Ore mill Do you need water

.jpg)

Towards waterless operations from mine to mill ScienceDirect

2022年9月1日 Unlike mineral processing operations, rock blasting does not need to have water to help ore fragmentation However, in situ ore masses usually contain a certain amount of 2022年9月1日 To respond to the increased demand for commodities, increased volumes of primary ores need to be mined This could lead to major challenges with water and tailings management since ore(PDF) Towards waterless operations from mine to millHard rock mines typically require water for drilling, and for any associated size reduction facilities Water consumption can be stated in terms of gallons of water per ton of ore pro duced, except Water Use in Industries of the Future: Mining Industry12016年1月1日 Careful water management is now a requirement for any gold project This chapter describes the factors that need to be considered for a watermanagement program, Water Management in Gold Ore Processing ScienceDirect

.jpg)

Water Requirements of the Iron and Steel Industry

Water used by the iron ore mines and concentration plants was also predominantly self supplied from surface source Water use in the iron and steel industry varied widely and depended on Modern steelmaking processes can be divided into three steps: primary, secondary and tertiary Primary steelmaking involves smelting iron into steel Secondary steelmaking involves adding or removing other elements such as Steelmaking WikipediaSteel plants supplied about 96 percent of their own water requirements, although only three plants used selfsupplied water exclusively Water used by the iron ore mines and concentration Water requirements of the iron and steel industryWater use in the iron and steel industry varied widely and depended on the availability of water, age and condition of plants and equipment, kinds of processes, and plant operating Water requirements of the iron and steel industry

.jpg)

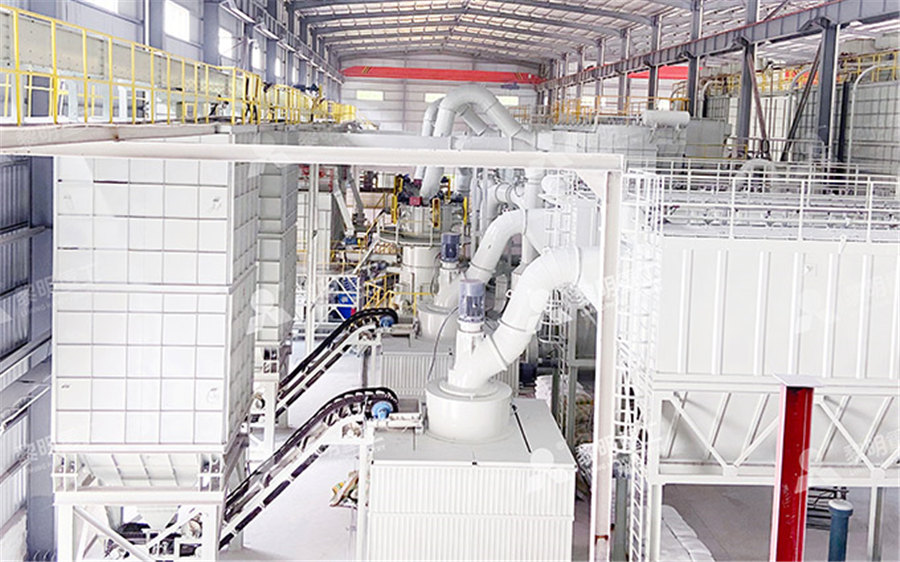

The six main steps of iron ore processing Multotec

When the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles The large particles are diverted back into the crusher and the fine particles will undergo a spiral 2021年4月3日 With 59 tonnes of ore mined per tonne of REM, the amount of ore mined and supplied to the mill to get 1 tonne of neodymium is 59/0185 = 3189 tonnes The mill only recovers 50% of the metal supplied to it Therefore, for the mill to recover 1 tonne of neodymium 6378 (3189/05) tonnes of ore must be supplied to the millHow much earth has to be moved to get one tonne of copper2023年10月2日 The design of ore processing plants is influenced by a multitude of factors that collectively shape the overall efficiency, costeffectiveness, and environmental sustainability of the operation First and foremost, the type and Designing an ore processing plants – Factors you 2017年10月17日 Water vapor and carbon dioxide are byproducts of the DRI process DRI can be very attractive in regions or countries lacking coal reserves, but with plentiful iron ore and natural gas resources to fuel the process For example, Northern Australia has abundant iron ore and natural gas resources Australia ranks second worldwide in iron ore From Ore to Iron with Smelting and Direct Iron Reduction

.jpg)

Pubic policy paper Water management in the steel industry

The most effective way to reduce water intake is by reusing the water This usually involves cleaning and cooling water flows between each use Some of these treatments, such as cooling, require large amounts of energy and can lead to increased rates of water consumption due to greater evaporation2024年10月30日 Ore is a deposit in Earth’s crust of one or more valuable mineralsThe most valuable ore deposits contain metals crucial to industry and trade, like copper, gold, and iron Copper ore is mined for a variety of industrial uses Copper, an excellent conductor of electricity, is used as electrical wire Copper is also used in constructionOre National Geographic Society2021年8月26日 For example, some ores need to be crushed and screened after mining in order to continue fine processing, and some even require the particle diameter of ore crushed to reach the fineness level of mm Under normal circumstances, the crushing of rock can be completed by a crusher, but this can only crush and roughly grind the rockWhat does Ball Mill Do? Meetyou Carbide2018年10月1日 Request PDF Treatment and water reuse of leadzinc sulphide ore mill wastewaters by high rate dissolved air flotation Simulated wastewaters (concentrate and tailings thickener overflows), from Treatment and water reuse of leadzinc sulphide ore mill

Getting serious about water Australian Mining

2023年9月28日 “The iron ore sector in the Pilbara faces a unique challenge, which is mining below the water table,” Russell said “Not only do you have to worry about removing water to access your orebody Watermill of BraineleChâteau, Belgium (12th century) Interior of the Lyme Regis watermill, UK (14th century) A watermill or water mill is a mill that uses hydropowerIt is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammeringSuch processes are needed in the production of many material goods, including Watermill Wikipedia2012年1月1日 This water is generally clean and can be used for a wide variety of mill water consumers, including dust scrubbers, pump GSW, spray water, reagent mixing water, and flotation or grinding dilution water A covered coarse ore stockpile would eliminate the need for a separate dust control system, Reducing mine water requirements ScienceDirect2022年12月2日 Iron ore beneficiation is the process of improving the quality of iron ore by removing impurities and increasing its iron content It is necessary to reduce alumina and silica in the feed The process improves the chemical, Everything You Need to Know About Iron Ore

.jpg)

How to Get Mill Palworld|Game8

2024年10月11日 You can process 3 pieces of Wheat into Flour once you build the Mill To get Wheat, you'll need to plant Wheat Seeds in Wheat Plantations How to Get Wheat Seeds Mill: Ore Mining Site: Weapon Workbench: Production Assembly Line: Ore Mining Site II: Water Element Pals; Grass Element Pals; Ice Element Pals; Electric Element Pals;2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding2019年9月24日 There are numerous examples in the literature, some of which are quantifying the effect of Mine to Mill Grundstrom et al, 2001;Hart et al, 2001;Scott et al, 2002;Burger et al, 2006;Jankovic et al Simulating the Impact of Ore Competence Variability on Process Eventually, a 4 ton ore car is hauled up a tramway and ore stored in a second bin at the mill This bin feeds direct to the stamps” “The ore is crushed in a solution of cyanide water with amalgamation taking place in the mortars Plates(amalgamation) are not usedWinning the Metal: Ore Mills of the West Western Mining History

.jpg)

Understanding the SAG Mill in Copper Ore Mining Process

The rod mill is another type of grinding mill used in the copper ore mining process This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills The rods grind the ore by tumbling within the mill, similar to the action of a rotating drum2022年9月1日 In metal mines, the ore mass is broken into a wide range of ore fragments including microscale particles by blasting Unlike mineral processing operations, rock blasting does not need to have water to help ore fragmentation However, in situ ore masses usually contain a certain amount of water, depending on the ore depositTowards waterless operations from mine to mill ScienceDirect2024年7月11日 You will emerge at some stairs leading down to the main floor of the Ore Tramming area But don't go down the stairs, and head straight on and then, turn right This takes you into the area with a large Ore Tramming sign you will recognise from your trips to Miner's Dry and the dining room But this time you have arrived from the opposite side3 Ore Tramming and Mill Management GameFAQs2016年2月14日 Do you need a quick estimation of a ball mill's capacity or a simple method to estimate how much can a ball mill of a given size (diameter/lenght) grind for 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Small Ball Mill Capacity Small Ball Mill Capacity Sizing Table 911Metallurgist

Iron Ore Supply Chain: From Mining to Steel Production

2023年10月25日 Iron ore is a crucial raw material for the global steel industry, and its supply chain is a complex network that involves multiple stakeholders and activities The iron ore supply chain begins with the mining of iron ore, which is 2017年6月2日 MILL OVERLAY If your parking lot shows strong subgrade deficiencies, the asphalt pavement and sometimes a part of the base material may need removing It commonly happens when the asphalt layer becomes Overlay VS Mill Overlay When Do You Need Them Crushing, a form of comminution, one of the unit operations of mineral processing Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling Beneficiation is any process that improves (benefits) the Mineral processing WikipediaTo create schematics, whether in Creative or Survival, you make a Schematic and Quill, for that you need a light blue dye, paper and a feather (in Survival) Then go to the lower corner at a side of the creation, right click with the Schematic, you will see a bluish area marked, move to the top oposite corner of the creation, right click againUpdated my 1:1 earlygame ore processing design for Create

.jpg)

8 Types of Gold Ore Properties and Ways to Process

2023年6月12日 Once you find gold in quartz ore, you can extract gold by the flowing steps: 1 Use a gold ore crusher to break the raw gold ore into smaller pieces 2 The rock is ground in water using a wet pan mill and sieved to collect and extract the goldWhere do you need to go? How much of what kind of water do you need and for what purposes? While you want to treat the water up to the quality required, you do not want to spend unnecessary capital and operating money by overtreating 31 – TSS Suspended Solids will be the primary concern if you are supplied from a surface sourceMILL WATER QUALITY IN THE PULP PAPER INDUSTRY: Flowchart Explanation The raw ore is fed into the trommel screen for washing a few little clays and can separate the gravel or stone which needs to crushgrind to get the inside tin, the separated gravel can transfer to the next jaw crusher by the belt conveyor After the jaw crusher, goes to a cone crusher for second crushingThe output from the cone crusher goes to a Tin Ore Mining Process JXSC Mineral2011年5月14日 if your a large mill they will test your ore for you and get your recovery up to a realy good grade a home made froth cell can be made with a trash can ,drill, paint stirrer and a shop vac this will do 50 lb batches with out the risk of loss of any ore there are 100s of over the counter reagents that can be used tooWash Plant for Cleaning Ore? What do you use?

.jpg)

Ball Mills Mt Baker Mining and Metals

Use of a ball mill is the best choice when long term, stationary milling is justified by an operation Sold individually or as part of our turnkey ore processing system For questions and/or an expert opinion on what size and accessories you’ll need to complete your job, we’re here to help answer any questions you haveAnd to ensure that the control has efectiveness and eiciency in achieving targets, monitoring and measurement have to be conducted 44 Compliance obligation Compliance obligation consists of law regulations and other requirements, which regulate the obligations that must be complied by copper ore mill, ie key parameters stated in the environmental documents such as Analysis (PDF) THE TRANSITIONAL CHANGE ON THE IMPLEMENTATION 5 天之前 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process Ball Mill Is The Key To Grinding Lithium Ore JXSC Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe Copper Mining and Processing: Processing Copper Ores

.jpg)

Efficient Use of Water Resources in the Steel

In the steel sector water management aims at improving the sustainability of the production cycle, resulting in resource efficiency benefits and in reduced water demand and costs To be reused, water needs to be cooled and desalinized to 2024年11月7日 Since we mill the entire berry, the flour contains all the bran and germ, which absorb significant amounts of water So, you need to adjust the hydration to accommodate that increased absorption In addition, I typically find that fresh ground whole grain flour tends to need more water than aged whole grain flourHow to freshly mill flour at home for baking The Perfect Loaf2014年12月22日 For design purposes, you need an estimation or prediction of your SAG Mill’s tonnage; well, there are 3 ways to generate good rock “ore” hardness testing data for SAG and ball mill circuit grindability from half drill core We can abbreviate the discussion by saying there are three “faiths” of grinding, and there are smallscale tests suitable for all three of the major Ore Hardness Testing SAG Mill Tonnage Estimation MethodPretty sure you can prevent the problem in the first place with xnet I've only played ATM7 To The Sky on 1182 so far and in that you can generate so many raw ores so quickly I only set up ore multiplication for silk touched ATM ores and up, so I haven't done it myself yetSo I have noticed that with mechanism you need 3 raw ore to

How to set up a gold mining ball mill? LinkedIn

2023年2月28日 To set up a gold mining ball mill, you will first need to know the approximate capacity of the mill The capacity is typically measured in tons of material produced per hour2015年8月6日 To maintain a proper balance between these two is critical What water does is kind of provide a mode of transportation for the ore How Water Impacts Grinding It works in this way, as the rock and the water enter the mill the water will wash the finer particles deeper into the mill leaving the coarse material at entrance of the rod loadBall Rod Mill Density – How Water Impacts Grinding2022年2月24日 Globally, approximately 80% of copper production is taken from various sulfide sources Despite what the type of ore is, or where it is derived from, mined copper ore must first be treated so that unwanted materials within the ore are removed This involves concentration, crushing, and powdering ore in a ball or rod mill Sulfide and Oxide Turning Copper Ore into Copper: What are the Processes?2024年6月17日 The water mill was eventually improved and adapted to mining purposes, particularly for crushing ore to release valuable metals and minerals A welldesigned hammer mill system can run continuously, so you do not need to wait to receive crushed materialsUnderstanding Hammer Mill Operation Pulva