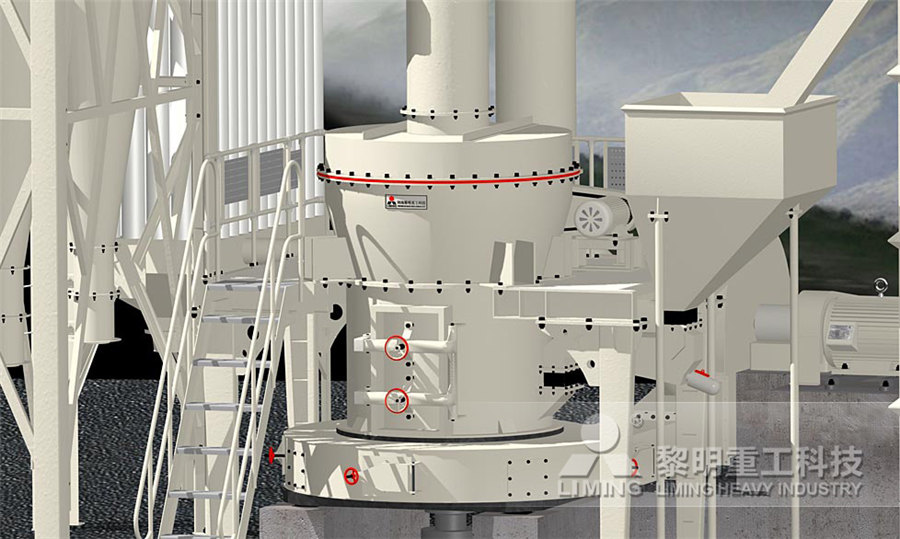

Clay grinding machine process flow

AP42, CH 113: Brick And Structural Clay Product Manufacturing

In the dry press process, clay is mixed with a small amount of water and formed in steel molds by applying pressure of 500 to 1,500 pounds per square inch (343 to 1028 megapascals)We define and deliver all the machinery required for preparation of raw materials and fabrication of products The first step of the ceramic process includes clays preparation Raw materials Raw materials processing and fabrication Cleia2019年8月23日 Need more fluorite processing solutions? Contact us now to get more fluorite processing flowsheet PDF and get a free customize processing flow by our mining experts and engineers 【Advantages】 1 Fully crushing and Fluorite Processing Equipment, Process Flow, Cases2019年8月23日 Clay mine needs a Trommel scrubber for washing without clay ore needs a Trommel screen and vibration screen to separate different sizes Shaking table jig separator centrifugal concentration spiral chute: this Chromium Processing Process Flow, Cases JXSC

.jpg)

Kaolinite Processing Equipment, Process Flow,

2019年8月23日 The wet process includes three stages of ore preparation, ore beneficiation processing and product processing The beneficiation stage may include hydraulic grading, flotation, selective flocculation, magnetic separation, 2023年11月26日 The stepbystep guide provided in this article highlights the equipment, chemical reactions, and methodologies employed in each stage of the chrome plant process flow By grasping the intricacies of the chrome plant process flow, professionals and enthusiasts can gain a deeper appreciation for the complexity and importance of the mining industryStepbyStep Guide: Chrome Plant Process Flow ExplainedClay Brick Typical Process Flow Diagram Metal detector Water added to clay in mixer Boulders removed Clay sand Magnet batching Clay quarried stockpiled Clay recycled Modern soft mud machines are capable of manufacturing in excess of 40,000 bricks per hour Waterstruck Waterstruck bricks are made using the same principalThe UK Clay Brickmaking Process General Guide 1 The UK ClayThe whole airflow system of the machine is closed and circulating, and it circulates under positive and negative pressure conditions There is a certain water content in the material to be ground in the grinding chamber The heat generated during grinding causes the gas in the grinding chamber to evaporate and change the gas flowclay grinding machine, clay powder making machine, clay processing

Kaolin Clay: Understanding Its Processing and Grinding Workflow

The ground material is graded by the classifier, and the unqualified part is returned to the host machine for regrinding Collection The powder that meets the fineness is collected by the air flow through the pipe into the powder collection system, and the finished powder is sent to the finished product warehouse2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles(PDF) A comprehensive review on the grinding process: Grinding X X X X X X Screening X X X X Mixing X X X Blunging X X X Air flotation X X Slurrying X X Extruding X X Drying X X X X X granulating, air classifying Dispersing Fire Clay Figure 11254 illustrates the process flow for fire clay processing Mined fire clay first is transported to the processing plant and stockpiled In some cases 1125 Clay Processing US EPA2023年2月15日 Kaolin clay grinding process Various industrial fields have different particle size requirements for kaolin clay, which promotes the development of grinding machines in the kaolin milling industry The following is the flow of the kaolin grinding process: 1 Crushing: Grinding Kaolin Clay? Now Is the Time to Know the Best Way

.jpg)

Understanding the Cement Grinding Process Flow News

This article will delve into the intricacies of the cement grinding process flow, Material Preparation:The cement manufacturing process begins with the extraction of raw materials, typically limestone, clay, Despatch machines for cameroon iron ore processing project 20/9/2024 Join Us at MinePro 2024 Mongolia International Mining Expo2019年9月25日 Tin ore is brittle and easier to over crush than other symbiotic minerals, therefore, the tin ores process generally adopts a twofour stage grinding circuit As for the tin process flow, if the sulfide needs to be removed, Tin Processing Equipment, Process Flow, Cases2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other Limestone crushing, sand making and grinding process2022年10月10日 Clay grinding process The clay grinding process is generally divided into three types of clay coarse powder processing (03MM), fine powder processing (20 mesh400 mesh), and ultrafine powder processing of clay (400 mesh3250 mesh) Stage 1: Broken The large pieces of clay are crushed by the crusher to the fineness (15mm50mm) that can enter Clay ultrafine grinding mill

Gold Extraction Recovery Processes 911Metallurgist

2016年2月29日 Some of the metallurgical relationships that must be considered from the testwork program as follows: ore grade relationship to gold recovery, crushing and grinding parameters and their relationship to the ore variability in the ore body, effect of other minerals on the process, minerals and/compounds that negatively impact processing cost such as oxidized Download scientific diagram Flow chart of grinding procedure from publication: Grinding Wheel Loading Evaluation by Using Acoustic Emission Signals and Digital Image Processing In the Flow chart of grinding procedure Download Scientific Diagram115 Refractory Manufacturing – US Environmental Protection Refractory manufacturing process flow diagram1 certain clays and the plaster added to refractory materials to induce brick setting Fluoride emissions » More detailed Emissions Estimation Technique Manual temperatures These clays are used in commercial refractory products such as firebrick and process flow diagram of refractory brick – Grinding Mill China2023年8月8日 To extract phosphorus from phosphate rock, Ftmmachinery will explain to you the process flow of phosphate rock and the equipment we can provide, from the four stages of crushing grinding flotation – dehydration Stage 1: Crushing Phosphate rock is transported to the raw ore bin and enters the jaw crusher through the vibrating feederPhosphate Rock Processing: 6 Useful Ways and 4 Stages

.jpg)

Mineral Processing Plants: What You Need to Know

2024年8月15日 Learn about mineral processing plants and relevant equipment to optimize your processing flow and equipment choices Home; Equipment Clay minerals: Such as kaolin and bentonite Minerals attach to the bubbles and float to the surface of the liquid for separation Although flotation machines require fine grinding and can be and then formed into brick in molds To prevent clay from sticking, the molds are lubricated with either sand or water to produce “sandstruck” or “waterstruck” brick Brick may be produced in this manner by machine or by hand DryPress Process This process is particularly suited to clays of very low plasticity Clay is mixed withManufacturing of Brick Brick Industry AssociationGrinding machining is a type of machine tool and it is similar to other machine tools such as milling machine, machining process and types of Grinding machine is discussed below These bonds are made with the help of clay mix and fluxes and harden like glass after firing to a temperature of about 1250 to 1300 degree centigradeGrinding Machining Process : Complete Notes Mech4studyProducing Process First stage: Since clay’s water content is relatively high, raw materials need to be dried to moisture less than 6% After drying, clay is transported by special vehicles to raw materials bin Second stage: Dry clay is lifted to the hopper by hoist, then transported by feeder Third stage: Qualified products after the grinding process enter the collector through classifier Clay Powder Process, Grinding Mill For Clay

Kaolin Processing Plant, China Clay Washing Process

Kaolin (china clay, kaolinite) processing and beneficiation can obtain highpurity products, increase the quality and utilization of minerals, and meet some high valueadded market applications Maximize kaolin grade and recovery rate; 2024年4月19日 Benefits and Uses of Clay Grinder Machine A clay grinder machine is a versatile tool that is used for grinding, mixing, and shaping clay materials It is also known as a clay mixer or a pugmill The machine has a mixing chamber where the clay is fed and a rotating blade that mixes and grinds the clay into a homogeneous mixtureThe Ultimate Guide To Choosing The Right Clay Grinder Machine 5 天之前 The manual processing flow is generally: raw ore – crushing – drying – grinding – packaging 2 flocculation method It is suitable for ore with a montmorillonite content of 3040% , adding sodium hexametaphosphate as a dispersant, and the Bentonite Processing Methods And Required EquipmentNow, the rectangular strips coming out the opening are cut by wires to get required thickness of brick So, these are also called wire cut bricks Now these raw bricks are ready for the drying process Dry clay machines Dry clay machines are more time saving machines We can put the blended clay into these machines directly without temperingManufacturing of Bricks for Masonry Construction – Methods and Process

Near Process Coolant Flow Field Measurements in a Grinding Machine

Keywords: Optical flow field measurement, shadowgraphy, particle image velocimetry, grinding, liquid jet flow Motivation In order to prevent grinding burn, coolant flows are used for lubrication and cooling of grinding processes [1], which are an important manufacturing step for metallic and optical components2023年8月23日 The fine powder that does not meet the conditions will be sent back to the grinding mill for further grinding The clay powder with required fineness will be transported to packaging machine and packed The above is the entire process flow of the clay processing production line Equipment in clay processing plant Crushing stageEfficient and moneysaving clay processing plant Zenith CrusherBoth processes will result in a good usable clay body when completed given that the natural clay is of reasonably good quality to begin with Here are some of the factors to weigh in deciding how to process your clay Labor The hard part of the dry process method is grinding the clayHow to Process Clay 4 Steps to Turning Dirt Into Usable ClayProduction Process First stage: limestone chunks are transported by special vehicles to raw materials bin, after the forklift / artificial then delivered to the jaw crusher for crushing by forklift or man Second stage: Crushed limestone is lifted to the hopper by hoist, then transported by feeder Third stage: Qualified products after the grinding process enter the collector through Limestone Processing Plant, Limestone Grinding Machine

Diamond Processing Flow Chart of Beneficiation

2016年4月14日 Diamond Processing Flow Chart #3 This flowsheet illustrates a more complex diamond recovery method developed in recent years With variations it can be used to process 100 to 500 tons per hour of Kimberlite ore 2023年10月28日 It is more economical and timesaving There are two types of machines used for machine moulding: plastic clay machines and dry clay machines Fig 5: Machine Moulding Plastic Clay Machines: These machines Manufacturing of Bricks Site Selection, Process, Raw 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLink2019年8月23日 Main factors influencing diamond processing flow 1 raw ore mineral composition and their properties 2 disseminated grain size 3 ore argillization property 4 surrounding rock fragmentation 5 content of clay in raw ore 6 value minerals content 7 diamond processing plant scale 8 requirements of diamond concentrate Diamonds processing flowDiamond Processing Equipment, Process Flow, Cases JXSC Machine

AP42, CH 117: Ceramic Products Manufacturing US EPA

Most ceramic products are claybased and are made from a single clay or one or more clays mixed with mineral modifiers such as quartz and feldspar The types of commercial clays used for ceramics are primarily kaolin and ball clay 1172 Process Description1,35 Figure 1171 presents a general process flow diagram for ceramic products 2019年8月26日 Quartz processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Gold Mining Equipment Chat on WhatsAppQuartz Processing Equipment, Process Flow, Cases JXSC Machine2021年8月27日 Kaolin is the deposit of naturally occurring minerals containing hydrated aluminum silicates Widely known as white clay or china clay, these minerals have desirable properties crucial for industrial and commercial applicationsFor that reason, the kaolin mining and processing steps thoroughly put the nature of the crude deposits and the enduse of the All Steps in Kaolin Production Mining and Processing Explained5000 Tons/Day New Type Dry Process Cement Production Line Pengfei 5000t/d dry process cement production line is excellent in saving energy It adopts various high efficient cement equipment and devices It is designed with a smooth and tight process flowe try to reduce production process and save transport costCement Production Line,Cement Machine,Rotary Kiln,Cement

.jpg)

Clay Crushing Machine MadeinChina

China Clay Crushing Machine wholesale China Factory Seller Ball Coal Grinding Mill Kayolin Clay Crushing Machine US$ 100050000 / Piece 1 Piece (MOQ) Shanghai Vostosun Industrial Co, Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, Machine: 1 Set MTM130 Grinding Mill Output Size: 100 Mesh D80 Capacity: 13T/H 15T/H Kaolin Powder Production Line in China Location: China Machine: 1 Set MTW175 Grinding Mill Output Size: 75 Micron D90 Capacity: 15T/H 10T/H Kaolin Powder Production Line in China Location: China Machine: 1 Set MTW138 Grinding Mill Output Size: 100 Kaolin Processing Plant, Kaolin Grinding Mill