Limestone briquette machine production line

Product LineZhengzhou Zhongzhou Briquette

Two stage crusher is designed and optimized in accordance with international latest crushing technology It can crush all kinds of hard ore/metallurgy materials such as limestone, clinker, coal,coke,manganese, silica, iron ore, zinc oxide Production: 0510t/h Application: The finished briquettes are widely used in industries of lime calcinations, blast furnace calcinations and metallurgy etc The application of lime briquetting Briquetting EquipmentThe briquette machine is where the charcoal ball briquettes are actually formed and is the core of the entire charcoal briquette production line The briquette machine compresses the mixed materials under high pressure into the desired Charcoal Briquette Production Line Henan Gomine4 Charcoal briquettes production in barbecue and home heating Briquette production line The briquette press machine is the core equipment of the briquetting making plant, and the supporting equipment includes hammer Briquette Machine Gomine Recycling Machinery

.jpg)

Product LineZhengzhou Zhongzhou Briquette

It can crush all kinds of hard ore/metallurgy materials such as limestone, clinker, coal,coke,manganese, silica, iron ore, zinc oxide etc minerals in the The technological level of high pressure briquette machine production line, Furthermore, when customers purchase a complete briquette production line, The common briquette machine has a small production capacity, Raw materials: Carbonized Clay with Limestone Capacity: 10t/h Output shape: round ball Feeding size: about 20100mmBriquette PlantFote MachineryBall Press Briquette Machine Applied Materials:various powders such as Coal Powder Iron Powder Magnesium powder iron powder manganese powder bauxite graphite powder clay limestone ilmenite concentrate powder titanium powder manganese powder silicon manganese alloy etc Briquette Production LineSinogomine Industrial Technology Co,LtdBriquette Machine2023年2月4日 We can roughly calculate the benefit, compared with the nonpressing production process, the daily value created by the briquetting ball production process is 40*(1002010)=$2800*365=$1,022,000 The profit per year would be about 1m USD! Lime briquette machine manufacturer and system designerLime/quicklime for metallurgy – how producing and briquetting

Best Coal Making Charcoal Briquette Production Line

Raw materials of charcoal briquette production line There are many raw materials for this charcoal briquette production line, which can be large logs, branches, rice husks, peanut husks, cotton husks, corn cobs, corn stalks, sorghum stalks, sawdust, shavings, pine The sawdust crusher crush the raw materials into sawdust, typically wood chips, biomass waste into smaller particles The aim is to achieve a fineness within 6mm, ensuring compliance with biomass briquette machine requirements Feed the raw materials into the sawdust crusher, as the highspeed rotation of the alloy steel blades in sawdust crusher, materials are continuously cut Biomass Briquette Production Line – Henan Gomine2023年8月22日 Charcoal production line is a series of interconnected processes and equipment designed to convert biomass or wood into charcoal Charcoal is a black, porous substance that is mainly composed of carbon and is commonly used as a fuel source for cooking, heating, and various industrial applicationsCharcoal Production Line Charcoal Machine Shuliy2024年7月5日 The reduced time to maturity and high biomass output lower the overall production costs, making bamboo a financially viable option for biochar briquette manufacturing This costeffectiveness is particularly beneficial for smallscale farmers and rural communities looking to adopt sustainable biochar production practicesbamboo charcoal briquette production MS2013

Lime Production Process and Required Equipment

2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines It can crush all kinds of hard ore/metallurgy materials such as limestone, clinker, coal,coke,manganese, silica, iron ore, zinc oxide etc minerals in the The technological level of high pressure briquette machine production line, production system operation regulation, control and alarm by PLC in the main control room Product LineZhengzhou Zhongzhou Briquette Machinery Plant2024年10月22日 Project type: Soft rock limestone sand making Production capacity: 800 t/h Feed size: 200 mm–900 mm Output sizes: 0 mm–5 mm, 5 mm–10 mm, 10 mm–15 mm, 15 mm–25 mm This sand production line boasts a large processing capacity and a high crushing ratio, producing cubical sand and gravel with a low content of flaky particlesA Comprehensive Guide to Sand Making Plants and MachinesCoal briquettes production line uses coal as raw material to produce briquettes, coal rods, and other finished products The coal powder briquette has the characteristics of no pollution, long burning time, and large market demand And the coal briquetting machine is the core equipment in the bbq coal briquette production lineOur factory provides custom mold and machine spare Coal Briquettes Production Line Coal Making Machine Shuliy

.jpg)

Cement Production Line In South Africa FTM Machinery

Processing materials: clinker, gypsum, fuel mixture, limestone, clay fuel mixture, limestone, clay, iron ore, etc, and coal and limestone are the most common raw materials of cement production line Home; Solution Stone Crusher Machine Mobile Crusher Ore Flotation Grinding Machine Cement Plant Dry Machine Briquette Machine Production Lines The charcoal briquette production line mainly includes buffer silos, double shaft mixer, screw conveyors, wheel mills, binder feeder, forming machine, dryers, etc Customers can be equipped with suitable equipment according to their needsCharcoal Briquette Making Machine Customized Production Line2024年5月15日 However, if you only need to produce a small volume of briquettes, a smaller machine may be more affordable and suitable for your needs We have types of charcoal briquette making machines for your choice Features and Technology Finally, the features and technology that a charcoal briquette machine offers can also affect its pricecharcoal briquette production line CMPPZhengzhou Zhongzhou Briquette Machinery Plant is the first specialized enterprise of manufacturing briquetting machine in domestic Since the first large highpressure briquetting machine ZZG530 was finished trialmanufacture in 1993, the company has formed more than 5 models after many years of research, tests, and improvementshigh pressure briquette machine,briquetting press ,briquette machine

Charcoal briquettes production line Shuliy Machinery

2023年3月3日 The production line mainly includes continuous carbonization equipment, charcoal crushing equipment, binder mixer, charcoal briquettes extruder machine, and briquettes dryer Among them, the briquettes extruder machine is the main equipment of the charcoal briquettes production line, which mainly processes the charcoal powder into various shapes Coal Briquette Production Line is specially designed for briquetting powder of coal, coke, iron, kaolin, tailings, gypsum, slag, sludge etc All suitable raw materials can be pressed into square, round, pillowed and many other shapes as you required Projects of 4 Tone Coal Briquette Production Line Feature of AGICO Coal Briquette Line4 Ton Coal Birquette Production Line2024年4月17日 Limestone pellets are an essential product in various industries, including agriculture, construction, and water treatment The production of limestone pellets requires specialized equipment to ensure the pellets are of high quality and meet industry standards Here are some of the essential equipment used in the production of limestone pelletslimestone pellets granulating production line CMPP2024年4月10日 Charcoal briquettes production line is a set of equipment and machinery designed to produce charcoal briquettes from various raw materials, such as wood waste, sawdust, rice husks, coconut shells, and other biomass SmallLarge Scale Charcoal Briquettes Production Line

.jpg)

Charcoal Briquettes Production Line Charcoal

Charcoal briquettes production line structure In fact, the structure of a charcoal production line is very similar to that of a hookah charcoal production line Their structure is carbonization, crushing, stirring, briquette, drying, and packing Project case: 500 t/d active lime production line in Thailand In June 2019, a customer from Thailand inquired about the lime production line According to his output and final product demand, we recommended this φ38m×58m rotary kiln to him Specific information is as follows:Lime Kiln for Lime Production Fote Machinery2023年6月16日 1The common shisha charcoal briquette machine/hookah charcoal press machine For making shisha charcoal briquettes, both the cubic shisha charcoal and the round tablet shisha charcoal, The honeycomb coal briquette production line can turn Shisha Charcoal Production LineFully Automatic Briquette Machine Prices Briquette machines are strong and durable machines that have been manufactured using different technologies for many years While manpower was used extensively in the machines produced in the past, in today’s machines, most of the processes can be performed by the device aloneFully Automatic Briquette Machine Globmac

.jpg)

Shandong GEMCO Briquette Machine Production Line

By comparing many briquette machine manufacturers, he finally decided to buy from GEMCOOur salesman communicate with him and provide him a solution base on his specific situation and requirement This briquette production line is simple and practical, without drying, saving time and labor Mr Li through is very satisfied with the briquetting plan we offered to himThe Design Plan of Biomass Briquette Production Line with Annual Capacity of 30,000t Keywords biomass fuel, biomass fuel production line, biomass briquette, briquetting machine, machines should be employed in this production line (note: 4 machines in operation and 1 machine in resting state) One machine is used as the standby machineThe Design Plan of Biomass Briquette Production Line withAs a professional Shisha Hookah Production Line manufacturers and Briquette briquette machine: The briquette briquette machine can be used to compress charcoal, clay, coke chips, coal, cryolite, fertilizers, plastics, limestone, pigments, urea, potassium salt, etc Agglomeration, granulation or briquetting Its purpose is Shisha Hookah Production Line Zhengzhou Runxiang 2024年7月17日 Charcoal briquette production line is used to convert raw materials such as wood chips, sawdust, coconut shells, rice husks, etc into charcoal briquettes with a capacity of 2t/d, 5t/d and 10t/d The basic charcoal making process is carbonizing→charcoal crushing→charcoal grinding→charcoal powder wheel mixing and grinding→charcoal briquette Good Price Charcoal Briquette Production Line For Coal Plant

.jpg)

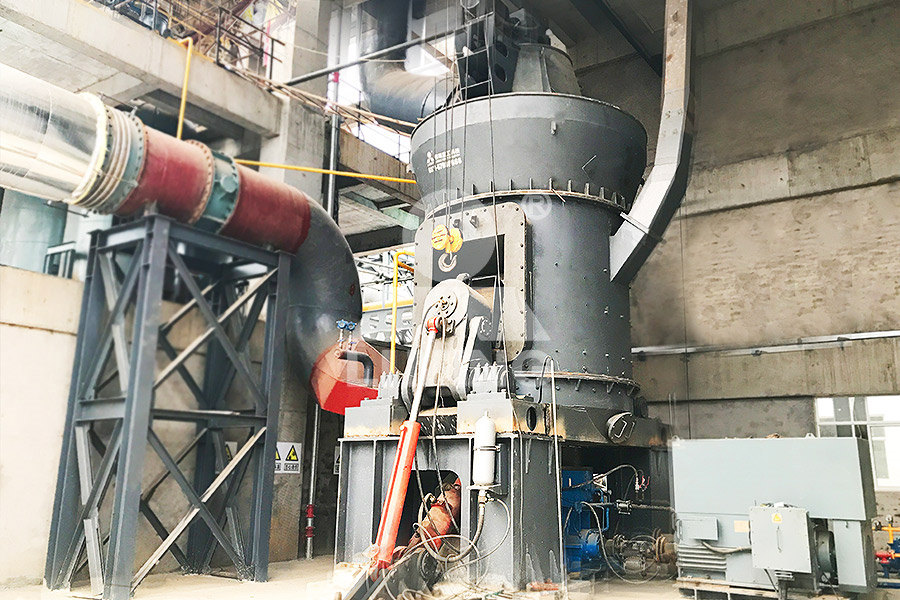

Mining Equipments Manufacturer, Minerals Processing

Science and technology as guide, constantly develop new products, improve product quality and perfect aftersales service, our plant successfully applied ISO9001: 2015 quality certificate and manage to design 10 to 5, 000 t/d 2019年11月13日 Charcoal Briquette Production Line for Ghana Clients 13:56:00 EP 3455 Original Summary :EP technical team designed the charcoal briquette production line according to requirements of Ghana clientsCharcoal Briquette Production Line for Ghana ClientsBriquette Machine We have produced various types of briquette machines: 135 t/h for a single machine; 1100 t/h for a production line Hydraulic Briquetting Machine; Iron Powder Briquetting Machine; Charcoal Briquette Machine; Crushing, Processing, Grinding Cement Making Professional manufacturer of briquette equipment and related machines, high quality and 100% factory price! Briquette Machine Charcoal Briquette Production Line The charcoal briquette production line or charcoal briquette plant converts biomass or other carbonaceous materials into charcoal through the application of heat and pressure It Henan Gomine

Charcoal Briquette Machine Charcoal Press Machine

2024年6月19日 Charcoal briquette machine is a equipment designed to press biomass and other industrial processes In the charcoal briquettes production line, this machine is the key machine Depending on the desired properties, manufacturers may add other additives like borax, sodium nitrate, or limestone to enhance the burning LECA production line The production of LECA generally requires 7 steps: crushing, mixing, grinding, granulating, sintering, cooling, and sieving Materials Needed for LECA: Clay: Choose a highquality, wellgraded clay with minimal impurities Shale or Slate: These materials provide the necessary expansion when heatedLightweight Expanded Clay Aggregate Production LineThe hookah charcoal briquette production line is a promising business for many customers engaged in charcoal production Therefore, it is a high rate of return project Welcome to inquire, and we will give you a discount shisha charcoal production line for sale Raw materials for hookah charcoal production lineShisha Charcoal Production Line Hookah Briquette Packing Machine2019年2月14日 Company Website: https://abcmachABC briquette plant can be used to press coal, charcoal, coke, mineral powder, etc The final briquettes can be transBriquette machine (complete briquette production line)

.jpg)

Oman 100t/h Complete Limestone Crushing Production Line

2024年6月14日 Capacity: 100 t/h; Processed Material: limestone; Applications:road construction; Device configuration:vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyors, and electric control panel The customer learned that 2 years ago a friend from the company purchased a stone crushing line, the model is small, but the operation is very stable, 2019年11月13日 Charcoal Briquette Production Line for Ghana Clients 13:56:00 EP Original 3475 Summary :EP technical team designed the charcoal briquette production line according to requirements of Ghana clientsCharcoal Briquette Production Line for Ghana Clients