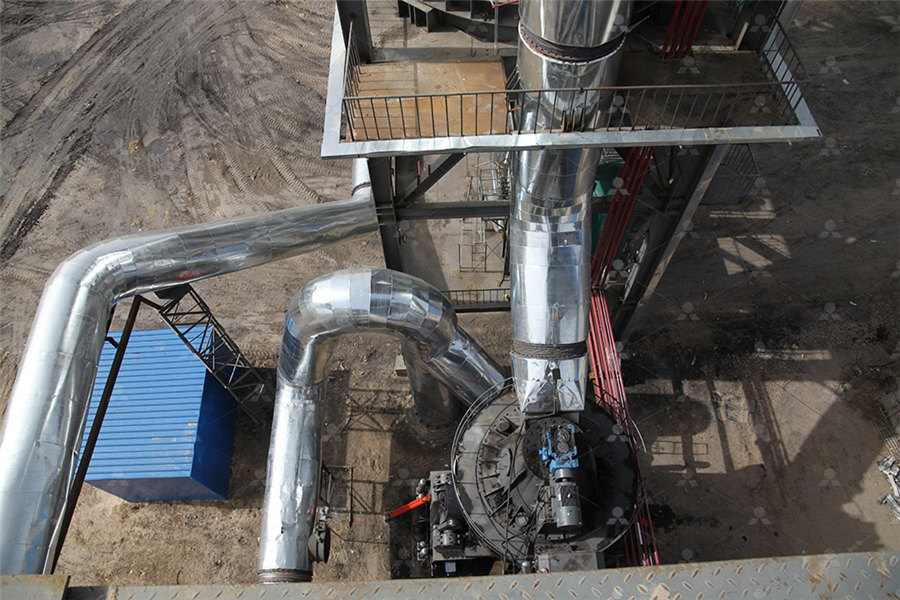

Vertical shaft asphalt coke petroleum coke mill structure

.jpg)

Introduction of a Vertical Shaft Kiln Coke at Ma’aden Green Mill

Due to the floating nature of calcined petroleum coke (CPC) in the marketplace globally in terms of supply and quality, it is always discussed to introduce vertical shaft kiln (VSK) CPC for Delayed petroleum coke is calcined in an internallyfired vertical shaft kiln A downwardlymoving bed of green coke is preheated in the top of the kiln by rising combustion gases, then heatUSA Method for calcining delayed coke Google PatentsThe green coke produced in crude oil refineries that meets quality requirements for size, impurities, and coke structure is calcined before production of anodes for the aluminum NEW GENERATION OF VERTICAL SHAFT CALCINER TECHNOLOGYCalcined Petroleum Coke (CPC) is produced from calcined coke technology by heating coke to a high temperature of 5501,150 °C using a rotary kiln or vertical shaft kiln The calcination Calcined Kiln Analysis and Proximate Simulation of HighQuality

CB01 Petroleum coke shaft calcining technology final

GPC is heated indirectly in the vertical shafts as the coke mass moves down slowly Unlike in rotary kiln calcining, the GPC is not exposed to the flames during the processThe long resident time of coke with shaft technology enables a higher degree of calcination ie higher real density for a correspondingly significant lower calcining temperature than in rotary CB01 Petroleum coke shaft calcining technology final ICSOBAAlibaba offers 91 vertical shaft kiln for petroleum coke products About 12% of these are cement making machinery A wide variety of vertical shaft kiln for petroleum coke options are vertical shaft kiln for coke calcinationIn this paper, a numerical tool is presented, which simulates a largescale Parallel Flow Regenerative (PFR) kiln that currently uses coke as main fuel The developed tool aims at Schematic presentation of vertical shaft kiln; (a) preheating zone,

EVALUATION AND ANALYSIS OF EXERGOECONOMIC

Key words: calcinations process, vertical shaft furnace, exergy analysis, exergy flow cost, exergoeconomic analysis Introduction Green petroleum coke (GPC), as the byproduct of The traditional process and structure of vertical shaft furnace (VSF) are described, and the problems existing in the traditional process are deeply analyzed Using CFD method and Research on Premixed Stable Combustion Process of Vertical Shaft 2013年10月2日 When a honeycomb of asphalt becomes large enough, it may dislodge and float to the top of the asphalt It floats even though it is denser than asphalt, because of the honeycomb structure The holes in the structure fill with asphalt and air, pushing the structure to the surface Although these chunks look large, the actual coke content is a ASPHALT COKE IKOVertical Shaft Calcination Process Description Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free The document discusses plans to build a vertical shaft calciner to produce 500,000 Vertical Shaft Calcination Process Description PDF

.jpg)

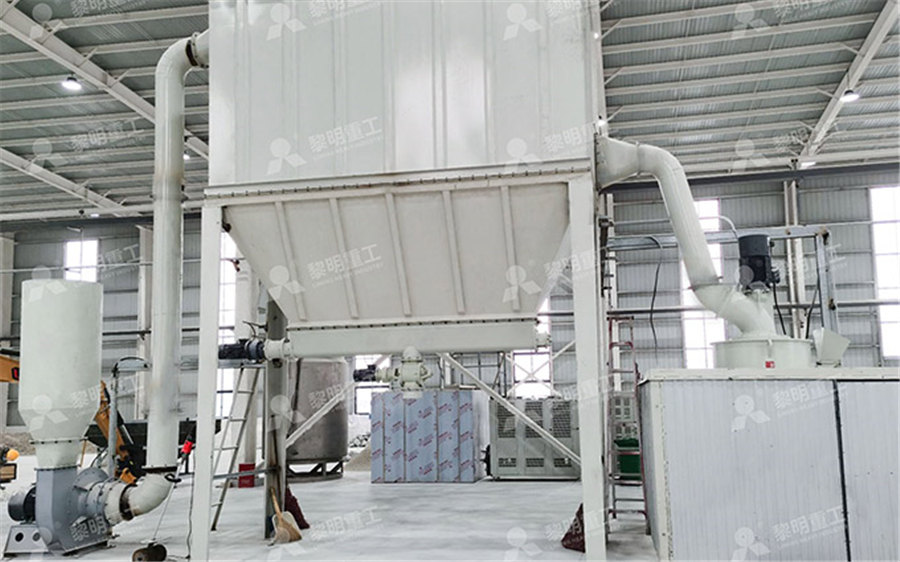

China Pet Coke Vertical Mill Manufacturers Pet Coke

Due to its special process and structure, the pet coke vertical mill has less dust and less noise in the production process, and the produced petroleum coke powder has an efficient gradation The petroleum coke vertical mill produced The calcination process of green petroleum coke in the vertical shaft furnace has been studied in the past years A schematic of the process is shown in Fig1EVALUATION AND ANALYSIS OF EXERGOECONOMIC Active lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Vertical Shaft Lime Kiln for Cement Plant2016年2月25日 A realtime mathematical model for the twodimensional temperature field of petroleum coke calcination in vertical shaft calciner was developed based on computational fluid dynamics In the modeling process, the petroleum coke discharging process was described by the solid viscous flow, the dynamic heat flux boundary condition was adopted to specify the heat A RealTime Mathematical Model for the TwoDimensional

Petroleum Coke Vertical Mill and Hrm MadeinChina

2018年8月29日 Hrm Petroleum Coke Vertical Mill, Find Details and Price about Petroleum Coke Vertical Mill Hrm from Hrm Petroleum Coke Vertical Mill Hefei Zhongya Building Material Equipment Co, Ltd Home Product Directory Manufacturing Processing Machinery Machine Tools Milling Machineenergy consumption and results in a porous coke structure [12] However, it was shown recently that the thermal desulfurization in a vertical shaft calciner at slow heating rates produces a coke that can possibly be used in blends at levels of 50% or lower [13] Hydrodesulfurization is aHydrodesulfurization of Petroleum Coke ICSOBAVertical Shaft Kiln (VSK) Engineering, Procurement Construction, Find Details and Price about Gree Petroleum Coke Calciner Calcined Petroleum Coke Produce from Vertical Shaft Kiln (VSK) Engineering, Procurement Construction Guiyang Aluminium Magnesium Design Research Institute CompanyVertical Shaft Kiln (VSK) Engineering, Procurement ConstructionNEW GENERATION OF VERTICAL SHAFT CALCINER TECHNOLOGY Jingli Zhao, Qingcai Zhao, Qingbo Zhao Jinan Aohai Carbon Corporation Ltd, Jinan, Shandong Province, China Keywords: green coke, CPC, vertical shaft calciner, heat recuperation, power generation Abstract The vertical shaft calciner has been widely applied in China for CPC calcinationThe New Generation of Vertical Shaft Calciner Technology

.jpg)

EVALUATION AND ANALYSIS OF EXERGOECONOMIC

Key words: calcinations process, vertical shaft furnace, exergy analysis, exergy flow cost, exergoeconomic analysis Introduction Green petroleum coke (GPC), as the byproduct of petroleum refineries [1, 2], could be used as the unique material to manufacture calcined petroleum coke (CPC) throughAt present,the petroleum coke is mainly calcined by vertical shaft furnace or rotary kiln to meet the requirement of prebaked anode used for aluminium reduction in ChinaVertical shaft furnace for calcination is quite different from rotary kiln for calcination in the principle of calcination process,calcined coke quality,product availability,production capacity,energy The comparison between vertical shaft furnace and rotary kiln for Petroleum coke, also known as petcoke, is a solid carbonrich material that is produced during the refining of crude oil Skip to main content; Skip to footer; This process is known as calcining, and involves heating the petcoke to high What is Petroleum Coke? EKT InteractiveXiao et al (2016b) developed a 3D mathematical model to consider petroleum coke pyrolysis and investigated the distribution characteristics of temperature, species, and velocity fields in a shaft A RealTime Mathematical Model for the TwoDimensional

.jpg)

Resistance characteristics and particle movement behavior of a

Because of the increasingly deteriorating quality of petroleum coke raw materials, abnormal furnace conditions, such as “firing and blasting”, frequently arise during the calcination of petroleum coke with a high powder/coke ratio in a vertical shaft calciner This poses an urgent technical challenge that needs to be addressed In iron and steel metallurgy, the burden 2024年6月2日 Petroleum coke, or pet coke, is a carbonaceous solid derived from oil refinery coker units or other cracking processes It serves as a valuable fuel source in various industries, including cement, power generation, and metallurgy To efficiently process pet coke, specialized equipment known as crushers is requiredPetroleum Coke Crusher: Choosing the Right Equipment2021年1月1日 petroleum coke physical sensible heat (ie 59028%) coming from the rotary kiln To maintain the calcined petrole um coke temperature to be below 80 o C for tran sportation, the cooling technologyA synergy model of material and energy flow analysis for the 2022年6月17日 Lowquality sulfur petroleum coke usually not widely qualified for use and is stockpiled at refineries around the world or used as solid fuel One of the promising uses of lowquality petroleum coke is its physical or chemical activation in order to obtain a highly porous carbon material that can be used as a catalyst carrier, adsorbent, the basis for capacitive Parameters influence establishment of the petroleum coke

.jpg)

CB01 Petroleum coke shaft calcining technology final ICSOBA

Petroleum coke shaft calcining technology salient features of construction and production techniques Oscar Mascarenhas1, Raghunath Prabhu2, Arun Mathur3 and Antonio Botelho4 1 General Manager (Projects) 2 Manager Commercial 3 General Manager (Engineering) 4 CEO Goa Petcoke Consultancy Private Limited, IndiaCALCINED PETROLEUM COKE (CP COKE) [EIRI/EDPR/4457] JC: 2668XL Calcined Petroleum Coke (CPC) is manufactured from Raw Petroleum Coke (RPC) by the process known as high temperature pyrolysis The process is carried out in a rotary or vertical kiln at temperatures exceeding 1300 deg C CalcCalcined Petroleum Coke (CP Coke) (Capacity: 30 MT/Day)PDF On Jan 1, 2014, Aliasghar Rohani and others published Calcinations of Petroleum coke Find, read and cite all the research you need on ResearchGate(PDF) Calcinations of Petroleum coke ResearchGateCALCINED PETROLEUM COKE [3595] Coke is a fuel with few impurities and high carbon content, usually made from coal It is the solid carbonaceous material derived from destructive distillation of lowash, lowsulphur bituminous coal Coke made from coal are grey, hard, and porous While coke cDetailed Project Report on calcined petroleum coke

.jpg)

(PDF) Prebaked anode based on petroleum coke

2023年10月27日 PDF Noncalcined petroleum coke can serve as an anode material for lithiumion batteries (LIBs) Nevertheless, this method results in materials with Find, read and cite all the research you 2016年2月25日 properties of petroleum coke on the calcination process and proposed an effective program to reduce energy consumption Compared with studies on a rotary kiln, fewer studies have been conducted on numerical simulations of petroleum coke calcination in a vertical shaft calciner Zhang et al9–11 studied the gas combustion in the flue and the A RealTime Mathematical Model for the TwoDimensionalCALCINED PETROLEUM COKE (CP COKE) (30 MT/Day )[CODE NO4457] Calcined Petroleum Coke (CPC) is manufactured from Raw Petroleum Coke (RPC) by the process known as high temperature pyrolysis The process is carried out in a rotary or vertical kiln at temperatures exceeding 1300 deg C Calcincalcined petroleum coke (cp coke) (30 mt/day )Fly ash vertical roller mill Nickel slag vertical roller mill Quicklime vertical roller mill Natural gypsum vertical roller mill Clay vertical roller mill Iron ore vertical roller mill Silica sand vertical roller mill Pyrophyllite vertical roller mill Phosphate rock vertical roller mill Petroleum coke vertical roller millPetroleum coke vertical roller mill

.jpg)

A RealTime Mathematical Model for the Two Semantic Scholar

2016年2月25日 A realtime mathematical model for the twodimensional temperature field of petroleum coke calcination in vertical shaft calciner was developed based on computational fluid dynamics In the modeling process, the petroleum coke discharging process was described by the solid viscous flow, the dynamic heat flux boundary condition was adopted to specify the heat HC Petroleum Coke mill structure: Powder Paint Grinding Mill From China Supplier, Mill Grinder, Coal Grind, Ultra Fine Mill, Petroleum Coke Vertical Roller Mill, Phone Tel 86 Email Email hcmkt@hcmilling Top Hit enter to search or ESC to close English; French; German;Grinding Petroleum Coke PowderPetroleum coke is usually calcined in a gasfired rotary kiln or rotary hearth at high temperatures, around 1200 to 1450 °C, to remove moisture, drive offProduction and Application of Calcined Coke In RotaryThe effect of pressure on the measured value for resistivity of different coke samples has also been reported elsewhere 66 The resistivity of bulk metallurgical coke is given as 0024 Ω m with a slightly lower value of 0020 Ω m at a pressure of 043 Pa, while for calcined fluid petroleum coke at zero applied pressure the resistivity was 002 Ω m, which decreased to 0002 Ω m Petroleum Coke an overview ScienceDirect Topics

News Advantages of petroleum coke environmental

How is the price of oil coke powder? Guilin Hongcheng environmental protection vertical mill plant learned that petroleum coke is the decompression slag oil of oil, through the coking unit, in 500550℃ cracking coking and generated black For further studies, all the obtained petroleum coke was ground on a Fritsch planetary ball mill and sieved through a 125 µm sieve on a Retsch AS 200 laboratory vibrating screen 23 Activated petroleum coke production 5 g of petroleum coke was mixed in a crucible with 15 g of KOH The resulting mixture was transferred to a NaberthermParameters influence establishment of the petroleum coke2018年12月1日 The production of petroleum coke from heavy oil tar and from asphalt (derived from heavy oil tar by means of propane) at excess pressures of 015, 025, and 035 MPa is consideredInfluence of Pressure in the Coking of Heavy Oil Tar American Pulverizer's Double Roll Crushers and Reversible Shredders are ideal for crushing and processing petroleum coke They are designed for high production with minimal maintenance We bring over 100 years of experience to the design and performance of our equipmentPetroleum Coke Crusher Equipment Shredders, Hammermills

Resistance characteristics and particle movement behavior of a

2024年5月29日 Because of the increasingly deteriorating quality of petroleum coke raw materials, abnormal furnace conditions, such as “firing and blasting”, frequently arise during the calcination of petroleum coke with a high powder/coke ratio in a vertical shaft calciner This poses an urgent technical challenge that needs to be addressed In iron and steel metallurgy, the This approach has been found on single shaft using natural gas [13,14] or heavy oil as fuel [15], ASK with natural gas as fuel [16,17], and mixedfeed shaft kilns with coke [18,19] Schematic presentation of vertical shaft kiln; (a) preheating Backgr pp 1–30 [18] Edward L 2011 Quality And Process Performance Of Rotary Kilns And Shaft Calciners Edited by: Stephen J L (USA: TMS (The Minerals, Metals Materials Society) [19] Ellis P J and Paul C A 2000 Tutorial: Petroleum coke calcining and the uses of calcined petroleum coke 3rd International Conference on Refining Processing: Topical Conference Proceedings Calcined Kiln Analysis and Proximate Simulation of HighQuality Coke 2014年1月1日 Calcined coke is the best material for making carbon anodes for smelting of alumina to aluminum Petroleum coke is usually calcined in a gasfired rotary kiln or rotary hearth at high temperatures (PDF) EProduction and Application of Calcined Coke In Rotary

Detailed Project Report on calcined petroleum coke

CALCINED PETROLEUM COKE [CODE NO3440] COKE Coke is a fuel with few impurities and a high carbon content, usually made from coal It is the solid carbonaceous material derived from destructive distillation of lowash, lowsulphur bituminous coal Cokes made from coal are The Petroleum coke ball mill, combined with the properties of pet coke, the structure of the liner and grinding media of the pet coke ball mill has been optimized many times vertical mill, rod mill and AG/SAG mill for grinding in a variety of industries and materials Contact : info@ballmillssupplier; Tel: +86 ;Petroleum Coke Ball Mill