution in the openpit coal mines of China is particularly severe in winter The aim of this study is to understand the pollution characteristics of particulate matter (PM) in winter and provide a basis for the prevention and control of particulate pollution We took the problem of PM concentration at the bottom of the Haerwusu Openpit Coal Mine (HOCM) Analyzing Characteristics of Particulate Matter Pollution in OpenPit Performance optimisation of vertical spindle coal pulverisers SR Chateya Dissertation submitted in fulfilment of the requirements for the degreePerformance optimisation of vertical spindle coal pulverisers2024年3月16日 A vertical coal mill is a type of industrial milling equipment used to crush and grind coal into powder for use in thermal power plants and the cement industry, the pulverized coal is carried upward by a highspeed airflow generated by the rotating table and directed towards a classifier located at the mill’s topHow Does a Vertical Coal Mill Work

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, O serviço do Google, oferecido sem custo financeiro, traduz instantaneamente palavras, frases e páginas da Web do português para mais de cem outros idiomasGoogle Tradutor2024年2月23日 1 Introduction Openpit mining is a method of extracting mineral deposits by excavating from the Earth’s surface It works by starting at the surface and removing noneconomic overlays to access profitable parts []Compared with the underground mining method, openpit mining has the advantages of high resource recovery, good safety conditions, high Midlong term boundary dynamic optimization of openpit coal The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40%Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

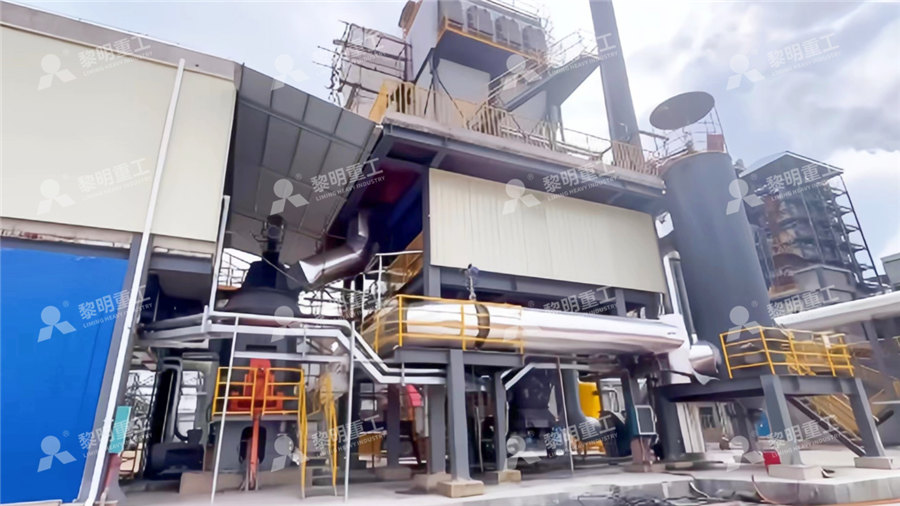

Vertical Coal Mill Great Wall

Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national standard of energy saving industryPDF On Jan 1, 2009, S Shafiee and others published Estimating average total cost of open pit coal mines in Australia Find, read and cite all the research you need on ResearchGateEstimating average total cost of open pit coal mines in Australia2022年6月10日 Assessment of vibration exposure of mine machinery operators a t three different openpit coal mines 243 The Journal of the Southern African Institute of Mining and MetallurgyAssessment of vibration exposure of mine machinery operators at 2021年2月11日 Phase Planning for Open Pit Coal Mines through Nested Pit Generation and Dynamic Programming(PDF) Phase Planning for Open Pit Coal Mines through Nested Pit

.jpg)

An investigation of performance characteristics and energetic

2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coal2018年3月1日 Through Deswik, I’ve published a set of guidelines for geometric pit design using design software (not just ours) Available to all – free, gratis, no chargeGUIDELINES AND CONSIDERATIONS FOR OPEN PIT 2023年5月1日 For an open pit mine, different pit limits have different pit diameters, ore amounts and waste rock volumes, which require different regions for mining, waste dumping and tailings discharge, resulting in greatly varying environmental damage (Adibi et al, 2015, Moradi and Osanloo, 2015, Rahmanpour and Osanloo, 2017, Xu et al, 2014)In addition, different mining Ultimate pit optimization with environmental problem for openpit coal Raw coal enters the coal ball mill through the feeding device At this time, hot air with a temperature up to 300℃ enters the coal mill barrel from the intake pipeCoal Ball Mill Grinding for Different Kinds of Pulverized Coal

The Landscape Pattern Evolution of Typical OpenPit Coal Mines

2022年8月4日 As the province most abundant in mineral resources in China, Inner Mongolia has more than 200 openpit coal mines The coal mining activities seriously hinder the sustainable use of regional land and the improvement of residents’ wellbeing Taking 13 typical openpit coal mines of Inner Mongolia as the study area, combining remote sensing images and the Google Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal Grinding pressure can be adjusted to account for variations in coalA Comparison of Three Types of Coal Pulverizers Babcock Power2024年9月18日 Since the 20th century, with the rapid development of the global economy, human demand for fossil energy such as coal has been increasing In the face of fierce competition, the state and various ministries and commissions have put forward the goals and requirements of building a worldclass enterprise, and how to become a worldclass openpit Research on Comprehensive Evaluation Indicators and Methods of Remote Sens 2019, 11, 1356 3 of 17 temperature is between 24 C and 22 C, while the highest and lowest temperatures recorded are 17 C and 485 C, respectivelyThe frostfree period is usually Analysis of the Development of an Erosion Gully in an OpenPit Coal

.jpg)

MPS ZGM Coal MillGrinding Equipment YingYong Machinery

The MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It provides suitable coal powder for the blast furnace ironmaking system2018年5月17日 Preparation and characterization of an agglomerationcementing agent for dust suppression in open pit coal mining Original Paper; Published: 17 May 5 g coal powder was spread evenly in a circular culture dish 100 mm in diameter to form a 1–2 mm thick Figure 13d shows the path line of dust in the vertical crosssectionPreparation and characterization of an agglomerationcementing