Lithium fly ash

.jpg)

Distribution and occurrence of lithium in highaluminacoal fly ash

2018年3月15日 Highaluminacoal fly ash (HAFA) with a high Li content is regarded as a potential resource for Li production To support the development of Li recovery technology 2024年3月1日 This work proposed an efficient process for recovering aluminum, lithium, iron and gallium from coal fly ash leachate Firstly, 981 %, 866 % and 998 % of iron, lithium and Efficient recovery of aluminum, lithium, iron and gallium from coal 2024年1月8日 In this study, fly ash and a mixed roasting agent (Na 2 CO 3 and K 2 CO 3 mass ratio of 3:1) were mixed at a mass ratio of 2:1 under 950 °C for 2 h The results showed that Lithium activation pretreatment mechanism and leaching process 2017年7月14日 A novel technique was developed for the recovery of lithium and aluminum from coal fly ash using a combination of predesilication and an intensified acid leaching process The main components of the highaluminum An Efficient Approach for Lithium and Aluminum

Lithium in Greek Coal Fly Ashes: Contents and

2023年11月6日 Eight coal fly ashes from different power plants in Greece were collected, and their major constituents were analyzed by Xray fluorescence spectroscopy (XRF); their mineralogy was studied by Xray powder diffraction 2016年2月8日 In this research, the use of fly ash from coal combustion as conductive enhancer for increasing the performances of lithium battery was investigated Lithium iron phosphate Improving lithiumion battery performances by adding fly ash 2019年1月25日 In order to realize the high additive value of fly ashes, in this work, we transform the solid waste fly ashes into nanostructured silicon (NanoSi) powders and apply them as Fly ashes as a sustainable source for nanostructured Si anodes in To clear understand the dissolution characteristics of lithium (Li) in fly ash, the dissolution characteristics of Li in acidic solution and alkaline solution from the original fly ash, activated 不同活化条件下粉煤灰中锂的酸碱溶出特性

烧结剂对新疆粉煤灰中锂浸出的作用特性

以新疆燃煤电站典型粉煤灰为研究对象,应用不同烧结剂与粉煤灰分别混合高温煅烧,通过盐酸和硫酸浸出锂,研究了烧结剂种类、煅烧温度、烧结剂添加量、浸出剂种类对锂浸出的影响。 另外本文将微波技术应用于锂的浸出,对比研究了 2021年10月1日 Coal fly ash (CFA) has been employed as a catalytic support for lithium ions by impregnation The basicity, basic strength, and stability of the resultant catalyst were further tuned by varying active species concentration (1 wt%–7 wt%) and calcination temperature (300–600 °C) The relationship between the basic properties of catalyst and their catalytic activity Lithium loaded coal fly ash as sustainable and effective catalyst for 2023年10月15日 A novel method of highefficiency extraction of aluminum (Al) and lithium (Li) from coal fly ash (CFA) is proposed The mixture of CFA and sodium pyrosulfate (Na 2 S 2 O 7) was subjected to mechanochemical activation, followed by the addition of sodium persulfate (Na 2 S 2 O 8) for pressure leachingThe results indicated that the leaching efficiency of Al and Li Highefficiency extraction of aluminum and lithium from coal fly ash 2016年2月8日 In this research, the use of fly ash from coal combustion as conductive enhancer for increasing the performances of lithium battery was investigated Lithium iron phosphate (LiFePO 4 ) was used as the active material of cathodeImproving lithiumion battery performances by adding fly ash

Activation Pretreatment and Leaching Process of HighAlumina Coal Fly

2020年7月5日 Experiments were conducted to investigate the process of aluminum and lithium extraction from highalumina coal fly ash (HCFA) generated from coalfired power plants located in northern China The presence of mullite and other aluminosilicates lead to low reactivity of coal fly ash An activation pretreatment that destroys an inert composition of coal is necessary2024年4月18日 In order to explore the application of these solid wastes in the road base, this paper studies the effect of adding lithium slag activated by an alkaline activator, fly ash (FA) and a combination of the two on the compressive strength, splitting strength and shrinkage performance of recycled cementstabilized macadam mixture (RCSM)Study on the Performance of Recycled CementStabilized 2014年2月1日 High performance concrete (HPC) was prepared using lithiumslag and fly ash,which are the industrial waste in Xinjiang Province,China,and its mechanical properties,crack resistance impermeability Properties and Microstructure of HPC with LithiumSlag and Fly Ash2023年5月15日 The catalytic potential of Na and LiNa fly ash (FA) obtained through a simple solidstate synthesis was investigated for the pyrolysis of Isochrysis sp microalgae using a fixed bed reactor at 500 °C While both LiNaFA and NaFA catalysts reduced the biooil yield and increased char and gas production, LiNaFA was found to enhance the quality of the resulting Lithium–Sodium Fly AshDerived Catalyst for the In Situ Partial

.jpg)

Extraction of lithium from coal fly ash by lowtemperature

DOI: 101016/jseppur2021 Corpus ID: ; Extraction of lithium from coal fly ash by lowtemperature ammonium fluoride activationassisted leaching @article{Xu2021ExtractionOL, title={Extraction of lithium from coal fly ash by lowtemperature ammonium fluoride activationassisted leaching}, author={Hai Ming Xu and Chunli Liu and Xue 2024年1月8日 The activation pretreatment that destroys an inert composition of fly ash is necessary In this study, fly ash and a mixed roasting agent (Na2CO3 and K2CO3 mass ratio of 3:1) were mixed at a mass ratio of 2:1 under 950 °C for 2 h The results showed that the leaching rate of lithium increased by 70% Direct acid leaching experiments show that Lithium activation pretreatment mechanism and leaching process 2019年10月15日 XRD patterns: (a) lithium slag, (b) fly ash, (c) ordinary Portland cement, and (d) fine tailings 22 Experimental program and methods (1) Cementitious characteristics of binders In order to observe the cementitious characteristics of the binders, the specimens were prepared with tap water and different combinations of LS, FA, and OPCLithium slag and fly ashbased binder for cemented fine tailings Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), [1] are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls: Diagram of the disposition of coal combustion wastes Fly ash is captured after coal combustion by filters (), Coal combustion products Wikipedia

Lithium in Greek Coal Fly Ashes: Contents and Characterization by

coal ash is estimated to be produced every year [6,16,26,27] China produces 500 million tons annually, while according to the statistics of the ECOBA (European Coal Combustion Products Association), of which Greece is a member, in 2016, more than 192 mt of fly ash was produced in Europe Coal fly ash is utilized directly as a raw resource or 2021年12月15日 A novel method, including ammonium fluoride activation and water leaching, was developed to extract lithium from coal fly ash Lithium was released from the glass phase in CFA by using ammonium fluoride activation More than 90 % of lithium was extracted at 155 °C and SiO 2 /NH 4 F mass ratio of 1:135Extraction of lithium from coal fly ash by lowtemperature 2022年1月20日 Silicon nanoparticles were firstly prepared from industrial waste fly ash via a solidstate and magnesiothermic reaction with molten salt The entire progression is feasible, green, economical, and scalable Si nanoparticles served as anode materials for lithiumion batteries (LIBs), delivering high specific capacity of around 31731 mAh g−1, and outstanding Trash to Treasure: Harmful Fly Ash Derived Silicon Nanoparticles 2022年2月1日 Li 4 SiO 4 (LiFA) derived from fly ash were tested for high temperature precombustion CO 2 sorption LiFA did not adsorb H 2 and CO in presence of steam CO 2 uptake of 42 mmol CO 2 /g was achieved at 700 °C, 45 bar CO 2 (15 bar P total) LiFA sorbent had an excellent cyclic stability over 10 cycles • SEM and elemental mapping showed retention of Evaluation of palmoil fly ash derived lithium silicate for CO2

.jpg)

Preparation of Manganese Dioxide Lithium Ion Sieve and Its

2024年2月10日 Coal fly ash (CFA) is considered as a substitute for lithium resources [11,12,13]As one of the solid wastes produced by coalfired power plants, CFA has the characteristics of flammability, corrosiveness, reactivity and toxicity, which are difficult to treat and pose a threat to the environment and public health [14,15]Although CFA is currently used in 2023年11月6日 The fly ash from Achlada (ACH) appears to possess the highest lithium content, 256 mg/kg Li This value corresponds to 006 weight percent (wt %) of lithium oxide (Li 2 O) and is comparable to the lithium content found in some industrialgrade Libearing pegmatite depositsLithium in Greek Coal Fly Ashes: Contents and Characterization by 2020年4月28日 China is the largest coal consumer around the world, and coal accounts for more than 60% of the country’s energy mix (Peng et al 2018; Wang et al 2019)Coal fly ash (CFA), a solid waste produced by coalfired thermal power plants during the combustion of pulverized coal, is currently one of the largest solid wastes in China (Yao et al 2015)Utilization of coal fly ash in China: a minireview on challenges 2021年5月16日 The present work used solvent extraction method to extract lithium from hydrochloric acid leaching solution of highalumina coal fly ash In extraction stage, the optimum conditions were explored, at 20 ℃ and O/A = 1:4, using 70%(Vol) tributyl phosphate30%(Vol) sulfonated kerosene036 mol/L Fe 3+ as extractant, extraction of lithium could reach 99% by Solvent extraction of lithium from hydrochloric acid leaching solution

Preparation of BatteryGrade Lithium Carbonate with Lithium

2021年8月4日 In this study, a process for preparing batterygrade lithium carbonate with lithiumrich solution obtained from the low lithium leaching solution of fly ash by adsorption method was proposed A carbonizationdecomposition process was carried out to remove impurities such as iron and aluminum First, primary Li2CO3 was treated by CO2 to get the more soluble Figure 5 A, Arsenic (As) elemental map of fly ash sample A showing relative concentrations; the relative highest concentrations of arsenic are shown in red and lowest concentrations are shown in blue B, Xray absorption spectrum of the region of analysis circled in A, and fit to spectrum with materials of known arsenic species, which demonstrates that two chemical forms ofTrace Elements in Coal Ash USGS Publications Warehouse2019年1月25日 The nanostructured silicon exhibits good electrochemical performance as lithiumion batteries anodes with high rate capacity (14503 mAh g−1 at current density 4000 mA g−1) and (2015) Conversion of coal fly ash to zeolite utilizing microwave and ultrasound energies: a review Fuel 140:250–266 Article Google ScholarFly ashes as a sustainable source for nanostructured Si anodes 2023年9月22日 Lithium slag, fly ash, kaolin and albite were used in the preparation of ceramsite Lithium slag and fly ash were sourced from Pujiang and Meishan in Sichuan Province, China Albite was taken from Tianjin Letai Chemical Co, LTD, China, and kaolin was purchased from Donggang Kaolin Development Company, Liaoning Province, ChinaPreparation of lightweight ceramsite from solid waste lithium slag

Review A review on fly ash highvalue synthesis utilization and its

2024年3月1日 Specifically, the glass phase in coal fly ash was converted to watersoluble fluoride salts after the salt activation process, which was followed by the extraction of lithium from the glass phase via water leaching This work provides a promising method for lithium recovery from fly ash to alleviate the scarcity of lithium resources2015年10月15日 The use of waste materials such as fly ash as precursors of CO 2 sorbents is also a very promising area of research, since they are lowcost and widely available [17], [5] OlivaresMarín and coworkers compared the CO 2 sorption capacity of pure lithium silicate and Lisilicate prepared from fly ash in presence of pure CO 2Development of sodium/lithium/fly ash sorbents for high 2021年10月1日 Coal fly ash (CFA) has been employed as a catalytic support for lithium ions by impregnation The basicity, basic strength, and stability of the resultant catalyst were further tuned by varying active species concentration (1 wt%–7 Lithium loaded coal fly ash as sustainable and effective catalyst 2015年2月1日 Coal fly ash accounts for 5–20 wt% of feed coal and is typically found in the form of coarse bottom ash and fine fly ash, which represent 5–15 and 85–95 wt% of the total ash generated, respectivelyCoal ash is discharged by both wet and dry methods of coal combustion Bottom ash refers to the ash that falls down through the airflow to the bottom of the boiler and A comprehensive review on the applications of coal fly ash

.jpg)

Development and Characterization of AlkaliActivated Lithium SlagFly

2024年11月26日 As the demand for environmental sustainability grows in the global construction industry, traditional cement production faces significant challenges due to high energy consumption and substantial CO2 emissions Therefore, developing lowcarbon, highperformance alternative cementitious materials has become a research focus This paper 2023年3月1日 1 Introduction As the demand for metals grows globally, the processing of secondary metal resources has become highly essential (Ghassa et al, 2020; Golzar Ahmadi and Mousavi, 2021)Coal fly ash (CFA) is one of the most important industrial wastes regarding environmental and economic concerns (Bu et al, 2021)It exhibits hazardous properties, such Spentmedium leaching of germanium, vanadium and lithium from coal fly 2020年7月5日 DOI: 103390/met Corpus ID: ; Activation Pretreatment and Leaching Process of HighAlumina Coal Fly Ash to Extract Lithium and Aluminum @inproceedings{Li2020ActivationPA, title={Activation Pretreatment and Leaching Process of HighAlumina Coal Fly Ash to Extract Lithium and Aluminum}, author={Shenyong Li and Peng Activation Pretreatment and Leaching Process of HighAlumina Coal Fly Request PDF On Sep 1, 2023, Changbin Li and others published Preparation of lightweight ceramsite from solid waste lithium slag and fly ash Find, read and cite all the research you need on Preparation of lightweight ceramsite from solid waste lithium slag

.jpg)

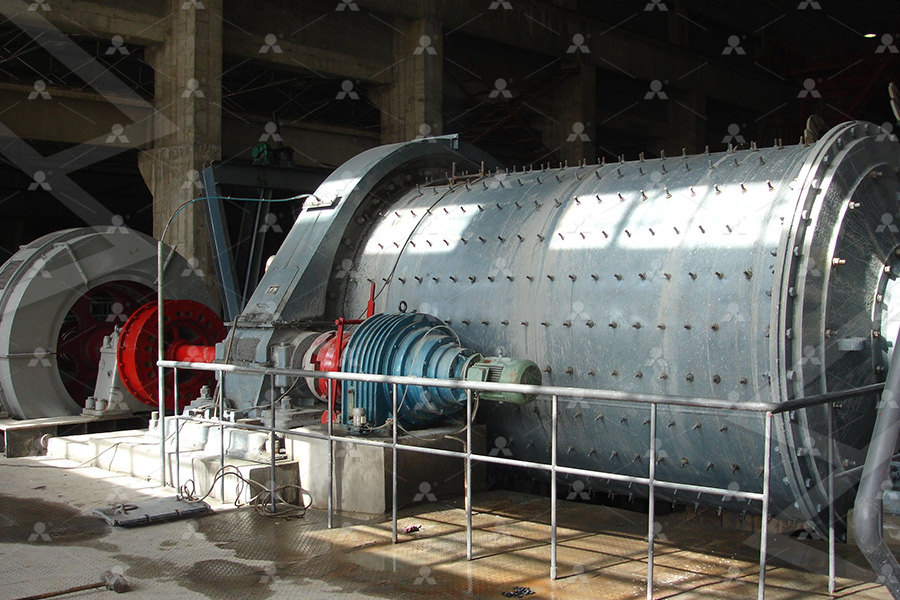

Lithium Infused Processed Fly Ash for the Production of High

A process is provided for treating raw fly ash used in cementitious material so as to increase the strength of the cementitious material while at the same time providing a near linear strength increase for the material as it cures by processing the raw fly ash, as by milling, and by mixing the processed fly ash with a catalyst such as lithium, with the lithium concentration in the fly ash 2024年1月8日 The activation pretreatment that destroys an inert composition of fly ash is necessary In this study, fly ash and a mixed roasting agent (Na 2 CO 3 and K 2 CO 3 mass ratio of 3:1) were mixed at a mass ratio of 2:1 under 950 °C for 2 h The results showed that the leaching rate of lithium increased by 70% Direct acid leaching experiments show Lithium activation pretreatment mechanism and leaching process 2022年4月1日 In this study, we investigated the performance of a synthetic resin for the adsorption of Li from predesilicated solution which is the waste liquid produced by extracting aluminum from fly ash The adsorption kinetics and isotherms of the resin were obtained and analyzed The saturated adsorption sites of the resin were in agreement with the quasisecond Performance of a synthetic resin for lithium adsorption in waste liquid This research work was an exploration of the feasibility of utilizing a lithium slag (LS) and fly ash (FA)based binder for cemented fine tailings backfill (CFTB) Extensive experiments were conducted with different combinations of LS and ordinary Portland cement (OPC), along with FA as an additive The unconfined compressive strength (UCS), micromorphology and slump Lithium slag and fly ashbased binder for cemented fine tailings

Iron Removal from a Highlithium Coal Fly Ash by Magnetic

This is an essay in the field of mineral processing engineering In this study, coal fly ash from a power plant in Guizhou was used as the research object A series of test methods were comprehensively applied to the determination of the mineral composition and element content of coal fly ash The results show that the main minerals in coal fly ash are mullite, quartz and iron 2022年4月1日 Fly ash, an atypical aluminosilicate material that can be considered a potential “urban mineral” resource, mainly consists of SiO 2 (356%–572% (mass)), The maximum lithium adsorption capacity decreased from 695 mgg −1 to 151 mgg −1 with the temperature increasing from 30 °C to 60 °CPerformance of a synthetic resin for lithium adsorption in waste liquid DOI: 103390/app Corpus ID: ; Preparation of Manganese Dioxide Lithium Ion Sieve and Its Application in Lithium Extraction from Coal Fly Ash @article{Zhang2024PreparationOM, title={Preparation of Manganese Dioxide Lithium Ion Sieve and Its Application in Lithium Extraction from Coal Fly Ash}, author={Pengpeng Zhang and Preparation of Manganese Dioxide Lithium Ion Sieve and Its 2022年3月15日 The current research examined the extraction of germanium, vanadium, and lithium from coal fly ash (CFA) using a sequential sodium salt roasting and organic acid leaching process To this end, three sets of experiments were performed In all experiments, CFA was roasted with salt at 850 °C and then leached with an organic acidA sustainable method for germanium, vanadium and lithium extraction

.jpg)

Distribution and occurrence of lithium in highaluminacoal fly ash

DOI: 101016/JCOAL201802011 Corpus ID: ; Distribution and occurrence of lithium in highaluminacoal fly ash @article{Hu2018DistributionAO, title={Distribution and occurrence of lithium in highaluminacoal fly ash}, author={Peng Hu and Xinjuan Hou and Jianbo Zhang and Shaopeng Li and Hao Wu and Anne Juul Dam{\o} and Huiquan Li and Qisheng Wu and