6000 grinding system ore mill drawing forum

DESIGNING GRINDING PLANTS FOR MILL RELINING TO MAXIMISE

Typically the relining of a mill represents between 2 – 5% of lost annual mill availability for grinding plants With declining ore grades creating additional production pressure, it is highly beneficial Russell Mineral Equipment relies on SOLIDWORKS design, simulation, product data management, and technical communication solutions to accelerate development of its world RUSSELL MINERAL EQUIPMENT SolidWorks2013年4月1日 A simple, novel and nonlinear model of runofmine ore grinding mill circuit is validated The model is developed for process control and estimation purposes The model Analysis and validation of a runofmine ore grinding mill circuit The document provides details on the model structure and equations used to relate operating conditions to grinding rates The document summarizes a method for simulating autogenous AG and SAG Mill Circuit Selection and Design by Simulation

A CRITICAL REVIEW OF GRINDING DESIGN PROCEDURES FOR THE

2021年1月8日 • Critical size is a term used to describe coarse ore that builds up in a SAG mill It is hard But the reason it builds up is that the mill does not have enough power to grind it • 2015年7月21日 This article discusses the range of application of ultrafine grinding for processing mineral raw materials and presents examples of the successful use of this technology in the Ultrafine Grinding in Contemporary Flow Diagrams for Mineral The scope of this thesis is to examine the dynamic relations between the SAG mill and the pebble crusher in a closed circuit and thus to optimize the circuit efficiency by controlling the pebble Dynamic Modeling and Simulation of SAG Mill Circuits with2017年9月1日 The objective of this work is to assess the influence of fine grinding in ball mills and stirred mills on valuable mineral liberation and particle shape characteristics of UG2 ore, a Fine grinding: How mill type affects particle shape characteristics

Investigation of some parameters affecting the Ultrafine grinding

2013年4月16日 ABSTRACT In this study, ultrafine grinding of a refractory silver ore tailings was studied A laboratory scale pintype vertical stirred mill and ceramic beads were employed for the grinding testsThe Autogenous Mill, also known as AG Mill, is a type of grinding mill used in the mining industry This machine uses ore and rock itself as grinding media to perform its job Unlike other types of mills that use steel balls or rods for Understanding the SAG Mill in Copper Ore Mining 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control2015年10月19日 The following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters (10 feet) diameter inside liners, the top size of the balls used affects the power drawn by the mill This is Ball Mill Motor Power Draw Sizing and Design Formula

SAG Mill Expert System Grinding Circuit 911Metallurgist

2017年10月13日 SAG Mill Expert System Grinding Circuit in SAG internal density below 72 percent solids and above 77 percent solids directly affected the optimum ball to ore impact within the mill The expert system had to maintain a the ClL feed) Optimum ball mill loading was 1040 KW with a maximum power draw of 1055 KW David 2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto the bottom of the mill to Friction and wear of liner and grinding ball in iron ore ball millapplied sciences Article Grinding Kinetics Adjustment of Copper Ore Grinding in an Innovative Electromagnetic Mill Marta WołosiewiczGłab˛ 1,*, Paulina Pieta˛ 1, Dariusz Foszcz 1, Szymon Ogonowski 2 ID and Tomasz Niedoba 1 1 Department of Environmental Engineering and Mineral Processing, Faculty of Mining and Geoengineering, AGH University of Science and Grinding Kinetics Adjustment of Copper Ore Grinding in an 2018年8月8日 The paper presents a study on the effectiveness of the grinding process in an electromagnetic mill devoted to ultrafine grinding, and the influence of processing parameters on the mill’s performance The research was focused on the optimization of the duration of the grinding process and selection of the grinding media type in order to obtain the highest relative Grinding Kinetics Adjustment of Copper Ore Grinding in an

Grinding Modeling and Energy Efficiency in Ore/Raw Material

2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration 67% and filling ratio 35% For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding Download scientific diagram Relationship between SAG mill power draw, bearing pressure and feed rate from publication: Supervisory Fuzzy Expert Controller for SAG Mill Grinding Circuits: Sungun Relationship between SAG mill power draw, bearing pressure and 2024年7月19日 This automated grinding media feeder is designed to maintain the optimal grinding media load in the mill, ensuring consistent power draw and efficient operation The PLC (Programmable Logic Controllers) is programmed to monitor the grinding mill’s power draw, automatically dispensing grinding media when needed to maintain the desired load and Grinding Mills in the Mineral Processing Industry2014年1月1日 Experimental and fitted breakage functions for wet grinding in 254 cm diameter mill Population balance model approach to ball mill

(PDF) Grinding in an air classifier mill Academia

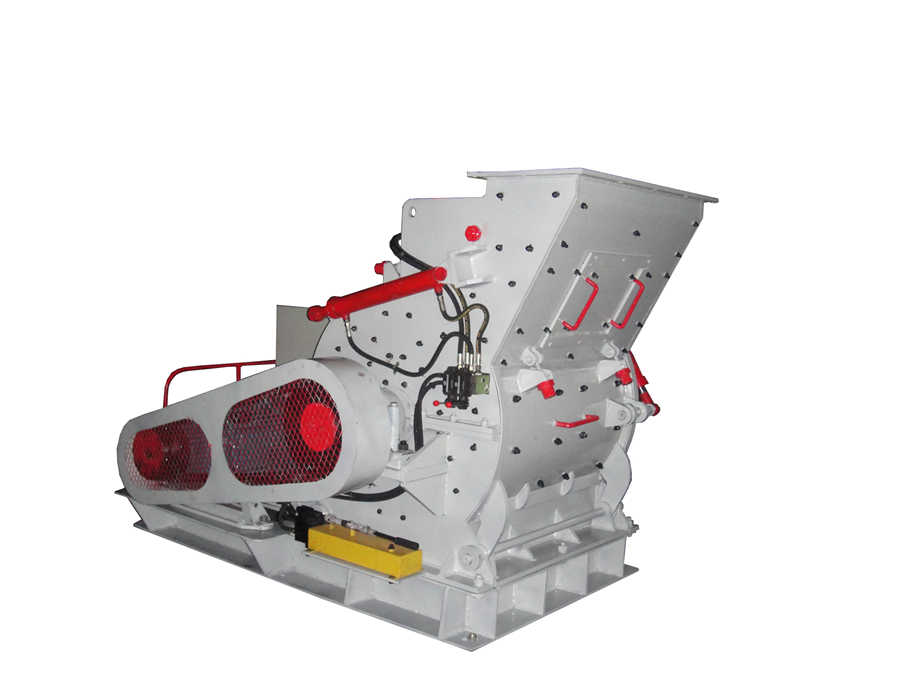

The mill itself consists of a rotating disk with 4 grinding pins at its periphery and an impeller wheel classifier integrated into the top section of the mill chamber The diameter of the grinding disk is 200 mm and the one of the classifier is herein The diameter of mill is 80 m with length of 131 m, operating at 12 rpm The height of mill shaft is 181 m above ground The weight of mill and charge (ore and grinding media) is 3,452 tonsDYNAMIC DESIGN FOR GRINDING MILL FOUNDATIONSThis document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to diameter ratios, percent loading, critical speed, and internals evaluation Methods for assessing ball charge, wear rates, and liner management are described Empirical relationships for power draw and grinding laws are presented The document also discusses Ball Mill Grinding Process Handbook2015年4月9日 The mill is normally used for grinding of ores Hammer mills are high speed mills operating at speeds of between 2000 rpm and 6000 rpm A set of ‘hammers’ rotate about a central axis in a vertical or horizontal plane The whole Grinding Mills and Their Types IspatGuru

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system areRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill System monitors including pressure switches and flow monitors are provided, along with temperature sensors Ball Mill Trunnion Bearing Lube System 911Metallurgist4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit xConsistently high product quality with minimum energy requirement, due to the integrated highefficiencyPolysius Roller Mills For grinding

Micro Powder Grinding Mill

SBM micro powder grinding mill is a highly efficient industrial grinding mill, its finished products: 3253000 mesh; it's capacity: 0245t/h2015年4月15日 For each ball mill grinding step, a Bond ball mill grindability test for Work Index at one mesh size coarser than the desired 80% passing size and at the mesh size of or just finer than the 80% passing size If 50 mm x 75 mm What Ore Testing is Required For Mill Selection2019年4月19日 Ore grinding mills are really just slowly rotating barrels, At new ore locations, power system stiffness doesn’t seem to be growing as fast as large mill sizes High starting current HP = 60008000/Mill RPM =720 (HS), 180 (LS), 10 (Mill)Electric Drives for Large Ore Grinding Mills 911Metallurgistthroughput and ore quality As a result, your mill runs at optimal speed with optimized cascading, leading to increased throughput and reduced energy consumption Optimized grinding at your fingertips Stable mill load — higher efficiency By keeping the mill at optimal point of operation, SmartMill™ increases energy efficiencyGrinding systems product SmartMill™ Exceeding your

Vortex Air Mill Ore Grinding Gold Refining Metal Extraction Forum

2023年9月26日 Help Support Gold Refining Forum: This site may earn a commission Messages 9 Location Virginia City Sep 26, 2023 #1 Hi! Has anyone here have had experience grinding ore with an air mill? if so, any info on its use and operation would be very helpful thank Help building a Aqua Regia System Latest: 4metals; Yesterday at 11: performance of a large diameter sag mill is shown in Figure 4 page I208 The top size data has been plotted in both raw and smoothed form It clearly shows that as top size increases the mill weight increases as the mill finds it increasingly difficult to break down the bigger rocks Power responds to the increased mill weight by also increasingI203 I204 INTRODUCTION SMC Testing1 Population balance model approach to ball mill optimization in iron ore grinding Patricia M C Faria1,2, Luís Marcelo Tavares2 and Raj K Rajamani3 1 Vale SA, Brazil 2 Department of Population balance model approach to ball mill optimization in iron ore classification system efficiency is the effective mill power draw * The effective mill power draw is the power draw that is applied to the grinding of coarse particles Figure 2 The "effective mill power draw" Now let's see how the remaining two terms, ore grindability and ball mill grinding efficiency* in the above figure, come into the MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING

Schematic diagram of a raymond mill system ResearchGate

In the raymond mill grinding process, precise control of operating load is vital for the high product quality However, strong external disturbances, such as variations of ore size and ore 2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 Ore Pretreatment Methods for Grinding: Journey and Prospects2023年7月20日 Therefore, the rod mill is mostly used for coarse grinding of the previous period of ball mill, or grinding of brittle materials and materials against overcrushing, such as tungsten and tin ore before gravity separation; and (3) autogenous mill – it refers to the materials which themselves are collided and ground mutually to be crushed when the grinding mill rotates, and Ore Grinding SpringerLinkMill Power Draw Models The mill power draw models are used to predict how much power will be consumed by a particular type of mill, mill geometry and set of mill operating conditions This power is transferred to the ore and used to predict the throughput when combined with the specific energy consumption modelsMill power draw models

BATU HIJAU MILL THROUGHPUT OPTIMIZATION: MILLING CIRCUIT CONFIGURATION

6,000 tph to 7,500 tph for both grinding lines • Ball Mill Limited: the overall grinding circuit is constrained by the Ball Mill capacity and the SAG mill and Pebble Crusher circuits have spare capacity This limitation is commonly experienced during the processing of the low grade ores (less than 04%Cu)2017年1月23日 In Hadizadeh et al [92], an advanced distributed control system (DCS) is developed for the successful control of mineral processing plants, presenting the basis of an expert fuzzy supervisory (PDF) Supervisory Fuzzy Expert Controller for SAG Mill Grinding 2021年1月22日 Request PDF An innovative approach for determining the grinding media system of ball mill based on grinding kinetics and linear superposition principle Herein, an innovative approach for An innovative approach for determining the grinding media system 2018年12月24日 EVALUATION OF THE ALTERNATIVES FOR GOLD ORE GRINDING CIRCUITS BY USING OF mineral processing plant and comminution system models to accurately predict grinding mill power drawEVALUATION OF THE ALTERNATIVES FOR GOLD ORE GRINDING

Simulation of industrial PGM and iron ore ball milling circuits from

2023年4月20日 The application of the attainable region (AR) technique to the analysis of ball milling is currently limited to batch data This paper introduces the use of the technique to continuous milling2021年7月1日 The simulations are carried out in an industrialscale SAG mill, which includes a case with polyhedral ore particles and spherical grinding media (PHSP grinding system), and a case with spherical ore particles and spherical grinding media (SP grinding system) The grinding media are steel balls with a constant diameter of 125 mmDEM investigation of SAG mill with spherical grinding media and 2016年2月2日 The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentGrinding Circuit Startup and Shutdown Procedurehammer mill 1pdf Free download as PDF File (pdf), Text File (txt) or read online for free This document summarizes research on improving the design, construction, and testing of a hammer mill Key points: 1) The researchers redesigned and constructed the hammer mill beater, chamber, and shaft They incorporated a gasoline engine directly to power and vary the speed Hammer Mill 1 PDF PDF Mill (Grinding) Bending