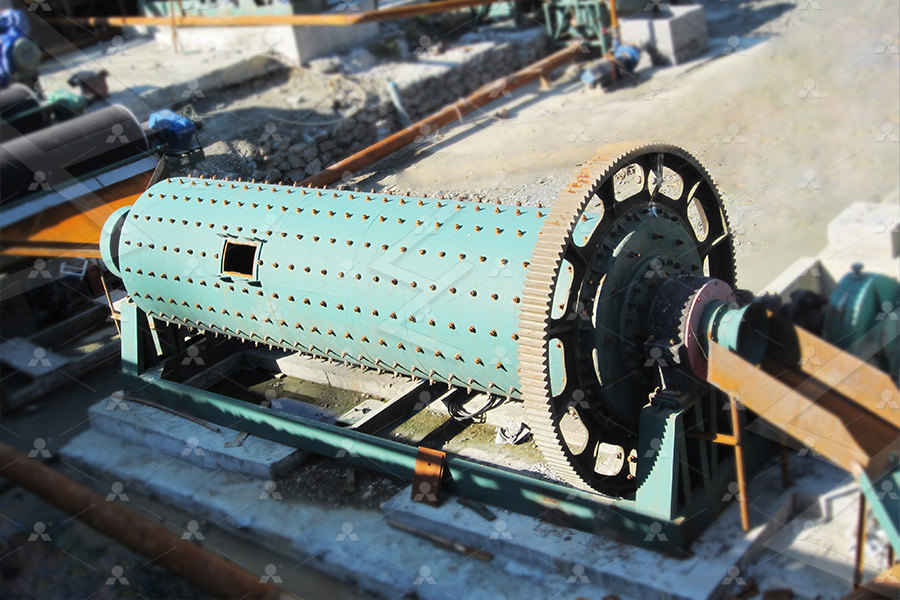

Sliding highpurity manganese sulfate manganese slag mill

.jpg)

Method for producing manganese sulfate by hightemperature

The invention provides a method for producing highpurity manganese sulfate by adopting a high temperature crystallization method, which includes that the ore pulp of manganese ore andHigh Purity Manganese Sulphate Monohydrate Production (HPMSM) • MNE is able to produce >99% purity manganese sulphate to meet and exceed current international BG specifications High Purity Manganese Sulphate Project综述了高纯硫酸锰生产各种方法的优缺点,其中包括电解金属生产法,氟化物除钙镁法,重结晶法,硫化锰法等。 重点介绍了低成本绿色全新技术生产超高纯和高纯硫 展开更多 高纯硫酸锰生产的 高纯硫酸锰生产技术现状【维普期刊官网】 中文 2020年8月31日 High purity manganese sulphate monohydrate, MSM (MnSO 4H 2 O) was produced from two types of FeMn smelter wastes (fumes) using a novel process developed Processing of ferromanganese fumes into highpurity manganese

.jpg)

Extraction Technology for Manganese Sulfate Solution Purification

2023年3月30日 The economically feasible process of using the leaching purification liquid and stripping liquid to preparation of high purity manganese compounds was designed, and the 2022年1月1日 These authors use different milling devices (ball milling, attrition milling and eccentric vibratory milling) to alter the reactivity of the slag before chemical activation To A review on characteristics of silicomanganese slag and its 2020年8月21日 Most of the XRT solutions on the market recognize and separate materials based on their specific atomic density, allowing a high level of sorting purity irrespective of From Ore Body to High Temperature Processing of Complex Ores: 2020年1月3日 This paper describes an efficient hydrometallurgical process for the utilization of high manganese slag instead of conventional usage of pyrometallurgical route for manganese Pressure Sulfuric Acid Leaching of ManganeseRich Slag with

.jpg)

Optimization of manganeserich slag extraction from low

A new technology for smelting manganeserich slag with lowmanganese highiron ore by smelting reduction optimization was proposed This technology has the advantages of a short erates more slag, which dissolves manganese and low so the purity is manganese sulfate, reductive roasting DOI: 103103/S60061 METALLURGY OF NONFERROUS METALSProduction of Electrolytic Manganese from Sulfate Solutions2021年8月25日 PDF In the process of preparing highpurity MnSO4 from industrial MnSO4 solution, of manganese sulfate decreased with the increase of temperature at 25–85 (PDF) The Efficient Removal of Calcium and Manganese sulfate solution is to be used for processing various manganese goods as the raw material of electrolytic manganese dioxide, highpurity manganese carbonate, electronicgrade trimanganese tetroxide, electronicgrade manganese monoxide, chemical manganese bioxide, technical grade manganese sulfate monohydrate, chemical grade manganese sulfate CNA Process for producing manganese sulfate solution by high

.jpg)

PURE MANGANESE – Manganese Unlimited

High Purity Manganese Sulfate Monohydrate – MnSO4H2O MnO2 Manganese Oxides >999% MnO Mn2O3 Mn3O4 Mn Green Manganese Metal >999% KMnO4 Potassium Experience the world of ultra high purity products Mineral Economics A world of transition elementsThe invention provides a method for producing highpurity manganese sulfate by adopting a high temperature crystallization method, which includes that the ore pulp of manganese ore and sulfurous iron ore is heated, removed of iron, removed of heavy metal, neutralized, pressurefiltered to obtain a manganese sulfate solution with the content of 160200g/L, which is Method for producing manganese sulfate by hightemperature Manganese metal is divided into metal manganese produced by fire reduction and electrolytic metal manganese produced by wet electrowinning The pyrometallurgical manganese is massive and difficult to crush; The wet electrolytic manganese metal is flake, easy to crush and high purity At the same time, the production scale of manganese metal powder is generally large, but the How To Select Equipment For Producing Manganese Powder From Manganese 2020年8月31日 The work presented propose a process to reprocess these wastes into high purity manganese sulphate monohydrate (MSM) Processing of wastes containing high potassium as KOH also yields high purity potassium sulfate used as fertilizers Some smelters spray oil onto the fume dumps to prevent material being blown onto the surrounding areaProcessing of ferromanganese fumes into highpurity manganese

.jpg)

High efficiency and costeffective innovative selfoxidation insitu

2024年10月15日 Manganese sulfate (MnSO 4), an alkaline manganese salt, serves as a crucial industrial intermediate in the production of electrolytic manganese, manganese oxide, and manganese carbonate [1], [2], [3]It finds extensive applications in the fields of medical chemistry, aerospace, highperformance environmentalfriendly batteries [4]With the promotion of the Semantic Scholar extracted view of "Electrorefining of high purity manganese" by Xiangzhi Cao et al Skip to search form Skip to main content Skip to account menu Semantic Abstract Manganese sulfate solution would be affected by various factors in Electrorefining of high purity manganese Semantic ScholarBattery Grade HighPurity Manganese Sulphate High Purity Manganese Sulphate is used in the cathode structure of lithiumion batteries, together with other minerals such as lithium, nickel and/or cobalt Our vision is to manufacture the highest purity of manganese sulphate using our proven purifying technologiesMn Energy Australia high purity Manganese Sulphatemanganese slag from ferromanganese alloy smelting, a great amount of ferromanganese slag accounted for about 2−3 times as much as ferromanganese alloy each year [4,5] The impurity categories included in ferro manganese slag are the same as those of manganese ore, and the content of MnO is higher than that of ordinary manganese slagPreparation of electronic grade manganese sulfate from

Preparation of Manganese Oxide and Its Adsorption Properties

2024年7月5日 The insitu oxidation of manganese sulfate solution with H2O2, sodium hypochlorite, potassium permanganate and oxygen as oxidants was investigated by means of SEM, EDS, XRD, BET and infrared analysis, and the effects of different oxidants on the morphology, phase composition, surface properties and specific surface area of manganese 2014年11月1日 Preparation of electronic grade manganese sulfate from ferromanganese slag, including grinding, leaching and purification, was studied The impurities, such as Fe3+, Al3+, Ca2+, Mg2+, heavy metal Preparation of electronic grade manganese sulfate from The remainder of global supply is used within the specialty market, including electrolytic manganese metal, electrolytic manganese dioxide and manganese sulphate monohydrate, with the lithiumion battery (LiB) market consuming only 05% of the total contained manganese Highpurity manganese, also known as batterygrade manganese, is produced High Purity Manganese Giyani Metals Corp2021年11月1日 So it is necessary to remove impurities in the manganese sulfate solution to obtain highpurity manganese sulfate products 10,11 The common impurity removal methods include the sulfide Separation of zinc and iron from secondary manganese sulfate leachate

.jpg)

HighPurity Manganese Sulphate Monohydrate (HPMSM)

High purity manganese products are essential materials needed by the EU’s fastgrowing electric vehicle and lithiumion battery industries The term “HighPurity Manganese” (HPM) refers to a suite of highly refined finished products that are critical to most lithiumion batteries2020年4月1日 Specifically, for the future processing of deep sea manganese nodules to produce battery qua lity highpurity manganese sulfate monohydrate, it was shown that this process could lead to a decrease Life cycle assessment of electrolytic manganese metal production 2021年3月31日 The best results were obtained by combining pyrometallurgical and hydrometallurgical treatments, which enabled the efficient recovery of manganese, nickel, copper, and cobalt Highpurity nickel Recovery of Manganese from Ferromanganese Slag by 2020年1月3日 Large amounts of manganeserich slag were generated from smelting lowgrade manganese ore containing high iron and high phosphorus in electric furnace or blast furnace, which contain 25–40 mass% Mn This paper describes an efficient hydrometallurgical process for the utilization of high manganese slag instead of conventional usage of pyrometallurgical route Pressure Sulfuric Acid Leaching of ManganeseRich Slag with

Silicomanganese production from manganese rich slag

2004年2月1日 Highmanganese slag is characterized by a high manganese content, low excess oxygen, A part of the mill scale generated in a steel plant is recycled for inhouse infrastructure, 2022年10月3日 The global ultrahigh purity manganese sulfate market is anticipated to grow at a substantial CAGR of 2410% in the upcoming years The global UltraHigh Purity Manganese Sulfate industry was estimated to be UltraHigh Purity Manganese Sulfate Market Size2017年8月16日 The ore is powdery, finegrained and soft in nature with varying specific gravity (28–39 g/cm3) and high thermogravimetric loss, It consists of manganese (δMnO2, manganite, cryptomelane (PDF) Recovery of Manganese Ore Tailings by High2016年4月1日 PDF The separation of manganese from sulfate solutions containing 1459 g/L Mn2+, 189 g/L Mg2+ and 154 g/L Ca2+ was preformed successfully by Find, read and cite all the research you need (PDF) Separation of manganese from calcium and

Highpurity manganese and method for producing same

Highpurity manganese having a purity of 3 N (999%) or more, and characterized in that nonmetal inclusions each having a size of 05 μm or more are contained at a density of 50000 particles or less per 1 g of the manganese A method for producing highpurity manganese, characterized by purifying a manganese raw material (a primary raw material) using an acid High Purity Manganese Sulphate Project August 2022 17 SIMON ANDREW–Director +61 488 434 483 Appendix –Macro Trends High Purity Manganese Sulphate Project August 2022 18 NMC Battery Chemistry • Different lithium ion batteries are distinguished by the metalsHigh Purity Manganese Sulphate Project2019年7月1日 One of the results at 350 rpm in mill Preparation of electronic grade manganese sulfate from ferromanganese slag, Poor iron control typically prevents the production of high purity manganeseEfficient removal of iron(II) from manganese sulfate solution by 2017年8月1日 Electrolytic manganese is conventionally produced from ammonium sulfate media due to some limitations of chloride media such as the removal of chlorine from the anolyte and consumption of ammonia (Lu et al, 2014) However, sulfate media is not suitable for the production of highpurity manganeseElectrorefining of high purity manganese ScienceDirect

[GYQ0R)ZQ]ESS4NJ.jpg)

Vibrantz Technologies Scales up Highpurity Manganese Sulfate

2023年7月20日 Vibrantz Technologies scales up highpurity manganese sulfate for North American lithiumion battery market Vibrantz Technologies announced the construction of a new pilot plant to process highpurity manganese sulfate (HPMSM) onsite at its facility in Tampico, Mexico, to meet the growing demand for batterygrade manganese sulfate as automotive manganese slag which is a waste material of local ferroalloy industry to recovery manganese through acid leaching Based on a total of 150 runs of experiments, the following conclusions were drawn from the present study: (i) Recovery of manganese increased with an increase in the sulfuric acid concentration upto 25N The optimumRecovery of Manganese from Ferromanganese Slag by Leaching 2002年4月1日 Pure manganese dioxide was successfully produced from low grade pyrolusite ore (βMnO2) and sulphur slag First, the reduction of βMnO2, introduced as pure pyrolusite was studied using Simultaneous extraction of manganese from low grade manganese High Purity Manganese Takes Center Stage in Battery Technology The battery industry has seen a significant shift towards high purity manganese sulfate as a key component in advanced batteries, driven by concerns over cobalt’s price volatility, ethical sourcing issues, and the ongoing evolution of battery chemistriesThe Critical Role of High Purity Manganese in Batteries CPM

.jpg)

Lithium and manganese extraction from manganeserich slag

2022年8月1日 Mn and Li were selectively extracted from the manganeserich slag by sulfation roasting−water leaching The extraction mechanisms of Mn and Li were investigated by means of XRD, TG−DSC, and SEM−EDS 7371% Mn and 7328% Li were leached under optimal experimental conditions: acid concentration of 82 wt%, acidtoslag mass ratio of 15:1, As viewed from application of the technoogy of producing highpure manganes carbonate using poor manganese, ferrisulphas and ammonium hydrogen carbonate as raw material is introduced 本文从应用的角度出发,介绍了以贫 矿、硫酸亚铁、碳酸氢控等为原料,生产高纯碳酸 的方法。欧路词典英汉汉英词典 manganese是什么意思manganese的 2022年3月16日 [0009] Based on this original observation, this invention mainly aims to propose a method for producing manganese sulfate monohydrate from manganesecomprising raw material, which would solve two technical problems simultaneously, namely: producing of high purity (more than 99%, mainly, not less than 999 %) manganese sulfate monohydrateMETHOD FOR PRODUCING MANGANESE SULFATE 2023年7月25日 From ore, the manganese is leached, purified and then crystallized in high purity crystals which can then be used in the process of manufacturing manganese sulfate “Alternatively, the ore is put through electrowinning by which electrolysis is used to extract the metal from a purified leach solution and shipped to a precursor maker, which would dissolve it Spotlight on sulfate: Volatility expected in manganese sulfate

(PDF) Separation of manganese from calcium and magnesium in sulfate

Preparation of electronic grade manganese sulfate from leaching solution of ferromanganese slag [J] Transactions of Nonferrous Metals Society of China, 2014, 24(11 Study on technology of preparing high purity manganese sulfate with lowgrade manganese carbonate ores [J] Inorganic Chemicals Industry, 2014, 46(11): 35−38 (in Chinese 2024年11月15日 HPMSM (High Purity Manganese Sulphate Monohydrate) HPMSM is currently a small portion of the overall Manganese industry Manganese has historically been used in the steel industry to produce alloys and to a much smaller degree has HPMSM Canadian Manganese2023年11月13日 NR 202319VANCOUVER, British Columbia (November 13, 2023) – Euro Manganese Inc (TSXV and ASX: EMN; OTCQX: EUMNF; Frankfurt: E06) (the "Company") is pleased to announce the successful production of highpurity manganese sulphate monohydrate ("HPMSM") from the dissolution and crystallization module at the Chvaletice Demonstration Euro Manganese Produces HighPurity Manganese Sulphate 2024年4月9日 The agitator is continuously supplied with an aqueous 25% solution of ammonia NH 4 OH, the pulp of manganese carbonate isolated during the preparation of a part of the sulfate solution for evaporation (to remove sodium and potassium sulfates from the technological cycle), and with ammonium sulfate (NH 4)2SO 4 solution to increase its content in the sulfate solution How is Manganese Processed: An InDepth Exploration M

.jpg)

Recovery of Manganese from Zinc Smelter Slag ResearchGate

2020年12月4日 would be wise to purify manganese sulfate solutions by selectiv ely precipitatin g the other metals as metalsulfides at lower pH values (Bryson and Bijste rveld, 199 1)