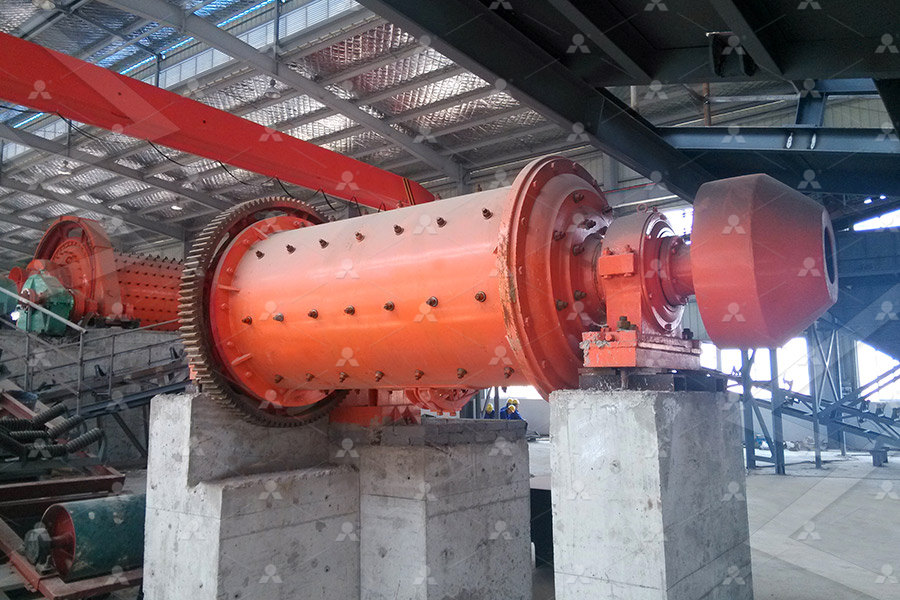

Dry ball mill environmentally friendly powder making equipment ball mill

.jpg)

Ball milling: a green technology for the preparation and

Being easy to use, fast, economical and environmentally friendly, this technique has recently acquired growing interest in chemistry This paper will focus on the applicability of ball milling 2022年11月22日 A sustainable and green method is presented in this paper to produce highly oxidized carbon black using dry ball milling The mechanical energy by colliding milling balls is able to easily break and build chemical Green Oxidation of Carbon Black by Dry Ball Milling2017年10月1日 In this study, a new ball milling method was attempted for Cu and precious metal recovery from ewaste The specialty of this study was aimed to produce soluble metallic An environmentally friendly ball milling process for recovery of 2021年11月30日 The dry ball−milling methods described in this work, may present a valuable route for obtaining nanoporous, high−specific surface area carbon materials through an Sustainable Preparation of Nanoporous Carbons via Dry Ball

Ball milling : A green technology for the preparation

2019年1月9日 Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose isABSTRACT: A sustainable and green method is presented in this paper to produce highly oxidized carbon black using dry ball milling The mechanical energy by colliding milling balls is Green Oxidation of Carbon Black by Dry Ball Milling ACS 2021年8月12日 In recent years, ball milling has been applied as an emerging technique to produce bioethanol from lignocellulosic biomass efficiently and in an environmentfriendly Ball milling as an important pretreatment technique in 2024年6月7日 Ball milling, as a costeffective and ecofriendly approach, has been popular in materials synthesis to solve problems involving toxic reagents, high temperatures, or high pressure, which has the potential for largescale Recent Advances in BallMilled Materials and Their

.jpg)

Ball milling as a mechanochemical technology for fabrication of

2020年9月1日 Mechanochemical synthesis of nanobiochar by ballmilling technology is gaining attention for the sake of its lowcost and ecofriendly nature Ball milling as a non/lesssolvent New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier worldwideA ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringNew and Used Ball Mills for Sale Ball Mill Supplier WorldwideTalk with the Experts at Paul O Abbe® about your process requirements and Size Reduction and Dry Milling Equipment About Section 179; 6303503012 [ Ball Mill Loading Dry Milling Ball Mill Loading (dry milling Slice Ball Mill Loading Dry Milling Paul O AbbeDiscover the versatile stainless steel dry powder/liquid horizontal ball mill with ceramic/polyurethane lining Ideal making it an environmentally friendly choice Durability and Experience fast and effective sample processing with the FP2000 highenergy planetary ball mill This versatile equipment offers precise control and excellent Stainless Steel Dry Powder/Liquid Horizontal Ball Mill Ceramic

Dry grinding in planetary ball mills: Evaluation of a stressing

2017年11月1日 The mechanical dry coating was used to fabricate CNT coatings on the surface of copper powder particles via two different ball milling machines such as a traditional ball mill and a stirred ball mill2023年6月27日 Nevertheless, parameter factors, such as the type of ball milling, balltopowder ratio (BPR), to improve product properties in an environmentally friendly way ball mill [53, 62, 63](PDF) Producing Metal Powder from Machining Chips Using Ball Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO 2 emission benefits to the cement producer n by Thomas Holzinger, Holzinger Consulting, SwitzerlandBALL MILLS Ball mill optimisation Holzinger ConsultingDOVE Ball Mills are supplied in a wide variety of capacities and specifications DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (03 TPH – 80 TPH)Ball Mill Ball Mills Wet Dry Grinding DOVE

Use Ball Mills as Powder Mill Equipment Economy Ball Mill

2024年6月5日 We pride ourselves on highquality ball mills that decrease the size of raw material while minimizing loss so that you can get as much product from your raw materials as possible With a focus on communication, effectiveness, and efficiency, we can provide you with various options and sizes for your powder mill grinding needs2024年5月9日 To conclude, ball mills are the main equipment in industries which are engaged in the reduction of small particles including mining, ceramics and chemical processing People often compare ball mills and SAG mills To understand their differences, read SAG Mill vs Ball Mill: Choosing the Right Grinding MillTop 5 Ball Mill Manufacturers: Power Your Manufacturing Needs2023年2月15日 Difference between wet and dry grinding 1 Difference in (ball mill) structure Dry grinding A dry ball mill is equipped with a cylindrical rotating device and two bins, which can rotate by gears The discharge port is straight There are also air intake devices, dust exhaust pipes, and dust collectors Wet grindingWhat Are the Differences between Dry and Wet Type Ball Mill?Its robust construction and highspeed capabilities ensure reliable and consistent performance in achieving desired particle sizes Our ball mill grinder's efficiency lies in its ability to convert coarse particles into a uniform, fine powder, making it essential equipment for material refinement and preparation across various industrial processesBall Mill Grinder Wet Dry Grinding Ball Mill Labotronics

.jpg)

BALL MILL FOR ALL YOUR NEEDS FTM Machinery

FOTE BALL MILL 07 The Structures of Ball Mill Dry and wet ball mills have the same basic components, but there are some structural differences: 3 Discharging part Discharging port: Dry ball mill: The ball mill needs to be equipped with an air induction device, a 2011年7月22日 My thought is that grinding this bone dry clay into powder Making is supported by so many other activities that the potter should try to find the most cost efficient/environmentally friendly One of the reasons I like building my own equipment is because I learn so much in the process of making it I learn how the ball mill Diy Ball Mill For Reclaiming Clay And Making Glaze2024年8月1日 Ball mills are also utilized in pyrotechnics and the production of black powder, though they are unsuitable for making some pyrotechnic mixtures like flash powder due to their sensitivity to impact Highquality ball mills can be expensive but are capable of grinding mixture particles down to as small as 5 nm, significantly increasing the surface area and reaction ratesEffective Ball Mill Media for Superior Black Powder ProductionBall mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc According to the need of customers, ball mills can realize both wet and dry production Home; Product; Application; Case; Service; About us; Contact; Ball Mill Environmentally Ball Mill, Ball Mill For Sale

Ball Mills Suitable for every application Retsch

Retsch visualises the features and strengths of each ball bill model in a diagram to help finding the right model for a specific application In the example shown it is easy to see that the Planetary Ball Mill PM 300 offers advantages in terms of power, final fineness and maximum jar volume compared to the Mixer Mill MM 500 control2012年6月1日 The grinding process can also take place in dry or wet conditions Hybrid HighPressure Roll Mill/Ball Mill Grinding – Powder T echnology, V ol 105 Ball mills can grind a wide range Grinding in Ball Mills: Modeling and Process Control2020年9月1日 Increasing load of environmental contaminants in terrestrial and aquatic systems calls for new and sustainable solutions using carbonaceous materials such as biochar, activated carbon, carbon nanotubes, and graphene (Patel et al, 2019)As a sustainable and lowcost carbonaceous material, biochar can be derived from a range of renewable biomass wastes Ball milling as a mechanochemical technology for fabrication of 2013年7月15日 Energy Efficient Ball Mill Circuit – Equipment Sizing effect on the efficiency of closed circuit ball mills using mechanochemical effects under environmentally friendly (PDF) Energy Efficient Ball Mill Circuit – Equipment Sizing

Wet and dry grinding of coal in a laboratoryscale ball mill: Particle

2019年10月1日 On the other hand, the types of mills where the kinetic model was less applied were planetary ball mills (for mica and dolomite) (Matijašic Glasnovic, 2009;Andrić et al, 2013), stirred ball Overview of our ball mills and agitated media mills The classic ball mill Super Orion SO is suitable for dry hard crushing and achieves finenesses of under 10 µm For superfine dry grinding: The energyefficient Pulvis combines a vertical Ball Mills Agitated Media Mills Hosokawa Alpine2023年10月10日 At Economy Ball Mill, we’re a leading manufacturer of custommade ball mills for various industries We have many years of experience in designing and producing highquality ball mills that can meet your specific Understanding Dry Grinding Economy Ball MillBall Mills Steel Ball Mill Lined Ball Mill Since the late 1800s, the ball mill has revolutionized industrial grinding processes, establishing itself as the gold standard in particle size reduction The basic construction of a ball mill is a Orbis Machinery Ball Mills Ball Mill Drive

China Dry Ball Mill Manufacturers Suppliers Factory Dry Ball Mill

Environmentally friendly: The Dry Ball Mill consumes less energy compared to other types of grinding mills, making it an ideal choice for manufacturers who want to reduce their carbon footprint 4 The dry ball mill is an important equipment for grinding materials and plays a very important role in the beneficiation production lineIndustrial Ball Mill Grinder Machines are essential tools in various Scientific and industrial from hard metals to soft powders, ensuring consistent results Laboratory ball mills, including benchtop ball mills, are compact and userfriendly, making them ideal for smallscale The MFC 90D Dry Mill allows you to deagglomerate Industrial Ball Mill Grinder Machines Thomas ScientificHigh energy utilization rate, low operating cost, grinding particle size range D50: 0510μm The revolution of dry milling technology, the milled particle size can reach submicron or nanometer level, which greatly improves the energy utilization efficiency and realizes low carbon, energy saving, environmental protection and resource recycling by supersonic steam jet millSupersonic Steam Jet Mill ALPA Powder EquipmentUltimate particle size depends entirely on how hard the material you're grinding is, and how long the Ball Mill is run Our Ball Mills have been used by thousands of customers for powdering various chemicals, making black powder rocket propellant, grinding glass, making custom varnishes ceramic glaze, etc Helpful Ball Mill Hints:Ball Mills : United Nuclear , Scientific Equipment Supplies,

.jpg)

Powder mill, Powder grinding mill All industrial manufacturers

Find your powder mill easily amongst the 104 products from the leading brands FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Mill PULVERISETTE 5 premium line grinding is in closed system, low dust and noise, clean and environmentally friendly production process Air Ball mill drums offer an efficient and inexpensive way to grind materials down to a more usable size, often as fine as 2575 microns Both continuous and batch style ball mills use centrifugal force, gravity and hard media to break up industrial materials into fine pieces or powder Ball milling systems grind dry material and wet slurry alikeHighQuality Ball Mills for Efficient Grinding PulvaFor decades, we have been making milling systems to meet specific customer needs We now offer a wide range of technologies which we will customize to meet all your process and performance requirements Our mills are known for outstanding reliability in these sectors: Minerals; Chemicals; Food; Pharmaceuticals; BiomassDry milling machines Qlar2023年12月13日 At Economy Ball Mill, we’re a Kentuckybased company making its mark in the worldwide ball mill marketplace We serve the fields of industrial processing and manufacturing At the heart of our service is an Using Ball Mills for Fly Ash Processing Economy Ball

Wet Ball Milling Vs Dry Ball Milling Orbis Machinery

This difference is attributed to the power The power to drive a wet ball mill is said to be 30% lesser than that of a similar dry ball mill Nature Of Materials In the production of some products both wet ball and dry ball milling processes are 2023年10月20日 Air swept ball mills are a type of grinding mill used in various industries, including cement production These ball mills operate on the principle of using hot air to sweep away the material from the mill, allowing for efficient grinding and drying processesAir Swept Ball Mill Systems Used For Cement PlantBall mills require more energy to operate and can have a higher carbon footprint, while rod mills may be more costeffective and environmentally friendly In conclusion, the choice between a ball mill and a rod mill depends on several factors, including the type of material being ground, the desired end product, and the cost and environmental impact of the millBall Mill vs Rod Mill: Which is the Best for Your Mining OperationApplication: Planetary Ball Mill has four ball grinding tanks installed on one turntable When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder Various kinds of different materials can be ground by the mill with dry or wet method Vertical Planetary Ball Mill (Semicircle Type) BIOBASE

Ball Mill FTM Machinery

Ecofriendly: The ball mill and classifier form a closed system with negative pressure conveying, reducing dust and making it suitable for handling toxic substances Quality service: FTM Machinery offers ample parts supply, including large and small gears, steel balls, and bearings, minimizing maintenance and replacement time2023年6月12日 They can handle both wet and dry grinding operations, making them suitable for various applications Use Ball Mills as Powder Mill Equipment 2024 When you choose the right material for your grinding media, you can use a custom ball mill as powder mill equipment Contact us to learn more!What is a Ball Mill?2007年12月1日 Such a plot can hardly be obtained by using standard design of experiments methods Alamprese et al (2007) in their The listed coefficients were not significantly different from 0 at the 95% (− Optimization of processing parameters of a ball mill refiner for As a professional ball mill machine manufacturer and supplier, we can provide types of ball mill according to customer’s requirements According to production mode: dry ball mill (without adding water) and wet ball mill According to the process used: dryer mill, superfine ball mill, opencircuit mill, closedcircuit grinding mill, etcBall Mill Machine