C100 calcite mill

.jpg)

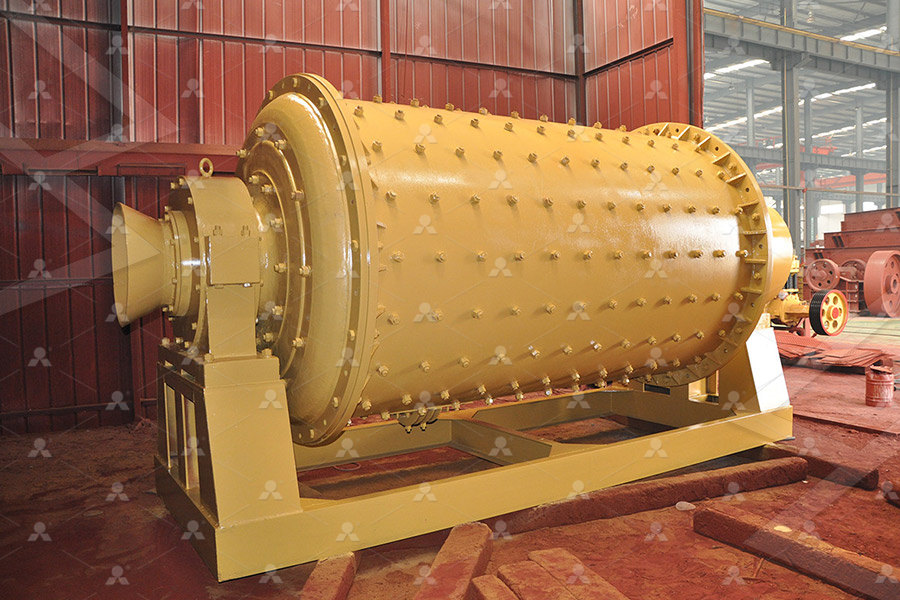

Calcined calcium carbonate grinding machine

Clirik Calcined calcium carbonatepowder grinding machine and Calcined calcium carbonate micro powder grinder mill can grind noninflammable, nonexplosive and brittle materials with Mohs’ hardness under six Such as calcite, chalk, Coarse Powder Hammer Mill Capacity: 10100t/h Max feeding size: 80mm Processing ability: 10100t/h Range of application: Barite, quartz, feldspar, mica, calcite, talc, apatite, gypsum, Coarse Powder Hammer MillHGM10036 Calcite Grinding machine is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs hardness under six Such as calcite, chalk, limestone, dolomite, Calcite Grinding machineThe popular grinding mills for calcite are Raymond mill, ultrafine powder grinding mill, coarse powder mill Calcite powder is available from 100 Mesh to 2500 Mesh Production Line Calcite Grinding Mill

C 语言经典100例 菜鸟教程

C 语言教程 C 简介 C 环境设置 C VScode C AI 编程助手 C 程序结构 C 基础语法 C 数据类型 C 变量 C 常量 C 存储类 C 运算符 C 判断 C 循环 C 函数 C 作用域规则 C 数组 C enum(枚举) C 指针 C 函数指针与回调函数 C 字符串 C 结构体 C 共用体 C 位域 C typedef C 输入 输出 C 文件 2023年1月8日 Particle size distributions of feed for calcite grinding by the stirred mill and ball mill (modified from [39,40] Mills used in this study (a) stirred mill [39], (b) ball mill [40] Figure 4(PDF) Comparison of Particle Shape, Surface Area, and The Effect of Stirred Mill Orientation on Calcite Grinding Serkan Cayirlia, Hasan Serkan Gokcenb 01 1 1 10 100 C SI GM 03) m m FIGURE 5 Relation between product fineness and stressThe Effect of Stirred Mill Orientation on Calcite Grindingサトーパーツ株式会社はスクリューレス端⼦台、ネジ端子台、ヒューズ管など電機部品に関わる製品の製造を行っております。納期・品質・サービスで、ものづくりに貢献します。サトーパーツ株式会社は納期・品質・サービスで

XZM Ultrafine Grinding Mill Zenith Crusher

XZM Ultrafine Grinding Mill Features Ultrafine Powder The fineness can be adjusted between 3252500 meshes, and the screening rate can achieve D97≤5μm once Higher Capacity With the same fineness and power, the capacity is 40% higher than that of jet grinding mill and stirred mill, and the yield is twice as large as that of ball millof calcite in a laboratory scale conventional ball mill Within the context, the influence of operating parameters such as mill speed, ball filling ratio, ball size distribution, powder filling ratio, grinding aid dosage and grinding time were studied The results of grinding tests were evaluated based on the product particle size (d 50, d 80Influences of operating parameters on dry ball mill performanceHCQ1500 Reinforced Coal Grinding Mill Plant 200 Calcite Powder Mill HCH980 Ultrafine Mill ໃນ N Calcite powder mill 100200 mesh 5TPH, HCQ1290 Raymond mill Calcite powder mill 100200 mesh 5TPH, HCQ1290 Raymond millCompaction creep of wet granular calcite by pressure solution at 28°C to 150°C Xiangmin Zhang,1,2 Christopher J Spiers,1 and Colin J Peach1 in the ranges of 100°C to 150°C and 150°C to 28°C, respectively The limestone was crushed in a ball mill and separated into particle size (d) fractions of 12 ± 4, 22 ± 6, Compaction creep of wet granular calcite by pressure solution at 28°C

Compaction creep of wet granular calcite by pressure solution at 28°C

Compaction creep of wet granular calcite by pressure solution at 28°C to 150°C Xiangmin Zhang,1,2 Christopher J Spiers,1 and Colin J Peach1 in the ranges of 100°C to 150°C and 150°C to 28°C, respectively The limestone was crushed in a ball mill and separated into particle size (d) fractions of 12 ± 4, 22 ± 6, Pa ge 1/ 13 Partitioning of REE between calcite and carbonatitic melt containing P, S, Si at 900650 °C and 100 MPa Dmitry A Chebotarev ( 4ebotarev@gmail )900650 °C and 100 MPa Partitioning of REE between calcite and The Influence of Stirred Mill Orientation on Calcite Grinding Serkan Cayirli1 Hasan Serkan Gokcen2 Received: 28 September 2020/Accepted: 7 April 2021 100 001 01 1 10 100 1000 C umulative Passin g (%) Particle Size (µm) Fig 2 The particle size distribution of the feed sampleThe Influence of Stirred Mill Orientation on Calcite Grinding100 mesh calcined powder is used as the raw material for hightemperature calcined alpha alumina powder, which is produced using a 1450 oC hightemperature tunnel kiln calcining process, special additives to reduce impurity content, improve alpha conversion rate, control crystal shape, and particle calcination under enough heat preservation time The micro calcite 100 Mesh Calcined Powder Price Calcite Powder Manufacturers

.jpg)

Calcium Carbonate Grinding Mill Powder Modify SBM

2022年5月5日 Calcium carbonate grinding mill is an efficient industrial powder grinder powder (1503000 mesh) Calcium carbonate grinding mill is an efficient industrial powder grinder machine It can grind 100+ kinds of ores into a fine powder (1503000 mesh) +17 [ to directly crush natural calcite, limestone 2022年12月27日 3 HGM Ultrafine Mill Ultrafine grinding mill is also named HGM ultrafine grinding millIt can be used for pumice, activated carbon, limestone, calcite, marble, talc, barite, gypsum, dolomite, bentonite, mica, pyrophyllite, sepiolite, diatomite, graphite, alumite, fluorite, potassium feldspar , Phosphate rock, pigment and other more than 100 kinds of non How To Make Calcite Powder?Calcite is a calcium carbonate mineral, widely distributed, usually white or colorless Common shapes are granular, massive, fibrous, earthy, and so on The calcite mill can grind calcite into a fine powder of 1503000 mesh, which is widely used Generally, calcite is used as industrial raw material such as chemical industry and cementCalcite Ultrafine Grinding MillPhase one: raw material crushing Calcite blocks will be crushed to 15mm50mm by crusher Phase two: grinding Crushed calcite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground Calcite Grinding Mill Calcite Powder Processing Solution

Grinding of calcite suspensions in a stirred media mill: Effect of

polyelectrolyte could help in processing calcite suspension avoiding the reaggregation of fine fragments The SPA concentration was kept constant at 8% (ie 8 g of SPA per 100 g of CaCO3) for all the runs All thegrindingexperiments were performedin alaboratory stirred media mill (Labstar from Netzsch) using the circulation mode (Fig 1)2022年2月28日 Here we present an experimental study of REE partitioning between carbonatitic melts and calcite in the system CaCO3Na2CO3 with varying amounts of P2O5, F, Cl, SiO2, SO3 at 650–900 °C and 100 Partitioning of REE between calcite and carbonatitic melt 2023年4月21日 Calcite crusher plays a very important role in mining, metallurgy, chemical industry, construction, cement, sand and gravel and other industries They also have double insurance and control over the hydraulic and lubricating systems Calcite Mill The calcite ball mill is the primary grinding instrument in the manufacturing plantCalcite Processing SBM Mill Crusher2021年8月5日 Recommendations for calcite industrial ultrafine powder grinder: Calcite can be ground into powder by industrial milling equipment, and calcite powder has a wide range of uses Common calcite powder has 3000 mesh, Calcite Industrial Ultrafine Powder Grinder SBM Mill

Effects of a High Temperature (500 °C) on the Fracture Springer

2019年8月12日 24 Xray Diffraction (XRD) Measurement for Rock Mineral and Clay Composition Analyses For XRD mineral analysis of calcitecemented sandstone minerals and clays, approximately 5 g of rock specimen was disaggregated with a mortar and pestle, transferred to reagentgrade isopropyl alcohol, and ground using a McCrone micronizing mill Coarse Powder Hammer Mill Capacity: 10100t/h Max feeding size: 80mm Processing ability: 10100t/h Range of application: Barite, quartz, feldspar, mica, calcite Coarse Powder Hammer Mill2018年9月30日 Abstract This study focused on ultrafine grinding of calcite powder (CaCO3) using a vertical stirred ball mill The influences of various operating parameters such as stirrer speed (rpm), ball filling ratio (J), powder filling ratio (fc), solid ratio (wt%) and grinding time were studied under wet conditionsOptimization of Wet Grinding Parameters of Calcite Ore in Stirred Ball MillDRM C100RE Combination Rolling Mill Features Benefits 'C100' Combination Rolling Mill 'R' 4to1 Reduction Gearbox 'E' Side Extension with Half Round Rolls (415mm) 9 Wire Rolling Grooves 7mm to 1mm Maximum Sheet Thickness of 55mm Roll Diameter 50mm Roll Width 100mm (65mm / 35mm)DRM C100RE Durston Tools

Dynamic image analysis of calcite particles created by different mills

PDF On Oct 24, 2014, Ugur Ulusoy and others published Dynamic image analysis of calcite particles created by different mills Find, read and cite all the research you need on ResearchGatec100a スーパーマグネットキャッチ(縦型) 大小2種類あるため用途に応じてお選びいただけます。 下記より絞り込んで商品選択してください。C100A スーパーマグネットキャッチ(縦型) TAKIGEN 2020年12月1日 The solubility of calcite was measured at 100, 120, 140 and 160 °C at 1–50 bar pCO2 in 10⁻³–01 molkg⁻¹ NaCl solutions using a new experimental setup involving in situ pH measurements Experimental determination of calcite solubility and the Type: Roller Mill Motor Type: AC Motor Motor Power: 132kw Rotationl Speed: 15003000 Rpm Application: Mine Materials: NonMetallic Minerals StonesCalcium Carbonate Powder Mill for Limestone, Calcite, Dolomite,

36.jpg)

Effect of microbialinduced calcite precipitation on shear strength

2023年7月26日 Mine tailings are often considered problematic materials because of their loose depositional fabric and susceptibility to static and cyclic liquefaction failures Yet, they are often stored behind tailings’ dams in a highly saturated state, posing significant environmental, social, and economical hazards This study examines the application of a microbially induced calcite 2021年4月1日 Ultrafine grinding of calcite powder was studied under batch wet conditions in a laboratory stirred mill After grinding, the suspension was allowed to age at 30°C for 12 and 24 hThe Influence of Stirred Mill Orientation on Calcite GrindingCalcite Mill Dynamic image analysis Circularity Aspect ratio In this study, particle shapes of calcite mineral ground by different mills namely ball, rod and autogenous millsDynamic image analysis of calcite particles created by2009年7月1日 a b s t r a c t An experimental investigation was carried out on the ultrafine grinding of inorganic powders using a stirred ball mill The power consumed in the grinding process was measured Effect of grinding aids on the kinetics of fine grinding energy

Compaction creep of wet granular calcite by pressure solution at 28°C

2010年9月30日 [1] Uniaxial compaction experiments have been carried out on wet calcite powders prepared from milled limestone, analytical grade calcite, and superpure calcite The tests were performed at 28°C–150°C, effective stresses of 20–47 MPa, and a pore pressure of 20 MPa, using presaturated CaCO 3 solution as the pore fluid Sample grain sizes ranged from 12 to 86 2022年2月22日 The choice of calcite grinding mill 1 Raymond Mill Raymond mill can process materials with Mohs hardness below 7, the moisture content of the material is required to be below 6%, the fineness range of the finished product is 080045mm, and the processing capacity is 0895 tons per hourWhich crushers and mills are suitable for processing calcite?2018年9月24日 One of the most energyintensive processes for producing submicron range calcite is stirred media mill In the present work, numerous operating parameters such as solid mass fraction, grinding media size, media filling ratio, and grinding time have been investigated using a vertical type stirred media mill The results are evaluated on the basis of mean particle Effect of Operating Parameters on the Breakage Process of Calcite There are five models of calcite grinding mill: HGM80, HGM90, HGM100, HGM125 and HGM1680L, both ultra fine grinding mill Finished production fineness: 250meshes2500meshes, 574 micronCalcite Grinding Mill

(PDF) Grinding of Calcite to NanoSize: Effect of Mill Capacity and

The calcite mineral was broken to 8 mm by impact crusher before feeding to the mill The grain size (d90) of the calcite feed to the mill is ~ 4 mm 2 Open Journal of Nano Abdül Vahap KORKMAZ Open Journal of Nano (2019) 4–1 Figure 2 In addition, the capacity of the conventional ball mill for the fabrication of nanosized products should be significantly reduced When the mill capacity is reduced by 75% (5 tph) and grinded with Cylpebs, the fineness (d 90) of the product reaches 1300 nanometers Key words: Ball Mill, Ball, Calcite, Cylpebs, Nano Grinding 1 IntroductionGrinding of Calcite to NanoSize: Effect of Mill Capacity